A widely available sleep surface provides temporary bedding solutions. Characterized by its brand, dimensions approximating standard queen bed sizes, and air-filled construction, it is frequently used for guest accommodations or travel. An example scenario would be deploying one of these for overnight visitors when permanent beds are unavailable.

Such products offer convenience and portability, readily deflating for storage and transport. Their affordability makes them accessible to a broad consumer base. Historically, these types of beds have evolved from simple air mattresses to more sophisticated designs incorporating features like built-in pumps and enhanced comfort layers.

Subsequent sections will delve into the product’s key features, construction materials, usage recommendations, and essential maintenance guidelines for optimal performance and longevity.

Usage and Maintenance Recommendations

The following guidelines are provided to ensure optimal performance and extended lifespan of the airbed.

Tip 1: Inflation Considerations: Inflate the bed to the recommended firmness, avoiding overinflation. Overinflation can stress the seams and reduce the lifespan. Consult the product manual for specific PSI recommendations. A slightly underinflated bed is preferable to one that is overinflated.

Tip 2: Surface Preparation: Prior to inflation, clear the surrounding area of any sharp objects. Place the product on a smooth, level surface free from debris. A protective layer, such as a blanket or tarp, can further minimize the risk of punctures.

Tip 3: Temperature Control: Avoid exposing the product to extreme temperatures, both hot and cold. Direct sunlight and prolonged exposure to freezing conditions can degrade the material and compromise its structural integrity.

Tip 4: Weight Distribution: Distribute weight evenly across the surface. Concentrated pressure in a single area can accelerate wear and tear. Encourage users to avoid sitting or kneeling in one spot for extended periods.

Tip 5: Regular Cleaning: Clean the surface regularly with a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, as these can damage the PVC material. Ensure the bed is completely dry before storing.

Tip 6: Proper Storage: When not in use, deflate the product completely and store it in a cool, dry place away from direct sunlight. Folding it neatly can prevent creases and potential weak spots.

Adhering to these recommendations will help maintain the product’s condition, extending its useful life and ensuring reliable performance. Prioritizing these practices helps maximize value and minimize potential issues.

The subsequent section offers troubleshooting guidance for common issues encountered with this type of inflatable bedding.

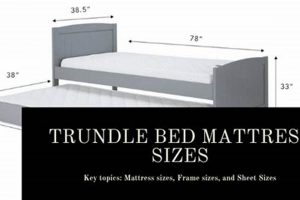

1. Dimensions

The dimensions of an “intex queen size inflatable mattress” are intrinsically linked to its intended use and market positioning. These dimensions, typically conforming to industry-standard queen size measurements (approximately 60 inches wide by 80 inches long), dictate the number of occupants it can comfortably accommodate, usually two adults. Any deviation from these standard dimensions directly impacts compatibility with queen-size bedding (sheets, blankets, and mattress protectors), potentially leading to fit issues and diminished user satisfaction. The dimensional aspect, therefore, is a primary consideration during the product design and manufacturing phases, influencing material requirements and production costs.

Real-life examples underscore the practical significance of accurate dimensions. A mattress that is significantly smaller than the standard queen size may be unsuitable for its intended users, rendering it less practical for couples or individuals requiring ample sleeping space. Conversely, dimensions exceeding the standard may result in an inability to use standard-size bedding, thereby adding to the overall expense and inconvenience. Furthermore, dimensions are crucial in determining the suitability of the mattress within specific environments, such as guest rooms or camping tents, where space constraints may exist. Careful consideration of dimensions ensures the “intex queen size inflatable mattress” meets user expectations and aligns with intended applications.

In summary, dimensions are a critical and defining characteristic of the “intex queen size inflatable mattress.” Their adherence to accepted queen-size standards dictates its usability, compatibility with bedding, and suitability for specific environments. Any discrepancies can introduce practical challenges, impacting user satisfaction and the overall value proposition. Accurate understanding and careful consideration of these dimensions are essential for both manufacturers and consumers, ensuring that the product meets the intended purpose effectively.

2. Material Durability

Material durability is paramount to the functionality and longevity of any “intex queen size inflatable mattress.” The selection and construction of materials directly influence the product’s resistance to punctures, air retention capabilities, and overall lifespan. Compromised durability negates the benefits of portability and cost-effectiveness, rendering the product unsuitable for its intended purpose.

- PVC Composition and Thickness

The primary material in most such mattresses is PVC (Polyvinyl Chloride). Variations in the PVC compound and its thickness directly correlate to puncture resistance. Thicker PVC layers are generally more resilient. The grade of PVC used impacts its flexibility and susceptibility to cracking over time. Real-world examples illustrate that thinner PVC is more prone to leaks caused by minor abrasions, while thicker PVC provides better protection against sharper objects. This difference in composition directly affects the usable life of the mattress.

- Seam Construction

Seams represent a critical vulnerability point. The method of seam constructionwhether heat-sealed, glued, or otherwisesignificantly influences its integrity. Weak seams are often the first point of failure, leading to gradual or sudden air loss. Reinforced seams, using multiple layers of material or specialized adhesives, enhance durability. Instances of seam failure due to inadequate construction underscore the importance of robust manufacturing processes.

- Flocking Material and Adhesion

Many models incorporate a flocked surface to enhance comfort. The quality of the flocking material and its adhesion to the PVC substrate affect durability. Poorly adhered flocking can peel or rub off with use, reducing comfort and creating debris. More durable flocking materials resist abrasion and maintain their texture over extended use. Examples include mattresses where the flocking has worn away prematurely, resulting in an uncomfortable and aesthetically unappealing sleeping surface.

- Resistance to Environmental Factors

Exposure to sunlight, temperature fluctuations, and humidity can degrade materials over time. UV radiation can cause PVC to become brittle, increasing the risk of cracking and leaks. Similarly, extreme temperatures can affect the elasticity of the material and the integrity of the seams. Mattresses designed with UV-resistant coatings and materials exhibit greater longevity when used outdoors or stored in fluctuating conditions. These factors are important where the intex queen size inflatable mattress is going to be often used in outdoor conditions.

Collectively, these material properties dictate the overall reliability of the “intex queen size inflatable mattress.” The interplay of PVC composition, seam construction, flocking quality, and environmental resistance determines its ability to withstand repeated use and maintain its integrity over time. A focus on high-quality materials and robust construction methods is essential for ensuring a durable and long-lasting product, maximizing user satisfaction and reducing the likelihood of premature failure.

3. Inflation System

The inflation system represents a critical component in the functionality and user experience associated with an “intex queen size inflatable mattress”. Its design and effectiveness directly impact the ease of setup, speed of inflation/deflation, and overall convenience of use. The type of inflation system employed significantly influences the target market and intended application of the product.

- Integrated Electric Pump

Many models feature an integrated electric pump, streamlining the inflation process. The pump is typically housed within the mattress itself, offering push-button operation. Inflation and deflation times are significantly reduced compared to manual methods. A potential drawback includes reliance on a power source, limiting usability in locations without electricity. Integrated pumps also add to the overall weight and complexity of the product. An example scenario includes using the mattress in a guest room where electrical outlets are readily available.

- External Electric Pump Compatibility

Some designs forego an integrated pump in favor of compatibility with external electric pumps. This approach offers potential cost savings and reduced weight. However, it necessitates the separate purchase and transport of an external pump. Standardized valve designs enable compatibility with various pump models. This configuration is often preferred by users who already own an electric pump or prioritize portability. Camping scenarios, where a portable power source may be used to power an external pump, exemplify this use case.

- Manual Inflation Options

Manual inflation, typically via a foot pump or hand pump, provides an alternative when electric power is unavailable. This method is generally slower and requires more physical effort. The valve design often incorporates features to prevent air leakage during manual inflation. This option offers independence from power sources, enhancing portability. Examples include using the mattress in remote locations or during power outages.

- Valve Design and Air Retention

The valve design is crucial for maintaining air pressure and preventing leaks. One-way valves prevent air from escaping during inflation. Secure sealing mechanisms ensure long-term air retention. High-quality valve materials resist wear and tear, contributing to the product’s overall lifespan. Poorly designed valves are a common source of air leaks, diminishing user satisfaction. Mattresses with robust valve designs demonstrate superior air retention over extended periods, ensuring consistent comfort. Examples would include valves using dual seals to prevent air leaking out.

The choice of inflation system fundamentally shapes the usability and convenience of an “intex queen size inflatable mattress.” Integrated electric pumps prioritize ease of use, while manual inflation methods offer greater portability. External pump compatibility provides a balance between cost and convenience. Valve design directly impacts air retention and long-term performance. Considering these factors allows consumers to select the system that best aligns with their individual needs and usage scenarios. Furthermore, it is beneficial to also consider whether you prefer to be able to setup the intex queen size inflatable mattress indoor or outdoor, or require to have specific types of valve design.

4. Portability

Portability constitutes a defining characteristic that distinguishes “intex queen size inflatable mattress” from conventional bedding solutions. The ability to deflate, fold, and transport this product readily broadens its applicability across diverse scenarios where permanent bedding is impractical or unavailable. The degree of portability hinges on several factors, which collectively determine its suitability for mobile applications.

- Deflated Size and Weight

The deflated dimensions and overall weight are primary determinants of portability. Smaller, lighter units are inherently easier to transport. Material thickness and construction methods influence both factors; thicker, more durable materials tend to increase weight while also reducing the ease of folding into a compact form. Example: a mattress constructed with reinforced PVC may offer superior puncture resistance but compromise portability due to increased weight and bulk.

- Included Carrying Case

The inclusion of a carrying case significantly enhances portability. The case provides a dedicated means of containing the deflated mattress, protecting it from damage during transport. The case design should facilitate comfortable carrying, incorporating features such as handles or shoulder straps. Example: a carrying case constructed from durable nylon with reinforced stitching can withstand the rigors of frequent travel, preserving the integrity of the mattress.

- Inflation/Deflation Speed

Rapid inflation and deflation contribute to overall portability by minimizing setup and takedown times. Systems incorporating electric pumps or large-diameter valves expedite these processes. Conversely, prolonged inflation/deflation times can detract from the convenience of mobile use. Example: a mattress equipped with an integrated high-output pump allows for swift inflation upon arrival at a destination and rapid deflation prior to departure, streamlining the transport process.

- Storage Considerations

The ease with which the deflated mattress can be stored also impacts portability. A mattress that folds neatly and compactly requires less storage space during transport. This is particularly relevant in scenarios with limited cargo capacity, such as camping trips or vehicle travel. Example: a mattress designed with strategically placed folding points allows for efficient compression, minimizing storage volume and maximizing available space within a vehicle or storage container.

These multifaceted aspects of portability collectively define the utility of an “intex queen size inflatable mattress” in mobile contexts. The interplay between deflated size/weight, carrying case functionality, inflation/deflation speed, and storage considerations ultimately determines its suitability for travel, temporary accommodations, and other scenarios where ease of transport is paramount. These factors are key for making the decision if the intex queen size inflatable mattress is most suited for portability for you, comparing the intex queen size inflatable mattress to all other portable sleeping items.

5. Cost-Effectiveness

The attractiveness of an “intex queen size inflatable mattress” is significantly influenced by its cost-effectiveness, particularly when juxtaposed with traditional bedding solutions such as innerspring mattresses or memory foam options. The initial purchase price is typically substantially lower, making it an accessible option for individuals on a budget, those requiring temporary bedding, or those furnishing guest rooms without committing to a permanent, expensive bed. However, a comprehensive evaluation of cost-effectiveness extends beyond the upfront expense. Factors such as durability, lifespan, and potential repair costs must also be considered to determine the true long-term value.

A key aspect of cost-effectiveness lies in the product’s versatility. Its portability and ease of storage translate to savings in space and transportation. For instance, individuals moving frequently or with limited storage space find this product a more economical choice compared to the cost and logistical challenges associated with transporting a conventional mattress. Additionally, the product’s temporary nature often reduces the need for extensive maintenance or professional cleaning services, further contributing to cost savings over time. Real-world examples illustrate this point: Students furnishing temporary housing or families accommodating occasional guests frequently opt for an “intex queen size inflatable mattress” precisely because of its lower overall cost relative to traditional alternatives.

While the initial investment is lower, it is crucial to acknowledge potential drawbacks affecting long-term cost-effectiveness. The lifespan of an “intex queen size inflatable mattress” is generally shorter than that of traditional mattresses, with susceptibility to punctures and air leaks. Repair costs, while often minimal, can accumulate over time. Therefore, a balanced assessment requires considering the trade-off between lower initial costs and potentially reduced longevity. In conclusion, the cost-effectiveness of an “intex queen size inflatable mattress” is multifaceted, encompassing affordability, versatility, and potential limitations in durability. A comprehensive analysis of these factors enables informed purchasing decisions aligned with individual needs and priorities.

6. Sleep Comfort

Sleep comfort, a pivotal factor influencing restorative rest, is intrinsically linked to the design and features of an “intex queen size inflatable mattress”. While offering advantages in portability and affordability, this bedding solution’s ability to deliver adequate sleep comfort directly impacts user satisfaction and overall well-being. The composition of the sleep surface, internal support structures, and air pressure regulation contribute to or detract from the quality of rest experienced. Real-world examples highlight the importance of considering these factors. A mattress with insufficient support may lead to back pain or discomfort, negating the convenience of its portability. Conversely, a model with enhanced comfort features can provide a surprisingly restful sleep experience, rivaling that of more conventional bedding.

Several design elements directly influence sleep comfort. The presence of a flocked top layer contributes to a softer, more comfortable sleep surface, minimizing the sensation of sleeping directly on PVC. Internal support structures, such as horizontal or vertical air chambers, help distribute weight evenly and prevent sagging. Adjustable air pressure allows users to customize the firmness level, catering to individual preferences. For example, users with back pain may benefit from a firmer mattress, while those who prefer a softer feel can adjust the air pressure accordingly. Furthermore, the mattress’s ability to maintain consistent air pressure throughout the night is crucial for preventing discomfort caused by deflation. Mattresses with effective sealing mechanisms and robust valve designs tend to provide more stable and comfortable sleep environments.

In summary, while an “intex queen size inflatable mattress” offers practicality and affordability, prioritizing sleep comfort is essential for maximizing user satisfaction. Design elements such as flocked tops, internal support structures, and adjustable air pressure play a significant role in enhancing the sleep experience. Potential buyers should carefully evaluate these features, considering individual sleep preferences and potential limitations, to ensure the chosen mattress provides a restful and restorative night’s sleep. The challenge lies in balancing the practical benefits with the need for adequate comfort, ultimately determining the long-term suitability of this bedding solution.

Frequently Asked Questions

This section addresses common inquiries regarding the product. These responses aim to provide clarity and informed understanding.

Question 1: How durable is an Intex queen size inflatable mattress?

Durability depends on the gauge of PVC material and usage. Thicker PVC is more puncture-resistant. Regular use and exposure to abrasive surfaces can shorten lifespan.

Question 2: Can an Intex queen size inflatable mattress be used outdoors?

While possible, outdoor use increases the risk of punctures from sharp objects. Protection via a ground tarp is recommended. Extended exposure to sunlight degrades the PVC.

Question 3: How long does it take to inflate an Intex queen size inflatable mattress?

Inflation time varies based on pump type. Integrated electric pumps typically inflate the mattress in 3-5 minutes. Manual pumps require significantly more time and effort.

Question 4: What is the weight capacity of an Intex queen size inflatable mattress?

Weight capacity typically ranges from 500 to 600 pounds. Overloading the mattress can damage internal support structures and seams.

Question 5: How should an Intex queen size inflatable mattress be stored?

Prior to storage, the mattress must be fully deflated. Folding neatly minimizes creases. Storage in a cool, dry place away from direct sunlight is recommended.

Question 6: Can an Intex queen size inflatable mattress be repaired if punctured?

Small punctures can be repaired with PVC repair patches. Larger tears or seam failures are often irreparable, rendering the mattress unusable.

The responses above provide insights into key operational and maintenance considerations.

The subsequent section will delve into competitive alternatives in the inflatable mattress market.

In Summary

This exposition has explored diverse facets of the air-filled bedding. From structural composition and inflation systems to portability and cost considerations, the analysis has illuminated critical aspects relevant to informed purchasing and practical application. Factors influencing durability, sleep comfort, and usage guidelines have been thoroughly addressed, providing a comprehensive understanding of this temporary bedding solution.

The information presented enables readers to evaluate whether the “intex queen size inflatable mattress” aligns with specific needs and expectations. A balanced assessment considering benefits and limitations is essential for ensuring optimal value and satisfaction. Continued advancements in materials and design may further enhance the functionality and longevity of these products in the future, solidifying their role in temporary bedding markets.