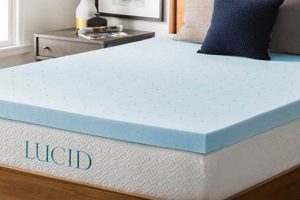

A conforming bed layer, often used to enhance the comfort of an existing mattress, typically composed of viscoelastic foam and measuring three inches in thickness. This product aims to improve sleep quality by distributing weight evenly and reducing pressure points. The defined thickness is a significant factor in determining the degree of support and cushioning provided.

The advantage of incorporating such an item into a sleep setup lies in its capacity to potentially alleviate discomfort associated with aging mattresses or those that are too firm. The material’s ability to contour to the body can result in reduced tossing and turning, leading to more restful sleep. Initially developed for NASA’s aircraft seats, this material has found widespread consumer application due to its pressure-relieving characteristics.

The ensuing sections will detail the various densities and construction methods available within this product category, along with considerations for selecting an appropriate model and maintaining its longevity. Focus will be given to factors impacting the user experience, such as heat retention and off-gassing, as well as the range of sizes and price points that are typically encountered.

Guidance on Optimization

The following guidelines are intended to assist in maximizing the potential benefits and longevity of the selected sleeping surface enhancement.

Tip 1: Evaluate Mattress Condition: Before implementation, assess the current mattress. This addition is most effective on surfaces that provide adequate support but lack desired comfort, not as a solution for significantly sagging or damaged mattresses.

Tip 2: Consider Density: Denser materials generally offer enhanced support and durability. Individual body weight and preferred firmness should guide density selection. Higher body weight may necessitate a denser option for optimal performance.

Tip 3: Address Off-Gassing: Allow adequate ventilation upon initial unboxing to mitigate potential odors from volatile organic compounds (VOCs) released during manufacturing. Airing the topper in a well-ventilated room for 24-48 hours is recommended.

Tip 4: Utilize Protective Coverings: Employ a mattress protector to safeguard against spills, stains, and dust mites, thereby extending the product’s lifespan and maintaining hygiene.

Tip 5: Rotate Periodically: Regular rotation, typically every 3-6 months, helps to distribute wear evenly and prevent impressions from forming in high-pressure areas.

Tip 6: Temperature Considerations: Understand this item tends to retain body heat. For those prone to overheating, explore options with cooling gel infusions or open-cell structures designed to improve airflow.

Tip 7: Proper Support: Ensure the mattress beneath provides stable, level support. An inadequate base can compromise the conforming layer’s effectiveness and potentially lead to premature wear.

By adhering to these recommendations, individuals can optimize the performance and prolong the usability, potentially enhancing sleep quality and overall satisfaction.

The subsequent sections will delve into product selection, maintenance protocols, and comparative analyses across various brands and models.

1. Conforming Capability

Conforming capability, in the context of viscoelastic mattress enhancements measuring three inches, refers to the degree to which the material adapts to the body’s contours. This adaptation is a direct consequence of the foam’s viscoelastic properties, which allow it to deform under pressure and slowly return to its original shape when the pressure is removed. The three-inch thickness plays a critical role, as it provides sufficient material to allow for significant conforming without sacrificing underlying support from the existing mattress. Inadequate conforming can lead to pressure points and discomfort, while excessive conforming may result in a feeling of being “swallowed” by the material.

The importance of this characteristic is exemplified by its impact on spinal alignment and pressure relief. A product with high conforming capability effectively distributes weight across a larger surface area, reducing pressure on bony prominences like the hips and shoulders. This can be particularly beneficial for individuals with arthritis or other joint pain. The practical significance of understanding conforming capability lies in the ability to select an item that aligns with individual sleep preferences and physical needs. For example, side sleepers often benefit from enhanced conforming to accommodate the curvature of the spine, whereas back sleepers may prefer a slightly firmer surface that provides greater spinal support.

In summary, conforming capability is a fundamental attribute of viscoelastic mattress layers of a specified thickness, influencing both comfort and physiological support. The optimal level of conformity depends on individual factors and preferences. Challenges may arise in accurately assessing this quality prior to purchase, highlighting the importance of reviewing product specifications and customer feedback to make an informed decision.

2. Pressure Redistribution

Pressure redistribution is a key function facilitated by a viscoelastic mattress overlay measuring three inches. This function is paramount in enhancing sleep comfort and mitigating potential musculoskeletal discomfort. The inherent properties of the foam material contribute to a more even distribution of body weight, thereby reducing concentrated pressure points.

- Contour Adaptation and Surface Area Maximization

The viscoelastic nature of the foam enables it to conform to the unique contours of the human body. This adaptation increases the surface area of contact between the body and the sleeping surface. By distributing weight over a larger area, the pressure exerted on specific points, such as the hips and shoulders, is significantly reduced. Individuals with joint pain or pressure-sensitive conditions may experience considerable relief.

- Reduction of Peak Pressure Zones

Without adequate pressure redistribution, certain areas of the body bear a disproportionate amount of weight during sleep. This can lead to localized discomfort and restricted blood flow. This item alleviates these peak pressure zones by cradling the body and preventing excessive compression of tissues and capillaries in vulnerable areas.

- Impact on Spinal Alignment

Proper pressure redistribution contributes to improved spinal alignment. By supporting the natural curves of the spine and preventing sagging or misalignment, muscle strain and nerve compression can be minimized. This is particularly beneficial for individuals with pre-existing back pain or those seeking to maintain optimal spinal health.

- Influence on Sleep Quality and Circulation

Effective pressure redistribution promotes uninterrupted sleep by minimizing the need for repositioning due to discomfort. Reduced pressure on blood vessels enhances circulation, preventing numbness or tingling sensations that can disrupt sleep patterns. The combined effect is an improved overall sleep experience characterized by greater comfort and reduced discomfort.

The facets of pressure redistribution provided by a three-inch viscoelastic mattress layer collectively contribute to a more supportive and comfortable sleep environment. These characteristics offer tangible benefits for individuals seeking to alleviate pressure-related discomfort and improve the quality of their sleep. The extent of pressure redistribution achieved is directly correlated to the density and quality of the foam material, underscoring the importance of selecting a product that aligns with individual needs and preferences.

3. Thickness Impact

Thickness directly influences the performance characteristics of a viscoelastic mattress overlay. The measurement of three inches represents a compromise between providing substantial contouring and avoiding excessive sinkage, impacting both support and comfort.

- Conforming Depth

A three-inch profile permits a significant degree of body contouring. This allows the material to adapt to individual body shapes, distributing weight and reducing pressure points. However, if the existing mattress lacks adequate support, this thickness alone may prove insufficient to prevent excessive sinking, particularly for individuals with higher body mass.

- Support Layer Integration

The overlay is not a standalone support structure; it integrates with the underlying mattress. A three-inch measurement provides a balance, offering noticeable comfort enhancement without completely negating the support characteristics of the existing mattress. The effectiveness relies on the condition and construction of the mattress beneath.

- Thermal Properties

Increased thickness contributes to greater heat retention. Viscoelastic materials are known for their tendency to trap body heat, and a three-inch profile exacerbates this effect compared to thinner alternatives. Individuals sensitive to temperature may need to consider models with cooling technologies, such as gel infusions or open-cell structures.

- Motion Isolation

This thickness provides a noticeable degree of motion isolation. The viscoelastic material absorbs movement, reducing the transfer of motion between sleep partners. While thinner options offer some motion isolation, the three-inch measurement enhances this characteristic, contributing to more undisturbed sleep.

The selection of a viscoelastic mattress enhancement with a three-inch measurement necessitates careful consideration of individual needs and preferences. The benefits of enhanced conforming and motion isolation must be weighed against potential drawbacks, such as increased heat retention and the dependence on the underlying mattress for adequate support. A comprehensive evaluation of these factors ensures that the chosen product aligns with specific requirements and contributes to an improved sleep experience.

4. Density Variations

Density variations in a three-inch viscoelastic mattress overlay profoundly affect its performance characteristics, influencing factors such as support, durability, and thermal properties. Understanding these variations is essential for selecting an appropriate product.

- Support and Firmness Levels

Higher density generally correlates with increased firmness and support. A denser foam will resist compression more effectively, providing greater resistance to sinkage. This is particularly relevant for individuals with higher body weights or those who prefer a firmer sleep surface. Conversely, lower density options offer a softer feel and greater conforming ability, but may lack adequate support for some users.

- Durability and Longevity

Density is a key determinant of the lifespan of a viscoelastic mattress layer. Denser foams tend to be more resilient and resistant to deformation over time. Over the long term, this translates to a product that retains its shape and support characteristics more effectively, minimizing the development of impressions or sagging. Lower density options may degrade more rapidly under consistent use.

- Thermal Properties and Airflow

Denser materials typically exhibit reduced airflow and greater heat retention. The tightly packed cell structure of high-density foam restricts ventilation, potentially leading to a warmer sleep environment. Lower density foams, with their more open-cell structure, generally promote better airflow and dissipation of heat. The density can be used for controlling thermal of this item.

- Responsiveness and Sinkage Rate

Density influences the responsiveness of the foam to pressure. Higher density options tend to exhibit slower response times, meaning they take longer to conform to the body’s shape and return to their original form. This can result in a feeling of being “stuck” in the foam. Lower density options respond more quickly to pressure changes, providing a more adaptable and buoyant feel.

In summary, the density of a three-inch viscoelastic mattress enhancement directly impacts the overall sleep experience. Selection requires careful consideration of individual preferences and physical needs, weighing the benefits of increased support and durability against potential drawbacks such as greater heat retention and reduced responsiveness. The ideal density is contingent upon factors such as body weight, sleep position, and sensitivity to temperature variations.

5. Heat Retention

Heat retention constitutes a significant consideration when evaluating a viscoelastic mattress overlay measuring three inches in thickness. The material’s inherent properties influence thermal regulation, impacting sleep comfort and potentially affecting sleep quality.

- Material Composition and Airflow Restriction

Viscoelastic foam, by its nature, possesses a dense cell structure that impedes airflow. This restricted airflow reduces the material’s capacity to dissipate heat effectively. Consequently, body heat generated during sleep can become trapped within the overlay, leading to an elevated sleeping surface temperature and potential discomfort. The denser the material, the more pronounced this effect becomes. In practice, this means that individuals who tend to sleep hot may experience increased sweating and restlessness when using a standard viscoelastic overlay.

- Thickness as a Contributing Factor

The three-inch thickness amplifies the effect of heat retention. A thicker overlay provides more material for heat to accumulate within, further hindering the dissipation of body heat. While a thinner viscoelastic layer may exhibit some degree of heat retention, the increased mass of a three-inch profile intensifies this characteristic. An example is a comparison to similar materials of different thicknesses, where the three-inch option consistently demonstrates higher temperature measurements in controlled settings.

- Mitigation Strategies: Gel Infusions and Open-Cell Structures

To address the issue of heat retention, manufacturers employ various strategies, including infusing the foam with cooling gel particles or utilizing open-cell structures. Gel infusions are intended to absorb and dissipate heat, creating a cooler sleeping surface. Open-cell structures, characterized by larger and more interconnected cells, promote airflow within the material, facilitating heat dissipation. These features aim to counteract the inherent heat-retentive properties of viscoelastic foam. The effectiveness of these strategies varies depending on the specific materials and construction methods employed.

- Impact on Sleep Quality and Comfort

Elevated sleeping surface temperatures can disrupt sleep patterns and diminish overall sleep quality. Discomfort caused by excessive heat may lead to increased tossing and turning, fragmented sleep, and reduced periods of deep sleep. Individuals who are particularly sensitive to temperature changes may find the heat-retentive properties of a three-inch viscoelastic mattress overlay detrimental to their sleep experience. In contrast, those who prefer a warmer sleeping environment may find this characteristic beneficial.

The interaction between heat retention and a three-inch viscoelastic mattress overlay necessitates careful consideration. While the material offers benefits in terms of pressure relief and conforming capability, its thermal properties may pose challenges for some individuals. The choice of a viscoelastic overlay should be informed by individual preferences and sensitivities to temperature, as well as a thorough understanding of mitigation strategies designed to enhance thermal regulation.

6. Longevity factors

The lifespan of a viscoelastic mattress enhancement, specifically one measuring three inches, is governed by several key factors that determine its long-term performance and value. Material quality, density, usage patterns, and maintenance practices collectively dictate how well it retains its shape, support, and comfort characteristics over time. Lower-grade materials are susceptible to quicker degradation, resulting in impressions and reduced support. High-density foams typically demonstrate superior resilience compared to lower-density counterparts, resisting deformation and maintaining their original form for extended periods. The intensity and frequency of use influence wear and tear. Continuous, heavy use accelerates material fatigue, whereas lighter, less frequent use extends the product’s lifespan. The adherence to recommended care protocols, such as regular rotation and the utilization of protective coverings, significantly impacts durability.

Neglecting proper maintenance accelerates the breakdown of the viscoelastic material, leading to premature failure. For example, consistent exposure to moisture or direct sunlight degrades the foam’s structure. Protective coverings shield against spills, stains, and dust mites, preserving the foam’s integrity. Rotating the topper periodically helps distribute wear evenly, preventing localized impressions and extending its usable life. Individuals considering purchasing such an item should evaluate the manufacturer’s specifications regarding material composition, density, and recommended maintenance practices. Warranties provide some assurance, but careful adherence to care instructions is essential to maximize product lifespan. Failure to follow these guidelines can result in a drastically shortened lifespan and compromised performance.

In conclusion, the longevity of a three-inch viscoelastic mattress overlay is not solely determined by the initial quality of materials. It depends on an ongoing commitment to proper care and maintenance. Understanding the interplay between material properties, usage patterns, and care protocols empowers consumers to make informed purchasing decisions and implement practices that maximize product lifespan, thereby ensuring a more sustainable and cost-effective investment in sleep comfort.

Frequently Asked Questions

The following addresses prevalent inquiries concerning viscoelastic mattress enhancements of a specified thickness. These responses aim to clarify common misconceptions and provide objective guidance.

Question 1: Is a viscoelastic mattress topper of this thickness suitable for all mattress types?

Suitability is contingent upon the condition of the existing mattress. This item is most effective when paired with a supportive, structurally sound mattress. It will not remedy significant sagging or inadequate support.

Question 2: How frequently should a conforming foam sleeping surface addition be replaced?

Replacement frequency varies depending on material quality, usage, and care. Signs of degradation, such as permanent impressions or reduced support, indicate the need for replacement. Typically, a high-quality product can last for 3-5 years with proper maintenance.

Question 3: Do these items retain heat?

Viscoelastic materials are known for heat retention. Opting for models with cooling gel infusions or open-cell structures can mitigate this issue. Proper ventilation of the sleeping area is also recommended.

Question 4: What is the recommended density for optimal support?

The ideal density depends on individual body weight and preferred firmness. Higher body weights typically require denser materials for adequate support. Lighter individuals may prefer lower-density options for enhanced conforming.

Question 5: Can a product of this type alleviate back pain?

While a viscoelastic sleeping surface addition can improve spinal alignment and reduce pressure points, it is not a substitute for medical treatment. It may alleviate some types of back pain, but consulting with a healthcare professional is advised for persistent or severe pain.

Question 6: How should a sleeping surface layer of conforming foam be cleaned?

Spot cleaning with a mild detergent and water is recommended. Avoid harsh chemicals or excessive moisture. Air drying is essential to prevent mold or mildew growth. The use of a mattress protector can minimize the need for cleaning.

The information provided aims to address common concerns regarding viscoelastic mattress additions of a specified thickness. Careful consideration of individual needs and preferences is crucial in selecting an appropriate product.

The subsequent sections will explore comparative analyses across various brands and models.

Concluding Remarks

This exposition has examined the characteristics, benefits, and potential drawbacks of a memory foam mattress topper 3 inch. The discussion encompassed conforming capability, pressure redistribution, density variations, heat retention, and longevity factors. The analysis underscores the importance of careful consideration of individual needs and preferences when selecting such an item. Further, proper maintenance practices are crucial in maximizing product lifespan and ensuring continued performance.

The decision to incorporate a memory foam mattress topper 3 inch into a sleep system represents a trade-off between enhanced comfort and potential challenges, such as heat retention. Informed consumers are encouraged to weigh these factors carefully and to prioritize products that align with their specific requirements and sensitivities. Ongoing research and development in material science may yield advancements that further mitigate the existing limitations and enhance the overall effectiveness of these sleep surface enhancements.

![Best 8-Inch Mattress [Guide] - Comfort & Support! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best 8-Inch Mattress [Guide] - Comfort & Support! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3770-300x200.jpg)