A support structure designed specifically to accommodate mattresses constructed with visco-elastic foam. These frames provide a stable and even surface, essential for maximizing the comfort and lifespan of the specialty mattress. Consider a platform bed with closely spaced wooden slats as an example; this configuration is often chosen to prevent sagging and ensure proper ventilation beneath the foam.

The use of an appropriate foundation is crucial for several reasons. It contributes significantly to the pressure relief properties that the visco-elastic material provides. A well-designed support can also improve the mattress’s durability, preventing premature wear and tear. Historically, simpler box springs were common, but the unique characteristics of this type of mattress have led to the development of more specialized support systems.

The subsequent sections will delve into the various types of supports available, the key factors to consider when selecting one, and the advantages of using a frame tailored to mattresses of this construction. Proper selection and maintenance are vital for long-term comfort and support.

Tips for Selecting a Compatible Support Structure

Choosing the correct foundation is paramount for optimal performance and longevity. These tips provide guidance for making an informed decision.

Tip 1: Ensure Adequate Support. A solid or closely-spaced slatted foundation is preferred. Gaps exceeding a few inches can lead to uneven compression and potential sagging.

Tip 2: Consider Ventilation. While providing support, the frame should also allow for air circulation. This helps to dissipate heat and prevent moisture build-up within the visco-elastic material.

Tip 3: Check Weight Capacity. Verify that the chosen frame can adequately support the combined weight of the mattress and its occupants. Exceeding the stated capacity can compromise structural integrity and void warranties.

Tip 4: Prioritize Frame Material. Steel or hardwood frames generally offer superior durability and stability compared to less robust materials. Consider the long-term investment when evaluating options.

Tip 5: Assess Noise Reduction. Opt for a frame designed to minimize noise. Squeaking or creaking can disrupt sleep. Look for features like rubber bushings or tightly fitted joints.

Tip 6: Evaluate Height Considerations. Select a frame height that aligns with personal preferences and accessibility needs. Low-profile options may be suitable for minimalist aesthetics, while taller frames facilitate easier entry and exit.

Tip 7: Review Warranty Information. Carefully examine the warranty provided by both the mattress and frame manufacturers. Confirm compatibility to avoid potential coverage issues.

Selecting the right support structure directly impacts the comfort and lifespan of the visco-elastic mattress, protecting the investment and ensuring restful sleep.

The subsequent sections will address common issues, troubleshooting steps, and maintenance practices to further optimize the sleep experience.

1. Support

Adequate support is a fundamental characteristic of a suitable frame. Visco-elastic foam mattresses, by design, conform to the sleeper’s body, distributing weight and alleviating pressure points. However, this inherent characteristic necessitates a stable and even foundation. Insufficient support, such as that provided by widely spaced slats or a sagging box spring, can compromise the foam’s ability to properly distribute weight. This can lead to localized pressure buildup, accelerated wear in specific areas, and ultimately, a reduction in the mattress’s overall lifespan. For example, if a frame lacks central support, the middle of the mattress will sag, potentially causing discomfort and spinal misalignment for the sleeper.

The type of support significantly influences the sleeper’s experience. A solid platform provides the most uniform weight distribution, while closely-spaced slats offer a balance between support and ventilation. In contrast, traditional box springs, often lacking in rigidity, may not provide the necessary level of support for visco-elastic foam, leading to premature wear. Furthermore, the frame’s construction material impacts its ability to maintain consistent support over time. Steel frames, for instance, generally offer greater durability and resistance to deformation compared to wooden frames, ensuring consistent support throughout the mattress’s lifespan. Therefore, the structural integrity and design of the frame are critical to ensuring the mattress performs as intended.

In summary, a suitable frame provides the necessary support for visco-elastic foam, ensuring proper weight distribution, extending the mattress’s lifespan, and maximizing sleep comfort. The selection of a frame that does not adequately provide such support can lead to compromised performance, premature wear, and a reduction in the overall benefits of the visco-elastic mattress. Prioritizing support during frame selection is essential for ensuring long-term sleep satisfaction and mattress longevity.

2. Ventilation

The construction of visco-elastic foam inherently restricts airflow, a factor which directly impacts temperature regulation and moisture management within the mattress. An appropriate support structure addresses this limitation through adequate ventilation. Without sufficient airflow, heat generated by the sleeper becomes trapped within the mattress, leading to discomfort and potential sleep disruption. Furthermore, moisture from perspiration accumulates, creating a breeding ground for mold and bacteria, potentially degrading the foam and reducing its lifespan. The frame’s design, therefore, plays a crucial role in mitigating these issues.

Frames featuring slatted designs, or open metal grids, allow for enhanced airflow beneath the mattress. This promotes the dissipation of heat and the evaporation of moisture, contributing to a cooler and more hygienic sleep environment. Conversely, solid platform beds, while offering excellent support, can impede airflow unless specifically designed with ventilation channels or breathable materials. Consider the example of a slatted frame constructed from untreated wood; the natural porosity of the wood further enhances ventilation compared to a frame constructed from solid, non-porous materials. Moreover, the spacing between the slats significantly impacts airflow; wider gaps provide greater ventilation, although a balance must be struck to maintain adequate support. The choice of frame material and design, therefore, necessitates careful consideration of ventilation characteristics.

In conclusion, the frame serves as an integral component in managing the inherent ventilation limitations of visco-elastic foam mattresses. Proper ventilation prevents heat buildup, reduces moisture accumulation, and contributes to a more comfortable and hygienic sleep surface. Failure to address ventilation can compromise sleep quality, accelerate mattress degradation, and potentially pose health risks. Therefore, selecting a frame that prioritizes airflow is essential for maximizing the long-term benefits and lifespan of the foam mattress, this is particularly essential in hot, humid environments.

3. Durability

The lifespan of a visco-elastic foam mattress is intrinsically linked to the durability of its support structure. A substandard support will undermine the inherent longevity of the mattress, leading to premature wear and a diminished return on investment. The frame, if constructed from inadequate materials or lacking in structural integrity, will inevitably compromise its ability to uniformly support the mattress over time. This manifests as sagging, uneven compression, and ultimately, a reduction in the mattress’s comfort and support characteristics. For example, a lightweight metal frame with poorly welded joints may buckle under the combined weight of the mattress and occupants, creating depressions and pressure points that accelerate foam degradation.

Consider a scenario involving a high-density visco-elastic foam mattress placed on a frame constructed from particleboard with widely spaced slats. The particleboard, susceptible to moisture and lacking in inherent strength, may warp over time, causing the slats to sag. This, in turn, concentrates pressure on specific areas of the mattress, leading to localized compression and a noticeable reduction in support. Conversely, a frame constructed from kiln-dried hardwood or heavy-gauge steel, engineered with closely spaced slats or a solid platform, will provide consistent and reliable support, distributing weight evenly and minimizing stress on the foam. Such a durable frame not only extends the mattress’s lifespan but also preserves its original comfort and support qualities for an extended period.

In summary, the durability of the chosen support structure directly influences the long-term performance and lifespan of the visco-elastic foam mattress. Prioritizing a robust and well-engineered frame is paramount to safeguarding the mattress investment and ensuring consistent, comfortable sleep for years to come. Selecting a frame based solely on cost considerations, without regard for its structural integrity and material quality, often results in premature frame failure and a consequential reduction in the mattress’s usable life. Therefore, frame durability should be a primary factor in the decision-making process.

4. Size

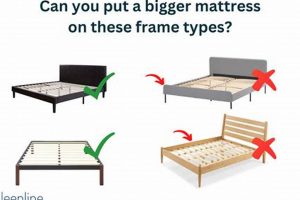

The dimensions of a support structure are inextricably linked to the performance and suitability of a memory foam mattress. The foundation must precisely match the mattress’s specified length and width. Deviations from these measurements compromise support and potentially void warranty coverage. For instance, if a queen-size memory foam mattress is placed upon a full-size frame, a significant portion of the mattress will lack support, leading to uneven weight distribution and accelerated wear along the unsupported edges. Conversely, a frame that is excessively large relative to the mattress will allow the mattress to shift, creating instability and potentially damaging the mattress over time through friction and deformation. A mismatch in dimensions leads to a compromised sleep surface and reduced mattress lifespan.

The height of the frame also presents a significant consideration. The combined height of the frame and mattress influences ease of entry and exit from the bed. A low-profile frame, coupled with a thick memory foam mattress, may result in a bed that is too low for comfortable access, particularly for individuals with mobility limitations. Conversely, an excessively tall frame, when combined with a thick mattress, may create a bed that is difficult to mount and dismount safely. This necessitates careful consideration of the overall bed height to ensure both comfort and safety. Additionally, the interior dimensions of the frame, specifically in platform bed designs, must precisely accommodate the mattress to prevent movement or slippage. Internal lips or retaining structures are often incorporated to maintain the mattress’s position on the frame.

In conclusion, the accurate sizing of the support structure is a critical determinant of a memory foam mattress’s performance, longevity, and the overall comfort and safety of the sleeping environment. A mismatched frame undermines support, accelerates wear, and poses potential safety hazards. Therefore, meticulous attention to dimensional compatibility is essential when selecting a frame, ensuring a stable, supportive, and comfortable sleep surface. Manufacturers’ specifications should be closely consulted to guarantee a proper fit and avoid potential warranty complications.

5. Material

The selection of materials for a memory foam mattress frame directly influences its durability, support capabilities, aesthetic appeal, and long-term environmental impact. The constituent materials dictate the frame’s capacity to withstand weight, resist wear, and maintain structural integrity over an extended period. The following outlines key facets related to material selection.

- Steel Construction

Steel frames, particularly those constructed from heavy-gauge steel, offer superior strength and resistance to deformation. This translates to consistent support for the memory foam mattress, preventing sagging and ensuring proper weight distribution. Steel is often powder-coated to resist rust and corrosion, further extending its lifespan. However, steel frames can be heavier than other options, potentially complicating assembly and relocation.

- Hardwood Frames

Hardwoods, such as oak, maple, or birch, provide a robust and aesthetically pleasing option for memory foam mattress frames. These materials offer significant strength and can be crafted into intricate designs. Kiln-dried hardwoods are preferred to minimize warping or cracking due to changes in humidity. The use of hardwoods often increases the cost compared to other materials, but the investment can be justified by the frame’s longevity and visual appeal.

- Engineered Wood Products

Engineered wood products, including plywood and MDF (Medium-Density Fiberboard), provide a cost-effective alternative to solid hardwoods. These materials are manufactured by bonding wood fibers together with adhesives, creating a stable and uniform product. High-quality engineered wood can offer sufficient support for memory foam mattresses, provided that the frame design incorporates adequate reinforcement. However, lower-grade engineered wood products may be susceptible to moisture damage and may not provide the same level of durability as solid hardwoods or steel.

- Upholstery Fabrics and Foams

Many frames include upholstered elements. The type and quality of these materials directly impact both the aesthetic appeal and structural longevity of the frame. High-quality fabrics are designed to resist stains and wear. Similarly, flame-retardant foams add safety and durability. A poorly selected fabric may become loose and unsightly over time, while low-density foam can degrade.

The materials utilized in a memory foam mattress frame represent a critical consideration, influencing the frame’s performance, lifespan, and overall value. Selection should balance cost, durability, aesthetic preferences, and environmental concerns. The decision to prioritize steel, hardwood, or engineered wood products necessitates careful evaluation of the trade-offs associated with each material category, ensuring compatibility with the intended use and expected lifespan of the memory foam mattress.

6. Assembly

The assembly process of a memory foam mattress frame directly affects its structural integrity and long-term stability. An improperly assembled frame, irrespective of material quality, compromises the support provided to the mattress, leading to potential sagging, uneven weight distribution, and reduced mattress lifespan. The connection points, such as bolted connections or interlocking mechanisms, are critical to the frame’s overall strength. For example, if bolts are not tightened sufficiently during assembly, the frame may develop instability over time, resulting in creaking noises and compromised support. Conversely, over-tightening can damage the frame components, especially those constructed from engineered wood products, potentially leading to structural failure. Thus, adhering strictly to the manufacturer’s assembly instructions is paramount to ensure the frame performs as intended.

Consider the practical implications of a platform bed frame designed for a memory foam mattress. The assembly typically involves connecting the side rails to the headboard and footboard, followed by the installation of the internal support slats. If the slats are not evenly spaced or securely fastened, the mattress will not receive uniform support, leading to localized areas of compression. This is further exacerbated in larger-sized mattresses, such as king or queen, where the weight distribution is more complex. Moreover, frames with integrated storage compartments require additional assembly steps, often involving the attachment of drawer slides and hinges. Proper alignment and secure fastening of these components are crucial for smooth operation and long-term reliability. The assembly process therefore extends beyond simply connecting the primary frame components and encompasses the precise integration of all ancillary elements.

In summary, the assembly of a memory foam mattress frame is not merely a procedural step but an integral determinant of its structural integrity and overall performance. A meticulously assembled frame ensures proper support, maximizes mattress lifespan, and minimizes potential issues related to noise and instability. Challenges during assembly, such as missing hardware or unclear instructions, should be addressed promptly to avoid compromising the frame’s functionality. Furthermore, periodic inspection and maintenance of the assembled frame, including tightening bolts and inspecting connection points, are essential to preserve its structural integrity and ensure continued support for the mattress.

7. Warranty

The warranty associated with both the memory foam mattress and its supporting frame represents a critical element of consumer protection and an indicator of product quality. Understanding the terms, conditions, and potential interplay between the warranties of these two components is essential for ensuring long-term satisfaction and mitigating potential financial risk.

- Frame Requirements for Mattress Warranty

Many mattress warranties stipulate that the mattress must be used with a compatible frame to maintain coverage. This often includes specific requirements regarding the type of support (e.g., solid platform, closely spaced slats), the distance between slats (typically no more than a few inches), and the frame’s overall weight capacity. Failure to adhere to these requirements can void the mattress warranty, leaving the consumer responsible for repair or replacement costs in the event of a defect. For example, using a weak or sagging frame might lead to uneven wear on the mattress, which would then be excluded from warranty coverage.

- Frame Warranty Coverage

The frame itself typically carries its own warranty, covering defects in materials and workmanship. This warranty may extend to issues such as broken welds, cracked wood, or malfunctioning mechanisms (e.g., adjustable bed frames). The duration and scope of the frame warranty vary considerably between manufacturers. Some warranties offer limited coverage for a specific period, while others provide more comprehensive protection. Consumers should carefully review the frame warranty to understand what is covered and what limitations apply.

- Interdependence of Warranties

A crucial aspect to consider is the potential interdependence of the mattress and frame warranties. If a mattress defect arises that is deemed to be caused by a faulty frame, the mattress manufacturer may deny warranty coverage, citing improper support. Conversely, if a frame defect leads to damage to the mattress, the frame manufacturer may argue that the damage is consequential and therefore not covered under their warranty. This can create a situation where the consumer is caught in the middle, facing difficulty obtaining coverage from either party. Careful documentation of the frame and mattress specifications, along with any issues that arise, is essential for navigating such situations.

- Warranty Registration and Documentation

To ensure warranty protection, consumers should register both the mattress and the frame with the respective manufacturers, if required. Retaining copies of the purchase receipts, warranty documents, and any relevant correspondence is also crucial. This documentation serves as proof of purchase and provides a record of the warranty terms and conditions. In the event of a warranty claim, having this information readily available can expedite the process and increase the likelihood of a successful resolution.

The warranty landscape surrounding memory foam mattresses and their frames underscores the importance of selecting compatible products and carefully reviewing the warranty terms of both. A proactive approach to warranty registration, documentation, and adherence to frame requirements can safeguard the consumer’s investment and provide peace of mind in the event of a product defect or failure. Understanding the potential interdependence of these warranties is important to be able to navigate the possible claim issues.

Frequently Asked Questions

This section addresses common inquiries regarding support structures designed for memory foam mattresses, providing clarity on compatibility, maintenance, and optimal performance.

Question 1: Does a memory foam mattress require a specific type of frame?

Yes, while a memory foam mattress can technically rest on various surfaces, optimal performance and warranty compliance often necessitate a specific type of frame. Solid platforms or closely-spaced slatted frames are generally recommended to provide adequate support and prevent sagging.

Question 2: What is the ideal slat spacing for a frame supporting a memory foam mattress?

The ideal slat spacing typically ranges from 2 to 3 inches. Wider gaps can lead to uneven weight distribution and premature wear of the mattress. Consult the mattress manufacturer’s warranty information for specific slat spacing requirements.

Question 3: Can a memory foam mattress be used with a box spring?

Traditional box springs are often not recommended for memory foam mattresses. Their springy construction may not provide the firm, stable support required, potentially leading to mattress deformation and reduced lifespan. Furthermore, using a box spring may void the mattress warranty.

Question 4: How does frame material impact the performance of a memory foam mattress?

The frame material influences durability and support. Steel frames generally offer superior strength and longevity compared to wood or engineered wood frames. However, hardwood frames can provide adequate support and an aesthetically pleasing appearance.

Question 5: What is the appropriate height for a frame used with a memory foam mattress?

The appropriate height is subjective and depends on personal preferences and accessibility needs. However, the combined height of the frame and mattress should allow for comfortable entry and exit from the bed. Consider bed skirts if aesthetics are a concern.

Question 6: How does weight capacity factor into frame selection for a memory foam mattress?

The selected frame must be capable of supporting the combined weight of the mattress and its occupants. Exceeding the frame’s weight capacity can lead to structural damage, compromised support, and potential safety hazards. Consult the frame manufacturer’s specifications for weight capacity information.

Proper frame selection extends the lifespan and comfort of the memory foam mattress, which should be considered a crucial aspect when investing in sleep system. Understanding the compatibility and requirements will improve user experience.

The subsequent section offers guidance on troubleshooting common issues encountered with memory foam mattress frames, providing solutions for maintaining optimal performance and addressing potential problems.

In Conclusion

This exploration has illuminated the critical function of the support structure in maximizing the lifespan and performance of memory foam mattresses. A memory foam mattress frame is far more than a mere accessory; it is a foundational element influencing support, ventilation, and overall comfort. The frame’s materials, design, assembly, and warranty considerations each contribute significantly to the long-term value and satisfaction derived from the mattress itself. A failure to properly select and maintain the support structure can negate the benefits of the memory foam technology, leading to premature wear and a diminished sleep experience.

Therefore, diligent research, informed decision-making, and adherence to manufacturer guidelines are paramount. As advancements in sleep technology continue to evolve, the memory foam mattress frame will remain a crucial component in the pursuit of optimal rest. Its significance should not be underestimated, and continued attention to its features and compatibility will safeguard sleep quality for years to come.