A large-sized storage solution designed to compress and protect substantial bedding, these bags typically utilize vacuum suction to remove air, significantly reducing volume for relocation or safekeeping. Examples include products marketed for protecting king-size mattresses during moves or long-term storage.

The reduction in bulk facilitates easier handling and lowers transportation costs. Furthermore, the sealed environment guards against dust mites, moisture, and other potential contaminants, preserving the integrity of the encased item. Historically, similar compression methods have been employed to optimize space utilization in shipping and storage across various industries.

The subsequent sections will delve into the material composition, proper usage techniques, factors influencing the selection of an appropriate product, and disposal considerations associated with this type of bedding protection.

Practical Guidance

The following constitutes important advice regarding the utilization of a storage solution specifically designed for oversized mattresses.

Tip 1: Prior to encasement, ensure the mattress is thoroughly cleaned and completely dry. Residual moisture can promote mildew growth within the sealed environment.

Tip 2: Inspect the product for any punctures or tears before use. Compromised structural integrity will negate the protective benefits.

Tip 3: When inserting the mattress, fold it carefully to avoid stressing the seams of the bag. Uneven distribution of weight can lead to tearing.

Tip 4: Employ a vacuum cleaner with an appropriate hose attachment to efficiently remove air. Follow the manufacturer’s instructions regarding valve placement and vacuuming duration.

Tip 5: After vacuuming, promptly seal the closure mechanism according to the provided guidelines. Secure closure is critical for maintaining compression and preventing air leakage.

Tip 6: Store the encased mattress in a dry, climate-controlled environment, away from direct sunlight and extreme temperatures. Fluctuations can affect the material and the integrity of the seal.

Tip 7: When unsealing, exercise caution to prevent damage to the mattress. A utility knife can be used to gently open the bag, avoiding any contact with the mattress itself.

Adhering to these guidelines enhances the efficacy of this preservation method and extends the lifespan of the stored mattress.

The subsequent sections will present comprehensive information on selecting the optimal product based on specific requirements, as well as disposal protocols.

1. Size Compatibility

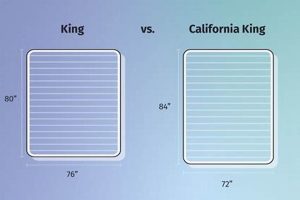

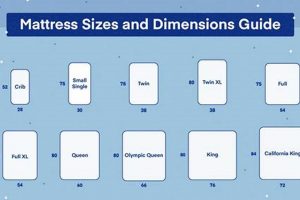

Size compatibility is a paramount consideration when selecting a storage solution for oversized mattresses. The intended purpose of a compression bag is undermined if the dimensions are not properly aligned with the mattress being stored. Insufficient bag dimensions necessitate excessive folding, which can damage the mattress or compromise the bag’s seams. Conversely, an excessively large bag may not compress effectively, negating the space-saving benefits. These points demonstrate size compatibility’s role as the main element of this type of solution.

A real-world illustration of this principle can be observed in instances where individuals attempt to use queen-size bags for mattresses of greater dimensions. The resulting stress on the material often leads to tears and a failure to maintain the vacuum seal. In practical terms, proper sizing ensures optimal compression, preventing damage to the mattress and maximizing storage efficiency.

In summary, precise sizing is non-negotiable for the effective utilization of a mattress storage product. Failure to account for mattress dimensions can lead to product failure, potential damage to the mattress, and a suboptimal storage outcome. Prior assessment of mattress size is therefore a critical first step.

2. Material Durability

Material durability is a cornerstone attribute influencing the functionality and longevity of any oversized mattress compression bag. The capacity of the bag to withstand repeated handling, potential abrasions during storage, and the sustained pressure exerted by the compressed mattress directly correlates with its structural integrity and overall effectiveness.

- Polymer Composition and Thickness

The specific type of polymer used in manufacturing, along with its thickness, significantly impacts puncture resistance and tear strength. Bags constructed from low-density polyethylene are generally less durable than those made from nylon-reinforced polyethylene or multi-layer composite materials. Thicker materials offer enhanced protection against sharp objects and reduce the likelihood of seam failure under stress.

- Seam Strength and Construction

The method by which the bag’s seams are joinedwhether through heat sealing, adhesive bonding, or stitchingplays a crucial role in preventing air leaks and tears. Weak or poorly executed seams represent a significant point of vulnerability, especially when the bag is subjected to the weight and pressure of a compressed king-size mattress. Reinforced seams and double-stitched designs enhance overall durability.

- UV Resistance and Temperature Stability

Exposure to ultraviolet (UV) radiation can degrade certain polymers, leading to embrittlement and a reduction in tear resistance. Similarly, extreme temperature fluctuations can affect the flexibility and strength of the material. Bags intended for long-term storage in uncontrolled environments should ideally incorporate UV-resistant additives and exhibit stability across a broad temperature range.

- Abrasion Resistance

During storage and relocation, bags may come into contact with rough surfaces. A material’s ability to withstand abrasion determines its resistance to thinning and subsequent tearing. Materials treated with specialized coatings or possessing inherently high abrasion resistance offer greater protection against such damage.

The durability of the material directly determines the long-term protective capability of these bags. Selecting products manufactured with robust materials and employing durable construction techniques ensures the preservation of the mattress against environmental contaminants and physical damage during storage and transit. Neglecting this aspect can lead to bag failure, rendering the mattress vulnerable and defeating the purpose of the storage solution.

3. Air-Tight Seal

The integrity of an air-tight seal is paramount to the functionality of a

vacuum storage bag intended for king-size mattresses. The intended compression and protection benefits are directly contingent upon the bag’s ability to maintain a vacuum after air extraction. A compromised seal negates the reduction in volume, exposes the mattress to environmental contaminants such as dust mites and moisture, and undermines the purpose of encapsulation. The presence of even minute breaches can result in gradual re-inflation, increasing the mattress’s dimensions and potentially leading to internal material degradation due to humidity exposure.

Consider a scenario where a mattress is stored in a self-storage unit utilizing a compression bag with a defective seal. Over time, the bag gradually re-inflates, allowing moisture to permeate the mattress fibers. This can result in the growth of mold and mildew, rendering the mattress unusable. Conversely, a bag with a robust, air-tight seal maintains the compressed state, creating a barrier against environmental factors and preserving the mattress’s condition. The closure mechanism, material quality surrounding the valve, and the absence of any punctures or tears are crucial determinants of seal efficacy.

In summation, the air-tight seal represents a critical component of the overall utility of these specialized storage solutions. Its performance directly impacts the longevity, hygiene, and space-saving capacity of the product. Proper inspection for seal integrity prior to use and selection of bags manufactured with high-quality sealing mechanisms are essential for realizing the intended benefits of compressed mattress storage. Failure to prioritize this aspect compromises the entire storage strategy.

4. Valve Efficiency

Valve efficiency is a critical performance parameter of a compression bag designed for king-size mattresses. It dictates the rate at which air can be evacuated from the bag, influencing the overall time and effort required for compression. A highly efficient valve expedites the process, minimizing the strain on vacuum cleaner motors and reducing user fatigue.

- Valve Diameter and Flow Rate

The diameter of the valve opening directly impacts the airflow capacity. Larger diameter valves facilitate more rapid air extraction. The internal design of the valve, including any obstructions or constrictions, further influences the flow rate. Valves with streamlined internal geometry minimize turbulence and maximize air passage, thereby enhancing overall efficiency. Consider valves designed with a wider internal pathway to facilitate greater airflow when considering its efficiency.

- Valve Material and Seal Integrity

The material composition of the valve, typically plastic or rubber, determines its durability and resistance to deformation under pressure. A valve constructed from robust, resilient materials maintains its shape and sealing properties over repeated use. Imperfect seals or valve body deformations can lead to air leakage, reducing compression effectiveness and necessitating repeated vacuuming. Valve integrity dictates how reliable vacuum sealing is. An improper seal will decrease the efficiency.

- Compatibility with Vacuum Cleaners

Valve design must consider compatibility with standard vacuum cleaner hose attachments. A universal valve design accommodates a wider range of vacuum cleaner types, enhancing user convenience. Valves with specialized adaptors or proprietary connectors may limit compatibility, potentially requiring users to purchase additional accessories. Valve adaptability should be optimized to work across all variations of vacuum cleaning devices. The more adaptable a valve is, the better.

- One-Way Valve Mechanism

The incorporation of a one-way valve mechanism prevents air from re-entering the bag after vacuuming. This feature is crucial for maintaining compression over extended storage periods. Defective or poorly designed one-way valves may permit backflow, requiring periodic re-vacuuming to maintain the compressed state. The efficiency of the valve relies on it being able to maintain its seal. As described above, if the seal is no good, there may be backflow, which causes air leakage.

These performance factors collectively influence the practical usability of compression bags used in conjunction with king-size mattresses. Selecting bags with high-efficiency valves optimizes the storage process, reducing the time and effort required to achieve effective compression and maximizing the preservation of the mattress. Prioritizing this aspect enhances the overall convenience and effectiveness of the storage solution. A well-engineered and reliable vacuum cleaner also plays a role in valve-efficiency in that it plays a part in a vacuum bag’s ability to compress its contents. However, the vacuum cleaner has a smaller role than that of a valve when considering its efficiency.

5. Puncture Resistance

The ability to withstand penetration by sharp objects, termed puncture resistance, is a critical attribute of vacuum storage bags specifically designed for king-size mattresses. The vulnerability of these bags to punctures directly impacts their capacity to maintain an air-tight seal and protect the encased mattress from environmental contaminants. Punctures compromise the vacuum seal, leading to re-inflation and negating the space-saving benefits. The causes of punctures can range from accidental contact with sharp edges during handling to abrasion against rough surfaces during storage. The effect is always a loss of compression and potential exposure of the mattress to damage.

Consider a scenario where a stored mattress, encased in a bag with low puncture resistance, is inadvertently brushed against a protruding nail in a storage unit. The resulting puncture, even if small, allows air to gradually seep back into the bag, negating the compression and potentially exposing the mattress to moisture and dust mites. In contrast, a bag constructed from a material with high puncture resistance would withstand such contact, maintaining the integrity of the vacuum seal and safeguarding the mattress. The selection of appropriate materials, such as reinforced polyethylene or multi-layer composites, is therefore crucial to ensure adequate puncture resistance.

In summary, puncture resistance is not merely a desirable feature but a fundamental requirement for effective utilization of a specialized bag. The cost of a compromised bag extends beyond the replacement of the bag itself, potentially including damage to the stored mattress. Prioritizing puncture resistance in the selection process ensures the long-term preservation of the mattress and the realization of the intended benefits of vacuum storage. This understanding directly affects the investment protection and long-term value of utilizing such a system.

6. Storage Space

The availability of storage space is the primary driver for employing compression bags with king-size mattresses. These items are typically large and cumbersome, occupying significant volume within residential or commercial environments. Compression reduces the mattress’s dimensions, creating more available area. This directly addresses space constraints often encountered duri

ng relocation, seasonal storage, or when repurposing rooms. The use of such a bag is fundamentally a response to the limitations of physical area. The reduced size increases options, from placement in smaller storage units to more efficient stacking within a moving truck. A family relocating to a smaller apartment utilizes this technology to consolidate belongings. A property manager uses this type of storage for spare beds used to furnish new rooms.

The effectiveness of volume reduction directly correlates to the utility of storage bags. Factors such as bag material, seal integrity, and valve design contribute to compression efficiency. However, the ultimate benefit is measured by the amount of space gained after the mattress is encased. For instance, a fully compressed king-size mattress might occupy half the volume of its uncompressed state, yielding substantial gains. If compression fails, or is reduced, the value of the bagging is diminished. The compression should be maximized without causing permanent damage to the mattress.

Understanding the relationship between storage space and the practical application of this is essential for informed decision-making. It ensures realistic expectations regarding compression levels and guides the selection of appropriate products based on specific dimensional needs. Effective employment of the described solution optimizes existing storage capacity and mitigates the challenges associated with storing bulky items.

7. Ease of Use

A critical factor in the adoption and effectiveness of storage solutions for king-size mattresses, the design for ease of use directly influences the practical application of compression bags. The cumbersome nature of a king mattress necessitates intuitive operation to mitigate physical strain and ensure proper execution of the compression process. Difficult or complex procedures reduce user compliance and increase the likelihood of improper sealing or material damage. A product deemed difficult to use is less likely to provide sustained protection and space-saving benefits. For example, bags requiring specialized equipment or multiple individuals for installation significantly limit their appeal to the average consumer.

The elements contributing to ease of use encompass several aspects of bag design and operation. These include clear and concise instructions, readily accessible valve locations, durable and easily manipulated closure mechanisms, and lightweight yet robust bag materials. An illustrative scenario involves an individual attempting to compress a king mattress alone. A bag with a user-friendly valve placement and an intuitive sealing system allows for efficient air extraction and secure closure without undue physical exertion. Conversely, a bag with a difficult-to-access valve or a cumbersome sealing mechanism complicates the process and increases the risk of seal failure. The design should enable a single user to complete the process efficiently.

Ultimately, ease of use dictates the accessibility and practicality of storage solutions for oversized mattresses. The design directly influences user satisfaction and the long-term preservation of the mattress itself. Prioritizing this aspect during product selection optimizes the storage experience, reduces the potential for damage, and ensures the intended benefits are realized. Complexity and difficulty act as barriers to adoption, regardless of the product’s other features, and result in suboptimal storage outcomes.

Frequently Asked Questions

The following section addresses common inquiries regarding the use, selection, and performance characteristics of vacuum compression bags designed for king-size mattresses.

Question 1: What is the typical lifespan of a product before it requires replacement?

The lifespan is dependent on several factors, including the quality of the material, the frequency of use, and the conditions under which it is stored. Products constructed from durable, multi-layer polymers can typically withstand several years of use, while those made from thinner, less resilient materials may require more frequent replacement. Proper handling and storage away from direct sunlight and extreme temperatures can extend the lifespan.

Question 2: Can this solution damage the internal structure of a memory foam mattress?

Prolonged compression can, in theory, alter the cell structure of memory foam. However, for typical storage durations (e.g., seasonal storage or during relocation), the risk of permanent damage is minimal. It is recommended to allow the mattress to fully decompress and air out after extended periods of compression. Avoid compressing for indefinite periods.

Question 3: Are all standard vacuum cleaners compatible for air extraction?

Most standard vacuum cleaners with a hose attachment are suitable for extracting air from these bags. However, valve designs vary, and some may require the use of a specific adaptor or nozzle. High-powered vacuums generally expedite the process, but care should be exercised to avoid over-compression.

Question 4: What is the recommended procedure for cleaning after use?

Surface cleaning with a damp cloth is generally sufficient for removing dust or debris. Avoid the use of harsh chemicals or abrasive cleaners, as these can damage the material. Ensure the product is completely dry before storing it.

Question 5: Is there a risk of mold or mildew growth during prolonged storage?

The risk of mold or mildew growth is minimized if the mattress is thoroughly dry prior to encapsulation. However, moisture can still accumulate over time, particularly in humid environments. It is recommended to periodically inspect the mattress and the interior of the bag for any signs of moisture or discoloration.

Question 6: How should a damaged unit be disposed of responsibly?

Depending on the material composition, it may be recyclable. Consult local waste management guidelines for appropriate disposal options. Some municipalities offer recycling programs specifically for plastic films and sheeting.

These answers provide a foundation for understanding the intricacies of utilization and maintenance. Consideration of these frequently asked questions ensures appropriate practices and increases performance.

The subsequent sections will present a comparative analysis of various products available on the market, focusing on the key attributes discussed herein.

King Mattress Vacuum Bag

This exposition has elucidated the multifaceted attributes of the king mattress vacuum bag, encompassing its definition, practical application, and the critical considerations involved in product selection. The discussion underscored the significance of size compatibility, material durability, seal integrity, valve efficiency, puncture resistance, space optimization, and ease of use. Each element plays a pivotal role in the overall effectiveness of the storage solution, impacting the preservation of the mattress and the efficient utilization of available space.

The proper implementation and diligent maintenance of a king mattress vacuum bag will ensure that the user can realize the full potential of this type of device. Continuous innovation in materials and design may further enhance the products functionality, extending the lifespan of mattresses and optimizing storage solutions for the future.

![Best King Size Split Mattress [Guide] For Couples! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best King Size Split Mattress [Guide] For Couples! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-8339-300x200.jpg)