A protective encasement designed for safeguarding bedding of a specific, smaller size is widely available. This type of covering typically shields against dust, moisture, and potential damage during storage or relocation. For instance, when moving a single bed, this covering ensures its cleanliness and protection.

The value of such protection lies in maintaining the hygiene and integrity of the bedding. Using such a product can prevent costly cleaning or replacement due to contamination. Historically, similar protective measures have been employed to preserve valuable household items during transit and storage, adapting over time with improved materials and construction.

This article will delve into the specific materials used in manufacturing these coverings, explore optimal usage techniques for effective protection, and examine disposal and recycling considerations.

Protective Covering Usage

The following guidelines ensure effective use of a specific protective covering, maximizing its protective capabilities and prolonging the lifespan of the item it encases.

Tip 1: Material Selection. Opt for durable polyethylene or vinyl options. Thicker gauge materials offer superior resistance to tears and punctures, especially crucial during relocation.

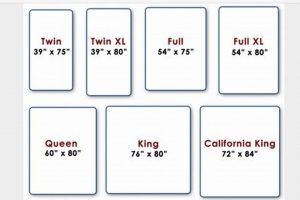

Tip 2: Proper Sizing. Confirm the covering is specifically designed for a particular single-size bedding. Oversized options may not provide adequate protection, while undersized options can lead to ripping during application.

Tip 3: Sealing Integrity. Ensure a complete and secure seal. Duct tape or specialized sealing tape is recommended to prevent ingress of dust, moisture, or pests. Inspect the seal regularly, especially during extended storage periods.

Tip 4: Handling Precautions. Exercise caution when moving or storing the encased bedding. Avoid dragging it across abrasive surfaces. Consider using furniture sliders or dollies to minimize stress on the covering.

Tip 5: Storage Environment. Store the protected bedding in a clean, dry environment away from direct sunlight and extreme temperatures. These conditions can degrade the covering material and potentially damage the contents.

Tip 6: Inspection and Maintenance. Periodically inspect the covering for any signs of damage, such as tears or punctures. Address any issues promptly to maintain its protective function. Clean the exterior of the covering as needed with a damp cloth to remove accumulated dust and debris.

Tip 7: Recycling Considerations. Explore recycling options for the covering when it is no longer needed. Some polyethylene products are recyclable, depending on local facilities and regulations. Proper disposal minimizes environmental impact.

Adhering to these guidelines will optimize the protective function of the specific bedding covering, safeguarding the contents from potential damage and contamination.

The subsequent sections will address frequently asked questions and offer troubleshooting advice for common usage scenarios.

1. Durability

The durability of a bedding encasement directly impacts its ability to effectively protect the enclosed item. A compromised barrier allows contaminants such as dust, moisture, and pests to penetrate, negating its intended function. The cause-and-effect relationship is clear: insufficient durability results in inadequate protection. For instance, a thin, low-grade polyethylene bag may easily tear during handling, exposing the bedding to potential damage. The importance of durability as a component is underscored by its role in preventing costly replacements or professional cleaning.

The selection of materials and construction methods significantly influences the encasement’s durability. High-density polyethylene or reinforced vinyl offer superior resistance to punctures and tears compared to thinner, less robust materials. Reinforced seams and robust zipper closures (if applicable) further enhance its structural integrity. Consider a real-world scenario: a family moving across state lines. A durable encasement ensures the single bedding arrives at its destination free from dust, dirt, and potential water damage sustained during transit. The practical significance lies in preserving the cleanliness and hygiene of the bedding, especially crucial for allergy sufferers or individuals with respiratory sensitivities.

In summary, durability is a critical attribute determining the effectiveness of a bedding encasement. Insufficient durability compromises its protective capabilities, leading to potential damage and increased costs. Selecting a product constructed from robust materials and featuring reinforced construction is paramount. Understanding the link between durability and protection is essential for making informed purchasing decisions and ensuring the long-term preservation of bedding items. Furthermore, proper handling and storage practices complement the durability of the encasement, maximizing its lifespan and protective capabilities.

2. Dimensions

Dimensional accuracy is paramount when selecting a protective covering for single bedding. An ill-fitting covering compromises its ability to safeguard the item effectively. Mismatched dimensions lead to either insufficient protection or undue stress on the covering material, potentially reducing its lifespan.

- Length and Width Compatibility

The internal length and width must accommodate the precise measurements of the single bedding. A covering that is too short leaves sections exposed, while excessive slack in an oversized covering creates opportunities for dust and moisture accumulation. For example, if the single bedding measures 75 inches in length and 39 inches in width, the protective covering should possess comparable internal dimensions, accounting for slight variations in material thickness.

- Depth or Thickness Allowance

Beyond length and width, the depth of the bedding must also be considered. An inadequate depth allowance causes the covering to stretch excessively, increasing the risk of tears or seam separation. Conversely, excessive depth results in unnecessary bulkiness and difficulty in sealing the covering securely. An example would be a deep pillow-top single needing a covering with sufficient gusseting to avoid compression and potential damage to the pillow-top.

- Impact on Seal Integrity

The dimensions directly influence the ability to achieve a secure and airtight seal. An improperly sized covering may hinder proper closure, allowing contaminants to enter. Taping or other sealing methods become less effective if the covering is either too tight or too loose. For example, a covering that is too small might prevent complete closure of the zipper or flap, while a covering that is too large creates folds that compromise the adhesive bond of the tape.

- Influence on Handling a

nd StorageThe overall dimensions of the encased single bedding affect ease of handling and storage. An overly bulky or awkwardly shaped covering may be difficult to maneuver, increasing the risk of damage during relocation or storage. Properly sized dimensions ensure a more compact and manageable package. As an illustration, if a single bedding encased in an oversized covering is stored in a confined space, it might be subject to unnecessary compression or abrasion, potentially damaging the bedding itself.

In conclusion, the dimensional compatibility between the single bedding and its protective covering is a critical factor in ensuring effective protection, maintaining seal integrity, facilitating handling, and optimizing storage. Accurate measurements and careful selection of appropriately sized coverings are essential for maximizing the lifespan and preserving the condition of the encased bedding.

3. Sealability

Sealability, regarding a protective bedding encasement, directly relates to its capacity to form a barrier against external elements. The degree to which this barrier is complete dictates the level of protection afforded to the enclosed item. An inadequate seal permits the entry of dust, moisture, and potential pests, directly counteracting the intended purpose of the encasement. For instance, a poorly sealed encasement provides minimal protection against moisture damage, leading to mold growth and rendering the bedding unusable. Therefore, sealability is a critical functional attribute.

The materials used, closure mechanisms, and design of the encasement significantly impact its sealability. High-quality polyethylene, vinyl, or specialized laminated materials, combined with airtight zippers or robust adhesive closures, contribute to a secure seal. Consider the practical application: an individual relocating to a humid climate. A properly sealed bedding encasement prevents moisture penetration during transit, safeguarding the contents from water damage and mildew. This consideration extends to long-term storage scenarios where temperature fluctuations and humidity levels can compromise unprotected bedding. The absence of proper sealability renders the encasement largely ineffective, regardless of other design features.

In summary, sealability is an indispensable characteristic determining the effectiveness of a protective bedding encasement. Compromised sealability undermines its protective function. Selecting an encasement with robust sealing mechanisms and ensuring their proper application is essential for preserving the hygiene and integrity of bedding during storage and relocation. Proper sealability, coupled with durable materials, maximizes the lifespan and protective capabilities of the encasement, mitigating the risk of damage and contamination. The consideration of sealability should thus be a primary factor in the selection process.

4. Material

The selection of materials for single bedding encasements directly influences their protective capabilities and longevity. Different materials offer varying degrees of resistance to tears, punctures, moisture, and pests. Inadequate material selection compromises the encasement’s ability to safeguard the enclosed bedding, potentially leading to damage and necessitating replacement. For instance, a thin, low-density polyethylene bag provides minimal protection against sharp objects encountered during moving or storage, resulting in tears and exposure to contaminants.

Polyethylene, vinyl, and woven polypropylene are common materials used in these coverings. Polyethylene offers a cost-effective solution for basic protection against dust and moisture. Vinyl provides enhanced durability and water resistance. Woven polypropylene offers superior tear resistance, making it suitable for more demanding applications. Consider a scenario involving long-term storage in a damp environment. A polyethylene encasement may allow moisture to permeate over time, leading to mold growth. In contrast, a vinyl or woven polypropylene encasement offers greater protection against moisture penetration, preserving the bedding’s condition. Furthermore, material choice affects recyclability. Some polyethylene products can be recycled, while vinyl typically requires specialized disposal methods.

In summary, the material composition is a crucial determinant of a single bedding encasement’s effectiveness. Selecting the appropriate material based on intended use, storage conditions, and environmental considerations is paramount. Insufficient material strength or inadequate barrier properties compromise the protection offered, leading to potential damage and increased costs. Careful consideration of material characteristics, coupled with proper handling and storage practices, maximizes the lifespan and protective capabilities of the encasement. The link between material and function is undeniable, requiring informed decision-making to ensure optimal preservation of bedding items.

5. Storage

The act of storing a single mattress necessitates a protective barrier to mitigate potential damage from environmental factors. The covering designed for this purpose facilitates long-term preservation, preventing dust accumulation, moisture absorption, and pest infestation. Without such a protective measure, mattresses left in storage are susceptible to degradation, leading to unsanitary conditions and reduced lifespan. For example, a mattress stored in a garage without a covering is prone to absorbing humidity, creating an environment conducive to mold and mildew growth. This highlights the crucial role of proper coverings in maintaining mattress integrity.

Optimal storage conditions are achieved through the combined use of a suitable protective covering and a controlled environment. Elevating the mattress off the floor prevents moisture wicking and facilitates air circulation. Storing it away from direct sunlight minimizes fading and material degradation. A protective encasement, specifically designed for a twin-sized mattress, complements these storage practices by providing a physical barrier against external elements. During relocation, a properly sealed encasement prevents abrasion and tearing, ensuring the mattress arrives at its destination in pristine condition. Furthermore, labeling the encased mattress with relevant information (date of storage, contents) allows for efficient inventory management, especially in multi-item storage facilities.

In summation, the relationship between storage and the protective encasement is interdependent and essential for safeguarding mattresses. A proper storage strategy incorporates environmental control and a robust protective covering, maximizing the mattress’s lifespan and maintaining its hygienic condition. The absence of either element compromises the long-term integrity of the stored item. Selecting an appropriate covering, coupled with adherence to optimal storage practices, provides a practical and cost-effective solution for preserving bedding during periods of inactivity.

6. Protection

The primary function of a mattress bag

designed for twin-sized bedding is protection. This protection encompasses a range of potential threats, including dust, moisture, pests, and physical damage. The effectiveness of the bag directly correlates to its ability to shield the mattress from these elements. A compromised bag, exhibiting tears or inadequate sealing, fails to provide adequate protection, rendering the mattress vulnerable. For instance, a tear in the bag during relocation could expose the mattress to dirt and debris, necessitating professional cleaning or, in severe cases, replacement. The consequence of insufficient protection is thus a diminished lifespan and compromised hygiene of the bedding.

The material composition and construction of the bag are critical determinants of its protective capabilities. Durable polyethylene or reinforced vinyl offers superior resistance to punctures and tears, effectively preventing physical damage. A secure closure mechanism, such as a heavy-duty zipper or adhesive seal, prevents the ingress of dust and moisture. Furthermore, specialized bags may incorporate antimicrobial treatments to inhibit mold and mildew growth, providing an additional layer of protection. In a real-world scenario, a mattress bag utilized during long-term storage in a garage protects the twin mattress from humidity fluctuations, preventing the development of mold and maintaining its integrity over time. The choice of material and construction, therefore, directly influences the level and duration of protection afforded.

In summary, the concept of protection is intrinsically linked to the purpose and value of a mattress bag for twin-sized bedding. The bag serves as a barrier against environmental hazards, safeguarding the mattress from damage and maintaining its cleanliness. Insufficient protection negates the bag’s intended function, resulting in potential financial and hygienic consequences. By selecting a bag constructed from durable materials and featuring a secure closure, and implementing proper handling and storage practices, individuals can maximize the protective benefits and extend the lifespan of their twin mattresses.

Frequently Asked Questions

The following questions address common concerns regarding the selection, usage, and disposal of protective coverings for single bedding.

Question 1: What is the appropriate gauge (thickness) for a reliable covering?

A minimum gauge of 2 mil (0.002 inches) is recommended for general use. Higher gauges, such as 4 mil or greater, provide enhanced durability and puncture resistance for heavy-duty applications.

Question 2: How can the risk of tearing the material during installation be minimized?

Ensure the covering is adequately sized for the mattress. Carefully fold the mattress edges inward to create a smoother profile. Enlist assistance from another individual to facilitate lifting and maneuvering.

Question 3: What is the recommended method for sealing the covering to prevent moisture intrusion?

High-quality packing tape or specialized sealing tape designed for polyethylene or vinyl is recommended. Overlap the tape edges to create a secure seal. Inspect the seal periodically and reapply tape as needed.

Question 4: Is it necessary to clean the mattress before encasing it in a protective covering?

Cleaning the mattress prior to encasement is advisable to remove dust, allergens, and potential contaminants. Vacuum the mattress thoroughly and spot-clean any stains. Allow the mattress to dry completely before sealing it in the covering.

Question 5: What are the environmental considerations for disposing of a used protective covering?

Check local recycling guidelines to determine if the material (polyethylene or vinyl) is recyclable. If recycling is not available, dispose of the covering responsibly in accordance with municipal waste management regulations.

Question 6: Can a protective covering be reused for multiple storage cycles?

Reuse is contingent upon the covering’s condition. Inspect the covering for tears, punctures, or compromised seals. If the covering remains intact and in good condition, it can be reused. Otherwise, replacement is recommended to ensure continued protection.

Proper selection and usage practices extend the lifespan of both the covering and the encased bedding.

The subsequent section provides troubleshooting advice for common problems encountered during the usage of single mattress coverings.

Mattress Bag Twin

This article has explored various facets of the mattress bag twin, encompassing material selection, usage guidelines, disposal considerations, and common inquiries. The critical role of this protective covering in safeguarding smaller-sized bedding during storage and relocation has been emphasized. The discussion underscores the importance of durability, dimensional accuracy, sealability, and appropriate storage practices in maximizing the encasement’s protective benefits.

Effective utilization of a mattress bag twin not only preserves the hygiene and integrity of the bedding but also contributes to long-term cost savings by preventing damage and contamination. Continued awareness and responsible application of these principles ensure the prolonged usability and value of protected single mattresses, promoting conscientious resource management.

![Best Twin Mattress Platform [Deals!] - Beds & More Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Twin Mattress Platform [Deals!] - Beds & More | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-5168-300x200.jpg)