A mattress of substantial width and length, typically designated for couples or individuals desiring ample sleeping space, constructed with bamboo-derived materials in its composition. This product category offers a blend of size and material properties intended to enhance sleep comfort.

The appeal of such bedding solutions stems from the potential benefits associated with bamboo fibers, including enhanced breathability, moisture-wicking capabilities, and a reportedly softer texture compared to traditional materials. Historically, consumer interest in natural and sustainable bedding options has driven the development and adoption of these products, reflecting a broader trend toward eco-conscious purchasing decisions within the home goods market.

The subsequent discussion will delve into specific aspects such as construction techniques, material sourcing, and comparative performance metrics, providing a more detailed examination of the factors to consider when evaluating this bedding type.

Considerations for King Bamboo Mattresses

This section offers guidance on the selection and maintenance of king-sized mattresses incorporating bamboo-derived materials.

Tip 1: Fiber Source Verification: Prior to purchase, ascertain the specific type of bamboo fiber used in the mattress construction. Rayon or viscose derived from bamboo often lack the inherent benefits of bamboo lyocell, which retains more of the plant’s natural properties. Examine manufacturer documentation for clarity.

Tip 2: Density Evaluation: Assess the density of the mattress core, typically composed of foam or innersprings. Higher density foams tend to offer greater support and durability, potentially extending the lifespan of the sleeping surface. Specifications should be readily available from the retailer.

Tip 3: Cover Composition Analysis: The mattress cover’s bamboo content may vary. Opt for covers with a higher percentage of bamboo fiber to maximize breathability and moisture-wicking performance. Blends with other materials, such as polyester, can influence the overall feel and thermal regulation.

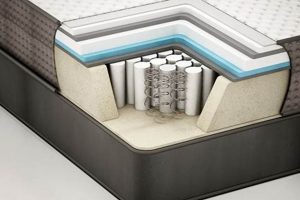

Tip 4: Support System Examination: Evaluate the underlying support system, whether it be an innerspring coil system or a foam core. Innerspring systems should specify coil gauge and count, while foam cores should detail the density and types of foam layers used. A robust support structure is critical for proper spinal alignment.

Tip 5: Off-Gassing Mitigation: New mattresses may exhibit an initial odor due to volatile organic compounds (VOCs). Allow adequate ventilation in a well-ventilated area for several days before use to minimize potential off-gassing. Mattresses certified by organizations like CertiPUR-US are generally considered to have lower VOC emissions.

Tip 6: Proper Foundation Selection: Ensure the mattress is paired with a compatible foundation or bed frame that provides adequate support across its entire surface. An inadequate foundation can compromise the mattress’s structural integrity and void warranty coverage.

Tip 7: Regular Rotation and Cleaning: Rotate the mattress periodically, typically every three to six months, to promote even wear and prevent localized sagging. Adhere to the manufacturer’s cleaning instructions for stain removal and general maintenance, avoiding harsh chemicals that could damage the fabric or internal components.

These considerations will aid in making an informed decision and prolonging the life of the king-sized mattress.

The following section will address common misconceptions surrounding this type of bedding.

1. Size

The “Size” attribute is a defining characteristic of a king bamboo mattress, directly influencing its suitability for specific sleeping arrangements and room dimensions. The standard king size, typically measuring 76 inches in width and 80 inches in length, is designed to accommodate couples comfortably or provide ample individual sleeping space. Discrepancies in room size relative to mattress dimensions can lead to practical challenges, such as limited maneuverability within the bedroom. For instance, a smaller bedroom may become overcrowded with a king-sized mattress, impacting overall functionality and aesthetics. Conversely, a larger room can readily accommodate a king size, enhancing the sense of spaciousness.

The increased surface area of a king-sized mattress, as a direct result of its dimensions, also affects weight distribution and support requirements. Mattress manufacturers must engineer internal support structures to adequately distribute weight across the broader area to prevent sagging and ensure consistent comfort. The choice of materials and construction techniques is therefore directly linked to the “Size” parameter. A mattress too soft for the individuals using it may exacerbate any weight distribution issues leading to premature degradation of the mattress. Furthermore, the increased surface area demands more materials, potentially influencing the overall cost and environmental footprint of the product. For example, the production of a king-sized mattress requires a greater volume of bamboo-derived fibers than that of a queen-sized mattress.

Therefore, the “Size” of a king bamboo mattress is not merely a specification but a foundational element that dictates its practical application, internal engineering, and environmental implications. Accurate dimensional understanding is crucial for aligning consumer expectations with product realities, ensuring optimal comfort and long-term value. Challenges can arise if size considerations are overlooked, potentially leading to dissatisfaction and necessitating costly replacements. Correctly evaluating size contributes towards maximizing the overall lifespan and usefulness of this bedding choice.

2. Material

The composition of a king bamboo mattress is central to its performance characteristics. The term “Material” encompasses both the specific type of bamboo-derived fiber used (e.g., lyocell, rayon, viscose) and the other components incorporated into the mattress construction, such as foam, innersprings, and ticking fabric. The bamboo fiber type significantly influences the mattress’s breathability, moisture-wicking properties, and overall texture. For instance, bamboo lyocell, produced through a closed-loop solvent spinning process, retains more of the bamboo plant’s inherent qualities, resulting in enhanced breathability and a softer feel compared to bamboo rayon or viscose, which undergo more intensive chemical processing. A mattress labeled as incorporating “bamboo” may, in reality, contain a high percentage of less desirable bamboo rayon if the material specifications are not scrutinized.

The interaction between the bamboo-derived material and other components also affects the mattress’s overall performance. For example, a mattress featuring a high-density memory foam core coupled with a bamboo-derived cover may offer excellent pressure relief and motion isola

tion, but the breathability benefits of the bamboo may be partially offset by the heat-retention properties of the memory foam. Similarly, the ticking fabric, which is the outermost layer of the mattress, plays a critical role in regulating temperature and moisture. A ticking fabric with a high percentage of bamboo fiber can enhance the mattress’s breathability, while a ticking fabric made from synthetic materials may impede airflow. An example is comparing 100% bamboo lyocell mattress cover with a blend of polyester/bamboo rayon; the lyocell version likely leads to improved breathability. The ratio of natural to synthetic components impacts the mattress’ environmental footprint.

Therefore, a comprehensive understanding of the “Material” composition of a king bamboo mattress is essential for making informed purchasing decisions. The selection of specific materials directly impacts comfort, durability, and environmental sustainability. Challenges exist in accurately assessing material claims, as manufacturers may not always provide complete transparency. Consumers must carefully evaluate product specifications and seek independent certifications to ensure that the mattress aligns with their performance and environmental goals. Choosing high-quality materials not only contributes to a better sleep experience but can also extend the mattress’ lifespan, reducing waste and promoting more sustainable consumption patterns.

3. Support

The “Support” structure within a king bamboo mattress is paramount to its functionality and longevity, directly influencing spinal alignment, pressure distribution, and overall sleep quality. Inadequate support can lead to discomfort, pain, and premature mattress degradation, negating the potential benefits of bamboo-derived materials. The support system, typically composed of innerspring coils or a foam core (polyfoam, memory foam, latex foam, etc), must be designed to withstand the weight and movements of multiple sleepers across the expansive surface area of a king-sized mattress. Failure to distribute weight evenly can result in sagging, particularly in areas of high pressure, such as the center or edges of the mattress. A real-life example includes observing that a king-size mattress with insufficient edge support may cause individuals sleeping near the perimeter to feel as though they might roll off, diminishing their sleep security.

The choice of support materials and construction directly correlates with the intended firmness and feel of the mattress. For instance, an innerspring system with individually wrapped coils often provides targeted support and reduces motion transfer between sleepers, which is particularly relevant on the large surface of a king-size bed. Conversely, a high-density foam core may offer enhanced pressure relief and contouring, conforming to the body’s shape to minimize pressure points. The specific type of foam used, its density, and the layering arrangement all contribute to the overall support characteristics. An example of this would be a king mattress featuring a base layer of high-density polyfoam for overall structure, a transition layer of softer polyfoam, and a top layer of memory foam to help alleviate pressure, ultimately working together to create the support system. Furthermore, the mattress’s construction needs to accommodate different body types and sleeping positions. Side sleepers typically require more pressure relief in the shoulder and hip areas, while back sleepers need firmer support to maintain spinal alignment.

In summary, the “Support” system is an indispensable element of a king bamboo mattress, governing its performance, comfort, and durability. A poorly designed or constructed support system undermines the benefits of any other high-quality components, emphasizing the need for careful evaluation during the purchase process. Challenges arise when manufacturers prioritize cost savings over structural integrity, potentially resulting in compromised support and premature product failure. A thorough assessment of the support system, considering individual sleep preferences and body types, is crucial for maximizing the lifespan and benefits of this bedding investment.

4. Comfort

The perceived “Comfort” associated with a king bamboo mattress represents a multifaceted evaluation encompassing tactile sensation, thermal regulation, and ergonomic support. The causal link between mattress materials and construction techniques directly influences a user’s subjective experience. For example, the inherent breathability of bamboo fibers, particularly in lyocell form, promotes airflow and reduces heat retention, leading to a cooler and potentially more comfortable sleep environment. Conversely, a poorly constructed mattress utilizing lower-quality bamboo rayon and inadequate ventilation may trap heat, resulting in discomfort and disrupted sleep. The importance of “Comfort” as a key component of a king bamboo mattress lies in its direct impact on sleep quality and overall well-being; a comfortable sleeping surface facilitates deeper, more restorative sleep, impacting daytime cognitive function and physical health. Consider an individual suffering from chronic back pain; a mattress that adequately balances support and pressure relief is essential for minimizing discomfort and promoting restful sleep.

The practical application of understanding this connection is evident in the mattress selection process. Consumers, equipped with knowledge of material properties and construction methods, can make informed choices based on their individual preferences and needs. For instance, an individual who sleeps hot may prioritize a mattress with a high bamboo content ticking, while someone with joint pain might opt for a mattress incorporating memory foam layers for enhanced pressure relief. Furthermore, understanding the relationship between “Comfort” and mattress characteristics allows for targeted adjustments. The addition of a mattress topper, for example, can modify the surface feel and provide extra cushioning, addressing specific comfort deficiencies. Regular maintenance, such as rotating or flipping the mattress, can also contribute to prolonged comfort by preventing localized sagging and uneven wear. The selection of appropriate bedding, such as breathable sheets and pillowcases, can further enhance the mattress’s thermal regulation properties.

In summary, the “Comfort” derived from a king bamboo mattress is not a singular attribute but an emergent property resulting from the interplay of materials, construction, and individual preferences. Challenges arise in objectively quantifying “Comfort,” given its subjective nature; however, a thorough understanding of material properties and construction techniques empowers consumers to make informed decisions. Recognizing the practical significance of this understanding is crucial for maximizing sleep quality and long-term satisfaction. Ultimately, the goal is to select a mattress that provides the optimal balance of support, pressure relief, and thermal regulation, thereby promoting restful sleep and enhancing overall well-being.

5. Durability

The longevity of a king bamboo mattress, encapsulated within the concept of “Durability,” is a critical consideration for consumers evaluating the long-term value of their investment. Various factors influence the lifespan of these bedding

products, directly impacting the return on expenditure and overall satisfaction.

- Material Composition and Resilience

The inherent resilience of the materials employed in the mattress’s construction dictates its ability to withstand prolonged use and resist deformation. Lower-density foams or inadequately tempered innerspring coils are prone to sagging and compression over time, compromising support and comfort. For example, a mattress employing high-density memory foam known for its shape retention will likely outlast one relying on conventional polyurethane foam. This is crucial because a larger king-size mattress bears more weight and sees more varied movement than a smaller size.

- Construction Quality and Reinforcement

The method of assembly and the presence of reinforcement elements significantly contribute to the mattress’s structural integrity. Reinforced edge support systems, for instance, mitigate sagging along the perimeter, prolonging the usable sleeping surface. Similarly, robust stitching and durable ticking fabrics enhance resistance to tearing and abrasion. A poorly constructed mattress may exhibit premature wear at stress points, leading to uneven support and reduced lifespan. A king-size mattress needs this kind of edge support more than any other size.

- Maintenance Practices and Environmental Factors

Adherence to recommended maintenance practices, such as regular rotation and the use of a protective mattress encasement, can substantially extend the product’s lifespan. Failure to rotate the mattress evenly distributes wear, potentially leading to localized sagging. Exposure to excessive moisture or direct sunlight can degrade materials and compromise structural integrity. Consider the impact of humidity on the foam layers within a king mattress; prolonged exposure can lead to deterioration and loss of support.

- Warranty Provisions and Manufacturer Reputation

Warranty coverage provides a degree of assurance regarding the manufacturer’s confidence in the product’s durability. A longer warranty period typically indicates a higher level of quality control and material selection. However, warranty provisions are only as valuable as the manufacturer’s commitment to honoring them. A reputable manufacturer with a track record of resolving warranty claims fairly provides greater assurance of long-term satisfaction. Checking customer reviews can reveal the real-world durability issues of the king mattress, as well as the ease of working with a certain manufacturer regarding a warranty.

The interplay of these factors ultimately determines the “Durability” of a king bamboo mattress. While bamboo-derived materials offer potential benefits in terms of breathability and moisture management, the mattress’s overall longevity hinges on the quality of construction, the resilience of all incorporated materials, and consistent adherence to proper maintenance practices. Consumers should prioritize a holistic assessment of these elements when evaluating the long-term value of their investment.

6. Breathability

The capacity of a king bamboo mattress to facilitate air circulation, or its “Breathability,” is a significant factor influencing sleep quality. This characteristic directly impacts temperature regulation and moisture management within the sleeping environment.

- Fiber Structure and Airflow

Bamboo fibers, particularly bamboo lyocell, possess inherent micro-gaps and channels that promote air movement within the mattress core. This structure facilitates the dissipation of heat generated by the body during sleep, preventing the buildup of excess warmth. Without adequate airflow, humidity may accumulate, potentially leading to discomfort and disrupted sleep cycles. A tightly woven cotton cover, for example, will inherently offer less airflow than a similar cover made of bamboo lyocell.

- Moisture-Wicking Properties

Effective “Breathability” also contributes to moisture management. Bamboo fibers exhibit hygroscopic properties, enabling them to absorb and wick away perspiration. This prevents the sleeping surface from becoming damp and uncomfortable, creating a drier and more hygienic environment. This is especially important in the larger area of a king size mattress, as more surface area translates to potentially more trapped humidity.

- Mattress Construction and Ventilation

The overall construction of the mattress impacts its “Breathability.” Open-cell foam structures and ventilation channels enhance airflow through the mattress layers. Conversely, dense foam cores or tightly sealed covers can impede air circulation, diminishing the beneficial properties of the bamboo fibers. The lack of airflow in a mattress with a solid foam base will result in the buildup of heat.

- Cover Composition and Permeability

The composition of the mattress cover plays a crucial role in regulating “Breathability.” Covers with a high percentage of bamboo fiber maximize airflow and moisture wicking. Conversely, synthetic covers or tightly woven fabrics can restrict air circulation and negate the advantages of the bamboo fiber within the mattress. Consider a mattress ticking consisting of 100% bamboo as compared to a synthetic blend.

The interplay of these factors dictates the overall “Breathability” of a king bamboo mattress. Optimizing airflow and moisture management can contribute to a more comfortable and restful sleep experience, particularly in larger mattresses where temperature regulation can be more challenging. Consumers evaluating this bedding option should carefully consider these aspects to maximize the potential benefits.

7. Sustainability

The intersection of “Sustainability” and “king bamboo mattress” centers on the environmental impact associated with material sourcing, manufacturing processes, and product lifespan. A comprehensive evaluation necessitates considering the entire lifecycle of the mattress, from raw material extraction to end-of-life disposal.

- Bamboo Cultivation and Resource Management

The sustainability of bamboo hinges on responsible cultivation practices. Bamboo, as a rapidly renewable resource, offers an alternative to conventional timber. However, unsustainable farming methods, such as deforestation to create bamboo plantations and excessive use of fertilizers or pesticides, can negate these environmental benefits. Responsible sourcing dictates ensuring bamboo is harvested from sustainably managed forests certified by organizations like the Forest Stewardship Council (FSC), guaranteeing ecological preservation and social responsibility. The environmental advantages of bamboo are diminished when unsustainable agricultural techniques are used.

- Manufacturing Processes and Chemical Usage

The conversion of bamboo into usable fibers for mattress construction can involve environmentally intensive chemical processes. The production of bamboo rayon or viscose, for instance, often utilizes toxic solvents that can contaminate water and air if not properly managed. Closed-loop manufacturing systems, which recycle solvents and minimize waste, represent a more sustainable approach. Bamboo lyocell, produced using a less toxic solvent and a closed-loop process, is generally considered a more environmentally friendly alternative. Manufacturers committ

ed to sustainability prioritize minimizing chemical usage, treating wastewater effectively, and adhering to stringent environmental regulations. - Transportation and Carbon Footprint

The transportation of raw materials and finished mattresses contributes to the product’s overall carbon footprint. Sourcing bamboo locally and manufacturing mattresses within closer proximity to consumers can reduce transportation distances and associated emissions. Optimizing packaging to minimize volume and weight further contributes to decreasing the environmental impact of distribution. Analyzing the overall transportation emissions can help identify more sustainable options.

- End-of-Life Management and Circular Economy

The disposal of mattresses at the end of their lifespan presents a significant environmental challenge, as they often end up in landfills. Promoting mattress recycling initiatives and designing mattresses with easily separable components can facilitate material recovery and reuse. Exploring innovative approaches, such as using biodegradable or compostable materials in mattress construction, aligns with the principles of a circular economy, minimizing waste and maximizing resource utilization. Some companies are developing mattress recycling processes to address this problem.

The incorporation of sustainable practices throughout the lifecycle of a king bamboo mattress directly influences its overall environmental footprint. While bamboo offers potential advantages, responsible sourcing, eco-friendly manufacturing, efficient transportation, and end-of-life management are crucial for realizing its sustainability potential. A comprehensive evaluation of these factors allows consumers to make informed choices that support environmental stewardship. Certification programs and transparent supply chains provide valuable tools for verifying sustainability claims and promoting accountability within the industry.

Frequently Asked Questions

This section addresses common inquiries regarding the characteristics, benefits, and considerations associated with king-sized mattresses incorporating bamboo-derived materials.

Question 1: What constitutes a “bamboo” mattress, and what variations exist?

The term generally refers to a mattress incorporating bamboo-derived fibers in its cover fabric or comfort layers. Common variations include mattresses using bamboo rayon (viscose), bamboo lyocell, or blends of bamboo fiber with other materials like cotton or polyester. Bamboo lyocell is often preferred due to its more sustainable manufacturing process and superior breathability.

Question 2: What are the purported benefits of sleeping on a mattress incorporating bamboo?

Proponents claim enhanced breathability, moisture-wicking properties, and a softer feel compared to traditional mattress materials. Bamboo fibers are naturally porous, facilitating airflow and temperature regulation. Additionally, some individuals with sensitive skin may find bamboo fabrics less irritating than synthetic alternatives.

Question 3: How does the durability of a king bamboo mattress compare to that of a traditional mattress?

Durability depends heavily on the quality of materials and construction. The presence of bamboo does not inherently guarantee greater longevity. Factors such as foam density, coil gauge (if applicable), and seam construction play crucial roles in determining the mattress’s lifespan. Selecting a mattress from a reputable manufacturer with a solid warranty is advisable.

Question 4: What are the potential drawbacks associated with king bamboo mattresses?

Potential drawbacks include price, as mattresses incorporating bamboo may be more expensive than conventional alternatives. Additionally, some bamboo fabrics, particularly bamboo rayon (viscose), are produced using chemically intensive processes, raising environmental concerns. Transparency regarding material sourcing and manufacturing processes is essential when evaluating these products.

Question 5: How does one properly care for and maintain a king bamboo mattress?

Regular rotation (every 3-6 months) is recommended to promote even wear and prevent localized sagging. Spot clean stains with a mild detergent and avoid harsh chemicals. The use of a mattress protector is advisable to shield against spills, dust mites, and allergens. Consult the manufacturer’s instructions for specific cleaning guidelines.

Question 6: Are there any certifications or labels to look for when purchasing a king bamboo mattress?

Certifications such as OEKO-TEX Standard 100 indicate that the fabric has been tested for harmful substances. CertiPUR-US certification applies to the foam components, ensuring low VOC emissions. FSC certification guarantees that the bamboo is sourced from responsibly managed forests. These labels provide a degree of assurance regarding product safety and environmental responsibility.

Careful consideration of these questions will aid in making an informed purchase decision.

The next section explores alternative mattress options.

King Bamboo Mattress

This exposition has provided a detailed examination of the king bamboo mattress, encompassing aspects from material sourcing and manufacturing processes to the end-user experience regarding comfort, support, durability, and breathability. The discussion has underscored the significance of informed decision-making, emphasizing the need to scrutinize material certifications, construction techniques, and maintenance requirements to ensure that a purchase aligns with individual needs and environmental consciousness.

The future of this bedding segment depends on continued innovation in sustainable manufacturing and increased transparency regarding material origins. Consumers are encouraged to prioritize diligent research and thoughtful evaluation to maximize their investment and contribute to a more responsible marketplace. The decision to acquire such a product should rest upon a solid understanding of its multifaceted attributes and potential long-term impact.

![Best Pillow Top Mattress King Size [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Pillow Top Mattress King Size [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-8286-300x200.jpg)