A cushioning pad designed specifically for use within the cargo area of a pickup vehicle provides a comfortable surface for sleeping or resting. These accessories are often constructed from durable materials like foam or inflatable vinyl, and may feature custom shapes to fit different truck bed sizes. For instance, an individual using a pickup for camping might utilize such a pad to create a sleeping area within the truck bed.

The primary advantage of employing such a product lies in the enhanced comfort it offers compared to sleeping directly on the hard surface of a truck bed. This can contribute to improved rest during activities like camping, road trips, or work breaks. Historically, makeshift solutions like blankets or sleeping bags were used for similar purposes, but purpose-built options offer superior support and protection from the elements.

The subsequent sections will delve into the various types of these vehicle bed pads available, examining their material composition, size variations, installation procedures, and key considerations for selecting the most suitable option for individual needs and vehicle specifications.

Selection and Utilization Guidance

The following guidelines aim to provide informed advice regarding the selection and proper use of cushioning designed for placement in a pickup vehicle’s cargo area.

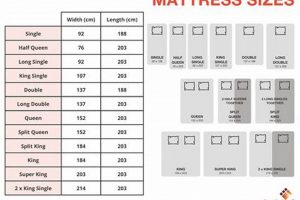

Tip 1: Determine Bed Dimensions. Accurate measurement of the truck bed is crucial. Consult vehicle specifications or physically measure the length and width to ensure compatibility with available pad sizes.

Tip 2: Evaluate Material Durability. Consider the environment in which the pad will be used. For frequent outdoor use, opt for water-resistant and puncture-resistant materials such as heavy-duty vinyl or closed-cell foam.

Tip 3: Assess Thickness and Support. Thicker pads generally provide greater comfort and support. However, consider the available headroom within the truck bed, especially if a camper shell is used.

Tip 4: Consider Inflation Options (for Inflatable Models). Electric pumps offer convenience for rapid inflation and deflation. Ensure the pump is compatible with the pad’s valve type.

Tip 5: Inspect for Leakage (for Inflatable Models). Prior to use, fully inflate the pad and inspect for any leaks. Repair kits are often included and should be utilized promptly to address minor punctures.

Tip 6: Utilize Protective Bed Liners. Employing a bed liner or mat beneath the pad can prevent abrasion and prolong its lifespan. This is particularly important in truck beds with rough or uneven surfaces.

Tip 7: Secure the Pad During Transit. If the pad is not a custom fit, secure it to the truck bed using straps or tie-downs to prevent shifting during vehicle movement.

By carefully considering these factors, individuals can select and utilize a cushioning system that provides optimal comfort and durability for use within a pickup vehicle’s cargo area.

The following sections will cover specific product reviews and comparisons, offering detailed analysis of various models available on the market.

1. Material Durability

Material durability is a critical factor in determining the lifespan and overall value of a pad intended for placement within a pickup vehicle’s cargo area. The ability of the material to withstand wear and tear, exposure to environmental elements, and repeated use directly impacts the product’s long-term performance.

- Resistance to Abrasion

The surface of a truck bed is often abrasive due to its texture and the potential presence of debris. A pad constructed from materials with high abrasion resistance, such as heavy-duty vinyl or reinforced nylon, will be less susceptible to damage from friction, thereby extending its usability. For example, a pad used frequently in a truck bed that is also used for hauling construction materials requires a higher level of abrasion resistance compared to a pad used exclusively for recreational camping.

- Puncture Resistance

Sharp objects within the truck bed, such as tools, cargo tie-downs, or small rocks, pose a puncture risk. Materials like thick, multi-layered PVC or closed-cell foam offer greater resistance to punctures. The implication of low puncture resistance is rapid deflation (in inflatable models) or tearing and degradation (in foam models), rendering the pad unusable. Imagine a camping scenario where a small twig punctures an inflatable pad during the night, resulting in a loss of support and discomfort.

- Weather Resistance

Exposure to sunlight, rain, and temperature fluctuations can degrade certain materials. UV-resistant coatings, waterproof membranes, and materials that remain flexible in cold temperatures are essential for pads used in outdoor environments. Failing to select a weather-resistant material can lead to cracking, fading, and loss of structural integrity over time. A pad left exposed to the elements in a truck bed without a cover requires robust weather-resistant properties.

- Seam Strength

For inflatable models, the seams are a critical point of potential failure. Reinforced seams, achieved through welding or durable stitching, are essential for preventing leaks and maintaining air pressure. Weak seams are prone to separation under pressure, especially when the pad is fully inflated and subjected to weight. A cheaply constructed inflatable pad with poorly reinforced seams might fail after only a few uses.

These facets of material durability collectively determine the long-term viability of a pad designed for use in a pickup vehicle’s cargo area. Selecting a product that incorporates robust materials and construction techniques is a sound investment that ensures comfort, reliability, and extended service life.

2. Size Compatibility

Size compatibility represents a foundational element in the selection of a cushioning pad for placement within the cargo area of a pickup vehicle. The dimensions of the pad must correlate directly with the internal measurements of the truck bed to ensure proper fit and functionality. A mismatch in size can lead to a variety of negative outcomes, undermining the intended purpose of the product. For instance, a pad that is too large may require forced compression, leading to premature wear and tear, while a pad that is too small will not provide complete coverage, resulting in discomfort and uneven support.

The impact of size incompatibility extends beyond mere comfort. An improperly sized pad can shift during vehicle movement, potentially posing a safety hazard or obstructing access to other items stored within the truck bed. Moreover, gaps created by an undersized pad can accumulate debris and moisture, fostering corrosion and reducing the overall lifespan of the veh

icle bed. Consider a scenario where an individual purchases a standard-sized pad for a short-bed truck. The excess material may need to be folded or cut, compromising its structural integrity and potentially interfering with the tailgate closure. Conversely, using a pad designed for a short-bed in a long-bed truck will leave a significant portion of the bed unprotected.

In summation, achieving accurate size compatibility is paramount to realizing the intended benefits of a pad designed for a truck bed. Careful measurement and adherence to manufacturer specifications are essential to avoid the adverse consequences of an ill-fitting product. This consideration underpins not only the comfort and convenience afforded by the pad, but also the safety and protection of the vehicle itself. Future sections will explore other key criteria that factor into the selection process, including material properties and ease of installation.

3. Thickness & Support

The thickness of a cushioning pad designed for a pickup truck bed and the level of support it provides are intrinsically linked to its overall functionality and user satisfaction. Thickness directly influences the degree of cushioning offered, mitigating the discomfort associated with sleeping or resting on the hard, often uneven, surface of a truck bed. Inadequate thickness results in insufficient protection from underlying contours and pressure points, negating the primary purpose of the pad. For example, a thin, low-density foam pad may prove inadequate for side sleepers, failing to provide adequate spinal alignment and resulting in discomfort or pain.

Support, in this context, refers to the pad’s ability to maintain its shape and resist compression under load. High-density materials and internal support structures contribute to superior support, preventing the user from sinking excessively into the pad. This is especially critical for individuals of greater body weight or for those who require firm support for medical reasons. Consider an individual recovering from a back injury who utilizes a truck bed pad for rest stops during long-distance travel. A pad lacking sufficient support may exacerbate their condition, rendering it unsuitable for their needs. The composition of the material, whether it is foam, inflatable, or a hybrid, significantly impacts its support characteristics. For instance, an inflatable pad with multiple internal chambers offers greater support and stability compared to a simple, single-chamber design.

In summary, the interplay between thickness and support is paramount in determining the efficacy of a pickup truck bed pad. Adequate thickness provides cushioning and pressure relief, while robust support ensures proper spinal alignment and prevents excessive sinking. Selection should be based on individual needs and body type, considering factors such as sleeping position, weight, and any pre-existing medical conditions. Ignoring these factors may result in discomfort, pain, and ultimately, a product that fails to meet the user’s expectations. Subsequent analyses will address additional factors, such as material durability and weather resistance, which further contribute to the overall value and suitability of truck bed pads.

4. Weather Resistance

Weather resistance constitutes a critical performance characteristic for any pad designed for use within the cargo area of a pickup vehicle. These pads are frequently exposed to the elements, necessitating materials and construction techniques that can withstand environmental stressors without compromising structural integrity or comfort. Prolonged exposure to moisture, ultraviolet radiation, and temperature fluctuations can degrade materials, leading to premature failure and reduced functionality. For instance, a non-weather-resistant foam pad left uncovered in a truck bed will absorb rainwater, becoming heavy, saturated, and prone to mold growth, rendering it unsuitable for sleeping. The absence of weather resistance directly impacts the lifespan and hygiene of the pad.

The practical significance of weather resistance is particularly evident in scenarios where the pad is used for camping or long-distance travel. Consider a situation where an unexpected rainstorm occurs overnight. A weather-resistant pad will prevent water from seeping into the cushioning material, ensuring a dry and comfortable sleeping surface. Conversely, a non-weather-resistant pad will become waterlogged, creating a breeding ground for bacteria and potentially leading to discomfort or illness. Furthermore, ultraviolet radiation from prolonged sun exposure can cause fading, cracking, and weakening of certain materials, diminishing the pad’s protective capabilities. Pads intended for use in climates with harsh sun exposure require UV-resistant coatings or materials to mitigate this degradation.

In conclusion, weather resistance is not merely a desirable attribute, but a fundamental requirement for pads designed for truck bed use. The ability to withstand moisture, ultraviolet radiation, and temperature fluctuations directly influences the pad’s longevity, hygiene, and overall performance. Selecting a pad with robust weather resistance ensures a comfortable and reliable sleeping or resting surface, regardless of environmental conditions. Overlooking this critical factor can lead to premature failure, discomfort, and potential health risks, underscoring the importance of prioritizing weather resistance when selecting a pad for a pickup vehicle cargo area.

5. Inflation Method

The inflation method is a significant factor influencing the utility and convenience of inflatable pads designed for placement within the cargo area of a pickup vehicle. The method by which these pads are inflated directly affects the speed and ease with which they can be prepared for use, as well as the portability of the pad itself. A poorly designed inflation system can render an otherwise comfortable and durable pad cumbersome and impractical, particularly in situations where quick setup is required. Examples include roadside rest stops during long journeys or impromptu camping scenarios where time and energy are limited. The choice of inflation method also impacts the overall size and weight of the packaged pad, affecting storage and transportation considerations. For instance, a pad requiring a bulky external pump is less convenient for packing and carrying compared to one with an integrated inflation mechanism.

Several inflation methods are commonly employed in these pads. Manual inflation, typically involving a hand or foot pump, offers a cost-effective and reliable option, but it requires physical exertion and can be time-consuming. Electric pumps, powered by a vehicle’s electrical system or a portable battery pack, provide a faster and more convenient alternative, but they add complexity and potential points of failure. Self-inflating pads incorporate open-cell foam that expands when a valve is opened, drawing air into the pad. This method is relatively effortless, but it typically requires additional manual inflation to achieve desired firmness. The choice of inflation method should be based on a careful assessment of individual needs and priorities, considering factors such as physical fitness, available power sources, and desir

ed setup speed. A user prioritizing portability and simplicity might opt for a manual inflation system, while one seeking maximum convenience might prefer an electric pump.

In conclusion, the inflation method is an integral component of inflatable pads designed for pickup vehicle beds. The selection of an appropriate inflation system depends on a balance between convenience, portability, and reliability, tailored to the specific needs and circumstances of the user. A well-chosen inflation method enhances the overall user experience and contributes to the practicality and enjoyment of using the pad. Conversely, a poorly designed or ill-suited inflation system can detract from the pad’s value, rendering it difficult to use and diminishing its appeal. Attention to this detail is crucial when selecting a pad for optimal performance and satisfaction.

6. Storage Capacity

Storage capacity, in the context of a pad designed for placement within a pickup vehicle’s cargo area, refers to the volume occupied by the product when not in use, and the ease with which it can be reduced to its minimum storage size. The relationship between storage capacity and the utility of these pads is directly proportional; smaller storage capacity enhances usability, particularly for individuals with limited storage space or those requiring frequent transport of the pad. Cause and effect are readily apparent: a pad with poor compressibility occupies significant space, impeding its convenient storage and transportation. Real-life examples include individuals who utilize their trucks for both work and recreation. A bulky, difficult-to-store pad would necessitate constant removal and re-installation, presenting a significant inconvenience. In contrast, a pad designed for compact storage allows for seamless transition between work-related cargo hauling and recreational use.

The practical significance of understanding storage capacity lies in its impact on the overall convenience and practicality of the pad. Inflatable models, by their nature, generally offer superior storage capacity compared to foam-based pads. However, even within inflatable designs, variations exist. Some utilize complex folding patterns that require significant effort to achieve compact storage, while others employ simpler designs that facilitate rapid deflation and folding. Foam pads, while typically offering less compressible storage, may utilize roll-up designs secured with straps to minimize the space occupied. Consideration must also be given to the presence of integrated storage bags or compartments, which further enhance the ease of organization and protection during storage. For instance, a pad used primarily for occasional camping would benefit from a design that prioritizes compact storage, even at the expense of slightly reduced comfort when deployed.

In summary, storage capacity is a key determinant in the practicality and convenience of a pad for use in a pickup truck bed. Compact storage minimizes space requirements, facilitating easier transportation and storage between uses. The relationship between storage capacity and other factors, such as material type and inflation method, necessitates careful consideration during product selection. The challenge lies in balancing the desired level of comfort and durability with the practical constraints of storage space. The successful integration of compact storage solutions contributes significantly to the overall utility and satisfaction derived from the use of a pad designed for a truck’s cargo area.

Frequently Asked Questions

This section addresses commonly encountered queries regarding pads specifically designed for use within the cargo area of pickup vehicles. The information provided aims to offer clarity and informed guidance to prospective users.

Question 1: What materials are typically used in the construction of these pads, and how do they affect durability?

Common materials include high-density foam, durable vinyl, and reinforced nylon. Material selection directly impacts the pad’s resistance to abrasion, punctures, and weather elements, thereby influencing its overall lifespan and suitability for various environmental conditions. Higher-quality materials generally correlate with increased durability.

Question 2: How does one accurately determine the appropriate size for a pad intended for their specific pickup vehicle?

Precise measurement of the truck bed’s internal dimensions is paramount. Consult vehicle specifications or utilize a measuring tape to determine length and width. Ensure the pad dimensions align closely with the measured values to avoid gaps or overhang, which can compromise comfort and stability.

Question 3: Are inflatable pads more prone to punctures compared to foam-based options, and what preventative measures can be taken?

Inflatable pads inherently possess a higher puncture risk. Mitigating measures include selecting pads constructed from puncture-resistant materials, utilizing protective bed liners, and avoiding sharp objects within the truck bed. Patch kits should be readily available for addressing minor punctures.

Question 4: What are the key considerations regarding cleaning and maintenance of these pads to prolong their lifespan?

Regular cleaning is essential. Remove debris and dirt using a brush or vacuum. For stains, utilize a mild detergent and water solution. Allow the pad to air dry thoroughly before storing. Avoid harsh chemicals or abrasive cleaners, which can damage the material. Store the pad in a dry, protected environment when not in use.

Question 5: How does the thickness of the pad affect comfort and support, and what thickness is generally recommended?

Greater thickness typically correlates with enhanced cushioning and pressure relief. However, excessively thick pads may reduce headroom, particularly in truck beds equipped with camper shells. A thickness ranging from 3 to 6 inches is generally recommended, but individual preferences and body weight should be considered.

Question 6: What are the implications of using a non-weather-resistant pad in an outdoor environment, and what features should be sought in a weather-resistant model?

Non-weather-resistant pads are susceptible to water damage, mold growth, and degradation from ultraviolet radiation. Weather-resistant models should incorporate waterproof membranes, UV-resistant coatings, and materials that remain pliable in varying temperatures. These features are crucial for maintaining the pad’s integrity and hygiene in outdoor settings.

The preceding information highlights essential considerations when selecting and maintaining a pad designed for use within a pickup vehicle. Prioritizing these factors will ensure optimal comfort, durability, and user satisfaction.

The subsequent sections will delve into product reviews and comparative analyses, providing further insights into the diverse range of options available in the market.

Conclusion

The preceding analysis has thoroughly examined the various facets of a “mattress for bed of truck,” encompassing material durability, size compatibility, support characteristics, weather resistance, inflation methods, and storage capacity. Each element plays a critical role in determining the suitability and long-term utility of such a product, influencing user comfort, convenience, and overall satisfaction. Informed decision-making hinges on a comprehensive understanding of these factors and their interdependencies.

The selection of an appropriate “mattress for bed of

truck” represents a significant investment, requiring careful consideration of individual needs and operational context. Prioritizing robust construction, accurate sizing, and relevant features is paramount to ensuring long-term performance and maximizing value. Further research into specific product models and independent reviews is encouraged to facilitate a well-informed purchasing decision, optimizing the benefits derived from this specialized automotive accessory.

![Best Toyota Tacoma Bed Air Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Toyota Tacoma Bed Air Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7271-300x200.jpg)