The process of filling an Intex air mattress with air is a fundamental aspect of its use. This procedure involves introducing air into the mattress’s internal chambers until a desired level of firmness is achieved. The methods can vary, employing integrated electric pumps, separate air pumps, or even manual inflation techniques.

Proper execution of this process is critical for user comfort and the longevity of the mattress. Adequate internal pressure ensures a supportive sleeping surface, while over-inflation can lead to seam stress and potential damage. Historically, advancements in pump technology have significantly streamlined this activity, making inflatable mattresses a more convenient bedding solution.

Understanding the different methods and considerations for achieving optimal firmness will allow for prolonged use and satisfaction with an Intex air mattress.

Optimizing Air Mattress Firmness

Achieving the desired firmness level when providing air to an Intex mattress involves several key considerations to ensure both comfort and longevity of the product.

Tip 1: Utilize the Correct Inflation Method: Employ the pump type designated for the specific mattress model. Refer to the manufacturer’s instructions to determine the appropriate nozzle or valve interface. Using an incompatible pump may result in damage or inefficient filling.

Tip 2: Monitor Air Pressure: Avoid over-inflation, which can stress the seams and potentially lead to ruptures. If using an electric pump, stop inflation periodically to assess firmness by applying moderate pressure to the mattress surface. A slight give is generally preferred over a rock-hard feel.

Tip 3: Adjust for Temperature Fluctuations: Air volume expands and contracts with temperature changes. During colder weather, the mattress may require additional air to maintain firmness. Conversely, in warmer conditions, a slight deflation may be necessary to prevent over-inflation.

Tip 4: Seal the Valve Securely: Ensure the air valve is properly sealed after inflation to prevent air leakage. Double-check that the valve cap is tightly closed and that no debris obstructs the seal. A poorly sealed valve can lead to gradual deflation throughout the night.

Tip 5: Distribute Weight Evenly: When multiple individuals are using the mattress, encourage even distribution of weight to prevent localized stress points. Concentrated pressure in one area can accelerate wear and tear and potentially compromise the mattress’s structural integrity.

Tip 6: Consider a Topper: If after inflation, the mattress feels too firm, consider using a mattress topper. This can add an extra layer of cushioning for enhanced comfort and can help distribute weight more evenly.

Adhering to these recommendations will promote a comfortable sleeping experience and extend the lifespan of the Intex air mattress.

Following these strategies will lead to greater satisfaction and prolonged use of the inflatable mattress.

1. Pump Compatibility

Pump compatibility is a foundational element of Intex air mattress inflation. The selection of an appropriate pump directly dictates the efficiency and effectiveness of inflating the mattress to its intended operational pressure. Incompatibility arises when the pump’s nozzle or valve interface does not properly align with the mattress’s air valve, resulting in air leakage, prolonged inflation times, or potential damage to the valve itself. For instance, attempting to use a high-pressure bicycle pump on a mattress designed for a low-pressure, high-volume electric pump will likely lead to a failed seal and inefficient filling. Real-life instances frequently reveal frustrated users struggling with improvised solutions due to mismatched equipment, ultimately compromising the mattress’s inflation level and structural integrity.

Furthermore, the pump’s pressure capacity must align with the mattress’s recommended inflation range. Over-pressurizing the mattress through an overly powerful pump increases the risk of seam rupture and material failure. Conversely, a pump with insufficient pressure may not be able to fully inflate the mattress to its desired firmness, leading to an uncomfortable sleeping surface. The practical significance of understanding this lies in the need to carefully consult the mattress’s specifications and select a pump that conforms to those requirements, preventing damage and ensuring optimal performance. An example of proper pump selection would be using the specific Intex electric pump designated for a Queen-sized air mattress, which is calibrated to provide the correct pressure and volume for that particular model.

In summary, pump compatibility is not merely a matter of convenience but a critical factor determining the success and safety of Intex air mattress inflation. Challenges such as universal adapter availability can sometimes obscure the importance of dedicated pump-valve alignment. However, prioritizing proper pump selection, based on the manufacturer’s recommendations, is essential for achieving adequate inflation, avoiding damage, and extending the mattress’s usable lifespan.

2. Valve Integrity

Valve integrity is a critical element in the context of Intex air mattress inflation, directly impacting the ability to achieve and maintain the desired level of firmness and air retention. A compromised valve can lead to gradual or rapid deflation, rendering the mattress unusable and negating the benefits of proper inflation techniques.

- Valve Material and Construction

The material composition and construction of the valve directly influence its durability and resistance to air leakage. Valves constructed from low-grade plastics are susceptible to cracking or deformation over time, especially with repeated use or exposure to extreme temperatures. A damaged valve seat prevents a tight seal, leading to constant air loss. Real-world scenarios include valves failing after a few uses, particularly in models with thinner plastic components.

- Valve Seal Design and Effectiveness

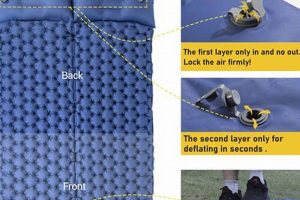

The design of the valve seal is paramount in maintaining air pressure within the mattress. Many Intex air mattresses utilize a one-way valve system with a spring-loaded mechanism to prevent backflow during inflation. However, if this mechanism becomes obstructed by debris or loses its spring tension, the seal is compromised. Regular inspection and cleaning of the valve can mitigate this issue. For example, grains of sand or small pieces of fabric can lodge within the valve, preventing a complete seal.

- Valve Thread and Cap Integrity

For valves that incorporate a threaded cap, the integrity of the thread is crucial. Stripped threads or a damaged cap can prevent a tight seal, allowing air to escape. Cross-threading is a common problem that can permanently damage th

e valve. Proper alignment and gentle tightening of the cap are essential to prevent this. Replacing a damaged valve cap is a straightforward remedy, provided a compatible replacement is available. - Valve Placement and Stress Factors

The location of the valve on the mattress and the stresses it endures during use contribute to its overall integrity. Valves positioned in areas prone to bending or compression are more likely to develop leaks over time. Users should avoid placing excessive weight directly on or near the valve. Reinforcing the area around the valve during manufacturing and careful placement can help prolong its lifespan.

In summary, maintaining valve integrity is not merely a minor consideration but a fundamental requirement for successful and lasting Intex air mattress inflation. The multifaceted aspects of valve design, material, and usage patterns collectively determine the mattress’s air retention capabilities and overall usability. Regularly inspecting the valve, ensuring proper cleaning and handling, and promptly addressing any signs of damage will significantly extend the air mattress’s lifespan and ensure continued functionality.

3. Pressure Monitoring

Pressure monitoring is an integral component of Intex air mattress inflation, directly affecting user comfort, structural integrity, and the lifespan of the product. Inadequate or absent pressure monitoring can lead to both under-inflation and over-inflation, each with distinct negative consequences. Under-inflation results in a soft, unsupportive sleeping surface, potentially causing discomfort or exacerbating pre-existing physical conditions. Conversely, over-inflation places undue stress on the mattress’s seams and internal structure, increasing the likelihood of rupture or accelerated wear. A real-life example includes users inflating a mattress until it feels “rock hard,” unaware they are exceeding the recommended pressure, which can lead to seam failure, particularly in areas of high stress. The practical significance of understanding the appropriate pressure range lies in optimizing both comfort and durability.

Effective pressure monitoring during Intex air mattress inflation involves several key steps. Initially, referencing the manufacturer’s guidelines for the specific mattress model is essential, as recommended pressure levels can vary. Tactile assessment, applying manual pressure to gauge firmness, offers a basic but useful method. Some advanced models feature integrated pressure gauges, providing real-time feedback. Regular pressure checks after initial inflation, particularly after a few hours of use, can identify and address any gradual air leakage or temperature-related fluctuations. For example, in colder climates, air volume may decrease, necessitating a slight pressure increase to maintain the desired firmness. Consistent pressure monitoring also aids in detecting slow leaks, prompting timely repairs or adjustments to prevent complete deflation during use.

In summary, pressure monitoring is not a peripheral activity but a critical element of successful Intex air mattress inflation. Addressing the challenges of accurately assessing pressure, understanding the mattress’s specifications, and accounting for environmental factors ensures both user comfort and the long-term viability of the product. By actively monitoring pressure, users can mitigate the risks of under-inflation and over-inflation, optimizing the lifespan and performance of their Intex air mattress.

4. Ambient Temperature

Ambient temperature exerts a direct and measurable influence on Intex air mattress inflation. As a gas, air within the mattress expands when heated and contracts when cooled, directly altering internal pressure. This phenomenon necessitates proactive adjustments to maintain optimal firmness. For instance, a mattress inflated indoors at room temperature and subsequently moved to a colder environment, such as a tent at night, will experience a pressure decrease, resulting in a softer sleeping surface. Conversely, a mattress inflated in a cool basement and then exposed to direct sunlight will exhibit increased pressure, potentially leading to over-inflation and seam stress. The practical significance of this connection lies in understanding the need to compensate for temperature-induced volume changes to ensure consistent comfort and prevent damage.

The degree of temperature fluctuation significantly impacts the required adjustments. Minor temperature shifts may necessitate only slight pressure modifications, while substantial changes can require significant additions or releases of air. This effect is particularly pronounced in seasonal camping scenarios, where daytime highs and nighttime lows can vary considerably. Users employing air mattresses in these conditions must actively monitor and adjust the inflation level accordingly. Moreover, differing materials within the mattress construction itself can respond variably to temperature changes, exacerbating pressure imbalances. Understanding these material properties is crucial for predicting and mitigating potential issues. Regularly feeling and adjusting the mattress allows you to maintain the intended firmness.

In summary, ambient temperature is a critical environmental factor that directly affects the performance of Intex air mattresses. Ignoring this influence can lead to discomfort, structural damage, and a shortened lifespan. By actively monitoring and adjusting inflation levels in response to temperature fluctuations, users can ensure optimal comfort, prolong the mattress’s usability, and mitigate potential risks associated with temperature-induced pressure changes. The challenge of maintaining consistent firmness is thus directly linked to acknowledging and addressing the inherent properties of gases and their response to temperature variations.

5. Surface Level

The evenness and characteristics of the surface on which an Intex air mattress rests exert a considerable influence on its performance, longevity, and the effectiveness of the inflation process. Irregularities or inappropriate surface conditions can compromise structural integrity, diminish comfort, and potentially lead to premature failure. Understanding the interplay between the support surface and the mattress is essential for optimal usage.

- Weight Distribution and Stress Points

An uneven surface causes localized stress points on the air mattress, leading to disproportionate weight distribution. This concentration of pressure on specific areas can accelerate wear and tear, potentially causing seam failure or punctures. For example, placing an air mattress on a surface with a protruding rock or sharp object will inevitably create a point of excessive stress, increasing the risk of damage. Consistent even support is crucial to distribute weight uniformly across the mattress’s surface.

- Inflation Stability and Shape Distortion

When inflating an Intex air mattress on an unlevel surface, the mattress’s shape can become distorted. This uneven inflation can result in an uncomfortable sleeping surface and reduce overall stability. One side of the mattress may be firmer than the other, creating an unstable and unsatisfying expe

rience. Ensuring the mattress is inflated on a flat and level surface allows for uniform air distribution and proper shape maintenance. - Material Degradation and Abrasion

Rough or abrasive surfaces can cause material degradation on the underside of the air mattress. Constant friction against coarse materials can wear down the mattress’s outer layer, making it more susceptible to punctures and air leaks. An example of this would be placing the mattress directly on a concrete floor without a protective layer. Using a protective barrier, such as a tarp or blanket, can minimize abrasion and extend the lifespan of the mattress.

- Valve and Seam Integrity

An unlevel surface can place undue stress on the mattress’s valve and seams, potentially compromising their integrity. Twisting or bending of the mattress due to an uneven base can strain the valve connection, leading to air leakage. Similarly, stressed seams are more likely to fail under pressure. Placing the mattress on a stable, level foundation reduces these stresses, preserving the integrity of critical components.

In summary, the characteristics of the surface underlying an Intex air mattress are not merely a passive consideration, but an active determinant of its performance and durability. By mitigating uneven weight distribution, minimizing abrasion, and reducing stress on critical components, users can optimize the inflation process and extend the useful life of their mattress. Selecting an appropriate surface is therefore an essential aspect of responsible air mattress ownership.

6. Firmness Adjustment

Firmness adjustment is an intrinsic aspect of Intex air mattress inflation, representing the user’s capacity to tailor the internal pressure to achieve a desired comfort level. The degree of firmness directly affects spinal alignment, pressure point relief, and overall sleep quality. Inflation, therefore, is not merely about filling the mattress with air, but rather about modulating the air volume to meet individual preferences and physical needs. For example, individuals with back pain may prefer a firmer mattress for increased support, while others may opt for a softer surface for enhanced cushioning. The connection lies in the cause-and-effect relationship: inflation provides the means to alter firmness, and the desired firmness dictates the extent of inflation. Inadequate ability to adjust firmness renders the inflation process incomplete and compromises the mattress’s primary function.

The practical application of firmness adjustment involves careful control of air input or output. Electric pumps often provide incremental settings, allowing for precise alterations in pressure. Manual pumps require a more intuitive approach, relying on user assessment and iterative inflation or deflation. Regular adjustments are often necessary, particularly during initial use as the material stretches or in response to ambient temperature fluctuations, where air volume changes affect firmness. Real-world instances reveal users experimenting with different inflation levels over several nights to identify their optimal setting. This process highlights the importance of a readily accessible and responsive valve system, enabling easy and accurate firmness modulation.

In summary, firmness adjustment is not a superficial element but a core functionality intertwined with the entire Intex air mattress inflation process. It presents both a challenge and an opportunity, requiring users to actively engage in fine-tuning the mattress to their specific requirements. By understanding the relationship between inflation and firmness, and by utilizing appropriate tools and techniques, users can maximize the comfort and utility of their Intex air mattress. The ability to achieve personalized firmness transforms the mattress from a simple inflatable object into a customizable sleep solution.

Frequently Asked Questions

The following addresses common inquiries regarding the proper inflation of Intex air mattresses, focusing on techniques, troubleshooting, and best practices.

Question 1: What is the recommended method for the most effective mattress filling?

The preferred method involves using an electric pump specifically designed for air mattresses. Integrated pumps, if available, are generally the most convenient. External electric pumps offer consistent and controlled filling, minimizing the risk of over-inflation.

Question 2: What causes an Intex air mattress to lose air after inflation?

Air loss may be attributed to several factors, including temperature fluctuations, minor leaks around the valve, or microscopic porosity in the mattress material. Initial stretching of the material after the first few uses can also contribute. Regular inspection of the valve and seams is advisable.

Question 3: How can one determine the correct pressure during inflation without a pressure gauge?

Tactile assessment is a viable alternative. The mattress should feel firm but yield slightly when moderate pressure is applied. Avoid inflating to the point where the surface becomes taut and rigid.

Question 4: Is it possible to over-inflate an Intex air mattress, and what are the potential consequences?

Over-inflation is possible and can lead to seam stress, material damage, and potential rupture. The risk is heightened when using high-pressure pumps. Adhering to recommended inflation guidelines and avoiding excessive firmness is crucial.

Question 5: Can an air mattress be inflated using alternative methods if a pump is unavailable?

While not ideal, manual pumps or even vacuum cleaners (used in reverse with appropriate adaptors) can be employed, but they require more effort and offer less precise control. Care must be taken to avoid overheating the vacuum cleaner or damaging the mattress valve.

Question 6: How does ambient temperature affect air mattress pressure after inflation?

Air volume is directly influenced by temperature. Colder temperatures cause air to contract, resulting in decreased pressure and a softer mattress. Warmer temperatures cause expansion, potentially leading to over-inflation. Adjustments may be necessary to compensate for these fluctuations.

These considerations will contribute to a more satisfying experience with Intex air mattresses.

The following will examine troubleshooting strategies.

Concluding Thoughts on Intex Air Mattress Inflation

This exploration of Intex air mattress inflation has underscored the critical interplay of pump compatibility, valve integrity, pressure monitoring, ambient temperature, surface level considerations, and firmness adjustment. Attending to each of these elements is essential for maximizing user comfort and prolonging the lifespan of the product.

Proper execution of the inflation process, informed by an understanding of these factors, will ultimately contribute to a more satisfactory and reliable experience. Prudent application of these principles will serve to enhance the utility and durability of Intex air mattresses.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)