A bed support designed for a singular sleeper, capable of being collapsed or compacted for ease of storage or transport. It typically accommodates a mattress of approximately 39 inches by 75 inches. These structures are frequently employed in situations where space is limited, such as guest rooms, dormitories, or temporary living arrangements.

The compact nature of these sleeping platforms offers significant advantages, allowing for maximized use of available area when not in service. The adaptability makes them well-suited for individuals who relocate frequently or require a bed option that can be easily stowed away. Historically, such designs have evolved from simple cots to more sophisticated frameworks offering increased comfort and durability.

The following discussion will delve into the various types, materials, assembly considerations, and common applications associated with these space-saving bed solutions.

Foldable Twin Mattress Frame

The selection and use of a bed support engineered for single sleepers and designed for collapsibility necessitates careful consideration to ensure optimal utility and longevity. This section provides essential guidelines for navigating the various aspects involved.

Tip 1: Material Assessment: Evaluate the construction material. Steel frames provide superior durability and weight-bearing capacity compared to aluminum or wooden variants. Examine the gauge of the metal used; a lower gauge indicates a thicker, more robust material.

Tip 2: Locking Mechanism Scrutiny: Inspect the locking mechanisms responsible for maintaining the frame’s integrity when deployed. Ensure these mechanisms are robust, easily engaged, and resistant to accidental disengagement. A thorough understanding of the locking system is crucial.

Tip 3: Folded Dimensions Verification: Before purchase, confirm the folded dimensions are compatible with the intended storage space. Precise measurements are essential to avoid storage-related complications after acquisition.

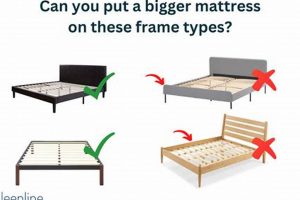

Tip 4: Mattress Compatibility Confirmation: Verify the bed support is explicitly designed for use with a twin-sized mattress. Mismatched dimensions can compromise support and lead to premature mattress degradation. Direct compatibility ensures proper function.

Tip 5: Weight Capacity Awareness: Ascertain the maximum weight the frame is rated to support. Exceeding this limit can lead to structural failure and potential injury. Adherence to the specified weight limit is non-negotiable.

Tip 6: Review Assembly Procedures: Prior to assembly, carefully review the provided instructions. Incomplete or incorrect assembly can compromise the frame’s stability and structural integrity. Meticulous adherence to the instructions is essential.

Tip 7: Evaluate Slat or Mesh Support: Consider the support structure beneath the mattress. Closely spaced slats or a tightly woven mesh provides more uniform support and prevents mattress sagging. Consistent support enhances sleep quality and extends mattress lifespan.

By adhering to these guidelines, individuals can make informed decisions regarding these types of bed support, maximizing utility and ensuring long-term satisfaction. This attention to detail leads to a more beneficial and reliable sleeping solution.

The following section will discuss some potential issues and considerations when using such a product, and offer guidance on how to best mitigate them.

1. Frame Material

The selection of material for the support structure profoundly influences its overall performance, longevity, and suitability for various applications. Material properties dictate strength, weight, portability, and resistance to environmental factors, all critical considerations when selecting a foldable twin mattress frame.

- Steel Construction

Steel frameworks provide superior strength and durability, capable of withstanding significant weight and resisting deformation under stress. A steel frame, commonly constructed from tubular steel, is highly resilient to bending and breaking, resulting in increased product longevity and making it suitable for frequent use and heavier individuals. However, its greater weight can slightly impede portability compared to lighter materials.

- Aluminum Alloys

Aluminum, particularly in alloyed forms, offers a compelling balance between strength and weight. These frameworks are lighter than their steel counterparts, enhancing portability and ease of handling. While not as structurally robust as steel, aluminum frames provide adequate support for most users. The corrosion resistance of aluminum alloys is also a significant advantage, particularly in environments with high humidity.

- Wood Components

While less common, some include wooden elements, often in the form of slats or supporting structures. Wood provides aesthetic appeal and can contribute to a warmer, more inviting appearance. However, wood is more susceptible to damage from moisture, impact, and insect infestation than metal alternatives. The strength and durability of wooden components depend heavily on the type of wood used and the quality of construction.

- Plastic and Composite Materials

These materials, offer lightweight and corrosion-resistant options. However, their load-bearing capacity is generally lower than that of steel or aluminum, limiting their suitability for heavier individuals. Composite materials may offer enhanced strength-to-weight ratios compared to plastics, but their cost is typically higher. The durability of plastic and composite frameworks depends on the specific materials used and the manufacturing process.

The choice of frame material represents a critical decision point in the purchase process, with implications for product lifespan, ease of use, and overall suitability for individual needs. Careful consideration of the material’s properties and trade-offs is essential for maximizing satisfaction and ensuring a durable and functional bed solution.

2. Folding Mechanism

The folding mechanism is a core determinant of a foldable twin mattress frame’s functionality and overall user experience. Its design and construction directly influence the ease with which the frame can be collapsed and redeployed, impacting storage convenience and setup time. A robust and well-engineered mechanism contributes to the frame’s stability when in use. Conversely, a poorly designed or cheaply manufactured mechanism can lead to difficulties in folding, reduced structural integrity, and a shortened lifespan of the entire unit. For instance, a frame utilizing a simple hinge system with a locking pin will be significantly less complex to operate than one with a multi-jointed, spring-loaded assembly.

The type of folding mechanism employed dictates the packed dimensions of the frame, a critical consideration for users with limited storage space. A frame that folds into a compact square or rectangle is generally more desirable than one that collapses into an awkward or elongated shape. Different types of mechanisms exist, including bi-fold, tri-fold, and accordion styles, each with its own advantages and disadvantages regarding size reduction and ease of operation. The quality of materials used in the mechanism’s construction, such as the gauge of steel or the type of plastic, directly affects its resistance to wear and tear. Repeated folding and unfolding cycles put stress on these components, and inferior materials are prone to failure, potentially rendering the entire frame unusable.

In summary, the folding mechanism is not merely an ancillary feature but an integral component of the product. The effectiveness and durability of the mechanism have a cascading effect on the convenience, longevity, and overall value proposition of the foldable twin mattress frame. Proper maintenance of this feature, including lubrication of moving parts and periodic inspection for signs of wear, is essential for maximizing its service life.

3. Mattress Support

The efficacy of a foldable twin mattress frame is intrinsically linked to the quality and design of its mattress support system. Inadequate support precipitates mattress sagging, leading to compromised sleep quality and a reduced lifespan for the mattress itself. The support structure bears the weight of the occupant and mattress, distributing the load across its surface. Therefore, a deficient support system will concentrate pressure in certain areas, causing uneven wear and potential deformation of the mattress over time. A practical example of this is observed when using a frame with widely spaced slats; the mattress tends to dip between the slats, creating uncomfortable pressure points and accelerating wear. Frames utilizing closely spaced slats or a tightly woven mesh generally provide superior, more uniform support.

Different support systems affect the overall comfort and stability of the sleeping surface. Slat systems, typically constructed of wood or metal, offer a firm foundation. The spacing and thickness of the slats determine the degree of support provided; closer spacing and thicker slats enhance weight distribution and minimize sagging. Mesh systems, often made of metal wires, provide a more flexible surface. The gauge and pattern of the mesh affect its ability to conform to the occupant’s body, potentially increasing comfort. Platform designs, where a solid surface underlays the mattress, offer the most consistent support but can restrict airflow, potentially leading to increased heat retention.

In conclusion, appropriate mattress support is a crucial aspect of a foldable twin mattress frame, influencing both comfort and the longevity of the mattress. Selecting a frame with a robust and well-designed support system is an investment in sleep quality and the lifespan of the associated bedding. Neglecting this aspect can lead to discomfort, premature mattress wear, and ultimately, a less satisfactory sleeping experience. The interconnectedness of these elements dictates the overall performance and value of the portable bed solution.

4. Portability

Portability is a defining characteristic and a primary driver of demand. The capacity to easily transport and relocate a sleeping surface addresses diverse needs. The design emphasizes lightweight materials and a compact folded form. The effectiveness of the folding mechanism and the frames overall weight directly correlate to the ease with which it can be carried, stored, and transported, whether within a residence or to a remote location. Real-world examples include students moving into dormitories, individuals setting up temporary accommodations during travel, or providing an extra bed in homes with limited space. The demand for these frames stems from their ability to provide a comfortable sleeping solution without the permanence and space requirements of a traditional bed.

The significance of portability extends beyond mere convenience. It offers a practical solution for disaster relief efforts, enabling the rapid deployment of temporary sleeping arrangements in shelters or field hospitals. Similarly, these frames are frequently used in camping and outdoor recreational activities, providing a more comfortable alternative to sleeping directly on the ground. Construction workers, traveling nurses, and other professionals who require temporary housing also benefit from the ease with which these sleeping supports can be transported and set up in transient living environments. The consideration of weight, folded dimensions, and the inclusion of features like carrying handles are critical factors in assessing the overall portability of such a system.

In summary, portability is not merely an added feature but an intrinsic and indispensable aspect of the design. Challenges remain in balancing the desire for reduced weight and compact dimensions with the need for structural integrity and long-term durability. Overcoming these challenges through innovative design and material selection will further enhance the utility and broaden the application of these sleeping platforms. This understanding highlights the critical role portability plays in defining the purpose and appeal of the product.

5. Weight Capacity

The weight capacity of a foldable twin mattress frame represents a critical performance parameter directly influencing its suitability for intended use and its overall lifespan. This specification defines the maximum load, including the mattress and occupant, that the structure can safely support without compromising its structural integrity. Exceeding the stated weight capacity can lead to deformation, breakage, or complete collapse of the frame, potentially resulting in injury and rendering the product unusable. Consequently, understanding and adhering to the weight capacity is paramount for safe and effective utilization.

The manufacturer’s specified weight limit is typically determined through rigorous testing and engineering calculations, taking into account the materials used, the design of the folding mechanism, and the overall construction. For instance, a frame constructed from heavy-gauge steel will generally possess a higher weight capacity than one made from lightweight aluminum or plastic. Neglecting to consider this parameter can lead to practical problems. A college student exceeding the weight limit, for example, might experience structural failure, necessitating replacement and potentially causing discomfort. Similarly, using the product in a guest room without awareness of its limitations could result in an embarrassing and potentially hazardous situation. Therefore, confirming the weight capacity aligns with the intended user is a crucial step in the purchase decision.

In summary, weight capacity is not merely a technical specification; it is a fundamental safety and performance characteristic of a foldable twin mattress frame. Careful consideration of this factor ensures user safety, prolongs product lifespan, and guarantees satisfactory performance under anticipated conditions. Prioritizing this understanding mitigates risks and optimizes the overall value derived from the bed frame.

6. Storage Footprint

The reduced storage footprint is a primary attribute sought when considering a foldable twin mattress frame. The term “storage footprint” refers to the amount of space the frame occupies when collapsed or folded, representing a key factor in its practicality. A smaller storage footprint allows the frame to be easily stowed in closets, under beds, or in other limited spaces, addressing the needs of individuals in apartments, dormitories, or those requiring a readily available guest bed. The frame’s design directly dictates the storage footprint, influencing its suitability for various living environments. A compact folded profile ensures minimal intrusion when the frame is not in use, preserving valuable floor space. The cause-and-effect relationship is clear: a well-designed folding mechanism leads to a smaller storage footprint, enhancing the product’s utility. Without this characteristic, the fundamental advantage of a foldable frame is negated.

The storage footprint is a critical component that determines its feasibility for short-term accommodation. Practical applications include stowing the collapsed frame in a vehicle for camping trips or keeping it in a home office for occasional overnight visitors. Furthermore, smaller storage footprint facilitates easier relocation. Individuals moving frequently, such as traveling nurses or temporary workers, benefit significantly from the ability to quickly pack and transport the frame, minimizing the burden of relocation. The design of the hinges, locking mechanisms, and overall frame structure contribute to the achievability of a reduced profile when not in use.

In summary, the storage footprint is intrinsically linked to the utility and desirability of a foldable twin mattress frame. It is a key consideration when evaluating its suitability for space-constrained environments and those requiring readily deployable sleeping solutions. Smaller folded dimensions amplify the product’s value proposition, making it a practical choice for diverse users. The optimization of the storage footprint remains a central focus for manufacturers seeking to enhance the product’s appeal and market competitiveness.

7. Assembly

The assembly process represents a critical juncture in the utilization of a foldable twin mattress frame, directly impacting its structural integrity and subsequent usability. Incorrect assembly, whether due to misinterpretation of instructions or failure to secure components properly, undermines the intended functionality, potentially leading to instability and a compromised sleeping surface. The correlation is direct: accurate assembly yields a safe and reliable bed frame, while flawed assembly results in a potentially hazardous and unusable product. Real-world examples abound, from college students struggling with unclear instructions to individuals overlooking critical locking mechanisms, all resulting in unstable or non-functional bed frames. A clear understanding of the assembly procedure is therefore paramount.

Different models require varying levels of assembly expertise. Some frames arrive pre-assembled, requiring only the unfolding and locking of a few key joints. Others necessitate the attachment of legs, slats, or support bars, demanding a more detailed and careful approach. The complexity of the assembly process directly influences the time investment required and the likelihood of errors. Manufacturers increasingly prioritize ease of assembly in their designs, often incorporating tool-free assembly mechanisms and providing clear, concise instructions with visual aids. This focus reflects the understanding that a simpler assembly process enhances customer satisfaction and reduces the risk of product returns due to assembly-related issues. A specific example of this trend is the replacement of screw-based assembly with snap-fit or interlocking components, significantly reducing assembly time and complexity.

In conclusion, the assembly phase is not a mere formality but a critical determinant of a foldable twin mattress frame’s performance and safety. The implementation of user-friendly designs and clear assembly instructions mitigates the risk of errors and ensures that the frame functions as intended, providing a stable and reliable sleeping surface. Proper execution of the assembly process is therefore essential for maximizing the value and utility of the product.

Frequently Asked Questions

This section addresses common inquiries regarding the purchase, use, and maintenance of a foldable twin mattress frame, offering clear and concise information to aid in informed decision-making.

Question 1: What is the typical weight capacity of a foldable twin mattress frame?

The weight capacity varies depending on the construction materials and design. Generally, it ranges from 250 to 350 pounds. Always consult the manufacturer’s specifications prior to use to avoid exceeding the limit.

Question 2: Are all twin mattresses compatible with these frames?

While most standard twin mattresses (approximately 39 inches by 75 inches) are compatible, variations in thickness or construction may affect suitability. Verify mattress dimensions and weight against the frame’s specifications.

Question 3: How durable are these frames for long-term use?

Durability depends on the quality of materials and construction. Steel frames generally offer greater longevity than aluminum or wood. Regular inspection and maintenance, such as tightening bolts and lubricating hinges, can extend lifespan.

Question 4: What is the best method for storing a foldable twin mattress frame when not in use?

Ensure the frame is clean and dry before folding. Store it in a dry location away from direct sunlight and extreme temperatures. A protective cover can prevent dust accumulation and damage.

Question 5: Can these frames be used directly on carpeting, or is a hard surface required?

These frames can be used on both carpeting and hard surfaces. However, carpeting may reduce stability, particularly if the pile is thick. Consider using furniture pads to distribute weight and prevent damage to the carpet.

Question 6: What types of folding mechanisms are typically used, and how do they affect ease of use?

Common mechanisms include bi-fold, tri-fold, and rollaway designs. Bi-fold and tri-fold mechanisms generally offer a balance between compactness and ease of use. Rollaway designs often require more space to maneuver but may offer greater structural support.

In summary, careful consideration of weight capacity, mattress compatibility, material durability, storage practices, surface suitability, and folding mechanisms will ensure optimal use and longevity. Adherence to these guidelines promotes a satisfactory experience with a foldable twin mattress frame.

The following section will provide information on troubleshooting common problems associated with such frames.

foldable twin mattress frame

The preceding discussion has detailed diverse aspects pertinent to a bed support engineered for single sleepers and designed for collapsibility. These details have covered from material selection and folding mechanisms to mattress compatibility and weight limitations, underscoring the necessity of informed decision-making. The effectiveness of such a design hinges on a cohesive integration of these factors, ultimately determining its suitability and long-term performance.

As consumer demands evolve, continued innovation in design and materials will undoubtedly yield further enhancements in portability, durability, and comfort. Prospective purchasers are encouraged to critically evaluate individual needs and prioritize features that align with specific usage scenarios to ensure optimal satisfaction and a worthwhile investment. Careful assessment translates into a reliable and space-saving sleeping solution.