The central topic concerns modifying the vertical positioning of a sleep surface within an infant’s bed. This involves adjusting the support structure upon which the mattress rests, effectively changing the mattress’s height relative to the crib’s top rail. An example would be lowering the mattress as a baby learns to sit or stand, preventing them from climbing out.

This adjustment is important for infant safety and caregiver convenience. Initially, a higher mattress position makes it easier for parents to lift a newborn in and out of the crib, reducing strain. As the infant develops motor skills, a lower position is essential to prevent falls and ensure secure containment within the crib’s boundaries. Historically, adjustable crib mattress heights have evolved alongside changing recommendations regarding infant sleep safety and parental ergonomics.

The following sections will address specific methods and considerations related to altering the height of the sleep surface in a crib, focusing on safety standards, recommended practices, and the selection of appropriate adjustment techniques.

Considerations for Crib Mattress Height Adjustment

Careful attention to detail is crucial when modifying a crib mattress’s vertical position. Prioritize safety and adhere to manufacturer guidelines during any adjustment process.

Tip 1: Consult the Crib’s Manual: Always refer to the manufacturer’s instructions before making any adjustments. The manual provides specific guidance for the crib model, ensuring compliance with safety standards.

Tip 2: Evaluate Infant Development: Lower the mattress position as the infant’s ability to sit, crawl, or stand increases. This reduces the risk of falls over the crib rail.

Tip 3: Ensure Secure Fastening: After adjusting the mattress support, confirm that all screws, bolts, or locking mechanisms are securely tightened. A loose support system can create a hazardous situation.

Tip 4: Maintain Proper Rail Height: The top of the crib rail should be at least 26 inches above the mattress support in its lowest position. This provides adequate containment for a standing infant.

Tip 5: Check for Gaps: After adjustment, inspect for gaps between the mattress and the crib frame. Gaps can pose an entrapment hazard.

Tip 6: Use Manufacturer-Approved Components: Only use components specifically designed and approved by the crib manufacturer for adjusting the mattress height. Avoid makeshift solutions.

Tip 7: Reassess Regularly: Periodically re-evaluate the mattress height relative to the infant’s development and adjust as needed to maintain a safe sleeping environment.

Following these recommendations promotes a secure sleep environment for the infant, minimizing potential risks associated with crib mattress height.

The subsequent discussion will cover potential problems encountered during the process and methods for addressing them.

1. Manufacturer's Instructions

Adherence to manufacturer’s instructions is paramount when adjusting the height of a crib mattress. These instructions provide critical, model-specific guidance that directly impacts the safety and proper functionality of the crib. Disregarding these guidelines can compromise the structural integrity of the crib and pose significant risks to the infant.

- Specific Height Settings

Manufacturer’s instructions detail the allowable height positions for the mattress support. These settings are determined by the crib’s design and are crucial for maintaining safe rail heights as the child grows. Deviating from these specified positions can result in rails that are too low, increasing the risk of the child climbing out, or create hazardous gaps between the mattress and crib frame.

- Approved Hardware and Tools

The instructions identify the correct hardware and tools necessary for adjusting the mattress support. Using unauthorized components can damage the crib’s structure, compromise the locking mechanisms, and lead to instability. Manufacturers often provide specific torque specifications for fasteners; adhering to these values ensures secure assembly without over-tightening and stripping the threads.

- Safety Warnings and Precautions

Manufacturer’s instructions include essential safety warnings and precautions related to the height adjustment process. These warnings address potential hazards such as pinch points, unstable configurations, and weight limits. Heeding these warnings minimizes the risk of injury during the adjustment procedure and ensures the crib remains safe for the infant’s use.

- Assembly Verification Steps

The instructions typically outline steps for verifying the correct and secure assembly of the mattress support after adjustment. These steps may include checking the tightness of fasteners, confirming the stability of the support structure, and inspecting for gaps between the mattress and crib frame. Proper verification ensures the crib is ready for safe use after the height has been altered.

The integration of these elements from the manufacturer’s instructions directly dictates the proper and safe method for adjusting a crib mattress. Ignoring these instructions significantly increases the risk of structural failure, potential injury, and non-compliance with safety regulations.

2. Secure locking mechanisms

Secure locking mechanisms are integral to the safe adjustment of a crib mattress’s vertical position. Their proper function directly influences the structural integrity of the crib and minimizes the risk of unintended support collapse, potentially leading to infant injury. These mechanisms are not merely incidental components; they are critical safety features.

- Engagement Integrity

Engagement integrity refers to the reliability and robustness of the locking mechanism’s ability to securely fasten the mattress support at a chosen height. A compromised locking system, due to wear, damage, or improper installation, can disengage under load, causing the mattress support to shift or collapse. Real-world examples include plastic clips that crack over time or screws that strip their threads. In the context of vertically adjusting a crib mattress, inadequate engagement integrity defeats the purpose of adjustability by creating an unstable sleeping surface.

- Redundancy Features

Redundancy features involve incorporating multiple locking elements or a fail-safe design. This means that even if one part of the locking mechanism fails, another component will prevent complete disengagement. Examples include a pin-and-clip system where the pin secures the support, and the clip acts as a secondary lock. In scenarios where vertically adjusting the crib mattress, redundancy provides an additional layer of security, mitigating the consequences of a single-point failure.

- Material Durability

Material durability pertains to the capacity of the locking mechanism’s components to withstand stress, wear, and environmental factors without degrading. A locking mechanism constructed from inferior materials, such as brittle plastic or corrosion-prone metal, is more likely to fail over time. Examples include plastic locking arms that snap under pressure or metal fasteners that rust and seize. Adjusting the crib mattress height involves placing stress on these locking elements, so the use of durable materials is paramount.

- Inspection and Maintenance Protocols

Inspection and maintenance protocols dictate the procedures for regularly examining the locking mechanisms for signs of damage, wear, or improper function. This includes visually inspecting for cracks, loose fasteners, and corrosion, as well as testing the engagement and disengagement of the mechanism. Examples include routine checks during bedding changes or after moving the crib. Incorporating regular inspection protocols ensures that any degradation of the locking mechanism is identified and addressed promptly, maintaining the safety of the adjustable crib mattress height.

In summary, the multifaceted role of secure locking mechanisms is essential for the safe adjustment of the crib mattress height. Each facet, from engagement integrity to maintenance protocols, contributes to a system that minimizes the risk of collapse or instability. The absence or compromise of any one of these facets can significantly impact the overall safety and reliability of the crib’s height adjustment feature.

3. Proper rail height

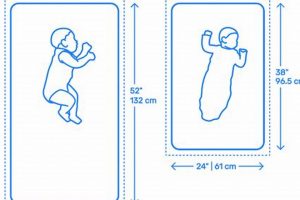

The process of modifying a crib mattress’s vertical position is intrinsically linked to maintaining proper rail height. Rail height, defined as the vertical distance from the top of the crib rail to the surface of the mattress when in its lowest position, directly influences infant safety. A mattress positioned too high, achieved during the adjustment process without considering rail height, negates the protective function of the rails, increasing the risk of a child climbing out. A real-life example involves a crib where the mattress was raised to a higher setting without lowering the crib’s side rail appropriately to compensate; the infant was able to climb over the railing and fell.

Achieving the correct rail height during mattress adjustment demands careful measurement and adherence to manufacturer guidelines. These guidelines specify minimum rail heights, typically around 26 inches above the mattress support in its lowest position, to ensure adequate containment as the infant grows and becomes more mobile. This measurement must be taken after each vertical adjustment of the mattress. A practical application of this understanding is routinely checking the distance between the mattress and the top of the rail to make sure a secure environment is created.

Ensuring proper rail height in conjunction with altering the mattress position presents a critical challenge in infant safety. Balancing caregiver convenience, achieved through higher mattress settings for younger infants, with the safety requirements of preventing falls requires a continuous assessment of the child’s developmental progress and diligent adherence to established safety standards. This interplay underlines the importance of considering rail height as an inseparable component of the crib mattress adjustment process and of creating a safe environment for the child.

4. Infant's development stage

The stage of infant development directly dictates adjustments to a crib mattress height. A newborn infant requires a higher mattress setting, facilitating easier access for caregivers during frequent feeding and comforting. However, this higher setting introduces potential risks as the infant’s motor skills advance. As an infant begins to sit independently, pull to a standing position, or demonstrate climbing behaviors, the mattress height must be lowered to prevent falls. A failure to adjust the mattress height in accordance with developmental milestones creates a scenario where the infant can climb out of the crib, resulting in serious injury. An example illustrates this point: a 9-month-old, capable of pulling to stand, fell from a crib where the mattress remained in the highest position, resulting in a fractured arm.

The practical application of understanding this developmental correlation necessitates continuous observation and proactive adjustment. Caregivers must be vigilant in monitoring the infant’s progress, recognizing emerging motor skills, and responding promptly by lowering the mattress. Furthermore, guidelines from pediatricians and safety organizations offer valuable insights into age-appropriate mattress heights. The convergence of observed behaviors, expert recommendations, and parental diligence promotes a safe sleeping environment. Regularly assessing the distance between the mattress surface and the top of the crib rail, as well as consulting growth charts, enables informed decision-making regarding mattress height adjustments.

In summary, aligning crib mattress height with the infant’s developmental stage represents a critical safety measure. Neglecting this relationship introduces avoidable risks. Vigilant observation, prompt action, and adherence to safety guidelines are essential components in establishing a secure sleeping environment throughout the infant’s developmental progression. Addressing this ensures the adjustment of a crib mattress is a function of developmental advancement.

5. Avoid makeshift solutions

The act of modifying the vertical positioning of a crib mattress introduces inherent safety considerations, making the avoidance of makeshift solutions a paramount concern. Improvised methods, such as employing books, wooden blocks, or other non-approved materials to elevate the mattress, circumvent established safety protocols and undermine the structural integrity of the crib. This action can destabilize the mattress support system, increasing the risk of collapse and potential infant injury. An instance of this involved using stacked magazines beneath a mattress, resulting in uneven support, the mattress tilting, and the infant becoming trapped. The direct correlation illustrates the importance of refraining from such practices when vertically adjusting the mattress.

Adherence to manufacturer-recommended adjustment mechanisms is vital to mitigate potential hazards. Crib manufacturers design their products to meet specific safety standards, with mattress support systems engineered to withstand defined weight loads and distribution. Utilizing only approved hardware ensures that these standards are maintained. Makeshift solutions introduce unpredictable variables that invalidate these engineering calculations, compromising the overall safety of the crib. A practical application is consistently verifying that all adjustment components are original to the crib, correctly installed, and securely fastened.

The avoidance of makeshift solutions while vertically adjusting a crib mattress constitutes a core component of infant safety. Improvisation introduces unacceptable risks, while strict adherence to manufacturer specifications promotes a secure sleeping environment. Vigilance in this regard is not merely a recommendation, but a necessity to prevent potential harm.

6. Gap inspection

The act of vertically adjusting a crib mattress necessitates a thorough gap inspection as a critical follow-up measure. The adjustment process, while designed to enhance caregiver access and infant safety at various developmental stages, inherently carries the potential to introduce or exacerbate gaps between the mattress and the crib frame. These gaps, even if seemingly minor, pose a significant entrapment hazard for infants, particularly those possessing the motor skills to maneuver themselves within the crib’s confines. A well-documented example involves instances where an infant’s limb becomes lodged in a newly created gap, leading to injury or, in extreme cases, positional asphyxia. Thus, gap inspection functions as an essential safety validation following any manipulation of the mattress height.

This inspection involves a systematic assessment of the perimeter of the mattress where it meets the crib frame. The focus rests on identifying any spaces exceeding the maximum permissible width, typically defined by regulatory standards. A simple, yet effective, method involves using a measuring device to quantify the gap’s dimensions. Corrective action must then be undertaken if the gap surpasses the established threshold. This action may necessitate re-adjusting the mattress position, utilizing manufacturer-approved gap fillers, or, if the problem persists, discontinuing use of the crib until a safe configuration can be achieved. This practical application of inspection protocols directly mitigates the entrapment risk associated with mattress height adjustments.

In conclusion, gap inspection constitutes a non-negotiable component of vertically adjusting a crib mattress. This practice serves as the final line of defense against potential entrapment hazards created or amplified by the adjustment process. Consistent, diligent gap inspection, coupled with prompt corrective actions, ensures that the enhanced caregiver accessibility and developmental appropriateness afforded by mattress height adjustment does not come at the expense of infant safety. The role of the caregiver in the detection and mitigation of gaps created by altering the mattress level is key to promoting a safe environment within the crib.

Frequently Asked Questions About Adjusting Crib Mattress Height

The following addresses common inquiries regarding the modification of crib mattress height to promote infant safety.

Question 1: Why is adjustment of the crib mattress height necessary?

Adjusting the mattress height is essential to adapt to the infant’s developmental progress. A higher position facilitates access for caregivers to a newborn, while a lower position prevents falls as the infant learns to sit, stand, or climb.

Question 2: When should the crib mattress height be lowered?

The mattress height requires lowering when the infant demonstrates the ability to sit unassisted, pull to a standing position, or shows signs of attempting to climb. This proactive measure reduces the risk of falls.

Question 3: What is the recommended distance between the top of the crib rail and the mattress surface?

A general recommendation stipulates that the distance between the top of the crib rail and the mattress surface, in its lowest position, should be at least 26 inches. However, adherence to the manufacturer’s specific guidelines is paramount.

Question 4: Are there risks associated with raising the crib mattress too high?

Yes. Raising the mattress too high compromises the protective function of the crib rails, increasing the likelihood of the infant climbing out and sustaining injuries from a fall.

Question 5: What steps should be taken after adjusting the crib mattress height?

After adjustment, ensure all locking mechanisms are securely engaged, confirm that no gaps exist between the mattress and crib frame, and verify that the top of the crib rail meets the minimum height requirement.

Question 6: Should makeshift methods ever be used to raise a crib mattress?

No. Makeshift methods, such as using books or blocks, are strictly prohibited. Employing only manufacturer-approved adjustment mechanisms ensures compliance with safety standards and maintains structural integrity.

Adherence to these principles contributes significantly to creating a secure sleeping environment for the infant.

The following section details potential issues encountered during the adjustment procedure and remedial actions.

Conclusion

The preceding discussion has explored the multifaceted process of how to raise crib mattress, emphasizing the significance of manufacturer guidelines, secure locking mechanisms, proper rail height, infant development considerations, the avoidance of makeshift solutions, and meticulous gap inspection. These elements are not isolated actions but rather interconnected components of a comprehensive safety strategy.

Given the critical role of a secure sleeping environment in infant well-being, diligent adherence to these principles remains paramount. Regular assessment, proactive adjustments, and a commitment to established safety protocols will contribute to mitigating potential hazards and ensuring the crib serves its intended purpose: a safe and secure space for infant rest and development.