A specialized sleeping surface designed to fit within the cargo area of a truck is a form-fitting cushion that allows for mobile rest. These typically consist of foam, air, or a hybrid of materials, providing varying levels of comfort and support for individuals seeking temporary lodging within their vehicle. For example, an over-the-road trucker might use this type of bedding solution for mandated rest periods.

The utilization of such a sleeping arrangement offers enhanced convenience for camping, road trips, and professions requiring on-the-go accommodation. Its importance lies in providing a designated, comfortable space for rest in situations where conventional lodging is either unavailable, impractical, or costly. Historically, improvised bedding materials were used, but specialized options now offer improved comfort and durability.

The subsequent sections will delve into the various types available, factors influencing selection, installation considerations, and maintenance procedures associated with these truck-specific bedding solutions, providing a comprehensive overview for potential users.

Selection and Usage Tips

The following provides essential guidelines for choosing and effectively utilizing a sleeping solution tailored to the dimensions of a pickup truck bed.

Tip 1: Measure the Truck Bed Accurately: Prior to purchase, precise measurements of the truck beds interior length and width are critical. These dimensions will ensure a proper fit, maximizing available sleeping space and preventing damage to the product.

Tip 2: Consider Material Durability: Evaluate the material composition based on anticipated usage frequency and environmental conditions. Heavy-duty, water-resistant fabrics are recommended for frequent outdoor use, while lighter materials may suffice for occasional trips.

Tip 3: Assess Comfort and Support: Foam density and thickness directly impact comfort. Individuals with back issues should prioritize thicker, high-density foam options to provide adequate support and minimize discomfort.

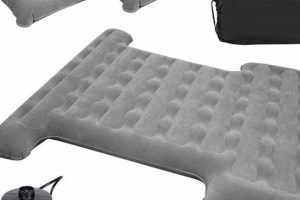

Tip 4: Evaluate Inflation/Deflation Systems (if applicable): Air mattresses designed for truck beds should feature reliable and efficient inflation/deflation systems. Consider models with built-in pumps for convenience and rapid setup.

Tip 5: Inspect Seam Strength and Construction: Robust seams are essential for preventing air leaks in inflatable models and for ensuring the long-term integrity of foam variants. Thoroughly inspect all seams before initial use.

Tip 6: Prioritize Storage Considerations: When not in use, consider the storage footprint of the chosen model. Compact, foldable designs offer convenience and minimize space requirements.

These considerations facilitate the selection of a durable and comfortable sleeping solution, optimizing the utility of the pickup truck bed for rest and relaxation.

The subsequent sections will conclude by providing considerations for proper care and cleaning.

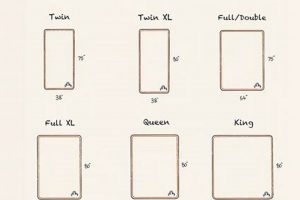

1. Bed dimensions

The utility of a “mattress for pickup truck bed” is fundamentally contingent upon accurate bed dimensions. Incorrect measurements result in a misfit, negating the primary purpose of providing a comfortable and secure sleeping surface. A mattress that is too large will be unusable, failing to conform to the bed’s contours, while one that is too small will slide and shift, compromising stability and safety. For example, a full-size mattress intended for a standard long-bed truck will prove unsuitable for a short-bed model, demonstrating the direct cause-and-effect relationship.

The practical significance extends beyond mere fit. Precise dimensions allow for maximizing available sleeping space within the confines of the truck bed. A custom-fit solution, achieved through accurate dimensioning, optimizes usability and prevents wasted space. Consider a scenario where a camper utilizes the truck bed as a primary sleeping area; an accurately sized mattress will provide ample room for comfortable rest, whereas an ill-fitting option introduces discomfort and limits mobility. Aftermarket bed liners and modifications must also be factored into dimensional considerations, as they alter the internal measurements.

In summary, bed dimensions serve as the foundational determinant of a suitable sleeping surface. The proper measurement and matching of mattress size to truck bed dimensions directly correlates with user comfort, safety, and efficient use of available space. Failure to prioritize this aspect undermines the entire purpose, and negates the functional advantages a tailored solution can offer.

2. Material Durability

Material durability is a critical factor influencing the longevity and utility of a sleeping surface designed for a pickup truck bed. The challenging environmental conditions and potential for abrasive contact inherent in truck bed use demand robust materials capable of withstanding wear and tear. The selection of appropriate materials directly translates to the lifespan and performance of the mattress.

- Abrasion Resistance

The truck bed environment frequently involves contact with rough surfaces and shifting cargo. Materials with high abrasion resistance, such as reinforced nylon or vinyl-coated fabrics, are essential to prevent tearing and degradation. For instance, a mattress used in a truck bed hauling construction materials requires greater abrasion resistance compared to one used solely for recreational camping.

- Water Resistance and Waterproofing

Exposure to moisture, whether from rain, condensation, or spills, can compromise the integrity of the mattress core, leading to mold growth and material breakdown. Waterproof or highly water-resistant materials, often incorporating sealed seams, are necessary to protect the inner components. Consider the difference between a water-resistant polyester cover, which repels light moisture, and a fully waterproof PVC coating, which provides complete protection against liquid penetration.

- UV Resistance

Prolonged exposure to ultraviolet (UV) radiation from sunlight can degrade many common mattress materials, causing fading, cracking, and loss of elasticity. Selecting materials with inherent UV resistance or applying UV-protective coatings extends the lifespan of the mattress. For example, a mattress stored uncovered in a truck bed during daylight hours requires superior UV protection compared to one primarily used at night.

- Puncture Resistance

The risk of punctures from sharp objects within the truck bed, such as tools or debris, necessitates materials with high puncture resistance. Reinforced fabrics and thick padding layers provide an added layer of protection. An air mattress constructed from multiple layers of puncture-resistant material is preferable t

o a single-layer design for applications where sharp objects are a concern.

These considerations regarding material durability collectively influence the overall value and suitability of a “mattress for pickup truck bed.” The initial investment in a more durable model can offset the cost of frequent replacements, while ensuring consistent comfort and performance over an extended period. Therefore, assessing these material properties is a crucial step in selecting a truck bed sleeping surface that aligns with the anticipated usage conditions.

3. Thickness and support

The attributes of thickness and support are paramount considerations when evaluating a sleeping surface intended for use within a pickup truck bed. These factors directly influence user comfort, postural alignment, and overall rest quality, thereby impacting the suitability of a given mattress model for mobile sleeping applications.

- Foam Density and Compression

Foam density, measured in pounds per cubic foot, dictates the level of support offered. Higher density foams resist compression, providing greater stability and preventing the sleeper from sinking excessively. This is particularly relevant in truck bed applications where uneven surfaces might exacerbate pressure points. For example, a high-density memory foam mattress will conform to the body while maintaining consistent support, whereas a low-density option may compress unevenly, leading to discomfort.

- Layered Construction and Zoning

Mattresses often incorporate multiple layers of foam with varying densities and properties to optimize both comfort and support. Zoned support systems, where specific areas of the mattress are engineered to provide greater firmness, are beneficial for maintaining spinal alignment. Consider a design with firmer support in the lumbar region to prevent lower back pain, a common complaint among those sleeping in less-than-ideal conditions. This targeted approach enhances ergonomic support within the confines of a truck bed.

- Air Mattress Chamber Design

For inflatable mattresses, the internal chamber design significantly affects support. Multiple chambers allow for independent inflation, enabling users to customize firmness levels in different areas of the mattress. This is advantageous in accommodating varying body weights and sleep preferences. Unlike a single-chamber air mattress, a multi-chamber design can distribute weight more evenly and provide enhanced stability, mitigating the rocking motion often experienced within a truck bed.

- Thickness and Edge Support

Overall mattress thickness contributes to both comfort and perceived support. A thicker mattress typically offers a more substantial cushioning layer, while adequate edge support prevents sagging and maximizes the usable sleeping surface. In the context of a truck bed, where space is often limited, robust edge support is crucial for utilizing the full width of the mattress without feeling like one is about to roll off. This feature enhances safety and comfort, particularly for individuals sharing the sleeping space.

These interrelated facets of thickness and support collectively determine the ergonomic properties of a “mattress for pickup truck bed.” The selection of a model that appropriately addresses these considerations will yield a more restful and restorative sleep experience, mitigating the challenges inherent in mobile accommodation. Conversely, neglecting these factors can result in discomfort, sleep disruption, and potential musculoskeletal issues.

4. Water resistance

Water resistance is a critical attribute for any sleeping surface intended for use in a pickup truck bed due to the potential for exposure to moisture from rain, humidity, spills, or condensation. The presence of moisture can compromise the integrity of the mattress, leading to reduced comfort, material degradation, and the growth of mold or mildew.

- Surface Material Protection

The outermost layer of the mattress must possess water-resistant properties to prevent liquids from penetrating the inner layers. Materials like coated nylon, polyester, or vinyl provide a barrier against water intrusion. For example, a spilled drink or rainwater seeping under a truck bed cover will be less likely to saturate a mattress with a durable, water-resistant outer shell, preserving its internal components and preventing staining.

- Seam Sealing Technology

Seams are potential entry points for water, requiring specialized sealing techniques to maintain water resistance. Heat-sealing, taping, or the use of water-resistant threads are common methods. A mattress with poorly sealed seams, even with a water-resistant surface, will eventually absorb moisture through these vulnerable points, leading to internal damage. Careful inspection of seam construction is therefore essential.

- Internal Component Protection

Even with a water-resistant exterior, the internal foam or inflatable components require protection. Closed-cell foam offers inherent water resistance compared to open-cell foam. Inflatable mattresses should utilize durable, airtight materials that are impervious to moisture penetration. Failure to protect these internal components will lead to material breakdown, reduced insulation, and potential health hazards from mold or mildew growth.

- Maintenance and Drying Procedures

Regardless of the level of water resistance, proper maintenance is crucial. Spills should be cleaned promptly, and the mattress should be allowed to air dry thoroughly after any exposure to moisture. Regular inspection for signs of water damage and adherence to the manufacturer’s cleaning instructions will extend the lifespan of the mattress and prevent the development of unwanted microbial growth. Ignoring proper drying procedures can negate the benefits of water-resistant materials.

The integration of effective water-resistant features, coupled with appropriate maintenance, ensures the longevity and hygienic condition of a “mattress for pickup truck bed.” Investing in a model with robust water-resistant construction is a prudent choice for individuals who anticipate using the mattress in potentially damp or humid environments, safeguarding against premature degradation and promoting a healthier sleeping environment.

5. Storage capacity

The attribute of storage capacity, often overlooked, is intrinsically linked to the practicality and user experience of a “mattress for pickup truck bed.” Given the typically confined space within a pickup truck, particularly when outfitted for camping or overlanding, efficient storage of bedding is crucial. The correlation is direct: a mattress that packs down compactly maximizes available cargo space for other essential gear, while a bulky, non-compressible model significantly impedes storage, impacting overall trip logistics.

Storage solutions vary significantly. Some mattresses are designed to fold or roll into a compact bundle, often secured with integrated straps. Others, particularly inflatable models, deflate to a min

imal volume, occupying negligible space when not in use. In contrast, some foam mattresses retain their full dimensions, presenting a storage challenge that may necessitate dedicated cargo boxes or roof racks. Consider the hypothetical scenario of a weekend camping trip: a quickly deployable and storable mattress frees up space for coolers, cooking equipment, and personal belongings, thereby enhancing the overall comfort and organization of the excursion.

In summary, the storage capacity of a truck bed sleeping surface is not merely an ancillary feature but a fundamental consideration that directly affects the utility and enjoyment of the product. Prioritizing a mattress with a compact storage profile optimizes available space within the truck, improving overall logistics and enhancing the practicality of mobile sleeping arrangements. The challenge lies in balancing comfort and durability with storable dimensions, leading manufacturers to innovate with folding designs and advanced compression technologies.

6. Inflation (if air)

For inflatable sleeping surfaces designed for pickup truck beds, the inflation mechanism is a critical determinant of user convenience and overall performance. The efficiency and reliability of inflation processes directly impact the practicality of utilizing such a mattress for mobile rest.

- Pump Type and Power Source

Inflation can be achieved through manual pumps, electric pumps powered by the vehicle’s DC outlet, or integrated battery-operated systems. Manual pumps require physical exertion and are slower, while electric pumps offer convenience but are dependent on a power source. Integrated battery systems provide independence but introduce the need for charging. For example, a remote campsite without vehicle access necessitates a battery-powered pump, while a developed campground might allow for the use of a DC-powered option.

- Inflation Speed and Effort

The time required to fully inflate the mattress and the physical effort involved are key considerations. Systems that offer rapid inflation with minimal user input are preferable. Consider two scenarios: one where a user seeks immediate rest after a long drive, and another where setup time is less critical. The former situation demands a high-speed inflation system, while the latter allows for manual methods. A slow or laborious inflation process diminishes the appeal of an inflatable solution.

- Inflation Valve Design and Durability

The valve mechanism must provide a secure seal to prevent air leakage and withstand repeated use. Durable materials and robust construction are essential for longevity. An unreliable valve negates the benefits of a well-designed mattress, rendering it unusable if inflation cannot be maintained. Leaks, either slow or rapid, can seriously compromise the sleeping experience.

- Deflation Mechanism and Speed

Equally important is the deflation process. A rapid and complete deflation mechanism facilitates compact storage and reduces the time required to pack up. Valves designed for efficient air release, sometimes coupled with integrated extraction systems, are advantageous. Residual air within the mattress hinders proper folding and increases storage volume, thus a quick deflation mechanism is crucial for ease of use.

These factors collectively define the utility of an inflatable “mattress for pickup truck bed.” The selection of a model with an appropriate inflation and deflation system, aligned with the user’s specific needs and usage context, ensures a convenient and reliable sleeping solution. An inadequate system compromises practicality, potentially outweighing the benefits of portability and comfort.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, utilization, and maintenance of sleeping surfaces designed for installation within the cargo area of pickup trucks.

Question 1: What are the primary factors influencing the selection of a suitable mattress for pickup truck bed?

Key determinants include accurate truck bed dimensions, material durability to withstand outdoor conditions, desired thickness and support level for optimal comfort, water resistance to mitigate moisture damage, and storage capacity for efficient packing when not in use. Inflation mechanisms are also a significant factor for air mattresses.

Question 2: How is the correct size of a mattress for pickup truck bed determined?

Precise measurements of the truck bed’s internal length and width are required. Consider any existing bed liners or modifications, as these may alter the available space. Manufacturers typically provide dimension specifications for their products, allowing for accurate matching.

Question 3: What materials offer optimal durability for a mattress for pickup truck bed?

Reinforced nylon, vinyl-coated fabrics, and closed-cell foam provide enhanced abrasion resistance, water resistance, and puncture resistance. Selecting materials with UV protection is also crucial to prevent degradation from prolonged sun exposure.

Question 4: How is the firmness or support level of a mattress for pickup truck bed assessed?

Foam density, layered construction, and zoning technologies dictate the level of support. Higher density foams resist compression, providing greater stability. In inflatable mattresses, the number of internal chambers influences weight distribution and overall firmness.

Question 5: What maintenance procedures are recommended for a mattress for pickup truck bed?

Promptly clean any spills, allow the mattress to air dry thoroughly after exposure to moisture, and regularly inspect for signs of water damage or wear. Adhere to the manufacturer’s cleaning instructions. Store in a dry, protected environment when not in use.

Question 6: How should an air mattress for pickup truck bed be inflated and deflated?

Follow the manufacturer’s instructions for the specific inflation mechanism. Ensure the valve is securely sealed to prevent air leakage. When deflating, use a valve designed for rapid air release and compress the mattress to expel any remaining air before folding for storage.

Proper attention to these frequently asked questions will facilitate an informed selection process and promote the longevity and performance of a sleeping surface designed for use within a pickup truck bed.

The next section provides additional insights into specialized features and advanced designs available within the market.

Conclusion

The preceding analysis elucidates the multifaceted considerations inherent in selecting a “mattress for pickup truck bed”. Key determinants span dimensional accuracy, material fortitude, ergonomic properties, resistance to environmental factors, and efficient storage solutions. These parameters collectively influence the suitability and longevity of a sleeping surface designed for mobile accommodation within a truck’s cargo area.

The efficacy of a chosen mattress ultimately hinges on a comprehensive evaluation of individual needs and intended usage scenarios. Prudent assessment and adherence to recommended maintenance practices will yield a durable, comfortable, and practical solution. Continued advancements in material science and design innovation are expected to further refine the functionality and performance characteristics of these specialized sleeping solutions.