A sleep surface supported by a metallic structure offers a blend of comfort and durability. This configuration often involves a bed base constructed from steel or aluminum, designed to provide stable and even support to the overlying cushion. Examples range from simple, foldable bed frames for temporary use to elaborate, decorative bed designs incorporating headboards and footboards.

The adoption of metallic support systems has increased due to their robustness, affordability, and ease of assembly. Historically, wooden bed frames were the standard, but metal alternatives have gained prominence because of their resistance to pests, superior load-bearing capacity, and ability to be mass-produced. These factors contribute to both cost-effectiveness and longevity in domestic and commercial settings.

The following sections will delve into the specific types of these support systems, their advantages and disadvantages, common materials used in their construction, and key considerations for selecting the appropriate setup for individual needs and preferences, ensuring optimal sleep quality and structural integrity.

Tips for Selecting a Mattress with Metal Frame

Selecting a sleep system utilizing a metallic support structure requires careful consideration to ensure optimal comfort, support, and longevity. The following tips provide guidance for making an informed decision.

Tip 1: Evaluate Frame Material: Consider steel or aluminum construction. Steel provides greater strength and weight capacity, while aluminum offers corrosion resistance, particularly in humid environments. Verify the gauge of the metal; a lower gauge indicates thicker, stronger material.

Tip 2: Assess Slat Spacing: The distance between the slats directly impacts the mattress’s support. Narrower spacing, typically no more than 2-3 inches, provides more uniform support and prevents sagging, especially for heavier mattresses or individuals.

Tip 3: Inspect Welding Quality: Examine the welds connecting the frame’s components. Clean, consistent welds indicate structural integrity and minimize the risk of failure under stress. Avoid frames with visible porosity or cracks in the weld seams.

Tip 4: Check for Center Support: For larger sizes (Queen, King), ensure the frame includes a center support beam and additional legs. This prevents bowing and ensures even weight distribution across the sleeping surface, extending the mattress’s lifespan.

Tip 5: Consider Headboard/Footboard Compatibility: If intending to attach a headboard or footboard, verify the frame’s compatibility. Check for pre-drilled holes and standard mounting brackets. Ensure the frame’s dimensions align with the intended headboard/footboard.

Tip 6: Examine Frame Height: Determine the desired bed height. A higher frame facilitates under-bed storage, while a lower frame may be more suitable for individuals with mobility concerns. Consider the mattress thickness when calculating the final bed height.

Tip 7: Research Assembly Requirements: Investigate the complexity of assembly. Some frames require specialized tools or extensive labor. Opt for designs with clear instructions and minimal hardware for ease of setup.

Proper selection of a metallic support structure requires careful assessment of material quality, structural design, and compatibility with other components. These considerations contribute to a stable, durable, and comfortable sleep environment.

The subsequent sections will explore specific product recommendations and delve into advanced considerations for maximizing the benefits of a metallic support system.

1. Durability

The long-term utility of a sleep system relying on a metallic support structure is fundamentally linked to its resistance to wear, deformation, and failure under sustained use. Durability, in this context, is a critical determinant of value and user satisfaction.

- Material Composition and Treatment

The type and quality of metal used directly influence structural integrity. Steel alloys, particularly those treated with powder coating or rust inhibitors, offer superior resistance to corrosion and physical stress compared to untreated or lower-grade metals. Examples include the use of high-carbon steel for load-bearing components versus thin-gauge steel for aesthetic elements. The implications are that a higher quality material translates to a longer lifespan and resistance to sagging.

- Weld Integrity and Joint Strength

The method and quality of joining metal components significantly affect the frame’s ability to withstand stress. Full-penetration welds provide greater strength compared to spot welds. Reinforced joints at stress points, such as corners and leg attachments, prevent premature failure. For example, a frame with consistently applied, high-quality welds will exhibit greater resistance to bending or breaking under load, extending its operational life.

- Design and Load Distribution

Frame design plays a crucial role in distributing weight evenly across the structure. Frames with center support beams and multiple support legs, particularly in larger sizes (Queen, King), minimize stress concentration and prevent localized deformation. A well-designed frame ensures that the weight of the mattress and occupants is distributed, reducing the risk of structural failure over time.

- Slat Construction and Fastening

The materials and spacing of the supports themselves impact the longevity of both the frame and the mattress. Solid wood or metal slats, securely fastened to the frame with screws or bolts, provide a more stable and durable support system compared to thinly spaced, poorly attached supports. The implications of this are less mattress sagging and increased frame integrity.

These interconnected aspects of durability, from the fundamental material properties to the intricacies of design and construction, collectively determine the lifespan and resilience of a sleeping system with a metallic support structure, ultimately influencing its value proposition and user experience over time. The absence of even one of these components can lead to premature wear, instability, and ultimately, failure of the bed system.

2. Support

The primary function of a metallic support structure for a sleep surface is to provide adequate support, directly impacting spinal alignment and sleep quality. Inadequate support can lead to discomfort, pain, and long-term musculoskeletal issues. The rigidity and design of the frame, in conjunction with the slat system, determine the degree to which the mattress is uniformly supported, preventing sagging and ensuring consistent firmness across the sleep surface. For instance, a frame with widely spaced slats may cause a memory foam mattress to sag prematurely, negating its pressure-relieving properties. Conversely, a frame with closely spaced, robust slats provides firm support, ideal for innerspring mattresses.

The type of support offered varies based on frame design and materials. Platform frames, offering a solid or nearly solid surface, provide the firmest support, suitable for individuals who prefer a firmer sleeping experience or require enhanced back support. Slat systems offer variable support depending on slat material (wood vs. metal), slat thickness, and spacing. Adjustability, such as with adjustable bed bases that incorporate metallic structures, offers customized support for specific needs, such as elevating the head or legs to alleviate sleep apnea or improve circulation. The importance of selecting an appropriate frame configuration lies in matching the support characteristics to the specific mattress type and individual sleeping preferences.

Understanding the relationship between metallic support structures and their impact on sleep surface support is crucial for informed purchasing decisions. The selection of an inappropriate support system can compromise the comfort and longevity of the sleep surface, leading to increased costs and diminished sleep quality. Therefore, a thorough assessment of the intended support characteristics should be a primary consideration when choosing a sleep system that incorporates a metallic frame. The impact on sleep health is direct and significant.

3. Stability

The structural integrity of a sleep system incorporating a metallic support structure is paramount to its functionality and safety. Stability, in this context, denotes the ability of the bed frame to resist movement, deformation, or collapse under load. Insufficient stability can lead to a range of issues, including disturbed sleep due to wobbling or creaking, premature wear of the sleep surface, and, in extreme cases, structural failure resulting in injury. The connection between stability and a metallic support structure is a direct cause-and-effect relationship: a poorly designed or constructed frame will exhibit instability, whereas a robust and well-engineered frame will provide a stable and secure platform. For example, a bed frame constructed from thin-gauge steel with inadequate welding is likely to exhibit instability, particularly under the weight of two occupants, leading to noise and discomfort. Conversely, a frame built with thick-gauge steel, reinforced joints, and a central support beam will maintain its stability even under significant load.

The importance of stability extends beyond mere comfort; it is a critical safety consideration. A stable bed frame minimizes the risk of accidental falls or collapses, particularly important for elderly individuals or those with mobility limitations. Furthermore, a stable platform provides optimal support for the sleep surface, ensuring proper spinal alignment and reducing the risk of back pain. In practical application, stability can be assessed through a series of simple tests: applying pressure to various points on the frame to check for wobbling or creaking, inspecting the welds for signs of weakness or cracking, and verifying the integrity of the leg attachments. The practical significance of understanding stability lies in the ability to identify potential weaknesses in a bed frame before purchase, allowing for informed decision-making and preventing future problems.

In summary, stability is an indispensable component of a sleeping arrangement that utilizes a metal frame, and its importance cannot be overstated. Challenges associated with achieving optimal stability include balancing cost-effectiveness with material quality and ensuring consistent manufacturing standards. The insights presented underscore the necessity of prioritizing stability when selecting a sleep system, ensuring not only a comfortable and restful sleep experience but also a safe and durable product. This understanding connects directly to the broader theme of optimizing sleep health through informed choices and appropriate product selection.

4. Assembly

The process of assembling a metallic support structure for a sleep surface represents a critical juncture in the overall user experience. Assembly directly impacts the stability, functionality, and longevity of the bed frame, and, by extension, the sleep surface it supports. Complex or poorly designed assembly procedures can lead to structural weaknesses, misalignments, and a compromised sleeping experience. For example, if bolts are not properly tightened during assembly, the frame may wobble or creak, leading to disturbed sleep and accelerated wear on both the frame and the mattress. The cause-and-effect relationship between assembly and mattress with metal frame is undeniable: a well-assembled frame provides a stable and durable foundation, whereas a poorly assembled frame compromises the entire system.

The importance of assembly as a component of a metallic mattress support system lies in its influence on structural integrity and user safety. A frame that is difficult to assemble may result in incorrect construction, increasing the risk of collapse or injury. Real-life examples include cases where improperly installed support legs have buckled under weight, leading to falls and property damage. Consequently, bed frame manufacturers are under increasing pressure to simplify assembly processes and provide clear, concise instructions. Many now incorporate tool-free assembly designs, pre-assembled components, and detailed visual aids to minimize the risk of errors. The practical significance of understanding the connection between assembly and mattress with metal frame is that it empowers consumers to evaluate the ease of setup before purchase, reducing frustration and ensuring a structurally sound sleeping platform.

In summary, the assembly process is an integral aspect of a sleeping arrangement that utilizes a metallic support structure. The ease and accuracy of assembly directly affect the stability, safety, and lifespan of the bed frame and sleep surface. Challenges include balancing design complexity with user-friendliness and ensuring consistent manufacturing quality to prevent assembly errors. Prioritizing ease of assembly and scrutinizing assembly instructions are therefore essential steps in selecting a durable and functional sleep system. This contributes to a better sleep experience and the long-term value of the purchase.

5. Size

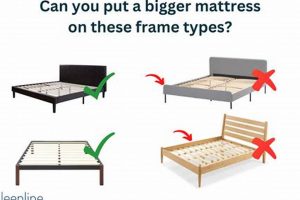

The dimensional compatibility between a sleep surface and its metallic support structure directly influences the system’s functionality, comfort, and safety. Size, in this context, refers to the length, width, and height of both the mattress and the frame. Mismatched dimensions can result in inadequate support, increased wear on the mattress, and potential safety hazards. For example, a mattress that is too small for its frame may shift or slide during use, leading to discomfort and disrupted sleep. Conversely, a mattress that is too large may overhang the frame, compromising edge support and potentially causing damage to the mattress itself. The cause-and-effect relationship between size and the “mattress with metal frame” is therefore evident: proper dimensional alignment ensures optimal performance, while misalignment leads to compromised functionality.

The importance of size as a component of a “mattress with metal frame” is underscored by its impact on weight distribution and structural integrity. An undersized frame may be unable to adequately support the weight of the mattress and occupants, increasing the risk of frame failure. Conversely, an oversized frame may create gaps that allow the mattress to sag, leading to uneven support and premature wear. Real-life examples include instances where mattresses have fallen through frames due to inadequate size matching, resulting in injuries and property damage. Manufacturers adhere to standardized sizing conventions (Twin, Full, Queen, King, California King) to mitigate these risks; however, variations in mattress thickness and frame design necessitate careful measurements to ensure a proper fit. The practical significance of understanding the size relationship lies in preventing such incidents and ensuring a safe, comfortable, and durable sleep environment.

In summary, accurate size matching between a mattress and its metallic support structure is crucial for optimal performance, safety, and longevity. Challenges include variations in manufacturing tolerances and the proliferation of non-standard mattress sizes. The insights presented emphasize the need for precise measurements and careful consideration of both mattress and frame dimensions during the selection process. This contributes to a more effective and satisfying sleep experience and reduces the risk of accidents or premature product failure.

6. Materials

The selection of materials used in the construction of a metallic support structure directly influences its durability, stability, and overall performance. Materials choice dictates the frame’s load-bearing capacity, resistance to corrosion, and longevity. For instance, a bed frame constructed from high-carbon steel offers superior strength and resistance to bending compared to one made from aluminum. However, aluminum provides increased resistance to rust, making it a more suitable option for humid environments. The materials used also affect the ease of assembly and the overall weight of the frame. A heavier frame, such as one made from solid steel, tends to be more stable but also more difficult to move. The connection between “Materials” and the “mattress with metal frame” lies in the direct impact that the materials have on the functionality and lifespan of the entire sleep system. Inappropriate material selection can lead to premature frame failure and compromised support for the mattress.

The type of coating or finish applied to the metallic components is equally significant. Powder coating provides a durable and aesthetically pleasing finish, protecting the metal from scratches and corrosion. Chrome plating offers a similar level of protection but can be more susceptible to scratching and peeling. Unfinished metal frames are prone to rusting and require regular maintenance. Real-world examples demonstrate the importance of material selection. Bed frames constructed from low-grade steel have been known to bend or break under normal use, leading to mattress damage and potential injury. Conversely, frames made from high-quality steel with a durable powder-coated finish have been shown to withstand years of use without significant degradation. The choice of materials, therefore, directly affects the long-term value and safety of the sleep system.

In summary, the materials used in the construction of a metallic support structure are critical determinants of its performance and longevity. Factors such as metal type, gauge, and finish should be carefully considered to ensure optimal support, durability, and resistance to environmental factors. The insights presented highlight the importance of prioritizing quality materials when selecting a “mattress with metal frame.” This understanding is crucial for ensuring a safe, comfortable, and cost-effective sleep environment.

7. Compatibility

The successful integration of a mattress with a metallic support structure hinges on compatibility, encompassing dimensional conformity, structural alignment, and functional harmony. A disconnect in any of these areas can compromise the system’s integrity, leading to diminished comfort, reduced lifespan, and potential safety hazards.

- Mattress Type and Support System

The type of sleep surface, whether innerspring, memory foam, latex, or hybrid, dictates the required support characteristics of the metal frame. Innerspring mattresses typically benefit from a rigid, closely spaced slat system to prevent sagging, while memory foam mattresses require a solid or near-solid platform to ensure uniform support and prevent compression. Real-world examples include the premature degradation of memory foam mattresses placed on widely spaced slat systems, negating their pressure-relieving properties. The structural alignment between mattress type and support structure is therefore critical for optimal performance.

- Headboard and Footboard Attachment

The ability to securely attach a headboard and footboard to the metal frame depends on the presence of compatible mounting points and standardized dimensions. Failure to ensure compatibility can result in instability, compromised aesthetics, and potential safety risks. For example, attempting to attach a headboard designed for a wooden frame to a metal frame lacking appropriate mounting brackets can lead to structural instability and potential detachment. Compliance with industry standards for headboard and footboard attachment is therefore essential.

- Bedding and Accessories

The size and profile of the metal frame must be compatible with standard bedding sizes and accessories, such as bed skirts and fitted sheets. An ill-fitting frame can lead to difficulties in securing bedding, resulting in an unkempt appearance and potential discomfort. For instance, a metal frame with an unusually high profile may require extra-deep pocket sheets to ensure a proper fit. Adherence to standard sizing conventions simplifies the process of selecting compatible bedding and accessories.

- Room Dimensions and Accessibility

The overall dimensions of the metal frame, including any protruding components, must be compatible with the available space in the bedroom. Overly large frames can impede movement and create accessibility issues. Real-world examples involve instances where oversized bed frames have obstructed doorways or limited access to closets and other furniture. Careful consideration of room dimensions and frame size is therefore essential to ensure comfortable and functional bedroom layout.

These interconnected facets of compatibility underscore the importance of careful planning and precise measurements when integrating a mattress with a metallic support structure. A comprehensive assessment of dimensional conformity, structural alignment, and functional harmony is crucial for maximizing comfort, durability, and safety. This integration ultimately impacts the user’s sleep quality and long-term satisfaction.

Frequently Asked Questions

The following addresses common inquiries regarding sleep surfaces supported by metallic frameworks. Clarification of these points is essential for informed decision-making.

Question 1: What are the primary advantages of a sleep surface supported by a metallic framework compared to other support systems?

Metallic support structures generally offer enhanced durability, improved load-bearing capacity, and resistance to pest infestations. They also tend to be more cost-effective than traditional wooden frames.

Question 2: Can any sleep surface be used with a metallic support structure?

While most sleep surfaces are compatible, it is essential to consider the frame’s slat spacing and support system in relation to the mattress type. Memory foam mattresses, for example, require a solid or closely spaced support to prevent sagging.

Question 3: How is the stability of a metallic support structure assessed?

Stability can be evaluated by examining the gauge of the metal, the quality of the welds, and the presence of center support beams. A robust frame will exhibit minimal wobbling or creaking under load.

Question 4: What are the key factors to consider when selecting a metallic support structure for a larger-sized sleep surface (Queen, King)?

For larger sizes, it is crucial to ensure that the frame includes a center support beam and additional legs to prevent bowing and ensure even weight distribution. The weight capacity of the frame should also be considered.

Question 5: How can corrosion be prevented in metallic support structures?

Corrosion can be minimized by selecting frames made from rust-resistant materials, such as aluminum or powder-coated steel. Regular cleaning and maintenance can also help to prevent rust formation.

Question 6: What are the implications of incorrect assembly of a metallic support structure?

Incorrect assembly can compromise the frame’s stability and load-bearing capacity, increasing the risk of structural failure and potential injury. It is essential to follow the manufacturer’s instructions carefully.

Careful consideration of these factors ensures the selection of a robust and reliable sleep system.

The next segment will delve into specific product recommendations and advanced considerations.

Conclusion

This exploration has detailed the multifaceted considerations surrounding the selection and utilization of a mattress with metal frame. From durability and support to compatibility and assembly, each aspect directly influences the overall performance and longevity of the sleep system. Material selection, frame design, and adherence to standardized sizing conventions are paramount for ensuring optimal comfort, stability, and safety. The presented insights underscore the importance of informed decision-making when integrating a mattress with a metallic support structure.

Ultimately, a thorough understanding of the factors discussed herein will empower consumers to choose a bed frame that not only meets their individual needs but also provides a secure and supportive foundation for restful sleep. Continued research and development in materials science and structural engineering hold the potential for further enhancements in the design and functionality of these systems, contributing to improved sleep quality and overall well-being.

![Best Adjustable Bed Frame Mattress Firm [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Adjustable Bed Frame Mattress Firm [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3170-300x200.jpg)

![Best Twin Mattress & Bed Frame [Guide + Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Twin Mattress & Bed Frame [Guide + Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3169-300x200.jpg)

![Best Frame Mattress [Guide] The Right Mattress Frame Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Frame Mattress [Guide] The Right Mattress Frame | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3168-300x200.jpg)

![Best Foldable Mattress Frame [Space Saver!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Foldable Mattress Frame [Space Saver!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3167-300x200.jpg)

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)