A standard-sized sleep system, commonly utilized by single sleepers desiring ample space or couples seeking a compact sleeping arrangement, consists of a rectangular support platform and a cushioning component designed to provide comfort and promote proper spinal alignment. For example, a student transitioning from a twin bed to a larger size might opt for this configuration, or a guest room may be equipped with such a setup to comfortably accommodate visitors.

The popularity of this sleeping configuration stems from its versatility and space-efficiency. It offers a significant upgrade in sleeping area compared to smaller options while remaining manageable in most standard-sized bedrooms. Historically, this size has been a staple in residential settings, providing a balance between individual comfort and efficient use of living space. Its dimensions allow for greater freedom of movement during sleep and can contribute to a more restful and restorative sleep experience.

The subsequent sections will delve into the various materials used in constructing support platforms and cushioning components, exploring the factors influencing comfort and durability, and examining the considerations relevant to selecting the optimal system for individual needs and preferences. Furthermore, the implications of size and dimensions within the context of bedroom design will be addressed, offering insights into maximizing spatial utilization and creating a harmonious living environment.

Selection and Maintenance Tips

The following guidelines offer practical advice for choosing and maintaining a sleep system of this configuration, aimed at maximizing lifespan and optimizing sleep quality.

Tip 1: Measure Room Dimensions Accurately: Prior to purchase, meticulously measure the intended location. Ensure sufficient space for comfortable movement around the perimeter and placement of other furniture. Failure to do so can result in an overcrowded and functionally compromised bedroom.

Tip 2: Evaluate Support Structure Integrity: The support platform must provide adequate support to prevent sagging and premature wear of the cushioning component. Inspect the quality of materials and construction, paying particular attention to the strength of joints and weight-bearing capacity.

Tip 3: Consider Material Composition: Different materials offer varying levels of support, comfort, and durability. Research the properties of innerspring, memory foam, latex, and hybrid options to determine the most suitable choice based on individual needs and preferences. Heavier individuals will generally require a firmer sleep surface.

Tip 4: Investigate Warranty and Return Policies: Understand the manufacturer’s warranty and return policies before committing to a purchase. This provides recourse in the event of defects or dissatisfaction with the product’s performance.

Tip 5: Utilize a Protective Cover: Employ a high-quality mattress protector to shield against spills, stains, and allergens. This proactive measure can significantly extend the lifespan and maintain the hygiene of the cushioning component.

Tip 6: Rotate Regularly: Rotate the cushioning component 180 degrees every three to six months to promote even wear and prevent localized compression. This practice helps maintain consistent support across the entire surface.

Tip 7: Inspect for Damage Periodically: Regularly inspect both the support platform and the cushioning component for signs of damage, such as broken slats, tears, or sagging. Addressing minor issues promptly can prevent them from escalating into more significant problems.

Adhering to these recommendations will contribute to a more informed purchasing decision, prolong the life of the chosen setup, and ultimately enhance sleep quality and overall well-being.

The final section will summarize the key considerations discussed throughout this article, reinforcing the importance of careful planning and informed choices in selecting and maintaining this essential component of the home.

1. Dimensions

The dimensions of the sleeping configuration significantly influence its suitability for specific bedroom layouts and individual comfort preferences. A standard rectangular footprint, typically measuring approximately 54 inches wide by 75 inches long, dictates the space required for placement and maneuverability within a room. Consequently, insufficient room dimensions render such a configuration impractical, potentially obstructing doorways or hindering the placement of other essential furniture. For instance, a smaller bedroom, intended for single occupancy, may become overly cramped with this bed size, thereby diminishing the room’s functionality and aesthetic appeal. Proper measurement and pre-planning are therefore crucial to avoid spatial constraints and ensure a harmonious integration of the bed within the existing environment.

The specific dimensional characteristics also affect the comfort level experienced by occupants. While offering more sleeping space than a twin-sized bed, this common size may prove inadequate for taller individuals or couples who require additional room to move during sleep. A taller person, exceeding six feet in height, might find their feet extending beyond the edge, leading to discomfort and disrupted sleep patterns. Similarly, two adults sharing this setup may experience restricted movement, potentially resulting in disturbed sleep due to proximity and shared space limitations. Thus, individual height and sleep habits are key determinants in evaluating the dimensional adequacy of the sleeping system.

Ultimately, understanding dimensional implications constitutes an essential step in selecting a suitable sleeping system. Overlooking this factor leads to spatial inefficiencies and compromised comfort. Prioritizing accurate measurement and carefully considering individual needs ensures that the chosen configuration aligns with both room dimensions and personal preferences, contributing to a more functional and restful sleep environment.

2. Support

The structural integrity of a sleeping configuration directly impacts the quality of sleep and the longevity of its components. The support system, comprised of both the frame and the mattress, functions as a foundation, dictating weight distribution and spinal alignment. Insufficient support leads to mattress sagging, resulting in uneven weight distribution and potential musculoskeletal discomfort. For example, a warped or weakened wooden frame with inadequate center support will cause the mattress to bow downwards, concentrating pressure on specific areas of the body and disrupting natural spinal curvature. This can manifest as back pain, stiffness, and a generally unrestful sleep experience. Conversely, a robust frame constructed from durable materials like steel, coupled with a mattress designed with reinforced edges and a supportive core, promotes proper spinal alignment and minimizes pressure points.

The interaction between the mattress and the frame is crucial. Even the highest-quality mattress will perform suboptimally when placed upon a substandard frame. The frame’s slat spacing, for instance, directly affects the mattress’s support and ventilation. Widely spaced slats offer insufficient support, allowing the mattress to sink between them and accelerating wear and tear. Close-set slats or a solid platform base provide a more uniform surface, enhancing mattress longevity and preventing premature sagging. Furthermore, proper frame construction facilitates airflow around the mattress, reducing moisture accumulation and inhibiting the growth of mold and mildew. This is particularly important for mattresses constructed from dense materials like memory foam, which tend to trap heat and moisture.

In summary, the structural support inherent in a sleeping configuration is not merely a matter of aesthetics or convenience but a critical factor in promoting sleep quality and preserving the lifespan of the investment. Compromising on frame quality to reduce initial costs can lead to accelerated mattress degradation and potential health issues associated with inadequate spinal support. Therefore, a balanced approach that prioritizes both mattress quality and frame integrity is essential for ensuring a comfortable, supportive, and durable sleeping environment. Further sections will delve into the specific materials used in frame construction and their corresponding impact on overall support and longevity.

3. Materials

The selection of materials fundamentally defines the performance characteristics, longevity, and overall value of a standard sleeping system. Material choices impact comfort, support, durability, and even allergenicity, thereby directly influencing sleep quality and long-term satisfaction. Understanding the properties of various materials is crucial for making informed decisions when selecting both the support platform and the cushioning component.

- Wood for Frames

Wood serves as a common frame material, offering varying levels of strength and aesthetic appeal. Hardwoods, such as oak and maple, provide superior durability and resistance to warping compared to softwoods like pine. The type of wood and its construction influence the frame’s weight-bearing capacity and overall lifespan. For instance, a solid hardwood frame can withstand significantly more weight and stress than a particleboard frame, making it a more suitable choice for heavier individuals or couples. The finish applied to the wood also affects its resistance to moisture and pests, further influencing its longevity.

- Metal for Frames

Metal frames, typically constructed from steel or aluminum, offer exceptional strength and durability. Steel frames are particularly robust, providing excellent support for heavier mattresses and individuals. Aluminum frames are lighter and more resistant to rust, making them suitable for humid environments. The gauge (thickness) of the metal directly correlates with its load-bearing capacity and resistance to bending. Welded joints in a metal frame provide superior strength compared to bolted connections, which can loosen over time. Metal frames are often more affordable than hardwood frames, making them a practical option for budget-conscious consumers.

- Innerspring Coils for Mattresses

Innerspring mattresses utilize coils to provide support and resilience. The gauge and configuration of the coils impact the firmness and responsiveness of the mattress. Lower-gauge (thicker) coils offer firmer support, while higher-gauge (thinner) coils provide a softer feel. Pocketed coils, where each coil is individually wrapped in fabric, minimize motion transfer, making them a good choice for couples. Bonnell coils, an interconnected system, offer a more uniform and budget-friendly support system. The coil count also influences support and durability; a higher coil count generally indicates a more supportive and long-lasting mattress.

- Foam for Mattresses

Foam mattresses, including memory foam, latex foam, and polyurethane foam, offer varying degrees of comfort and support. Memory foam conforms to the body’s shape, providing pressure relief and minimizing motion transfer. Latex foam is naturally derived, offering a responsive and durable support system. Polyurethane foam is a synthetic material that can be manufactured in a range of densities and firmness levels. The density of the foam influences its durability and resistance to compression; higher-density foams offer greater support and longevity. Foam mattresses are often layered to provide a balance of comfort and support, with different foam types strategically placed to optimize sleep quality.

These material considerations are paramount in ensuring a sleeping configuration that provides adequate support, comfort, and longevity. While aesthetic preferences undoubtedly play a role in the selection process, prioritizing material quality and suitability is essential for maximizing the value and ensuring a restful sleep experience. The subsequent discussion will address the impact of frame and mattress dimensions on overall comfort and functionality.

4. Durability

The long-term usability of a standard-sized sleep setup is intrinsically linked to the durability of its constituent parts. The capacity to withstand continuous use and external forces, such as weight and movement, defines the service life and overall cost-effectiveness of this configuration. A poorly constructed support platform or a mattress fabricated from inferior materials degrades rapidly, leading to sagging, reduced support, and ultimately, the need for premature replacement. For instance, a frame constructed from low-density particleboard exhibits a diminished capacity to bear weight over time, potentially resulting in structural failure and rendering the entire system unusable. Similarly, a mattress comprised of low-density foam compresses permanently with repeated use, losing its ability to provide adequate spinal alignment and comfort. The selection of robust and high-quality materials directly translates to extended usability and a reduced frequency of replacement, thereby providing a greater return on investment.

The interplay between the frame and the mattress significantly influences the cumulative durability. A robust frame, manufactured from materials like solid hardwood or high-gauge steel, provides a stable and supportive foundation, mitigating stress on the mattress and preventing premature wear. Conversely, a flimsy or inadequate frame imparts undue stress on the mattress, accelerating degradation and compromising its structural integrity. Consider, for example, a scenario where a mattress is placed on a frame with widely spaced slats. The mattress sags between the slats, concentrating weight on specific areas and leading to uneven compression and accelerated wear. Regular maintenance practices, such as rotating the mattress and utilizing a protective cover, further contribute to extended durability by minimizing localized compression and preventing damage from spills or allergens. The absence of such maintenance accelerates the degradation process, diminishing the overall lifespan of the system.

In conclusion, durability represents a critical attribute of a full-sized sleep system, directly impacting its cost-effectiveness and the quality of sleep experienced. Understanding the material properties and construction techniques that contribute to durability is essential for making informed purchasing decisions. While the initial cost of a more durable setup may be higher, the extended service life and reduced replacement frequency ultimately offer a greater long-term value. Overlooking durability in favor of short-term cost savings often results in a compromised sleep experience and a more frequent need for costly replacements. Prioritizing robust construction and appropriate maintenance practices ensures that the sleeping configuration provides sustained support and comfort, maximizing its useful life and contributing to overall well-being.

5. Cost

The economic dimension of a full-sized sleeping configuration constitutes a significant factor in purchase decisions, reflecting a complex interplay between initial investment, long-term expenditure, and perceived value. The price point for a support platform and cushioning component of this size varies considerably, influenced by factors such as material quality, construction techniques, brand reputation, and retailer markups. Consequently, a consumer confronts a spectrum of choices, ranging from budget-friendly options fabricated from inexpensive materials to premium offerings incorporating advanced technologies and durable components. For example, a basic metal frame paired with an innerspring mattress may represent the most economical choice upfront, but its lifespan and support characteristics could be compromised, necessitating more frequent replacements. Conversely, a solid hardwood frame coupled with a memory foam or latex mattress involves a higher initial outlay, but its enhanced durability and superior comfort may justify the increased expenditure over the long term. The practical significance of understanding these cost implications lies in enabling informed decision-making, allowing consumers to align their purchase with both budgetary constraints and desired performance characteristics.

Beyond the initial acquisition cost, additional expenses associated with ownership further contribute to the overall economic impact. These supplementary costs encompass mattress protectors, bed linens, and potentially, professional assembly services. A high-quality mattress protector, while representing an additional investment, safeguards the cushioning component from spills, stains, and allergens, thereby extending its lifespan and mitigating the need for premature replacement. Similarly, durable and comfortable bed linens enhance the sleep experience and contribute to overall satisfaction. The necessity of professional assembly services depends on the complexity of the support platform’s construction; intricate designs or heavy components may warrant professional assistance, incurring an additional expense. A comprehensive assessment of these ancillary costs provides a more accurate representation of the total economic commitment associated with a specific sleeping configuration.

In summary, the cost of a full-sized sleeping system extends beyond the initial purchase price, encompassing a multifaceted equation that considers material quality, construction techniques, expected lifespan, and associated maintenance expenses. A thorough evaluation of these factors empowers consumers to make informed decisions, balancing budgetary considerations with desired performance characteristics and long-term value. Challenges arise in navigating the diverse range of options and accurately assessing the long-term economic implications of each choice. Ultimately, a well-informed purchasing decision, grounded in a comprehensive understanding of cost dynamics, contributes to a more satisfying and cost-effective sleep experience.

6. Assembly

The process of assembling a standard-sized sleeping configuration represents a critical juncture between purchase and functionality. Proper assembly directly influences the structural integrity, stability, and ultimately, the user experience of the bed system. Failure to adhere to manufacturer instructions or a lack of attention to detail during assembly can compromise the bed’s support capabilities and lead to premature wear or even structural failure.

- Component Identification and Inventory

Prior to commencing assembly, a thorough inventory of all components is essential. This includes verifying the presence of all frame pieces, hardware (bolts, screws, washers), and any specialized tools required for the process. A missing component can halt the assembly process and necessitate contacting the manufacturer for replacement, delaying the bed’s usability. Accurate identification of each part, often facilitated by an instruction manual with diagrams, is crucial for correct assembly sequence. Misidentification can lead to improper connections and structural instability.

- Frame Construction Sequence

The order in which the frame components are assembled is paramount for achieving a stable and structurally sound foundation. Typically, the headboard and footboard are connected to the side rails first, forming the perimeter of the bed frame. Subsequently, the center support system, which may consist of slats, crossbeams, or a solid platform, is installed to provide central support for the mattress. Deviation from the recommended sequence can result in difficulty aligning components or compromising the frame’s overall strength. Tightening hardware incrementally as the assembly progresses ensures proper alignment and prevents uneven stress distribution.

- Hardware Tightening and Security

The security of the assembled bed frame hinges on the proper tightening of all connecting hardware. Over-tightening bolts or screws can strip threads or damage the frame material, while insufficient tightening can lead to instability and creaking during use. A torque wrench, if specified in the instructions, ensures that hardware is tightened to the manufacturer’s recommended specifications. Periodically checking and re-tightening hardware is advisable to maintain the bed frame’s structural integrity over time, particularly after the initial settling period.

- Mattress Placement and Support Verification

Upon completion of the frame assembly, the mattress is placed onto the support structure. It is critical to verify that the mattress is evenly supported and that there are no areas of sagging or unevenness. The support system should distribute the mattress’s weight uniformly to prevent localized compression and premature wear. If slats are used, the spacing between them should conform to the manufacturer’s recommendations to provide adequate support and ventilation. Adjustments may be necessary to ensure proper mattress placement and optimal support distribution.

In conclusion, assembly is not merely a perfunctory step in acquiring a standard-sized sleeping system; it is an integral process that significantly impacts the bed’s structural integrity, stability, and overall user experience. Diligent adherence to manufacturer instructions, meticulous attention to detail, and proper hardware tightening are essential for ensuring that the bed frame provides a stable and supportive foundation for the mattress, thereby maximizing comfort and longevity.

7. Warranty

The warranty associated with a sleeping configuration serves as a manufacturer’s assurance regarding product quality and durability. It represents a contractual agreement that outlines the conditions under which the manufacturer will repair or replace the item due to defects in materials or workmanship, offering a degree of financial protection to the purchaser.

- Coverage Duration

Warranty coverage duration signifies the period during which the manufacturer assumes responsibility for defects. This period can range from a few months to several years, depending on the manufacturer and the specific components. A longer coverage period typically indicates greater confidence in the product’s longevity. For instance, a support platform may carry a longer warranty than the cushioning component, reflecting the perceived difference in expected lifespan and susceptibility to wear. The coverage duration directly impacts the consumer’s financial risk and provides a measure of security against unforeseen product failures.

- Specific Exclusions

Warranties invariably contain specific exclusions that delineate the circumstances under which coverage is void. Common exclusions encompass damage resulting from misuse, improper cleaning, or failure to utilize a suitable support structure. Stains, tears, or burns caused by the consumer are typically excluded. Some warranties may also exclude gradual wear and tear, such as minor sagging or softening of the cushioning component over time. A thorough understanding of these exclusions is essential to avoid invalidating the warranty and to ensure realistic expectations regarding coverage.

- Claim Procedures

The process for filing a warranty claim typically involves contacting the manufacturer or retailer, providing proof of purchase, and describing the defect in detail. The manufacturer may require photographic evidence or a physical inspection of the product to assess the validity of the claim. Consumers should familiarize themselves with the specific claim procedures outlined in the warranty document to ensure a smooth and efficient resolution process. Failure to adhere to these procedures may result in denial of the claim.

- Remedies Provided

The remedies offered under a warranty typically include repair, replacement, or a refund of the purchase price. The manufacturer retains the discretion to determine the most appropriate remedy based on the nature and severity of the defect. Repair may involve fixing the defective component or replacing it with a new or refurbished part. Replacement involves providing a new or comparable product. A refund may be offered if repair or replacement is not feasible. The specific remedies available are outlined in the warranty document and constitute the manufacturer’s contractual obligation.

The warranty associated with the “full bed mattress and frame” provides valuable insights into the manufacturer’s confidence in the product’s construction and expected lifespan. Understanding the coverage duration, exclusions, claim procedures, and remedies provided is crucial for making informed purchasing decisions and protecting the consumer’s investment. Comparing warranty terms across different brands and models allows consumers to assess the relative value and potential long-term costs associated with each option. The presence of a comprehensive and clearly defined warranty enhances consumer confidence and mitigates the financial risk associated with potential product defects.

Frequently Asked Questions

The following addresses common inquiries regarding a prevalent sleeping setup, providing factual information to aid informed decision-making.

Question 1: What are the standard dimensions of this sleeping configuration, and how does this affect room suitability?

The dimensions typically measure 54 inches wide by 75 inches long. This footprint requires adequate floor space for comfortable movement and placement of additional furniture. Smaller rooms may feel cramped, while larger rooms may accommodate it easily.

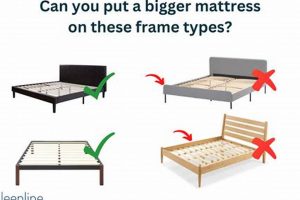

Question 2: What types of support platforms are recommended for optimal mattress performance?

Solid platforms or closely spaced slats (no more than 2-3 inches apart) provide the most uniform support, preventing mattress sagging. Inadequate support accelerates mattress wear and compromises sleep quality.

Question 3: How does mattress material impact comfort and durability in this configuration?

Material affects support, pressure relief, and lifespan. Memory foam contours to the body, while innerspring offers more bounce. Latex provides both support and durability. The selected material should align with individual preferences and weight.

Question 4: What maintenance practices extend the life of a setup of this size?

Regular rotation (every 3-6 months) promotes even wear. The use of a mattress protector guards against spills and allergens. Promptly addressing any frame damage prevents further deterioration.

Question 5: How does the warranty typically apply to a setup of this configuration, and what are common exclusions?

Warranties cover manufacturing defects. Exclusions often include misuse, improper cleaning, and normal wear and tear. Review the warranty document carefully to understand its terms and limitations.

Question 6: Can the sleeping system weight capacity be a determining factor?

The stated maximum load capacity for both the mattress and the bedframe shouldn’t be exceeded to ensure proper support. Reviewing load capacity can prolong the lifespan of both the frame and the mattress.

Understanding these key aspects facilitates the selection of a suitable system. Careful consideration of dimensions, support, materials, maintenance, and warranty terms ensures a comfortable and durable sleep environment.

The following will present the key takeaways of the discussion.

Full Bed Mattress and Frame

The preceding analysis elucidates critical attributes of the full bed mattress and frame. Dimensions, support mechanisms, material composition, durability expectations, assembly requirements, and warranty provisions collectively determine its suitability and long-term value. Strategic selection, based on individual needs and careful consideration of these factors, maximizes comfort and ensures structural integrity over its lifecycle. Neglecting any of these elements increases the potential for dissatisfaction and premature replacement costs.

Recognizing the complexity inherent in choosing a sleeping configuration, consumers are encouraged to approach the selection process with diligence. Prioritizing informed decision-making, grounded in a comprehensive understanding of product specifications and individual requirements, ensures a sustained investment in a foundational aspect of personal well-being. The full bed mattress and frame, when thoughtfully chosen, provides a lasting contribution to restorative sleep and overall quality of life.

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)

![Best Extra Long Twin Mattress Frame [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Extra Long Twin Mattress Frame [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3164-300x200.jpg)

![Best Bed Frame for Tempurpedic Mattress [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Bed Frame for Tempurpedic Mattress [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3163-300x200.jpg)

![Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3162-300x200.jpg)