Pinpointing the origin of escaping air from an inflatable sleeping surface is essential for maintaining its functionality and comfort. This process typically involves a systematic examination of the mattress surface to identify the point where air is exiting, often through a small puncture or seam separation.

The ability to effectively identify and repair such breaches provides several benefits. It extends the lifespan of the air mattress, saving on replacement costs. Furthermore, it ensures a more restful and comfortable sleep experience by preventing gradual deflation during use. Historically, methods for finding these leaks have evolved from simple visual and auditory inspections to more sophisticated techniques involving soapy water and specialized detectors.

The following sections will detail practical approaches to successfully undertake this diagnostic task, encompassing visual inspection, auditory assessment, the application of soapy water solutions, and other useful strategies. These methodologies provide a framework for efficient defect detection and subsequent repair.

Locating Air Mattress Leaks

Effective leak detection requires a methodical approach and careful observation. The following tips provide guidance for locating the source of air loss in an inflatable mattress.

Tip 1: Visual Inspection: Begin by carefully examining the entire surface of the air mattress. Look for any obvious signs of damage, such as punctures, tears, or abrasions. Pay close attention to seams and areas around the valve, as these are common points of failure.

Tip 2: Auditory Detection: Inflate the mattress fully and listen intently for the sound of escaping air. In a quiet environment, even a small leak can produce a faint hissing sound. Move slowly around the mattress, concentrating on areas suspected of being damaged.

Tip 3: Soapy Water Application: Mix a solution of mild dish soap and water. Apply the solution to small sections of the inflated mattress using a sponge or spray bottle. Observe closely for the formation of bubbles, which indicates the presence of a leak.

Tip 4: Submersion Testing: If practical, submerge sections of the inflated air mattress in water. Observe for bubbles rising from the submerged area, indicating the location of the leak. This method is particularly effective for smaller mattresses or sections of larger ones.

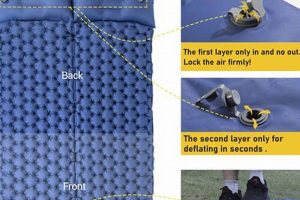

Tip 5: Valve Inspection: The valve is a common source of leaks. Ensure the valve is properly closed and sealed. Apply soapy water around the valve area to check for leaks. Consider tightening or replacing the valve if necessary.

Tip 6: Check the Seams: Air mattress seams are vulnerable points. Run your fingers along the seams to feel for escaping air. Use soapy water to confirm any suspected leaks along the seams.

Tip 7: Use a Bright Light: In a darkened room, shine a bright light behind the air mattress. This can help to reveal small holes or thin spots that might be difficult to see in normal lighting conditions.

Adhering to these strategies significantly increases the likelihood of successfully identifying the leak’s source, enabling prompt repair and restoration of the air mattress’s functionality.

With the leak located, appropriate repair measures can be implemented, preserving the mattress and ensuring a comfortable sleeping surface.

1. Visual Surface Examination

Visual surface examination constitutes the initial and often most straightforward step in determining the location of a leak in an air mattress. This process involves a meticulous inspection of the mattress’s exterior for discernible signs of damage that could compromise its airtight seal. Punctures, tears, abrasions, and seam separation are all potential indicators of air leakage. Success in this stage often depends on adequate lighting and a systematic approach to ensure the entire surface area is thoroughly reviewed. For example, a visible puncture caused by a sharp object is a clear indication of a leak point that can be immediately addressed. Furthermore, areas subjected to high stress, such as those near seams or the valve, should receive particularly close attention due to their elevated susceptibility to wear and tear. Detecting these visual cues early can substantially reduce the time and effort required for more complex leak detection methods.

The efficacy of visual surface examination is enhanced by understanding the types of damage most likely to occur in different usage scenarios. Air mattresses used outdoors, for example, are more prone to punctures from rocks or thorns, while those used indoors might suffer abrasions from rough flooring. Careful observation of the mattress’s material can also reveal subtle defects not immediately apparent. For instance, a stretch mark near a seam might indicate an area of impending failure. A well-executed visual inspection serves as a critical filter, allowing for the rapid identification of obvious leaks and the elimination of undamaged areas from further scrutiny. However, it is important to acknowledge that many leaks, especially those caused by minute punctures or slow seam degradation, may not be visible to the naked eye, necessitating the deployment of supplementary detection techniques.

In summary, visual surface examination forms an indispensable initial phase in the “how to locate a leak in an air mattress” procedure. Its value lies in its simplicity, non-invasiveness, and potential for rapid leak identification. While not foolproof, this step streamlines the diagnostic process by eliminating undamaged areas and highlighting potential problem spots for more targeted investigation. The technique necessitates patience, careful observation, and an understanding of common failure points, contributing significantly to the overall efficiency of leak detection and subsequent repair efforts.

2. Auditory detection of escaping air

Auditory detection of escaping air represents a fundamental method within the procedures of how to locate a leak in an air mattress. This technique leverages the human ear’s ability to perceive subtle sounds generated by pressurized air exiting a confined space through a breach in the mattress’s material. Its effectiveness hinges on environmental conditions and the operator’s attentiveness.

- Quiet Environment Importance

The efficacy of auditory detection is significantly influenced by the surrounding noise level. A quiet environment allows for the subtle hissing or whistling sounds of escaping air to be more readily discernible. In noisy surroundings, these sounds may be masked, rendering this method ineffective. The implication for leak detection is that a controlled, quiet space is necessary for reliable results.

- Proxim

ity and MovementThe distance between the listener and the air mattress directly affects the detectability of escaping air. Proximity is crucial; closer proximity increases the intensity of the sound reaching the ear. Slow, deliberate movement around the inflated mattress allows for systematic coverage, increasing the chances of pinpointing the leak’s source as the listener’s ear moves closer to it. The implications for leak detection is that scanning slowly and getting near the mattress surface can improve the detection rate.

- Distinguishing Leak Sounds

The sounds emanating from a leak can vary depending on the size and nature of the breach. Larger leaks produce a more pronounced hiss, while smaller leaks generate a softer, higher-pitched whistle. Experience in differentiating these sounds is valuable in accurately locating the source of the leak. The background noise can sometimes be a challenge to the auditory perception. The implication is understanding that various sound leak emits can assist in locating one.

- Limitations and Combinations

Auditory detection, while useful, possesses inherent limitations. Very small leaks may produce sounds too faint to be heard, even in quiet environments. Therefore, it is often employed in conjunction with other methods, such as soapy water application, to confirm suspected leak locations. This combined approach provides a more comprehensive and reliable assessment.

In conclusion, auditory detection of escaping air serves as a valuable, though not infallible, component of the overall process of locating a leak in an air mattress. Its effectiveness is dependent on a controlled environment, deliberate technique, and an understanding of its limitations, making it best suited as part of a multi-faceted approach to leak detection.

3. Soapy water bubble method

The soapy water bubble method is a widely employed and highly effective technique for pinpointing leaks within inflatable structures, notably air mattresses. Its utility stems from its simplicity, cost-effectiveness, and visual clarity, enabling precise identification of even minute breaches in the mattress’s airtight seal.

- Principle of Operation

The method relies on reducing the surface tension of water by adding soap, thereby facilitating the formation of bubbles. When applied to a pressurized air mattress, the soapy water solution seeps into any existing leaks. The escaping air then forces the solution outwards, creating visible bubbles at the point of egress. This visual indicator directly identifies the location requiring repair. For example, a slow leak might produce a cluster of small, persistent bubbles, while a larger leak generates larger, more rapidly expanding bubbles. The size and rate of bubble formation are often proportional to the size of the leak itself.

- Preparation and Application

Proper preparation is crucial for successful application. The ideal solution consists of a mild dish soap diluted in water. Overly concentrated solutions can leave residue, while insufficient soap may not produce stable bubbles. The solution is typically applied using a sponge or spray bottle, ensuring thorough coverage of the suspected leak area. Gradual application is recommended, as excess solution can obscure small leaks. It is imperative to observe closely for bubble formation immediately after application. A targeted approach, focusing on seams, valves, and areas of visible wear, maximizes efficiency.

- Advantages and Limitations

The primary advantage of this method is its ability to detect even very small leaks that are difficult to locate visually or audibly. The visual nature of bubble formation leaves little ambiguity, facilitating precise repair. However, the method is not without limitations. Drafts or air currents can distort or disperse bubbles, making leak identification challenging. Furthermore, certain materials may not readily wet, requiring repeated application. The method is also less effective in identifying leaks within deeply recessed areas or complex folds in the mattress material.

- Complementary Technique

While the soapy water bubble method is highly effective, it is often used in conjunction with other leak detection techniques. For example, a visual inspection may first identify areas of potential concern, followed by targeted application of the soapy water solution. Similarly, auditory detection of escaping air can narrow down the search area before employing the soapy water method for precise localization. This integrated approach enhances the overall effectiveness of leak detection and repair efforts.

In summary, the soapy water bubble method is an invaluable tool in “how to locate a leak in an air mattress” protocols. Its straightforward application and clear visual indication of leak points render it accessible to users of all skill levels. While limitations exist, they can be mitigated through careful preparation, controlled application, and integration with complementary detection methods, ensuring efficient and effective leak identification.

4. Valve integrity verification

Valve integrity verification is a critical aspect of procedures that address how to locate a leak in an air mattress. The valve, serving as the primary point of air entry and retention, is a common source of leaks. Consequently, its thorough inspection is essential for accurate diagnosis and effective repair.

- Seal Assessment

The initial step in valve integrity verification involves assessing the physical condition of the valve seal. This includes visually inspecting the valve seat and the valve stem or cap for any signs of damage, such as cracks, tears, or debris accumulation. A compromised seal permits air leakage, even when the valve is nominally closed. For instance, a small crack in the valve seat can allow a continuous, slow escape of air, leading to gradual deflation of the mattress. This assessment provides immediate insight into potential leak sources at the valve.

- Closure Mechanism Evaluation

Beyond the seal, the closure mechanism itself must be evaluated. Many air mattress valves employ a one-way or multi-stage closure system. Proper functionality of this mechanism ensures that air cannot escape once the mattress is inflated. A malfunctioning closure, due to a broken spring or damaged threads, can prevent the valve from fully sealing, resulting in a leak. Testing the closure mechanism involves manually opening and closing the valve to ensure it engages correctly and provides a secure seal.

- Soapy Water Testing at the Valve

Even with a seemingly intact seal and a functional closure mechanism, microscopic leaks can still occur around the valve’s perimeter or within the valve assembly. The application of soapy water solution around the valve body and its connection point to the mattress fabric can reveal these subtle leaks. Bubble formation indicates air escaping through minute gaps. This test provides definitive evidence of valve-related leakage and aids in distinguishing it from leaks elsewhere on the mattress.

- Valve Tightness Confirmation

The physical tightness of the valve within its mounting on the air mattress is a factor often overloo

ked. Over time or due to repeated use, the valve may loosen, creating a pathway for air to escape between the valve body and the mattress material. Confirming the valve’s tightness involves carefully attempting to tighten the valve without causing damage. If the valve is loose, gentle tightening can often restore the seal. However, excessive force can exacerbate the problem by stripping threads or damaging the valve itself.

These facets underscore the importance of a comprehensive approach to valve integrity verification within the broader context of how to locate a leak in an air mattress. Addressing valve-related issues early in the diagnostic process can often streamline the search and lead to quicker, more effective repairs, ultimately extending the lifespan of the air mattress and ensuring user comfort.

5. Seam inspection

Seam inspection constitutes a critical component in how to locate a leak in an air mattress, primarily due to the inherent vulnerability of these joining points. The manufacturing process involves bonding separate pieces of material to form the mattress’s structure. These seams, often created through heat sealing or adhesive bonding, represent areas of potential weakness where failures can initiate and propagate, leading to air leakage. A thorough seam inspection aims to identify any defects, separations, or compromised sections that could permit air to escape. The efficacy of the inspection directly impacts the success of locating and subsequently repairing leaks, thereby extending the functional lifespan of the air mattress. For example, a poorly executed heat seal can create microscopic channels through which air gradually escapes, resulting in a slow but persistent leak. Similarly, degradation of adhesive along a seam can lead to complete separation, creating a more significant and easily detectable leak.

The practical application of seam inspection involves a systematic visual and tactile examination of all seams present on the air mattress. This process includes closely observing the seams for any signs of separation, discoloration, or distortion. Running a hand along the seam can reveal subtle areas of weakness or incomplete bonding. The use of a bright light source can further aid in identifying minute defects that might otherwise be overlooked. In addition to visual and tactile methods, soapy water solutions can be applied to suspected areas. The formation of bubbles along the seam indicates a leak, confirming the presence of a compromised section. The systematic nature of seam inspection ensures that no potentially problematic area is overlooked, increasing the likelihood of identifying all existing leaks.

In summary, seam inspection plays a vital role in the efficient location of leaks in air mattresses. The inherent vulnerability of seams as joining points necessitates a thorough and methodical examination. Challenges in seam inspection can arise from the microscopic nature of some defects or the presence of complex seam geometries. Despite these challenges, the systematic application of visual, tactile, and soapy water-based inspection techniques provides a reliable means of identifying leaks originating from compromised seams, facilitating effective repair and extending the service life of the air mattress.

6. Submersion testing, if possible

Submersion testing, when feasible, provides a highly effective method for how to locate a leak in an air mattress. The principle hinges on immersing the inflated mattress, or sections thereof, in water. This immersion creates a pressure differential, forcing air to escape through any existing leaks. The escaping air manifests as visible bubbles, thereby directly revealing the leak’s precise location. The effectiveness of submersion testing stems from its capacity to identify even minute leaks that might otherwise remain undetected through visual or auditory methods alone. For instance, a microscopic puncture, undetectable by the naked eye, will produce a steady stream of small bubbles when submerged, allowing for precise pinpointing of the defect. The feasibility of this approach is, however, contingent upon the size of the mattress and the availability of a suitable container.

Practical application of submersion testing involves inflating the air mattress and systematically immersing sections of it in a water-filled tub or pool. Careful observation is crucial to identify the source of any emerging bubbles. Areas suspected of leaks, such as seams or valve regions, should be prioritized. Smaller air mattresses can be fully submerged, whereas larger models may require sectional immersion. In instances where full submersion is impractical, a smaller basin or container can be utilized to test specific areas of concern. Successful implementation requires a calm water surface to facilitate bubble detection. Real-world examples demonstrate the efficacy of this method, with users routinely reporting successful leak identification in situations where other techniques have failed. This underscores the value of submersion testing as a component of leak detection protocols.

In summary, submersion testing provides a robust and visually clear method for how to locate a leak in an air mattress. Its effectiveness in revealing even the smallest leaks makes it a valuable addition to standard leak detection procedures. While practical limitations exist regarding the size of the mattress and the availability of suitable submersion containers, the technique remains a highly reliable option when feasible. When integrated with other methods, submersion testing contributes significantly to comprehensive leak detection and facilitates effective repair strategies, ultimately extending the lifespan of the air mattress and ensuring continued functionality.

Frequently Asked Questions About Air Mattress Leak Detection

This section addresses common inquiries regarding methods for locating leaks in air mattresses. The goal is to provide clear, concise answers to enhance understanding and improve the success rate of leak detection efforts.

Question 1: What is the most common cause of leaks in air mattresses?

The most prevalent causes include punctures from sharp objects, seam separation due to stress or degradation of adhesives, and valve malfunction preventing a complete seal. Material fatigue also contributes to leak development over time.

Question 2: Can a leak be too small to detect?

Yes, microscopic leaks can be challenging to identify using standard methods. These often necessitate the application of soapy water or submersion testing to visualize air escaping, as auditory or visual detection may prove insufficient.

Question 3: Is it safe to use dish soap on an air mattress?

Mild dish soap is generally safe for use in leak detection. However, it is advisable to use a diluted solution and avoid abrasive soaps that could damage the mattress material. Thoroughly rinse any residue after leak detection to prevent material degradation.

Question 4: How can the valve area be effectively checked for leaks?

The valve area should be inspected for physical damage, such as cracks or debris. Applying a soapy water solution around the valve and observing for bubble formation is a reliable method for detecting leaks emanating from the valve assembly.

Question 5: What should be done if a leak cannot be fou

nd despite thorough inspection?

If a leak remains elusive, consider re-inflating the mattress and repeating the detection process. Minute leaks may require multiple attempts to locate. Alternatively, professional repair services may possess specialized equipment for leak detection.

Question 6: Does the type of material affect the ease of leak detection?

Yes, the material composition influences leak detection. Porous materials can complicate the process, as air may diffuse through the material itself, masking the location of the actual leak. Non-porous materials typically provide more straightforward leak detection.

Effective leak detection hinges on a methodical approach and the utilization of appropriate techniques. Addressing the underlying causes of leaks and employing preventative measures can significantly extend the lifespan of an air mattress.

The subsequent section will delve into strategies for repairing identified leaks, ensuring the continued functionality of the air mattress.

Conclusion

The preceding discussion has systematically explored essential methodologies concerning how to locate a leak in an air mattress. A comprehensive approach necessitates visual inspection, auditory assessment, the application of soapy water solutions, valve integrity verification, thorough seam inspection, and, when practical, submersion testing. Successfully employing these techniques significantly enhances the probability of pinpointing the source of air loss.

Mastery of these diagnostic skills ensures both prolonged utility of air mattresses and mitigation of unnecessary replacement costs. Continued vigilance in applying these strategies will yield greater efficiency in leak detection, contributing to a more sustainable and cost-effective approach to maintaining inflatable sleeping surfaces. Focus on these techniques for future success.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)