A sleep system engineered for enhanced support and comfort typically includes a viscoelastic foam sleeping surface combined with a structural foundation. This pairing aims to distribute weight evenly, alleviate pressure points, and promote proper spinal alignment during rest. The foundation provides essential support, ensuring the longevity and performance of the conforming surface above.

Such configurations offer potential advantages, including reduced motion transfer, which can lead to less sleep disturbance for partners. The conforming nature of the upper layer can provide customized comfort, while a stable base contributes to overall durability and prevents sagging. Originally developed for aerospace applications, the conforming material has found widespread use in sleep products due to its pressure-relieving qualities and ability to contour to the body.

The following sections will delve into specific considerations for selecting a compatible sleep surface and base, examining factors such as material composition, construction techniques, and intended use, to facilitate an informed decision regarding optimal sleep support and comfort.

Selecting a Viscoelastic Foam Sleep Surface and Support Structure

The selection process for a viscoelastic foam sleep surface and its corresponding support structure requires careful consideration of various factors to optimize comfort and ensure product longevity. The following tips offer guidance for navigating this decision.

Tip 1: Assess Individual Sleep Needs: Determine individual sleep preferences, including preferred sleep position (side, back, stomach) and any specific pressure point sensitivities. This assessment informs the selection of foam density and firmness level.

Tip 2: Evaluate Foam Density: Higher density foam typically offers greater support and durability, while lower density foam provides a softer feel. Consider the trade-offs between comfort and long-term performance based on individual needs and budget.

Tip 3: Consider Layer Construction: Examine the layering within the sleep surface. Multiple layers with varying densities can provide a more nuanced balance of support and comfort compared to a single layer.

Tip 4: Research Support Structure Options: Explore available support structures, including platform bases, slatted foundations, and adjustable frames. The chosen structure must provide adequate support and ventilation to prevent sagging and maintain the integrity of the foam.

Tip 5: Verify Compatibility: Ensure the chosen sleep surface is compatible with the selected support structure. Incompatible combinations can lead to premature wear and compromise overall support.

Tip 6: Evaluate Airflow and Temperature Regulation: Viscoelastic foam can retain heat. Look for features that promote airflow, such as open-cell foam construction or gel-infused layers, to mitigate heat buildup and enhance sleep comfort.

Tip 7: Check Warranty and Return Policies: Review the manufacturer’s warranty and return policies to protect against potential defects and ensure satisfaction with the product.

These guidelines offer a framework for making an informed decision regarding the selection of a viscoelastic foam sleep surface and its corresponding support structure. A thoughtful approach can contribute to improved sleep quality and long-term product satisfaction.

The subsequent sections will address specific aspects of maintenance and care to further optimize the lifespan and performance of the selected sleep system.

1. Support and Stability

The structural integrity of a sleep system, encompassing both the sleeping surface and its foundational support, is paramount for optimal sleep quality and longevity. The interaction between the viscoelastic foam layer and the frame is critical in ensuring consistent support and minimizing premature degradation.

- Frame Material and Construction

The material composition and design of the frame directly impact its capacity to withstand the weight and pressure exerted by the viscoelastic foam and occupants. Robust materials, such as steel or reinforced wood, coupled with appropriate construction techniques (e.g., welded joints, adequately spaced slats), are essential for preventing sagging or deformation over time. Inadequate frame support can lead to uneven weight distribution, compromising the pressure-relieving properties of the foam.

- Slat Spacing and Support

For slatted frames, the spacing between individual slats significantly influences the level of support provided. Excessive spacing can allow the viscoelastic foam to sink or compress between the slats, creating uneven support and potentially damaging the foam structure. Closely spaced slats or the addition of a solid platform can mitigate this issue and ensure uniform support across the entire surface.

- Edge Support Reinforcement

Edge support is crucial for facilitating ease of entry and exit from the sleep surface and preventing edge collapse. Frames with reinforced edge support, often achieved through the use of perimeter rails or additional bracing, provide enhanced stability and prevent the edges of the viscoelastic foam from compressing excessively, particularly for individuals who frequently sleep near the edge of the sleeping surface.

- Load Distribution Capacity

The frame’s ability to distribute weight evenly across its structure is critical for preventing concentrated stress points. Frames designed with integrated support systems or a network of interconnected supports are better equipped to handle varying weight distributions and minimize the risk of localized sagging or deformation. Adequate load distribution capacity contributes to the overall lifespan and consistent performance of the viscoelastic foam sleeping surface.

The interplay between frame design, material selection, and load distribution capacity collectively determines the level of support and stability provided to the viscoelastic foam. A robust and well-engineered frame ensures the sleeping surface functions optimally, providing consistent comfort and minimizing the risk of premature wear, thereby extending the overall lifespan of the complete sleep system.

2. Conforming Comfort

The term “conforming comfort,” when associated with a viscoelastic foam sleeping surface and frame, describes the capacity of the sleep system to adapt dynamically to the unique contours of an individual’s body. This adaptation aims to distribute weight evenly, thereby minimizing localized pressure points. For instance, a side sleeper often experiences concentrated pressure on the shoulders and hips. A viscoelastic foam layer, coupled with a properly supportive frame, should mold to these areas, effectively spreading the load and reducing discomfort. The efficacy of this conforming action is intrinsically linked to the foam’s density, thickness, and responsiveness, as well as the underlying frame’s ability to maintain structural integrity and prevent sagging. Without a stable and supportive frame, the conforming properties of the viscoelastic foam may be compromised, leading to uneven weight distribution and diminished comfort.

The practical significance of conforming comfort extends beyond mere subjective satisfaction. It is directly correlated with improved sleep quality and reduced musculoskeletal strain. Individuals with conditions such as arthritis or fibromyalgia may find significant relief from pressure-induced pain through the use of a sleep system designed to contour precisely to their body shape. Conversely, a poorly designed or unsupported viscoelastic foam surface can exacerbate these conditions, leading to increased discomfort and disrupted sleep patterns. The frame’s role in providing uniform support is therefore critical in allowing the foam to perform its intended function. For example, a slatted frame with excessive spacing may create “hot spots” of pressure where the foam sags between the slats, negating the benefits of its conforming properties.

In summary, conforming comfort is not merely a marketing term but a quantifiable attribute directly impacting sleep quality and physical well-being. It is contingent upon the synergistic interaction between the viscoelastic foam layer and the underlying support frame. Challenges remain in objectively measuring and quantifying conforming comfort, as individual preferences and body types vary considerably. However, understanding the principles of weight distribution, material properties, and structural support is essential for selecting a sleep system that effectively delivers the intended benefits of conforming comfort.

3. Durability Assessment

Evaluating the expected lifespan and resistance to degradation of a viscoelastic foam sleep surface and its foundation is critical for maximizing investment and ensuring sustained comfort. Durability assessment encompasses various factors influencing the long-term performance and structural integrity of both components.

- Foam Density and Resilience

The density of the viscoelastic foam core directly correlates with its durability. Higher density foams generally exhibit greater resistance to compression and deformation over extended periods. Resilience, the foam’s ability to recover its original shape after compression, is also a key indicator of longevity. Low-resilience foams may exhibit permanent indentations or sagging, compromising support and comfort. For example, a high-density viscoelastic foam mattress with a high resilience rating is likely to withstand years of use without significant loss of support, whereas a lower density, lower resilience foam may degrade more rapidly.

- Frame Material and Construction Quality

The materials used in the frame’s construction and the quality of assembly significantly impact its ability to withstand the weight and stresses imposed by the viscoelastic foam and occupants. Solid wood or reinforced steel frames are typically more durable than those constructed from particleboard or thin metal tubing. Reinforced joints, properly spaced slats, and robust center support are critical design features that enhance the frame’s ability to maintain structural integrity over time. A well-constructed frame will prevent sagging or warping, which can compromise the support provided to the viscoelastic foam and accelerate its degradation.

- Fabric Cover and Stitching Integrity

The quality of the fabric cover and the integrity of the stitching are often overlooked aspects of durability assessment. A durable fabric cover, resistant to abrasion and tearing, protects the viscoelastic foam from dirt, moisture, and physical damage. Reinforced seams and high-quality stitching prevent the cover from separating or fraying, maintaining the structural integrity of the mattress. For example, a tightly woven, stain-resistant fabric cover with double-stitched seams will significantly extend the lifespan of the mattress compared to a thinner, less durable cover with weaker stitching.

- Weight Capacity and Load Distribution

Exceeding the recommended weight capacity of either the viscoelastic foam or the frame can significantly reduce its lifespan. Overloading the system can lead to premature compression of the foam, warping of the frame, and ultimately, a loss of support and comfort. Proper load distribution is also critical. Concentrated weight in specific areas can create stress points, accelerating wear and tear. Frames with evenly spaced slats and a robust center support system are better equipped to distribute weight effectively, minimizing the risk of localized damage.

In conclusion, durability assessment is a multifaceted process requiring careful consideration of foam density, frame materials, construction quality, fabric integrity, and weight capacity. A thorough evaluation of these factors is essential for selecting a viscoelastic foam sleep surface and frame that will provide sustained comfort and support for an extended period.

4. Compatibility Considerations

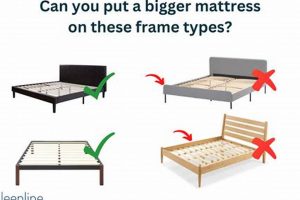

The successful integration of a viscoelastic foam sleeping surface and its supporting structure is predicated on adherence to compatibility considerations. These considerations encompass the alignment of material properties, structural design, and intended usage, preventing premature degradation, optimizing comfort, and ensuring long-term performance. Neglecting compatibility can result in a cascade of adverse effects, including compromised support, accelerated wear, and reduced lifespan of the entire sleep system. For example, placing a thick, high-density viscoelastic foam mattress on a frame with widely spaced slats can cause the foam to sag prematurely between the supports, negating its pressure-relieving properties and creating uneven sleeping surface. Such an issue is because viscoelastic foam, particularly in high densities, requires a stable, continuous support base to maintain its shape and functionality.

Another critical aspect of compatibility lies in the dimensional alignment between the sleeping surface and the frame. A frame that is significantly smaller than the mattress will lead to overhang and unsupported edges, increasing the risk of edge collapse and discomfort. Conversely, a frame that is excessively large may allow the mattress to shift or slide, creating instability and potential safety hazards. Moreover, certain frame designs may be incompatible with adjustable bed bases, which are increasingly popular for their therapeutic benefits. For instance, a traditional box spring foundation is typically not suitable for use with an adjustable base, as it lacks the flexibility to conform to the base’s articulating sections. Instead, a platform frame or a specifically designed adjustable base foundation is required to ensure proper functionality and prevent damage. Therefore, understanding the intended use of the sleep system, including the potential for future integration with adjustable components, is essential for making informed compatibility decisions.

In summary, compatibility considerations are not merely ancillary details but fundamental prerequisites for optimizing the performance and longevity of a viscoelastic foam sleeping surface and its frame. They involve careful attention to material properties, dimensional alignment, intended usage, and potential integration with adjustable components. Failure to address these considerations can lead to compromised support, accelerated wear, and reduced overall satisfaction. A comprehensive understanding of these factors is essential for ensuring that the selected sleep system provides consistent comfort, adequate support, and lasting value.

5. Thermal Regulation

Thermal regulation within a sleep system comprised of a viscoelastic foam sleeping surface and support structure constitutes a crucial factor influencing sleep comfort and overall physiological well-being. Viscoelastic foam, by its inherent properties, possesses a tendency to retain heat, potentially leading to elevated surface temperatures and discomfort. Addressing thermal regulation is therefore paramount in mitigating these effects and creating a more conducive sleep environment.

- Foam Density and Airflow

The density of viscoelastic foam plays a significant role in its thermal properties. Higher density foams, while offering enhanced support and durability, tend to exhibit reduced airflow, thereby exacerbating heat retention. Open-cell foam structures, characterized by interconnected air pockets, facilitate improved ventilation and heat dissipation compared to closed-cell counterparts. The integration of channels or perforations within the foam core can further enhance airflow, promoting a cooler sleep surface. A dense foam mattress on a solid platform will retain more heat than a similar mattress supported by a slatted frame that allows for air circulation.

- Material Composition and Phase Change Materials

The incorporation of specific materials can significantly influence the thermal behavior of the sleep surface. Gel-infused viscoelastic foam, for example, is designed to absorb and dissipate heat, creating a cooler sleeping environment. Phase change materials (PCMs), capable of absorbing or releasing heat as they transition between solid and liquid states, can be incorporated into the foam or cover fabric to regulate temperature fluctuations. These materials buffer temperature extremes, maintaining a more consistent and comfortable sleep surface temperature. For instance, a PCM-treated cover can help to wick away heat from the body during warmer periods, enhancing sleep comfort.

- Support Structure Ventilation

The design of the support structure directly impacts the overall thermal regulation of the sleep system. Solid platforms, while providing uniform support, can impede airflow beneath the sleeping surface, contributing to heat buildup. Slatted frames, with their inherent spacing, allow for greater ventilation, facilitating heat dissipation and reducing the potential for overheating. The material composition of the frame also plays a role, with metal frames typically conducting heat more readily than wooden frames. Therefore, selecting a support structure that promotes airflow is crucial for optimizing thermal regulation, especially when paired with a viscoelastic foam sleeping surface.

- Cover Fabric and Moisture Wicking

The cover fabric encasing the viscoelastic foam significantly influences moisture management and thermal regulation. Breathable fabrics, such as cotton, bamboo, or specialized performance knits, facilitate airflow and allow moisture to evaporate, preventing the accumulation of sweat and reducing the sensation of dampness. Moisture-wicking fabrics actively draw moisture away from the body, promoting a cooler and drier sleep environment. The use of these fabrics can effectively mitigate the heat-retaining properties of viscoelastic foam, enhancing overall sleep comfort. A cover made of a synthetic, non-breathable material can trap heat and moisture, leading to discomfort.

Addressing thermal regulation in viscoelastic foam sleep systems requires a holistic approach, encompassing foam density, material composition, support structure ventilation, and cover fabric selection. By carefully considering these factors, it becomes possible to create a sleep environment that promotes optimal temperature regulation, enhancing sleep comfort and overall well-being. Proper thermal regulation extends the life span of your mattress by reducing internal moisture.

Frequently Asked Questions Regarding Viscoelastic Foam Sleep Surfaces and Support Structures

The following provides answers to common inquiries concerning viscoelastic foam sleeping surfaces and their corresponding support structures. These responses aim to clarify prevalent misconceptions and provide objective information.

Question 1: What is the expected lifespan of a viscoelastic foam sleeping surface?

The longevity of such a sleep surface is contingent upon factors including foam density, usage patterns, and maintenance practices. High-density foam, under typical use conditions, can maintain its supportive properties for approximately seven to ten years. Regular rotation and the utilization of a protective mattress cover can extend this lifespan.

Question 2: What type of support structure is most suitable for a viscoelastic foam sleeping surface?

Optimal support is generally achieved through the use of a platform bed frame or a slatted foundation with closely spaced slats (typically no more than three inches apart). These structures provide a stable and uniform base, preventing sagging and ensuring proper weight distribution. A traditional box spring is generally not recommended, as it may not provide adequate support.

Question 3: How does viscoelastic foam respond to temperature fluctuations?

Viscoelastic foam is temperature-sensitive, exhibiting increased firmness in colder environments and increased pliability in warmer environments. This characteristic may influence the perceived comfort level. Some manufacturers incorporate gel infusions or open-cell foam structures to mitigate temperature-related variations.

Question 4: Is viscoelastic foam suitable for individuals with allergies?

Viscoelastic foam, by its inherent density, is generally resistant to dust mites and other allergens. However, individuals with sensitivities should consider hypoallergenic mattress covers and ensure proper ventilation to minimize potential allergen accumulation.

Question 5: What is the recommended weight capacity for a viscoelastic foam sleeping surface and its frame?

The weight capacity varies depending on the construction and materials used. It is imperative to consult the manufacturer’s specifications to ensure that the combined weight of the occupants does not exceed the recommended limit. Exceeding the weight capacity can compromise the structural integrity and reduce the lifespan of the sleep system.

Question 6: How should a viscoelastic foam sleeping surface be cleaned and maintained?

Regular vacuuming is recommended to remove dust and debris. Spot cleaning with a mild detergent and water is suitable for addressing spills or stains. Avoid the use of harsh chemicals or excessive moisture, as these can damage the foam. A waterproof mattress protector can provide additional protection against stains and spills.

Adherence to these guidelines can optimize the performance and longevity of a viscoelastic foam sleep surface and its corresponding support structure.

The subsequent section will address advanced topics related to viscoelastic foam technology and emerging trends in the sleep industry.

Concluding Assessment

This exploration has provided a comprehensive overview of the viscoelastic foam sleeping surface and supporting structure, highlighting critical factors related to material properties, structural integrity, thermal regulation, and compatibility considerations. Careful evaluation of these aspects is essential for selecting a sleep system that delivers sustained comfort, adequate support, and long-term value. The interaction between the conforming properties of the foam and the stability of the frame is paramount for optimizing sleep quality and minimizing potential drawbacks.

The information presented underscores the importance of informed decision-making in the purchase and maintenance of a memory foam mattress and frame. A thoughtful approach, encompassing a thorough understanding of individual needs and product specifications, can contribute to improved sleep outcomes and enhanced overall well-being. Continued research and innovation in sleep technology will likely yield further advancements in materials and designs, offering even greater potential for personalized comfort and support.

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)

![Best Extra Long Twin Mattress Frame [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Extra Long Twin Mattress Frame [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3164-300x200.jpg)

![Best Bed Frame for Tempurpedic Mattress [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Bed Frame for Tempurpedic Mattress [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3163-300x200.jpg)

![Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3162-300x200.jpg)