A device utilized to inflate air mattresses through manual operation, this mechanism relies on physical exertion to introduce air into the mattress chamber. Typically involving a hand-operated piston or a foot-powered bellows, it requires no external power source like electricity. An example is a double-action hand pump, which inflates on both the push and pull strokes.

This type of inflation device offers portability and independence from electrical outlets, making it suitable for camping and other off-grid situations. It also presents a cost-effective alternative to electric pumps. Historically, these devices represent a basic yet reliable solution for inflating various inflatable items before the widespread adoption of motorized alternatives. Their enduring presence signifies a continued demand for simplicity and self-sufficiency.

The subsequent sections will delve into the different types of these devices, their optimal usage techniques, maintenance best practices, and factors to consider when selecting one for purchase.

Essential Usage Guidance

Optimal performance of a device intended to inflate air mattresses through manual operation hinges on understanding proper techniques and preventative measures.

Tip 1: Secure Valve Connection: Ensure a tight seal between the inflation device nozzle and the air mattress valve. A loose connection will result in air leakage, prolonging the inflation process and diminishing efficiency.

Tip 2: Utilize Full Stroke Range: Employ the complete range of motion when operating the piston or bellows. Partial strokes reduce the volume of air transferred per action, increasing the time and effort required.

Tip 3: Maintain Consistent Rhythm: Establishing a steady and even rhythm minimizes fatigue and optimizes airflow. Avoid jerky or erratic movements, which can strain the user and the device.

Tip 4: Prevent Over-Inflation: Exercise caution to avoid over-inflating the air mattress. Excessive pressure can damage the seams and reduce the lifespan of the mattress. Consult the manufacturer’s specifications for recommended inflation levels.

Tip 5: Clean the Device Regularly: Periodically clean the device to remove dirt and debris. Accumulated particles can obstruct airflow and degrade performance. A damp cloth and mild detergent are generally sufficient.

Tip 6: Store Properly When Not in Use: Store the device in a clean, dry environment to prevent damage and prolong its usability. Avoid prolonged exposure to direct sunlight or extreme temperatures.

Tip 7: Inspect for Damage: Before each use, carefully inspect the device for any signs of wear or damage, such as cracks in the housing or tears in the bellows. Addressing these issues promptly prevents further deterioration.

Adherence to these guidelines ensures efficient and reliable inflation, maximizing the utility and longevity of the device.

The subsequent sections will explore the different types of these devices, their optimal usage techniques, maintenance best practices, and factors to consider when selecting one for purchase.

1. Portability

Portability is a defining characteristic of manual air mattress inflation devices. This feature dictates their suitability for applications where access to electricity is limited or unavailable, emphasizing their role as a self-contained inflation solution.

- Lightweight Construction

The utilization of lightweight materials, such as durable plastics and fabrics, minimizes the overall weight. This enables effortless transport in backpacks, luggage, or camping gear, promoting ease of use in remote settings. Reduced weight alleviates the burden on users during transit, enhancing practicality.

- Compact Size

Designs are frequently engineered for minimal dimensions when disassembled or collapsed. Smaller forms facilitate convenient storage in confined spaces, such as car trunks or storage closets. Diminished size reduces the spatial footprint, maximizing available space during travel or storage.

- Absence of External Power Requirements

The inherent nature of manual operation eliminates the need for electrical outlets or batteries. This removes dependence on external power sources, granting operational freedom in diverse environments. Independent function assures usability irrespective of infrastructure availability.

- Integrated Carrying Mechanisms

Many models incorporate handles, straps, or carrying bags to simplify handling and transport. These features enhance user ergonomics, enabling comfortable and secure carrying over various distances. Dedicated carrying mechanisms improve manageability and prevent accidental damage during transportation.

These factors collectively contribute to the inherent portability of manual inflation devices. Their lightweight and compact nature, combined with their operational independence, renders them ideal for scenarios requiring inflation capabilities in the absence of electrical power. As such, portability stands as a paramount consideration when evaluating these devices for specific applications.

2. Manual Operation

The core functionality of a manual air mattress pump is predicated upon manual operation. This denotes the application of human physical force as the driving mechanism for air displacement. The effect of this manual input is the inflation of the air mattress. Without physical actuation by a user, the pump remains inert, incapable of fulfilling its designated purpose. The dependency highlights manual operation as an indispensable component.

Consider a camping scenario: an individual relies on a manually operated pump to inflate an air mattress far from any electrical grid. The repetitive action of depressing a foot pump or manipulating a hand pump directly translates into the transfer of air volume into the mattress. The rate of inflation is directly proportional to the effort expended by the user. The practicality of this setup lies in its simplicity and reliability; a well-maintained device will function consistently, provided there is a physical input. Alternatively, a manual bicycle pump can also serve as a manual air mattress pump if the valve fits.

Understanding the connection between manual operation and air mattress inflation reveals the underlying mechanical principles at play. The user becomes the power source, and the pump serves as a mechanical intermediary. This connection emphasizes self-sufficiency and underscores the importance of a robust and ergonomic pump design, as user fatigue directly impacts inflation efficiency. While challenges exist in terms of required effort compared to electric alternatives, the inherent reliability and independence of manual systems remain practically significant in specific contexts.

3. Inflation Time

Inflation time, in the context of a manual air mattress pump, refers to the duration required to fully inflate an air mattress using exclusively human power. This metric is directly influenced by the pump’s design, the mattress’s volume, and the user’s physical capacity. A larger mattress, naturally, necessitates a longer inflation period compared to a smaller one, assuming all other factors remain constant. The efficiency of the pump mechanism, measured by the volume of air displaced per stroke, correspondingly affects the total time investment. For example, a double-action pump, which inflates on both the push and pull strokes, typically reduces inflation time relative to a single-action alternative. Inflation time is significant as it directly impacts the convenience and usability of the pump, particularly in situations where speed is critical, such as camping or accommodating unexpected guests.

Practical considerations related to inflation time involve trade-offs between portability and efficiency. Compact, lightweight pumps are often less efficient, leading to longer inflation times and increased user fatigue. Conversely, larger, more robust pumps may offer faster inflation but compromise portability. Users must therefore balance these competing demands based on their specific needs and anticipated usage scenarios. For instance, a backpacker prioritizing weight and space might accept a longer inflation time as a necessary compromise, whereas a homeowner seeking a convenient guest bed solution might opt for a larger, more efficient model. Real-world examples demonstrate significant variability; inflating a queen-sized air mattress with a small foot pump could take upwards of 20 minutes, while a larger hand pump might accomplish the same task in 10-15 minutes.

In summary, inflation time constitutes a critical performance attribute of a manual air mattress pump. Its impact on user experience, combined with the inherent trade-offs between speed, portability, and physical exertion, underscores the importance of carefully considering this parameter when selecting an inflation device. Optimizing inflation time contributes directly to the overall practicality and utility of the pump, particularly in situations where external power sources are unavailable or impractical.

4. Valve Compatibility

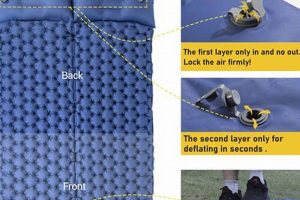

Valve compatibility represents a crucial factor in the effective operation of any manual air mattress pump. The capacity of the pump to connect securely and efficiently to the air mattress valve directly determines the speed and ease of inflation. An incompatible interface compromises the entire process, rendering the pump ineffective regardless of its other features.

- Valve Type Variations

Air mattresses employ a variety of valve designs, including Boston valves, pinch valves, and stem valves. Each type exhibits unique dimensions and sealing mechanisms. A manual air mattress pump equipped with a nozzle designed for a Boston valve will not effectively inflate a mattress fitted with a pinch valve. Adapters may exist to bridge such differences, but their availability and effectiveness vary. Failure to match valve types results in air leakage and prolonged inflation attempts.

- Nozzle Dimensions and Fit

Even within a specific valve type, variations in nozzle diameter and thread pitch can impede proper connection. A nozzle that is too small will not create a secure seal, leading to air escaping during inflation. Conversely, a nozzle that is too large may damage the valve or be physically impossible to attach. The precision of the nozzle-to-valve interface is paramount for efficient air transfer.

- Adapter Availability and Reliability

Universal adapters, designed to accommodate multiple valve types, offer a potential solution to compatibility issues. However, the performance of these adapters can be inconsistent. Some adapters may not create a sufficiently airtight seal, negating their intended benefit. Furthermore, adapters introduce an additional point of failure, increasing the risk of malfunction during use. The reliability of adapters should be carefully evaluated.

- Impact on Inflation Efficiency

Incompatible or poorly fitting valves directly impact inflation efficiency. Air leakage caused by a compromised seal necessitates increased pumping effort and extends the overall inflation time. In extreme cases, the air loss may exceed the pump’s capacity to inflate the mattress fully. Efficient air transfer is only achievable when valve and nozzle compatibility is assured.

These elements underscore the significance of valve compatibility in the context of manual air mattress pumps. Selection of a pump with a nozzle configuration appropriate for the target mattress valve is essential for practical and efficient operation. The use of adapters, while sometimes necessary, introduces potential complications and should be approached with caution, emphasizing the importance of primary valve compatibility.

5. Storage Requirements

Storage requirements are a tangible consequence of a manual air mattress pump’s design and materials. The pump’s size, whether disassembled or fully assembled, dictates the physical space necessary for its safekeeping when not in active use. Smaller, more compact designs inherently demand less storage volume. This dimension is especially pertinent for users with limited storage capacity, such as apartment dwellers, campers, or travelers. A bulky pump, despite its potential operational advantages, may prove impractical if it cannot be conveniently stowed when not in operation. Therefore, a pump’s dimensions directly correlate with its practical usability within constrained environments.

The importance of manageable storage requirements becomes evident in various real-world scenarios. Consider a family embarking on a camping trip. Limited cargo space within a vehicle necessitates prioritizing essential items, and a bulky inflation device may be deemed expendable. Conversely, a homeowner anticipating infrequent guest visits may prioritize inflation efficiency over storage compactness, selecting a larger pump despite its greater spatial footprint. The practical significance of this understanding lies in informed purchase decisions, aligning pump selection with individual spatial constraints and usage patterns. For example, some manual air mattress pumps can be compressed to a flat, disc-like form, significantly reducing their storage profile and making them suitable for minimalist packing. Other pumps, while offering enhanced inflation capacity, require dedicated storage bins or shelves.

In summary, storage requirements form an integral component in evaluating the overall utility of a manual air mattress pump. They present a tangible constraint, influencing portability, convenience, and suitability across diverse applications. The challenge lies in balancing desired performance attributes, such as inflation speed and power, with the inherent spatial demands of the device. Recognizing this interplay ensures informed decision-making, fostering satisfaction and maximizing the pump’s long-term value within the user’s specific context. Failing to consider storage needs can lead to pr

actical limitations and potential dissatisfaction, thereby underscoring the importance of this often-overlooked factor in pump selection.

Frequently Asked Questions

The following questions address common inquiries regarding the functionality, usage, and selection of devices intended to inflate air mattresses through manual operation.

Question 1: What is the typical lifespan of a manual air mattress pump?

The longevity of a manual air mattress pump is contingent upon several factors, including the quality of materials, frequency of use, and adherence to proper maintenance practices. Models constructed with durable plastics and robust mechanisms generally exhibit a longer lifespan. Regular cleaning and appropriate storage can extend the pump’s operational period. However, consistent heavy usage may accelerate wear and necessitate eventual replacement.

Question 2: How does the inflation speed of a manual pump compare to an electric pump?

Manual pumps invariably require a longer inflation time compared to their electric counterparts. The rate of inflation is directly proportional to the user’s physical effort and the pump’s design efficiency. Electric pumps, powered by an external energy source, typically deliver a higher volume of air per unit of time, resulting in significantly faster inflation. A manual pump offers the advantage of independence from electrical outlets, though at the cost of increased exertion and a prolonged inflation period.

Question 3: Can a manual pump over-inflate an air mattress?

Yes, it is possible to over-inflate an air mattress using a manual pump. Excessive pressure can damage the mattress seams and compromise its structural integrity. Users are advised to monitor the mattress’s firmness during inflation and adhere to the manufacturer’s recommended pressure levels. Intermittent pauses to assess the mattress’s state are advisable to prevent over-inflation.

Question 4: Are manual pumps suitable for inflating large air mattresses?

While manual pumps can inflate large air mattresses, the process can be physically demanding and time-consuming. The suitability depends on the user’s physical capacity and tolerance for exertion. For frequent inflation of larger mattresses, an electric pump may represent a more practical alternative. Manual pumps are generally better suited for smaller air mattresses or occasional use.

Question 5: What maintenance procedures are recommended for manual pumps?

Recommended maintenance includes regular cleaning with a damp cloth to remove dust and debris. Periodic inspection for cracks or damage to the housing or bellows is also advisable. Lubricating moving parts, such as the piston or hinges, can improve operational smoothness and prevent premature wear. Proper storage in a dry, protected environment is essential to prolong the pump’s lifespan.

Question 6: Can any type of manual pump be used for any air mattress?

No, valve compatibility is a critical consideration. Air mattresses utilize different valve types, and the pump’s nozzle must correspond to the mattress valve for effective inflation. While adapters are available, their reliability can vary. It is essential to verify compatibility between the pump nozzle and the mattress valve before attempting inflation. Forcing an incompatible connection can damage both the pump and the mattress.

In summary, manual air mattress pumps offer a reliable, portable, and cost-effective solution for inflating air mattresses. While slower than electric alternatives, their independence from external power sources makes them suitable for diverse applications. Proper usage, maintenance, and attention to valve compatibility are crucial for ensuring optimal performance and longevity.

The subsequent section will delve into purchasing considerations, offering guidance on selecting the most suitable manual air mattress pump for individual needs and circumstances.

Concluding Remarks

The preceding analysis has elucidated the core attributes of the manual air mattress pump. From its inherent portability and operational independence to considerations of inflation time, valve compatibility, and storage requirements, a comprehensive understanding of this inflation device has been established. The practical significance of manual inflation, especially in contexts lacking electrical power, underscores its enduring relevance.

Future innovation may focus on enhancing efficiency and reducing user exertion. However, the fundamental principles of manual operation will likely remain integral. Recognizing the limitations and advantages of the manual air mattress pump enables informed decision-making, ensuring its appropriate application within the diverse spectrum of inflation needs. Careful evaluation of individual requirements remains paramount for maximizing the utility and longevity of this device.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)