Locating punctures in inflatable sleeping pads is essential for maintaining their functionality and preventing air leakage. This process involves systematically examining the mattress’s surface to identify the source of escaping air, which could manifest as a small opening, tear, or weakened seam. A common method involves using soapy water to generate bubbles at the point of the leak, visually confirming its location.

Addressing air leaks promptly preserves the comfort and support provided by the mattress. Failure to detect and repair these imperfections results in a gradual deflation during use, leading to discomfort and disrupted sleep. Historically, locating these leaks relied on simple observation and auditory clues; however, modern techniques and specialized solutions now offer a more efficient and accurate means of detection and repair.

The following sections detail several effective techniques applicable for pinpointing air leaks in inflatable sleeping pads, encompassing methods suitable for both indoor and outdoor environments, and employing readily available materials and specialized repair solutions.

Locating Air Leaks

The detection of air leaks in inflatable sleeping pads necessitates a methodical approach. The following guidance provides practical steps to effectively identify and address these imperfections.

Tip 1: Auditory Inspection. Initiate the search by listening closely near the inflated mattress. Air escaping from a puncture often produces a hissing sound, albeit faint. Conduct this auditory assessment in a quiet environment to maximize the chances of detecting subtle leaks.

Tip 2: Soapy Water Solution. Prepare a solution of mild dish soap and water. Apply this mixture to the surface of the inflated mattress using a sponge or spray bottle. Air escaping from a leak will cause bubbles to form at the precise location of the puncture.

Tip 3: Visual Examination. Carefully inspect the mattress surface for any signs of damage, such as small tears, pinholes, or abrasions. Pay particular attention to seams and areas where the material may be stressed or creased.

Tip 4: Submersion Test. If practical, submerge sections of the inflated mattress in a tub of water. Observe for streams of bubbles rising from the submerged area, indicating the presence of a leak. This method is particularly useful for identifying leaks on the underside of the mattress.

Tip 5: Pressure Application. Apply localized pressure to suspected areas of the mattress while observing for escaping air. This technique can help to accentuate subtle leaks that may be difficult to detect under normal pressure.

Tip 6: Marker Usage. Once a leak is identified, mark its location with a permanent marker. This ensures accurate placement of the repair patch and prevents overlooking the puncture during the repair process.

Successfully locating and marking air leaks enables prompt and effective repairs. Applying these strategies ensures the continued functionality and longevity of the inflatable sleeping pad.

Following the detection of leaks, implement suitable repair methods to restore the mattress’s airtight integrity. Options may include patch kits or specialized adhesives, selected based on the material composition of the mattress.

1. Auditory detection

Auditory detection forms a foundational element in the process of locating punctures within inflatable sleeping pads. The underlying principle rests on the acoustic signature generated by escaping air. A breach, irrespective of its size, causes a pressure differential, resulting in airflow from the mattress’s interior to the surrounding environment. This airflow, if sufficiently forceful, produces an audible hissing sound.

The effectiveness of auditory detection hinges significantly on the ambient noise level. In quiet environments, the faint hissing sound emanating from a small puncture becomes more discernible. Conversely, elevated background noise can mask this acoustic signature, rendering auditory detection ineffective. Consider, for instance, an air mattress leak during a camping trip in a forest versus a repair attempt inside a bustling city apartment. The former presents a more conducive environment for auditory detection.

Despite its limitations concerning ambient noise, auditory detection offers a non-invasive initial assessment method. It provides a preliminary indication of potential leak locations, thereby streamlining subsequent, more precise leak detection techniques. Its value lies in its simplicity and its ability to quickly identify more substantial punctures before employing methods requiring material application or immersion. Therefore, auditory detection serves as a fundamental, albeit not definitive, component in the comprehensive process.

2. Soapy water

The application of a soapy water solution represents a crucial method for pinpointing air leaks in inflatable sleeping pads. Its efficacy stems from the ability of soap to reduce surface tension, facilitating bubble formation at the precise location where air escapes.

- Bubble Formation Mechanism

When a soapy water solution is applied to an inflated mattress, the soap molecules lower the surface tension of the water. This allows air escaping from a puncture to form bubbles at the surface. The presence of these bubbles visually indicates the leak’s precise location, even for minute holes that are otherwise imperceptible.

- Solution Concentration Impact

The concentration of soap within the water solution influences bubble formation. Too little soap may not sufficiently reduce surface tension, hindering bubble formation. Excessive soap, conversely, can produce an overwhelming number of small bubbles, obscuring the precise leak location. A moderate concentration, typically a few drops of mild dish soap per cup of water, provides optimal results.

- Application Technique Considerations

The method of application affects the accuracy of leak detection. A spray bottle delivers a fine mist of soapy water, allowing for even coverage of the mattress surface. Alternatively, a sponge can be used to gently apply the solution, particularly in areas where spraying might be impractical or undesirable. Avoid saturating the mattress, as excess moisture can complicate leak detection.

- Environmental Factor Effects

Environmental factors such as temperature and humidity can influence bubble formation and persistence. High humidity may cause the soapy water solution to evaporate more slowly, potentially prolonging the detection process. Conversely, high temperatures can accelerate evaporation, requiring more frequent reapplication of the solution. Optimal conditions involve moderate temperature and humidity levels.

The ju

dicious use of soapy water, considering concentration, application, and environmental factors, significantly enhances the ability to accurately identify air leaks in inflatable sleeping pads. This technique, when properly executed, minimizes the need for invasive inspection methods and facilitates targeted repair efforts.

3. Visual inspection

Visual inspection forms a critical initial step in locating punctures within inflatable sleeping pads. Its importance derives from the direct observation of physical imperfections that serve as potential air leak sources. This process involves a thorough examination of the mattress surface, focusing on areas susceptible to damage or wear. The primary effect of a successful visual inspection is the rapid identification of visible punctures, cuts, abrasions, or seam defects, thereby accelerating the overall leak detection process.

The importance of visual inspection as a component of the leak detection process lies in its non-destructive nature and ability to identify obvious problems quickly. For example, a large tear caused by a sharp object during storage would be readily apparent upon visual inspection, obviating the need for more complex detection methods. Similarly, a manufacturing defect in a seam, evidenced by uneven stitching or material separation, would be easily identified. This technique is especially useful in conjunction with other methods; it can reduce the area to be inspected when using the soapy water test or submersion method, making those techniques more efficient. However, visual inspection alone cannot guarantee the detection of all leaks, as minute pinholes or internal seam failures may not be visually apparent.

In summary, visual inspection provides a foundational and efficient method for initiating the leak detection process. It offers the advantage of immediate identification of macroscopic damage, saving time and resources. While not a comprehensive solution in itself, visual inspection serves as a crucial preliminary step, enabling a more targeted and effective application of subsequent leak detection techniques, ensuring a greater likelihood of locating all existing punctures within the inflatable sleeping pad.

4. Submersion

Submersion, when applied to the process of locating leaks in air mattresses, represents a highly effective diagnostic technique. The underlying principle relies on displacing air within the mattress through an opening, which is then visually manifested as a stream of bubbles when the submerged mattress is immersed in water. This method is particularly useful for locating small, difficult-to-detect punctures that other methods, such as auditory inspection, may miss. The cause-and-effect relationship is straightforward: a puncture (cause) allows air to escape into the surrounding water, creating a bubble stream (effect). Its importance as a component of leak detection stems from its ability to provide definitive, visual confirmation of the leak’s location.

The practical application of submersion involves several key steps. First, the air mattress should be inflated to a pressure level suitable for use, though not to the point of overinflation. The mattress is then gradually submerged in a body of water, such as a bathtub or swimming pool, ensuring that all surfaces are immersed. The operator should carefully observe the submerged mattress for any streams of bubbles, marking the locations of these streams as the puncture sites. Real-world examples highlight the effectiveness of this technique: a slow leak on the underside of the mattress, undetectable by soapy water due to surface tension, will become immediately apparent when submerged. The methods usefulness extends to locating leaks along seams or in areas where the material is folded or creased, as these areas are prone to hidden punctures.

In conclusion, submersion offers a reliable means of definitively locating leaks in air mattresses, particularly those that are small or located in hard-to-reach areas. The challenges associated with this method include the need for a large water source and the potential for water damage if the mattress is not properly dried after testing. However, the benefits of accurate leak detection, leading to timely repair and prolonged mattress lifespan, outweigh these drawbacks, making submersion a valuable tool in the process of maintaining inflatable sleeping pads.

5. Pressure application

Pressure application, in the context of locating imperfections in inflatable sleeping pads, serves as a technique to amplify subtle air leaks that may not be readily detectable through other methods. By strategically applying localized pressure to suspected areas, the rate of air escape from a small puncture can be increased, thereby facilitating its detection.

- Localized Stress and Leak Amplification

Applying pressure to a specific area of the mattress increases the stress on the material surrounding a potential puncture. This stress forces a greater volume of air to escape through the opening, even if it is microscopic in size. For example, gently pressing down on a seam while listening for a hissing sound may reveal a leak that would otherwise remain undetected.

- Enhancement of Bubble Formation

When combined with the soapy water method, pressure application significantly enhances bubble formation. The increased airflow caused by pressure application results in larger, more easily visible bubbles at the leak site. This method is particularly effective for identifying leaks in areas with complex geometry, such as corners or valve attachments.

- Detection of Intermittent Leaks

Some leaks may be intermittent, only becoming apparent when the mattress is subjected to specific pressures or movements. Applying pressure and observing for air escape over a period of time can help to identify these elusive leaks. This approach is particularly useful for detecting leaks caused by material fatigue or minor abrasions that only open under stress.

- Differentiation from Background Noise

In environments with ambient noise, it can be challenging to distinguish the sound of a small air leak. Applying pressure can temporarily increase the intensity of the hissing sound, making it easier to differentiate from background noise. This is particularly useful in outdoor settings or in areas with machinery operating nearby.

By strategically applying localized pressure, subtle leaks can be amplified, and the effectiveness of other detection methods, such as soapy water and auditory inspection, can be enhanced. This technique plays a crucial role in ensuring comprehensive leak detection and facilitating timely repairs to inflatable sleeping pads, ultimately prolonging their lifespan and maintaining user comfort.

6. Marking

The process of marking, following the identification of an air leak in an inflatable sleeping pad, represents a critical step in ensuring effective and durable repair. The cause-and-effect relatio

nship is direct: accurately marking the puncture’s location (cause) enables precise patch placement or adhesive application (effect). The absence of precise marking can lead to misaligned repairs, inadequate sealing, and the continued loss of air. Its importance is underscored by the need to visually register the exact position of the leak, preventing oversight during subsequent repair stages.

Consider a scenario where a soapy water test reveals several small punctures clustered within a localized area of the mattress. Without marking each individual puncture site, the application of a repair patch may inadvertently cover some leaks while missing others entirely. Another example involves leaks discovered along seams, where visual distortions can make precise location challenging; marking ensures the repair material adequately bridges the compromised seam section. Furthermore, marking serves as a valuable reference point should the initial repair attempt prove unsuccessful, facilitating reinspection and targeted corrective action.

In conclusion, the act of marking identified punctures within an air mattress is not merely a perfunctory action but an essential component of the overall repair process. It directly contributes to the success of the repair, minimizes the risk of incomplete sealing, and enhances the long-term functionality of the inflatable sleeping pad. While seemingly a minor detail, the precision afforded by proper marking significantly impacts the durability and effectiveness of the restoration effort, ultimately extending the lifespan of the mattress.

Frequently Asked Questions

The following addresses common inquiries regarding the identification of air leaks in inflatable sleeping pads, offering clarity and guidance on various techniques and troubleshooting scenarios.

Question 1: Why is locating a small air leak in an air mattress often difficult?

Small air leaks can be challenging to locate due to the subtle nature of escaping air, which may not produce a readily audible sound or visually apparent disturbance. The small size of the puncture restricts airflow, making it difficult to pinpoint the precise location without employing specialized techniques.

Question 2: Is soapy water safe for all air mattress materials?

Generally, a mild soapy water solution is safe for most air mattress materials, including vinyl and rubber. However, it is advisable to test a small, inconspicuous area of the mattress first to ensure no discoloration or material degradation occurs. Avoid using harsh detergents or solvents.

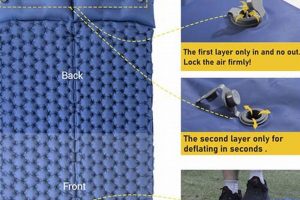

Question 3: Can air leaks occur in the mattress valve?

Yes, air leaks can develop in the valve mechanism due to wear, damage, or improper sealing. Inspect the valve for cracks, debris, or loose components. Consider lubricating the valve with silicone grease or replacing the valve if necessary.

Question 4: What should be done if a leak cannot be found using standard methods?

If standard methods fail to locate a leak, re-inflate the mattress to a higher pressure (within safe limits) and repeat the soapy water or submersion tests. Consider inspecting the mattress in a darkened room with a flashlight to highlight subtle air disturbances. If the leak remains elusive, seek professional repair services.

Question 5: Can temperature affect the detection of air leaks?

Temperature can influence air pressure within the mattress, affecting the rate of air escape from a leak. Warmer temperatures increase air pressure, potentially making leaks more noticeable. Conversely, colder temperatures may reduce air pressure, making leak detection more challenging.

Question 6: How long should an air mattress retain air before suspecting a leak?

The rate of air loss varies depending on the mattress quality, material, and environmental conditions. However, if an air mattress loses a noticeable amount of air within a few hours of inflation, it is reasonable to suspect a leak and initiate the detection process.

Accurate leak detection is paramount for maintaining the functionality and longevity of inflatable sleeping pads. By employing the appropriate techniques and addressing common concerns, effective repairs can be implemented.

The following sections provide guidance on repair techniques and material selection for addressing identified air leaks.

Conclusion

The preceding analysis has detailed the systematic approaches necessary to ascertain the presence and location of imperfections within inflatable sleeping pads. Emphasis has been placed on methods ranging from auditory assessment to submersion techniques, underscoring the importance of meticulous examination and diagnostic precision when addressing pressure loss issues.

Effective application of these methodologies serves not only to prolong the lifespan of such equipment but also to ensure user comfort and safety. Continuous vigilance and prompt corrective action remain paramount in maintaining the integrity of inflatable sleeping solutions. Future advancements in material science and detection technology may further refine leak identification processes.

![Best Toyota Tacoma Air Mattress [Sleep Easy!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Toyota Tacoma Air Mattress [Sleep Easy!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6744-300x200.jpg)