Large protective encasements specifically designed to accommodate king-sized mattresses are available. These coverings offer a barrier against dust, moisture, and potential damage during relocation, storage, or disposal of the bedding. The dimensions are tailored to fit standard king mattress sizes, typically around 76 inches wide and 80 inches long.

The utility of these oversized coverings lies in their capacity to safeguard valuable bedding investments. Preservation of the mattress from environmental contaminants extends its lifespan and maintains hygiene. Historically, rudimentary methods were employed for mattress protection; modern materials offer superior durability and ease of use, providing a secure and efficient means of preventing damage during transport or long-term storage. Their use ensures the mattress arrives in the same condition as when it was packed.

The following sections will delve into the materials used in construction, proper usage techniques, selection criteria based on individual needs, and disposal considerations for these protective items.

Usage and Selection Tips

Optimizing the protection offered by these large mattress protectors requires careful consideration of both the selection process and proper handling techniques. The following tips offer guidance on maximizing their effectiveness.

Tip 1: Material Selection: Evaluate the material composition based on the intended application. Polyethylene options offer basic protection at a lower cost, while thicker, reinforced materials provide superior tear resistance for demanding moves. Consider the gauge or mil thickness as an indicator of durability.

Tip 2: Proper Sealing: Secure complete enclosure by utilizing packing tape specifically designed for plastic. Ensure that all seams and openings are thoroughly sealed to prevent the ingress of dust, moisture, or pests. Overlap tape generously for enhanced adhesion.

Tip 3: Mattress Preparation: Clean the mattress surface thoroughly before encasing it. Vacuum the mattress to remove dust mites, allergens, and debris. This prevents the entrapment of contaminants within the protective covering.

Tip 4: Handling Precautions: Exercise caution when moving or handling the protected mattress. Avoid dragging it across abrasive surfaces. Use furniture sliders or a dolly to minimize friction and prevent tears in the covering.

Tip 5: Storage Considerations: Store the encased mattress in a dry, climate-controlled environment. Avoid exposure to direct sunlight or extreme temperatures, which can degrade the material and compromise its integrity.

Tip 6: Inspection Before Use: Before reusing these mattress protectors, carefully inspect them for any signs of damage, such as tears, punctures, or compromised seals. Replace them if any defects are identified.

Tip 7: Disposal Practices: Adhere to local recycling guidelines when disposing of used coverings. Many polyethylene options are recyclable, contributing to environmentally responsible waste management. Check with local waste disposal services for specific instructions.

Implementing these practices will contribute to the long-term preservation of the mattress and maximize the utility of the chosen covering.

The concluding sections will offer a summary of key features and address common questions regarding these items, providing a comprehensive overview.

1. Durability

The durability of a king-size mattress bag is directly proportional to its ability to protect the enclosed mattress from physical damage and environmental contaminants. A fragile covering is susceptible to tearing during handling, transportation, or storage, thereby negating its protective function. Conversely, a durable bag constructed from robust materials withstands abrasion, punctures, and other stresses, maintaining an intact barrier between the mattress and external elements. For example, a mattress bag used during a cross-country move requires significant durability to survive the rigors of handling by movers and potential shifts within a moving truck.

The correlation between durability and protection also extends to the longevity of the bag itself. A more durable bag can be reused multiple times, reducing waste and associated costs. Furthermore, the material’s resistance to degradation from environmental factors, such as UV exposure or extreme temperatures, contributes to its overall lifespan. For instance, a mattress stored in a garage or attic necessitates a covering with UV protection to prevent the material from becoming brittle and prone to tearing over time. High gauge polyethylene is also recommended so bag is not flimsy.

In conclusion, durability is not merely a desirable attribute of king-size mattress bags but a fundamental requirement for effective mattress preservation. The selection of a bag with adequate durability safeguards the investment in the mattress, minimizes the risk of damage, and promotes long-term usability. The financial and environmental costs associated with replacing damaged mattresses highlight the practical significance of prioritizing durability when choosing a protective covering.

2. Material Composition

The material composition of king-size mattress bags directly influences their protective capabilities, durability, and overall suitability for various applications. The selection of appropriate materials is therefore a critical factor in ensuring the mattress remains shielded from environmental contaminants and physical damage.

- Polyethylene (PE)

Polyethylene represents a common and cost-effective material used in the construction of mattress bags. It offers a basic level of protection against dust and moisture. However, its tear resistance is limited, rendering it less suitable for rigorous moving conditions. For example, a thinner polyethylene bag might suffice for short-term storage within a clean environment but would be inadequate for cross-country transport.

- Polypropylene (PP)

Polypropylene offers enhanced strength compared to polyethylene, providing improved tear resistance and durability. While still a relatively economical option, it is better equipped to withstand the stresses associated with moving and handling. An example would be the use of polypropylene in bags intended for local moves or temporary storage in potentially rougher environments.

- Reinforced Polyethylene/Polypropylene

Reinforced versions of polyethylene or polypropylene incorporate interwoven fibers or multi-layer construction, significantly bolstering tear resistance and overall durability. These bags are designed for demanding applications, such as long-distance moves or extended storage periods in uncontrolled environments. A real-world application would be the use of a reinforced polyethylene bag for protecting a valuable mat

tress during international relocation. - Woven Polyethylene

Woven polyethylene provides the highest level of durability among commonly used materials. The woven structure creates a robust barrier against tears and punctures, making it suitable for heavy-duty applications. These bags are often employed in situations where the mattress will be subjected to considerable stress or rough handling. An example would be the use of a woven polyethylene bag for protecting a mattress being stored in a construction site or a potentially infested warehouse.

The material selected for a king-size mattress bag directly dictates its protective efficacy. By understanding the properties of each material, informed decisions can be made to ensure the appropriate level of protection is afforded to the mattress, based on its intended use and environmental exposure.

3. Seal Integrity

Seal integrity, in the context of king-size mattress bags, refers to the completeness and effectiveness of the closure system that prevents contaminants from entering the bag. Compromised seal integrity directly undermines the bag’s primary function: to protect the mattress from dust, moisture, pests, and other potential sources of damage. The seal acts as the final barrier against environmental intrusion, and its failure can render the entire encasement ineffective. For instance, if a mattress is sealed within a bag with a faulty closure and subsequently exposed to moisture, mold growth and irreversible damage may occur. Therefore, the quality and reliability of the seal are paramount.

The correlation between seal integrity and effective mattress protection extends beyond mere closure. The type of sealing mechanism, the material used for the seal, and the application technique all contribute to the overall integrity. Some bags rely on adhesive closures, while others utilize zippers or heat-sealed seams. Adhesive closures, if improperly applied or of insufficient strength, are prone to failure, particularly under stress or temperature fluctuations. Zippers, while offering a potentially more robust closure, can also fail if the teeth are damaged or the slider malfunctions. Heat-sealed seams provide a permanent bond but require careful manufacturing to ensure consistent and complete fusion of the material layers. A real-world example might involve a mattress bag utilized for long-term storage. If the adhesive seal degrades over time, the mattress becomes vulnerable to dust accumulation and potential pest infestation, even if the bag itself remains intact.

In summary, seal integrity constitutes a critical, often overlooked, aspect of king-size mattress bags. Its absence nullifies the protective benefits offered by the encasement, potentially leading to costly mattress damage. Prioritizing bags with robust and reliable sealing mechanisms, coupled with meticulous application techniques, is essential for ensuring long-term mattress preservation. The challenge lies in identifying and selecting bags that demonstrably provide superior seal integrity under varied environmental conditions and usage scenarios.

4. Size Accuracy

The dimensional precision of mattress encasements designated as “king size” is paramount to their effective functionality. Deviations from specified measurements can compromise the bag’s ability to adequately protect the mattress, leading to potential damage during storage or transit. Understanding the facets of size accuracy is crucial for consumers and manufacturers alike.

- Proper Enclosure

Accurate dimensions ensure the mattress is fully encased within the bag, preventing exposure to dust, moisture, and pests. An undersized bag may not fully cover the mattress, leaving vulnerable areas exposed. Conversely, an oversized bag can lead to excess material that creates snagging hazards or compromises the integrity of the seal. For example, a bag that is too short will leave the foot of the mattress exposed, negating the bag’s intended purpose.

- Ease of Application

Precise sizing facilitates the effortless application of the bag. A bag that is too tight requires excessive force to install, increasing the risk of tearing the material. A bag that is too loose can be cumbersome to manage and may not provide a secure fit. The correct size allows for a smooth, hassle-free process, minimizing the potential for damage to both the bag and the mattress. Incorrect dimensions also affect the bag’s tear resistance.

- Structural Integrity

Dimensional accuracy contributes to the overall structural integrity of the encased mattress. A properly fitted bag provides uniform support, preventing localized stress points that can lead to deformation or damage to the mattress during handling. An ill-fitting bag, on the other hand, can exacerbate existing weaknesses or create new ones. For instance, a tight bag may compress the mattress unevenly, potentially damaging the internal springs or foam layers.

- Standard Compatibility

Adherence to industry-standard king-size dimensions ensures compatibility with a wide range of mattresses. Variations in mattress dimensions necessitate corresponding adjustments in bag sizes to maintain optimal performance. Manufacturers must adhere to specified tolerances to ensure their bags are compatible with the majority of king-size mattresses available on the market. Lack of adherence creates consumer confusion and frustration and increases product return rates.

These facets underscore the importance of precise sizing in mattress encasements. A bag labeled “king size” must adhere to specified dimensions to ensure proper enclosure, ease of application, structural integrity, and standard compatibility. Accurate sizing directly translates to enhanced protection and prolonged mattress lifespan, justifying the emphasis on dimensional precision in both manufacturing and consumer selection.

5. Tear Resistance

Tear resistance, concerning mattress bags designed for king-size mattresses, is a critical attribute directly influencing the bag’s capacity to safeguard its contents. The ability of the bag to withstand punctures, rips, and tears determines its effectiveness in maintaining a protective barrier during handling, transportation, and storage. A diminished resistance to tearing renders the bag vulnerable to breaches, thereby compromising its protective function.

- Material Composition & Thickness

The inherent tear resistance of a king-size mattress bag is fundamentally linked to the materials used in its construction. Polyethylene, a common material, offers varying levels of tear resistance based on its density and thickness. Reinforced polyethylene, incorporating interwoven fibers or multiple layers, exhibits significantly improved tear resistance. Thicker materials, measured in mils (thousandths of an inch), generally provide greater resistance to punctures and tears. For example, a high-density polyethylene bag of 6 mils thickness will offer substantially more tear resistance than a standard polyethylene bag of 2 mils thickness. The material impacts the bag’s ability to handle weight and abrasive surfaces.

Seam StrengthEven if the primary material of a mattress bag possesses adequate tear resistance, weak or poorly constructed seams can create points of vulnerability. Seams are the areas where different sections of the bag are joined together, and they are often subjected to concentrated stress during handling. Reinforced seams, achieved through techniques like double stitching or heat sealing, enhance the overall tear resistance of the bag. A bag with strong material but weak seams is analogous to a chain with a weak link: it will fail at the weakest point. Poor seam construction is a frequent failure point in lower-quality bags.

- Handling & Usage Conditions

The level of tear resistance required in a king-size mattress bag is directly influenced by the anticipated handling and usage conditions. Bags intended for short-term storage in relatively benign environments may require less tear resistance than those used for long-distance moves or storage in potentially abrasive or harsh conditions. Rough handling, sharp objects, and uneven surfaces can all contribute to tears. For instance, dragging a mattress bag across a concrete floor significantly increases the risk of tearing compared to carefully carrying it across a smooth surface.

- Load Distribution

The manner in which the mattress is loaded into the bag can also affect its tear resistance. Uneven weight distribution can create localized stress points, increasing the likelihood of tears, especially in areas prone to stretching or sagging. Proper loading techniques, such as ensuring the mattress is centered within the bag and evenly supported, can minimize stress on the material. A bag with high tear resistance can still fail if subjected to excessive stress concentrated in a single area due to improper loading.

In conclusion, tear resistance in king-size mattress bags is a multifaceted characteristic influenced by material composition, seam strength, handling conditions, and load distribution. Selecting a bag with adequate tear resistance is paramount to ensuring the mattress remains protected from environmental factors and physical damage during its intended use, thereby preserving its value and extending its lifespan. A higher initial investment in a bag with superior tear resistance can ultimately prove more cost-effective than repeatedly replacing inferior bags that fail to provide adequate protection.

6. Waterproof Quality

The capacity of king-size mattress bags to resist water penetration is a crucial determinant of their effectiveness in preserving the integrity of the enclosed mattress. Waterproof quality is not merely a desirable feature, but a fundamental requirement in safeguarding against moisture-related damage, which can compromise the mattress’s structural integrity, hygiene, and overall lifespan.

- Material Impermeability

The primary determinant of waterproof quality lies in the inherent impermeability of the materials used in the bag’s construction. Polyethylene, a common material, offers varying degrees of water resistance based on its density and thickness. However, truly waterproof bags often incorporate specialized coatings or laminates that prevent water molecules from permeating the material. For instance, a bag constructed from multi-layered polyethylene with a polyurethane coating provides a significantly higher level of waterproof protection compared to a single-layer polyethylene bag. Material Impermeability is important for bag’s durability.

- Seam Sealing Techniques

The seams of a mattress bag represent potential weak points where water can infiltrate, even if the primary material is waterproof. Effective seam sealing techniques, such as heat welding or taping, are essential to create a continuous, impermeable barrier. Heat welding fuses the material layers together, while taping involves applying waterproof tape over the seams to prevent water penetration. A bag with waterproof material but poorly sealed seams is susceptible to leaks, rendering its overall waterproof quality inadequate. These Seam Sealing Techniques prevent water from getting in.

- Closure System Integrity

The closure system, whether it be a zipper, adhesive flap, or folding mechanism, must maintain a waterproof seal to prevent water from entering the bag through the opening. Zippers should be equipped with waterproof seals or flaps to prevent water from seeping through the teeth. Adhesive flaps must provide a strong, airtight bond to ensure a complete seal. The closure system represents a critical vulnerability if not properly designed and executed. A waterproof closure system is required for mattress bag.

- Environmental Exposure Considerations

The required level of waterproof quality in a mattress bag depends on the anticipated environmental exposure. Bags intended for outdoor storage or use in humid climates necessitate a higher degree of waterproof protection than those used solely for indoor storage in dry environments. Exposure to rain, snow, or high humidity can quickly compromise the integrity of a non-waterproof bag, leading to significant mattress damage. Environmental exposure makes mattress bag need to be waterproof.

These facets reinforce the critical role of waterproof quality in king-size mattress bags. Selecting a bag with appropriate waterproof characteristics, based on anticipated usage conditions, is essential to ensure long-term protection against moisture-related damage. A bag’s inability to withstand water intrusion undermines its primary function and can lead to costly consequences, highlighting the importance of prioritizing waterproof quality in the selection process. Waterproof quality is very important to consider buying.

7. UV Protection

The presence or absence of ultraviolet (UV) protection in king-size mattress bags significantly impacts their suitability for specific storage conditions. Prolonged exposure to sunlight can degrade mattress materials and the bag itself; thus, UV resistance becomes a crucial factor for long-term preservation.

- Material Degradation

UV radiation causes the breakdown of polymers commonly used in mattress bags, such as polyethylene and polypropylene. This degradation manifests as embrittlement, discoloration, and a reduction in tensile strength. Consequently, a bag without UV protection becomes more susceptible to tearing and puncturing upon prolonged exposure to sunlight. A mattress bag stored near a window without UV protection may become brittle and crack within a few months, losing its ability to protect the mattress.

- Mattress Damage

Even if the bag remains intact, UV radiation can penetrate the material and affect the mattress itself. Foam and fabric components are particularly vulnerable to UV damage, leading to fading, discoloration, and a loss of elasticity. This is especially critical for mattresses with light-colored or delicate fabrics. A mattress stored in direct sunlight without UV protection might exhibit significant fading and material breakdown over time, reducing its resale value and comfort.

- Additives and Coatings

UV protection in mattress bags is typically achieved through the addition of UV stabilizers to the polymer resin during manufacturing or the application of a UV-resistant coating to the fin

ished bag. These additives absorb or reflect UV radiation, preventing it from reaching the mattress and the bag material itself. The effectiveness of these additives depends on their concentration and the specific UV wavelengths they are designed to block. The cost of a bag with UV protection is higher, reflecting the cost of these additives. - Storage Environment

The necessity of UV protection is directly related to the anticipated storage environment. Mattress bags stored indoors, away from direct sunlight, may not require UV protection. However, bags used for outdoor storage or in locations with significant sun exposure benefit significantly from UV-resistant properties. Considering the storage location is essential when choosing the right protection. UV protection extends the life and appearance of the mattress.

These considerations underscore the importance of assessing the potential for UV exposure when selecting a king-size mattress bag. While not essential for all storage scenarios, UV protection provides a valuable safeguard against material degradation and mattress damage, particularly in environments with prolonged sunlight exposure. It is a key feature for ensuring the longevity of both the mattress and the bag itself.

Frequently Asked Questions

This section addresses common inquiries regarding king-size mattress bags, providing concise and informative answers to assist in product selection and usage.

Question 1: Are all king-size mattress bags dimensionally identical?

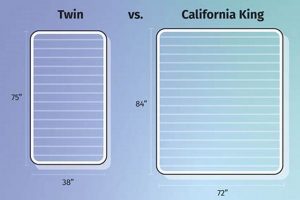

No. While designed to accommodate standard king mattresses (approximately 76 inches wide and 80 inches long), slight variations in manufacturing tolerances exist. It is advisable to verify the bag’s dimensions against the specific mattress measurements prior to purchase.

Question 2: Can king-size mattress bags be reused?

Reusability depends on the material’s durability and the conditions of prior use. Bags constructed from heavy-gauge polyethylene or reinforced materials may be suitable for reuse if undamaged. However, bags exhibiting tears, punctures, or compromised seals should be discarded.

Question 3: Is ventilation necessary when storing a mattress in a king-size bag?

Generally, sealing the mattress within a non-breathable bag is acceptable for short-term storage. However, for extended periods, consider using a bag with ventilation features or desiccant packs to minimize moisture accumulation and prevent mold growth.

Question 4: What is the proper method for sealing a king-size mattress bag?

The recommended sealing method depends on the bag’s design. Adhesive-closure bags should be sealed with heavy-duty packing tape, ensuring complete coverage of the closure flap. Zippered bags should be fully zipped and, optionally, taped for added security.

Question 5: Do king-size mattress bags protect against bed bugs?

While a properly sealed mattress bag can prevent bed bugs from entering or escaping, it is not a guaranteed solution for existing infestations. Prior to encasing a mattress, inspect it thoroughly for signs of bed bugs and treat accordingly.

Question 6: What is the environmentally responsible way to dispose of a used king-size mattress bag?

Check local recycling guidelines to determine if the bag material (e.g., polyethylene) is recyclable in the area. If recycling is not an option, dispose of the bag responsibly, minimizing its environmental impact.

These FAQs offer essential guidance for the effective use and disposal of king-size mattress bags. Prioritizing careful selection and adherence to recommended practices ensures optimal mattress protection.

The subsequent section will summarize the key benefits and features associated with these protective encasements.

Conclusion

This exploration has underscored the multi-faceted benefits and considerations associated with mattress bags king size. From material composition and tear resistance to waterproof quality and UV protection, the selection of an appropriate covering is paramount to safeguarding valuable bedding investments. Proper usage, including meticulous sealing and careful handling, further enhances the effectiveness of these protective encasements.

The informed selection and responsible utilization of mattress bags king size represent a proactive approach to preserving mattress integrity, mitigating potential damage during relocation or storage, and ultimately, extending the lifespan of a significant household asset. Continued adherence to best practices ensures sustained protection and contributes to a more sustainable consumption cycle.