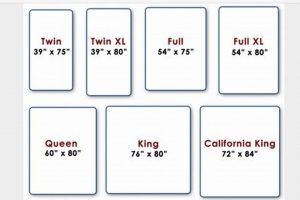

An inflatable sleeping surface designed to accommodate a single occupant, manufactured by Intex, this product provides a portable and often temporary bedding solution. It typically features a flocked top for added comfort and is inflated using an external pump. Intended for indoor use, it sees common application as a guest bed or temporary sleeping arrangement.

Its significance lies in its convenience and affordability. It offers a readily available sleeping space that can be easily stored when not in use, proving advantageous for individuals with limited space or those who frequently host visitors. Historically, air mattresses of this type have evolved from simple rubberized fabrics to more sophisticated constructions utilizing durable vinyl and integrated support systems.

The following sections will delve into the construction materials, inflation methods, maintenance procedures, and suitable use cases for this type of inflatable bedding. Additionally, a comparison with alternative sleeping solutions, such as traditional mattresses and other portable bed options, will be provided to offer a complete overview.

Enhancing the Longevity and Performance of Intex Twin Mattress

The following guidelines are presented to optimize the utilization and lifespan of the Intex twin mattress. Adherence to these recommendations will contribute to a more satisfactory user experience and minimize potential issues.

Tip 1: Select an Appropriate Location: Placement of the Intex twin mattress is crucial. Avoid positioning it on uneven or abrasive surfaces. A smooth, clear floor or a protective base layer, such as a blanket or rug, is recommended to prevent punctures or abrasions to the vinyl material.

Tip 2: Regulate Inflation: Overinflation places undue stress on the seams and internal structure of the mattress, increasing the risk of rupture. Inflate the mattress to the point where it is firm but still yields slightly to pressure. Refer to the manufacturer’s instructions for recommended pressure levels.

Tip 3: Maintain Consistent Temperature: Extreme temperature fluctuations can affect the air pressure within the mattress. Avoid prolonged exposure to direct sunlight or extreme cold, as this can lead to either overexpansion or contraction of the air, potentially damaging the seams.

Tip 4: Implement Regular Cleaning: Surface cleaning is essential to prevent the buildup of dirt, dust, and allergens. Use a damp cloth and mild soap to wipe down the mattress surface periodically. Ensure the mattress is completely dry before storing it.

Tip 5: Secure Proper Storage: When not in use, the Intex twin mattress should be completely deflated, folded neatly, and stored in a cool, dry place, away from sharp objects or heavy items that could cause damage. The original packaging or a dedicated storage bag is advisable.

Tip 6: Employ a Mattress Protector: A mattress protector provides an additional layer of defense against spills, stains, and general wear and tear. It can significantly extend the lifespan of the mattress and maintain its hygienic condition.

Tip 7: Monitor for Leaks: Periodically inspect the mattress for signs of air leakage. If a leak is detected, use a vinyl repair kit to patch the affected area promptly. Follow the instructions provided with the repair kit carefully.

By implementing these strategies, owners can maximize the durability, comfort, and overall value derived from their Intex twin mattress. Consistent maintenance and careful handling will ensure a reliable and convenient sleeping solution for years to come.

The subsequent sections will address troubleshooting common issues and exploring advanced care techniques for the Intex twin mattress.

1. Affordability

The Intex twin mattress owes a significant portion of its market appeal to its affordability. The relatively low cost of production, utilizing vinyl and simplified internal construction, directly translates to a lower retail price compared to traditional mattresses or higher-end air beds. This price point makes it an attractive option for individuals on a budget, those requiring a temporary sleeping solution, or those needing extra beds for occasional guests. Its affordability enables access to a functional sleeping surface where higher-priced alternatives are not feasible. For instance, college students in dormitories, campers seeking lightweight bedding, or individuals setting up temporary housing frequently opt for this type of mattress due to financial constraints and space limitations.

The impact of affordability extends beyond initial purchase. The lower upfront investment reduces the financial risk associated with acquiring a secondary or temporary bed. Should the mattress experience damage or wear, the replacement cost remains relatively low, further solidifying its position as a cost-effective solution. Furthermore, this affordability allows for a wider distribution of sleeping surfaces to accommodate emergency situations or unexpected accommodation needs. For example, disaster relief efforts often utilize these mattresses due to their low cost and ease of deployment, providing immediate sleeping arrangements for displaced individuals.

In conclusion, the affordability of the Intex twin mattress is not merely a superficial price advantage, but a core characteristic that defines its utility and target market. It enables widespread access to a functional sleeping solution, especially in situations where budgetary constraints or temporary needs preclude more expensive options. While long-term durability might be less than that of traditional mattresses, the significantly lower price point often justifies the tradeoff for its intended application. Understanding this affordability factor is paramount to appreciating the overall value proposition of the Intex twin mattress.

2. Portability

Portability constitutes a fundamental attribute of the Intex twin mattress, directly influencing its suitability for diverse applications. The inherent design of an inflatable mattress, facilitating deflation and compact storage, enables easy transportation and relocation. This characteristic differentiates it significantly from traditional mattresses, which are typically cumbersome and difficult to move. The cause of this portability lies in the material composition and construction method; deflated vinyl occupies considerably less volume than the springs and padding of a conventional mattress.

The importance of portability as a component of the Intex twin mattress manifests in several real-life scenarios. Individuals residing in small apartments or dormitories, where space is limited, benefit from the ability to store the mattress when not in use. Campers and travelers appreciate its lightweight and packable nature, allowing for a comfortable sleeping surface without the burden of transporting heavier alternatives. In emergency situations, such as natural disasters or tempor

ary housing arrangements, the mattress’s portability enables rapid deployment and setup, providing immediate sleeping accommodations. The practical significance of this understanding lies in recognizing the intended use cases and appreciating the value of a readily transportable sleeping solution. For example, a family expecting occasional guests can store the mattress efficiently, deploying it only when needed, thereby optimizing space utilization within the home. Similarly, disaster relief organizations can distribute these mattresses quickly to affected populations, addressing immediate needs for shelter and rest.

In summary, the Intex twin mattress’s portability is not merely a convenient feature, but a core element that defines its functionality and broadens its applicability. Its design and materials inherently support ease of transport and storage, addressing the needs of individuals facing space constraints, temporary accommodation requirements, or emergency situations. Recognizing this inherent portability is crucial for understanding the mattress’s value proposition and its advantages over more permanent, less adaptable sleeping solutions. Challenges remain in ensuring durability during frequent transport and repeated inflation/deflation cycles; however, the benefits of portability significantly outweigh these concerns in many contexts, solidifying the mattress’s position as a practical and versatile option.

3. Ease of Inflation

The rapid and straightforward inflation process is a defining characteristic of the Intex twin mattress, critically impacting user satisfaction and overall product utility. The implementation of integrated or easily compatible external air pumps significantly reduces the time and effort required to prepare the mattress for use. This ease of inflation stems from the valve design, which facilitates efficient airflow, and the standardized pump connections, ensuring compatibility with a wide range of inflation devices. The cause-and-effect relationship is evident: a well-designed inflation system leads to quicker setup times and reduced physical exertion for the user.

Ease of inflation is a crucial component because it directly affects the convenience and practicality of the Intex twin mattress, particularly in temporary or emergency situations. Consider a scenario where unexpected guests arrive late at night. A mattress that requires extensive time and effort to inflate would be less desirable than one that can be prepared within minutes. Similarly, in camping or disaster relief scenarios, where time and resources are often limited, the ability to quickly inflate multiple mattresses becomes paramount. The practical significance of this feature extends to individuals with physical limitations, such as the elderly or those with mobility impairments, who may find manually inflating a mattress challenging. Real-life examples of this include families quickly setting up a guest room, campers preparing their sleeping arrangements after a long day of travel, and aid workers distributing and inflating mattresses in disaster relief shelters.

In summary, ease of inflation is not merely a superficial convenience, but a defining attribute that enhances the Intex twin mattress’s practicality and suitability for diverse applications. Quick and effortless inflation translates to immediate usability, making it a valuable asset in temporary, emergency, or space-constrained scenarios. While advancements in material durability and comfort continue, the enduring benefit of rapid inflation remains a core strength, contributing to the mattress’s overall appeal and functionality. The continued refinement of pump technology and valve design will likely further enhance this attribute, solidifying its position as a key differentiator in the inflatable mattress market.

4. Storage Efficiency

Storage efficiency represents a critical advantage of the Intex twin mattress, distinguishing it from conventional bedding solutions. The mattress’s design allows for significant space savings when not in use, addressing a primary concern for individuals with limited living areas or temporary accommodation needs.

- Deflated Volume Reduction

The primary component of storage efficiency is the drastic reduction in volume achieved upon deflation. A deflated Intex twin mattress occupies a fraction of the space required by a traditional mattress of the same dimensions. This attribute is facilitated by the flexible vinyl construction, which allows the mattress to be folded and compressed into a compact form. The implications are significant for apartments, dorm rooms, and guest rooms, where space is at a premium. For example, a deflated mattress can easily be stored in a closet, under a bed, or in a storage container, freeing up valuable floor space when the sleeping surface is not needed.

- Lightweight Design Contribution

Storage efficiency is further enhanced by the mattress’s lightweight design. Unlike heavy spring or foam mattresses, the Intex twin mattress can be easily lifted and maneuvered during the storage process. This ease of handling reduces the physical strain associated with storing and retrieving the mattress, making it a practical option for individuals with physical limitations or limited assistance. The combination of reduced volume and lightweight design simplifies the entire storage process, contributing to its overall efficiency.

- Packaging and Storage Solutions

The Intex twin mattress is often packaged in a compact box or comes with a dedicated storage bag, further contributing to storage efficiency. The original packaging or a designated storage container provides a convenient and protective enclosure for the deflated mattress, preventing damage and minimizing the space required for storage. This thoughtful design element streamlines the storage process and ensures that the mattress remains in good condition when not in use. The utilization of compact packaging solutions demonstrates a commitment to maximizing storage efficiency.

- Comparison with Traditional Mattresses

The most significant illustration of storage efficiency lies in direct comparison to traditional mattresses. Conventional mattresses are notoriously difficult to store due to their bulk and weight. They often require dedicated storage rooms or professional moving services. In contrast, the Intex twin mattress offers a readily storable alternative, eliminating the logistical challenges associated with traditional bedding. This contrast underscores the practical advantages of the inflatable mattress for individuals prioritizing space conservation and ease of handling.

In conclusion, the storage efficiency of the Intex twin mattress is a multifaceted attribute encompassing reduced volume, lightweight design, and thoughtful packaging solutions. This characteristic offers a compelling advantage over traditional mattresses, particularly for individuals seeking space-saving sleeping solutions. The implications extend beyond mere convenience, impacting living space optimization and simplifying the logistics of temporary accommodation.

5. Comfort Level

Comfort level is a crucial, though often debated, attribut

e of the Intex twin mattress. Unlike traditional mattresses constructed with springs, foam, and padding designed for ergonomic support, an inflatable mattress relies primarily on air pressure and surface texture to provide a comfortable sleeping experience. The cause of varying comfort levels stems from the materials used, the internal structure, and the degree of inflation. Insufficient inflation results in a sagging surface, compromising support. Overinflation creates a rigid, unyielding bed, detrimental to spinal alignment. Surface texture, typically flocked vinyl, impacts skin contact comfort. The importance of comfort level as a component lies in its direct impact on sleep quality and overall user satisfaction. A poorly designed or improperly inflated mattress can lead to discomfort, disrupted sleep, and potential musculoskeletal issues.

Real-life examples illustrate the practical significance. Individuals using the Intex twin mattress for camping or temporary guest accommodations frequently report varying levels of satisfaction depending on factors such as ambient temperature, which affects air pressure, and the presence of underlying support structures. A mattress placed directly on a hard floor, for instance, offers considerably less comfort than one situated on a carpeted surface or a bed frame. Furthermore, the addition of a mattress topper or thick bedding can significantly enhance the perceived comfort level. The practical application of this understanding involves adjusting inflation levels to individual preferences, using appropriate bedding to mitigate surface discomfort, and selecting suitable placement locations to optimize support and reduce pressure points. The inherent limitations of air-based support must be acknowledged, and users seeking long-term, high-quality sleep should consider alternative mattress types.

In summary, the comfort level of the Intex twin mattress is a variable attribute influenced by inflation, surface texture, and environmental conditions. While it provides a convenient and affordable sleeping solution, its comfort cannot always match that of traditional mattresses. Understanding the factors that contribute to comfort level allows users to optimize their sleeping experience within the constraints of the mattress’s design. Challenges remain in achieving consistent and reliable comfort, particularly for individuals with specific orthopedic needs or preferences. Future advancements in material technology and internal structure may improve the comfort level of inflatable mattresses, but for now, users must actively manage inflation, bedding, and placement to maximize their sleeping comfort. The trade-off between portability, affordability, and comfort remains a central consideration in the decision to utilize an Intex twin mattress.

6. Material Durability

Material durability constitutes a critical performance characteristic of the Intex twin mattress, directly influencing its lifespan, reliability, and overall value proposition. The materials used in construction, primarily vinyl and flocked surfaces, are subject to wear and tear, puncture risks, and degradation over time. The inherent properties of these materials, coupled with the stresses induced by inflation and usage, determine the mattress’s capacity to withstand real-world conditions.

- Vinyl Composition and Thickness

The primary structural component of the Intex twin mattress is vinyl, a synthetic plastic polymer. The grade and thickness of the vinyl directly correlate with its resistance to punctures, abrasions, and stretching. Thicker vinyl offers increased protection against sharp objects and reduces the likelihood of seam failure under pressure. Conversely, thinner vinyl is more susceptible to damage, shortening the mattress’s lifespan. In practical application, mattresses constructed with heavy-gauge vinyl exhibit greater resilience in outdoor or rough-use environments compared to those with thinner vinyl layers. The vinyl’s formulation also impacts its flexibility and resistance to temperature fluctuations, affecting comfort and long-term durability. For example, repeated exposure to sunlight can cause the vinyl to become brittle and crack, leading to air leaks.

- Flocked Surface Integrity

Many Intex twin mattresses feature a flocked surface, consisting of short, synthetic fibers adhered to the vinyl. This flocking provides a softer, more comfortable sleeping surface compared to bare vinyl. However, the durability of the flocked layer directly impacts the mattress’s long-term usability. Frequent friction and abrasion can cause the flocking to wear away, resulting in bald spots and a less pleasant sleeping experience. The adhesion quality of the flocking determines its resistance to peeling and shedding. In real-world scenarios, mattresses used regularly without a protective sheet are more prone to flocking degradation. The flocked surface’s resistance to moisture and staining also influences its long-term appearance and hygiene.

- Seam Strength and Construction

The seams, where the vinyl panels are joined together, represent a critical vulnerability point in the Intex twin mattress’s construction. The strength and integrity of these seams determine the mattress’s ability to withstand internal air pressure and external stresses. Weak or poorly constructed seams are prone to failure, leading to air leaks and rendering the mattress unusable. The manufacturing process, including the type of adhesive or welding technique employed, significantly impacts seam durability. Mattresses with reinforced seams or multi-layered construction exhibit greater resistance to tearing and separation. In practical terms, mattresses subjected to frequent inflation and deflation cycles experience increased stress on the seams, potentially leading to premature failure. Regular inspection of the seams for signs of wear or separation is crucial for preventing catastrophic air leaks.

- Resistance to Environmental Factors

Material durability is also defined by the Intex twin mattress’s resistance to environmental factors, such as temperature, humidity, and UV exposure. Extreme temperature fluctuations can cause the vinyl to expand and contract, potentially stressing the seams and leading to air leaks. High humidity levels can promote mold and mildew growth on the flocked surface, compromising hygiene. Prolonged exposure to UV radiation can degrade the vinyl, causing it to become brittle and crack. Mattresses stored in uncontrolled environments are more susceptible to environmental damage. Practical examples include mattresses stored in garages or attics, where temperature extremes are common, and mattresses used in humid climates, where mold growth is a concern. Proper storage and maintenance practices, such as cleaning and UV protection, can mitigate the impact of environmental factors on material durability.

These facets of material durability, encompassing vinyl composition, flocked surface integrity, seam strength, and environmental resistance, collectively determine the Intex twin mattress’s longevity and overall performance. Understanding these factors enables informed purchasing decisions and facilitates appropriate usage and maintenance practices. While inherent limitations exist due to the materials’ cost and construction, diligent care can extend the mattress’s lifespan and ensure a more satisfactory user experience. The balance between affordability and durability remains a central consideration in the design and utilization of the Intex twin mattress.

7. Weight Capacity

Weight capacity is a fundamental specification of the Intex twin mattress, directly influencing its structural integrity, user safety, and long-term performance. It represents the maximum load, typically expressed in pounds or kilograms, that the mattress can safely support without experiencing deformation, damage, or compromising its intended function. Understanding and adhering to the specified weight capacity is paramount to ensure both user safety and the longevity of the product.

- Structural Integrity and Load Distribution

The weight capacity is intrinsically linked to the internal structure and material properties of the Intex twin mattress. Exceeding the stated weight limit places undue stress on the vinyl seams, internal baffles (if present), and overall construction. This stress can lead to gradual deformation, weakening of the material, and eventual failure. Proper load distribution is also crucial; concentrated weight in a single area can create localized stress points that exceed the material’s capacity, even if the total weight remains within the specified limit. In practical terms, this means that while the mattress may be rated for, say, 300 pounds, placing a 300-pound object concentrated in a small area could still cause damage.

- Safety Implications

Exceeding the weight capacity poses a safety risk to the user. Overloading the mattress can cause it to collapse or rupture, potentially leading to falls or injuries. Moreover, a mattress that is consistently overloaded may develop subtle structural weaknesses that are not immediately apparent but increase the risk of sudden failure. The practical implication is that it is always advisable to err on the side of caution and avoid exceeding the stated weight limit, even by a small margin. The stated weight capacity is a maximum limit, not a target.

- Impact on Longevity

Consistently operating the Intex twin mattress near or above its weight capacity significantly reduces its lifespan. The increased stress on the materials leads to accelerated wear and tear, increasing the likelihood of seam failures, air leaks, and overall degradation. While occasional, minor overloads may not cause immediate damage, repeated instances will inevitably shorten the mattress’s usable life. The long-term financial implications are that frequent replacement of overloaded mattresses negates the initial cost savings associated with their affordability. Proper adherence to the weight capacity extends the usable life and provides better value for the initial investment.

- Manufacturer Specifications and Warranty

The weight capacity is a clearly stated specification provided by the manufacturer of the Intex twin mattress. Adhering to this specification is typically a condition of the product warranty. Exceeding the weight limit may void the warranty, leaving the user responsible for any repairs or replacements necessitated by the overloading. The practical implication is that users should carefully review the manufacturer’s documentation and adhere to all specified limits to maintain warranty coverage and protect their investment. The manufacturer’s weight capacity rating reflects their assessment of the mattress’s safe operating parameters, and deviating from these parameters carries inherent risks.

In summary, weight capacity is a critical consideration when utilizing an Intex twin mattress. Its influence extends beyond mere convenience, encompassing structural integrity, user safety, product longevity, and warranty adherence. The interplay between these factors underscores the importance of understanding and respecting the manufacturer’s specified weight limit to ensure a safe, reliable, and cost-effective sleeping solution. The affordability and portability benefits are offset by the necessary constraints of respecting the weight capacity.

Frequently Asked Questions Regarding Intex Twin Mattress

The following questions address common inquiries and misconceptions concerning the Intex twin mattress, providing objective and informative responses.

Question 1: What is the maximum weight capacity for the standard Intex twin mattress?

The typical weight capacity for a standard Intex twin mattress is approximately 300 pounds (136 kilograms). This limit is crucial to observe to prevent damage and ensure user safety.

Question 2: How does one properly inflate the Intex twin mattress?

Inflation should be performed using a compatible air pump. Over-inflation must be avoided. The mattress should be firm but yield slightly to pressure. Adherence to the manufacturers inflation guidelines is recommended.

Question 3: What is the best method for storing the Intex twin mattress when not in use?

The mattress should be fully deflated, folded neatly, and stored in a cool, dry location, away from sharp objects or extreme temperatures. The original packaging or a dedicated storage bag is recommended.

Question 4: What material is the Intex twin mattress constructed from?

The primary material is PVC vinyl. The top surface often features a flocked layer for added comfort. Material composition directly influences the mattress’s durability and puncture resistance.

Question 5: How can minor punctures or leaks be repaired?

Small punctures can typically be repaired using a vinyl repair kit. The affected area should be cleaned, and the adhesive patch applied according to the kit’s instructions. Prompt repair prevents further air loss.

Question 6: What is the expected lifespan of an Intex twin mattress with regular use?

The lifespan varies depending on usage frequency, care, and environmental conditions. With proper care and adherence to weight limits, a reasonable lifespan of 1-3 years can be anticipated.

These answers provide fundamental guidance regarding the Intex twin mattress. Diligent adherence to these recommendations contributes to the longevity and optimal performance of the product.

The subsequent section will provide a comparative analysis of the Intex twin mattress versus alternative sleeping solutions, further clarifying its advantages and limitations.

Concluding Remarks on the Intex Twin Mattress

The preceding analysis has explored the various facets of the Intex twin mattress, encompassing its affordability, portability, ease of inflation, storage efficiency, comfort level, material durability, and weight capacity. Each attribute contributes to the mattress’s overall utility and suitability for specific applications. The low cost and ease of storage render it an accessible solution for temporary or space-constrained situations. However, its limitations in comfort and long-term durability necessitate careful consideration of its intended use and user expectations. Proper maintenance and adherence to weight limits are crucial for maximizing its lifespan and ensuring user safety.

The Intex twin mattress serves a valuable purpose as a readily available and cost-effective sleeping solution. Its benefits are most pronounced in situations where convenience and portability outweigh the demands for long-term comfort and support. Future advancements in materials and construction may address some of the existing limitations. Until such improvements materialize, a thorough understanding of its capabilities and limitations remains paramount for making informed purchasing decisions and achieving satisfactory user experiences. The discerning consumer will evaluate the tradeoff between cost, convenience, and long-term durability before selecting this type of inflatable bedding.

![Best Twin Mattress Platform [Deals!] - Beds & More Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Twin Mattress Platform [Deals!] - Beds & More | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-5168-300x200.jpg)