The selection of a sleep surface often involves choosing between different core technologies. Two prominent types involve the utilization of visco-elastic foam or a network of metallic coils. Each approach offers distinct characteristics influencing comfort, support, and durability. The core differentiation lies in the materials and construction methods employed.

The significance of this choice extends beyond mere personal preference, impacting spinal alignment, pressure point relief, and overall sleep quality. Historically, coil-based designs dominated the market, but advancements in material science have propelled foam-based options to the forefront, offering alternative advantages. Understanding these differing qualities allows for a more informed purchasing decision.

The subsequent sections will delve into the specific attributes of each construction, examining factors such as motion isolation, temperature regulation, lifespan, and cost. A comparative analysis of these critical elements will enable a comprehensive understanding, facilitating a more personalized and optimized sleep experience.

Guidance on Optimal Sleep Surface Selection

The following recommendations are designed to assist in making an informed decision regarding sleep surface selection, taking into account individual needs and preferences.

Tip 1: Assess Individual Sleep Style: Side, back, and stomach sleepers require varying degrees of support. Side sleepers may benefit from enhanced pressure relief, while back sleepers often need firmer support to maintain spinal alignment. Determining dominant sleep position is a crucial first step.

Tip 2: Consider Body Weight and Type: Individuals with higher body weight often require a more robust support system to prevent excessive sagging and maintain proper posture. Conversely, lighter individuals may find softer surfaces more comfortable.

Tip 3: Evaluate Motion Isolation Needs: If sharing the sleep surface with a partner, motion isolation becomes a significant consideration. Foam-based options generally excel in minimizing motion transfer, while innerspring designs can sometimes transmit movement more readily.

Tip 4: Inquire About Temperature Regulation: Certain materials retain heat more than others. Individuals prone to overheating during sleep should explore options with enhanced breathability and cooling technologies, such as gel-infused foams or open-coil innerspring constructions.

Tip 5: Review Warranty and Trial Periods: Reputable manufacturers offer warranties and trial periods. Thoroughly examine these terms to ensure adequate protection against defects and the opportunity to assess the sleep surface’s suitability within a home environment.

Tip 6: Research Material Certifications: Look for certifications such as CertiPUR-US, which ensures that foam materials meet specific standards for content, emissions, and durability, providing assurance regarding product safety and environmental impact.

Tip 7: Compare Construction and Materials: The quality of components used significantly impacts performance and longevity. Research the types of coils, foam densities, and cover fabrics employed, paying attention to their respective properties and potential advantages.

Selecting the appropriate sleep surface involves a careful evaluation of individual requirements and a thorough understanding of the characteristics of different construction methods and materials. A well-informed decision contributes to enhanced sleep quality and overall well-being.

The final segment will provide concluding thoughts, summarizing key considerations and offering a holistic perspective on sleep surface selection.

1. Support and Alignment

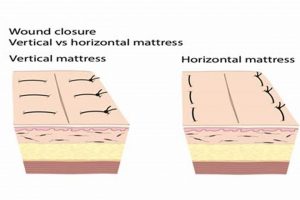

The relationship between sleep surface construction and spinal support is paramount to musculoskeletal health. Inadequate support can lead to improper spinal alignment, potentially exacerbating existing back pain or contributing to the development of new discomfort. The capacity of a sleep surface to maintain the spine’s natural curvature during sleep is, therefore, a crucial consideration. A surface exhibiting poor conformity may allow the hips or shoulders to sink too deeply, creating an unnatural curvature that strains the surrounding muscles and ligaments.

Different core technologies offer varying degrees of support and alignment. Visco-elastic foam, commonly referred to as memory foam, is characterized by its ability to conform to the body’s contours, distributing weight more evenly and minimizing pressure points. This conformity can promote proper spinal alignment, especially for individuals who sleep on their side. In contrast, spring-based designs typically rely on the tension of metallic coils to provide support. The level of support provided by a spring mattress depends on factors such as coil gauge, coil density, and the presence of additional support layers. For example, a firmer innerspring mattress with a substantial layer of high-density foam may provide adequate support for back sleepers, while a softer mattress could lead to spinal misalignment.

Achieving optimal spinal alignment during sleep is a function of both the sleep surface and individual body characteristics. Selecting a surface that adequately supports the spine in its natural position is vital for mitigating musculoskeletal strain. The ability to differentiate between the support characteristics of foam-based and spring-based surfaces is essential for making an informed choice, ultimately promoting better sleep quality and long-term spinal health.

2. Pressure Relief

Pressure relief is a critical performance aspect in sleep surfaces, directly influencing sleep quality and comfort. Localized pressure points, typically occurring at the shoulders, hips, and knees, can restrict blood flow and trigger involuntary tossing and turning throughout the night. The effectiveness of a mattress in mitigating these pressure points is a key differentiator. A surface that fails to adequately distribute weight results in concentrated pressure, potentially leading to discomfort and disrupted sleep cycles. For instance, an individual with arthritis might experience heightened pain and inflammation due to inadequate pressure relief. Foam designs and coil designs address this need to varying degrees.

Visco-elastic foam, commonly deployed in core technologies, exhibits viscoelastic properties which allow it to conform closely to the body’s shape. This conformity distributes weight across a broader surface area, thereby reducing concentrated pressure. The degree of pressure relief afforded by memory foam depends on its density and thickness. Conversely, spring systems provide pressure relief through a combination of coil design and comfort layers. Pocketed coil systems, where each spring operates independently, offer more targeted support and pressure relief compared to interconnected coil systems. Furthermore, the materials used in the comfort layers atop the coil system, such as latex or memory foam, significantly influence the overall pressure-relieving characteristics. As an example, a pocketed coil mattress topped with a thick layer of high-density memory foam might provide a balance of support and pressure relief suitable for individuals with back pain.

Ultimately, the suitability of a sleep surface for pressure relief depends on individual needs and preferences. Factors such as body weight, sleep position, and pre-existing medical conditions play a role in determining the optimal level of pressure relief. While foam is often associated with superior pressure relief due to its contouring capabilities, advanced spring systems with sophisticated coil designs and carefully selected comfort layers can also provide adequate pressure relief. The key is to assess the specific features of each design in relation to individual requirements to ensure a comfortable and restful sleep experience.

3. Motion Isolation

Motion isolation, the ability of a sleep surface to minimize the transfer of movement, is a critical factor in sleep quality, particularly for couples. The degree to which movement generated on one side of the surface is transmitted to the other directly impacts the likelihood of sleep disruption. The underlying construction materials and design play a pivotal role in determining the motion isolation characteristics of a sleep surface. Different materials exhibit varying capacities for absorbing and dissipating kinetic energy. For instance, if one partner frequently tosses and turns, a surface with poor motion isolation may result in the other partner experiencing frequent awakenings due to the transmitted movement. This can lead to fragmented sleep and reduced overall sleep quality.

Visco-elastic foam excels in motion isolation due to its inherent properties. The dense, conforming nature of memory foam effectively absorbs and dissipates movement, preventing it from traveling across the surface. This is attributed to the foam’s ability to dampen vibrations and minimize the ripple effect associated with movement. Conversely, traditional innerspring systems typically exhibit less effective motion isolation. The interconnected nature of the coils allows movement to transfer more readily across the surface. However, advancements in spring design, such as individually pocketed coils, aim to mitigate this issue. Pocketed coil systems allow each spring to move independently, reducing the transfer of motion compared to interconnected coil systems. For example, a couple where one partner is a light sleeper might find that a memory foam mattress significantly reduces sleep disturbances caused by the other partner’s movements.

In summary, motion isolation is a significant determinant of sleep quality, especially for co-sleepers. Foam-based designs generally offer superior motion isolation compared to traditional spring systems. Pocketed coil innerspring systems represent an attempt to bridge this gap, but the overall motion isolation performance remains contingent on the specific materials and construction methods employed. Understanding these differences allows consumers to select a sleep surface that minimizes sleep disturbances caused by partner movement, ultimately promoting more restful and uninterrupted sleep.

4. Temperature Regulation

Temperature regulation is a critical determinant of sleep quality, influenced significantly by the materials and construction of sleep surfaces. Maintaining a consistent and comfortable sleep temperature minimizes disruptions and promotes restorative rest. A surface that traps heat can lead to discomfort, increased tossing and turning, and fragmented sleep patterns. Understanding the differing temperature regulation properties of various mattress types is, therefore, a crucial aspect of selecting an appropriate sleep surface. The breathability and heat retention characteristics of a mattress contribute significantly to the overall sleep experience.

- Airflow and Breathability

Airflow refers to the capacity of a material to permit the passage of air. Enhanced airflow facilitates the dissipation of heat and moisture, preventing the buildup of uncomfortable temperatures. Spring designs typically exhibit greater inherent breathability due to the open spaces between the coils. The increased airflow within a spring system allows for more efficient heat transfer, promoting a cooler sleep environment. Foam, by contrast, tends to have a denser structure that restricts airflow, potentially trapping heat. However, advancements in foam technology, such as open-cell foam and gel infusions, aim to improve breathability. For example, a spring mattress with a breathable cotton cover will generally sleep cooler than a dense memory foam mattress with a synthetic cover.

- Material Heat Retention

Different materials possess varying degrees of heat retention. Certain foams, particularly traditional memory foam, tend to retain heat due to their density and closed-cell structure. This heat retention can lead to discomfort and increased body temperature during sleep. Spring mattresses, with their open coil structure, generally exhibit less heat retention. The open space allows for better ventilation, preventing the buildup of heat. Latex foam, often used in mattresses, offers a balance between conformity and breathability, exhibiting lower heat retention than traditional memory foam. For instance, a latex mattress may be a suitable option for individuals who desire the conforming properties of foam but are concerned about overheating.

- Construction and Design Features

Mattress construction plays a significant role in temperature regulation. Hybrid designs, combining coils with foam layers, often incorporate features to enhance breathability. These features may include ventilated foam layers, breathable covers, and strategically placed air channels. The placement and density of foam layers can also influence heat retention. Thicker layers of dense foam tend to trap more heat than thinner layers of less dense foam. The design of the coil system itself can impact airflow. For example, pocketed coil systems, with their individual fabric encasements, may restrict airflow to some extent compared to open coil systems. A mattress designed with a focus on temperature regulation will incorporate features that promote airflow and minimize heat retention.

- Cover Materials

The material used for the mattress cover also contributes to temperature regulation. Breathable fabrics, such as cotton, Tencel, and bamboo, promote airflow and wick away moisture, helping to maintain a comfortable sleep temperature. Synthetic fabrics, on the other hand, may restrict airflow and trap heat. Some mattress covers incorporate cooling technologies, such as phase change materials, which absorb and release heat to regulate temperature. The choice of cover material can significantly impact the overall thermal performance of a mattress. For instance, a mattress with a moisture-wicking Tencel cover will typically sleep cooler than a mattress with a polyester cover.

The thermal characteristics of sleep surfaces depend on an interplay of materials, design features, and construction methods. While foam has traditionally been associated with heat retention, advancements in foam technology and construction techniques have led to improved temperature regulation. Spring systems, with their inherent breathability, generally offer cooler sleep environments. Understanding these differences allows consumers to make informed choices based on their individual needs and preferences. For instance, individuals prone to overheating may prioritize a spring mattress with a breathable cover, while others may find that a foam mattress with cooling technologies provides adequate temperature regulation.

5. Durability/Lifespan

The longevity of a sleep surface constitutes a significant economic and practical consideration. The lifespan, or useful period, of a mattress directly affects its overall value proposition, influencing the long-term cost per year of ownership. Variances in materials, construction techniques, and usage patterns result in considerable differences in the typical lifespan of foam and spring-based designs. A premature failure necessitates replacement, incurring additional expense and inconvenience. Therefore, assessing the potential durability of each type is paramount.

- Foam Density and Degradation

The density of foam utilized in core or comfort layers is a primary determinant of its long-term resistance to compression and degradation. Higher-density foams generally exhibit greater resistance to sagging and deformation over time. Lower-density foams are more susceptible to breakdown and a reduction in support capabilities, leading to a shorter lifespan. Factors such as humidity, body weight, and usage frequency can accelerate the degradation process. The chemical composition of the foam also influences its resistance to oxidation and breakdown from UV exposure. For example, a high-density polyurethane foam core will generally outlast a low-density conventional foam core.

- Coil Gauge and Fatigue

The gauge, or thickness, of the steel wire used in coils within spring-based designs directly impacts their resistance to fatigue and permanent deformation. Thicker gauge coils are inherently more resilient and capable of withstanding repeated compression cycles without losing their structural integrity. Over time, repeated stress can cause coils to weaken, resulting in sagging and a loss of support. The type of steel used and any tempering processes employed also contribute to the overall fatigue resistance of the coils. Individually pocketed coils can sometimes offer extended durability compared to interconnected coil systems, as stress is distributed more evenly. For example, a mattress with thick-gauge, tempered steel coils will typically maintain its support characteristics longer than a mattress with thin-gauge, untempered coils.

- Construction Quality and Bonding

The overall quality of construction, including the methods used to bond different layers and reinforce edges, significantly influences the long-term structural integrity. Weak seams, inadequate edge support, or poorly bonded layers can create points of vulnerability that accelerate wear and tear. The quality of adhesives used and the precision of the manufacturing process play a crucial role in preventing delamination and maintaining the mattress’s intended shape. Edge support systems, often consisting of reinforced foam or additional coils around the perimeter, help prevent sagging and maintain a consistent sleeping surface. For example, a mattress with reinforced edges and meticulously bonded layers is more likely to withstand long-term use than a mattress with poorly constructed seams and inadequate edge support.

- Support System Design and Weight Distribution

The fundamental design of the support system, whether foam or springs, plays a critical role in distributing weight and minimizing localized stress. A well-designed support system evenly distributes body weight across the surface, reducing the likelihood of concentrated pressure points that can lead to premature sagging. The specific arrangement of coils or the layering of different foam densities contributes to the overall effectiveness of weight distribution. Hybrid designs, combining foam and springs, aim to leverage the strengths of both materials to optimize support and durability. For example, a mattress with a multi-layered foam core designed to evenly distribute weight will generally exhibit greater longevity than a mattress with a single layer of low-density foam.

In summary, the durability and lifespan of sleep surfaces are influenced by a complex interplay of factors related to material quality, construction techniques, and design principles. Higher-density foams, thicker-gauge coils, meticulous construction, and effective weight distribution contribute to extended product longevity. The selection between foam and spring-based designs should consider these durability factors alongside individual comfort preferences and budgetary constraints to maximize the long-term value of the investment.

6. Cost Considerations

The purchase of a sleep surface represents a significant investment, requiring careful evaluation of initial acquisition costs and long-term economic implications. Analyzing the price points associated with different construction methods is critical for informed decision-making. Variations in materials, manufacturing processes, and brand positioning contribute to the spectrum of available options. Understanding the cost drivers related to these products facilitates a more balanced assessment of value and suitability.

- Initial Purchase Price

The upfront cost often serves as the primary decision-making factor. Spring models typically present a lower entry point, particularly for basic innerspring designs utilizing open coil systems and limited comfort layers. Conversely, foam options, particularly those incorporating high-density visco-elastic materials or specialty formulations, tend to command a higher initial price. Hybrid models, combining elements of both, occupy a middle ground, reflecting the cost of integrating different component technologies. For example, a queen-size innerspring model might retail for several hundred dollars less than a comparable foam alternative.

- Material Composition and Manufacturing

The cost of raw materials significantly influences the final retail price. The price of high-density visco-elastic foam exceeds that of commodity-grade polyurethane foam. Similarly, the type and quantity of steel used in coil systems, as well as the complexity of the coil configuration, impact manufacturing expenses. Labor costs associated with specialized construction techniques, such as hand-tufting or zoned support systems, further contribute to the overall production cost. A model incorporating certified organic materials or advanced cooling technologies will invariably reflect these additional expenses in its price.

- Longevity and Replacement Frequency

While a less expensive option may appear attractive initially, its lifespan and replacement frequency warrant consideration. A product exhibiting premature sagging or degradation necessitates earlier replacement, negating any initial cost savings. Higher-quality spring models, employing durable coil systems and robust construction, may offer extended longevity compared to budget-priced foam alternatives. Evaluating the expected lifespan and considering the long-term cost per year of ownership provides a more accurate assessment of economic value. A model with a longer warranty and demonstrable durability may represent a more cost-effective choice over time.

- Warranty and Trial Periods

The terms and conditions of the warranty, as well as the availability of trial periods, indirectly impact cost considerations. A comprehensive warranty provides protection against manufacturing defects and premature failure, mitigating the risk of unexpected replacement expenses. Generous trial periods allow for in-home assessment of comfort and suitability, reducing the likelihood of buyer’s remorse and potential return costs. A product backed by a strong warranty and a risk-free trial period often justifies a higher initial investment, providing greater peace of mind and long-term economic security.

The selection between foam and spring options should not be solely driven by initial cost. A thorough evaluation of material composition, manufacturing techniques, expected lifespan, and warranty provisions provides a more nuanced understanding of value. By considering these factors, consumers can make a more informed purchase decision that aligns with their budgetary constraints and long-term sleep needs, thus maximizing return on investment.

7. Material Composition

The fundamental distinction between foam and spring lies in their constituent materials, directly influencing performance characteristics. Foam designs primarily utilize viscoelastic polyurethane, often layered with other synthetic or natural materials like latex. The density, type, and processing of the foam dictate its conformity, support, and temperature regulation capabilities. Spring systems, conversely, rely on tempered steel coils for support, coupled with various comfort layers of foam, fiber, or padding. The coil gauge, arrangement, and the composition of these layers determine the overall feel and durability.

The specific materials employed dictate the long-term performance and suitability of a sleep surface. For example, a model incorporating high-density memory foam will likely exhibit superior pressure relief and motion isolation compared to one constructed with low-density conventional foam. Similarly, an innerspring design with individually pocketed coils provides more targeted support and reduced motion transfer compared to a traditional interconnected coil system. The choice of cover fabric, whether natural fibers like cotton or synthetic blends, also affects breathability and moisture management. The presence or absence of flame retardant chemicals further contributes to the overall material composition, influencing consumer health and environmental impact considerations.

A thorough understanding of material composition enables consumers to make informed choices aligned with their specific needs and preferences. Selecting a surface with appropriate materials can directly enhance sleep quality, alleviate discomfort, and promote long-term spinal health. Evaluating certifications, such as CertiPUR-US for foam or Oeko-Tex Standard 100 for textiles, provides assurance regarding the safety and environmental responsibility of the materials used. Therefore, scrutinizing the constituent elements is essential for discerning the functional differences and overall value proposition of foam and spring-based designs.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the selection of a sleep surface, focusing on the attributes of differing construction methods.

Question 1: Is one type inherently better for back pain?

The suitability of a sleep surface depends on individual factors. Foam designs may offer pressure relief and spinal alignment for some, while firmer innerspring models might provide better support for others. There is no universal solution; individual preferences and specific back conditions are key determinants.

Question 2: Do foam designs always sleep hotter than spring designs?

Traditional memory foam tends to retain heat. However, advancements in foam technology, such as open-cell structures and gel infusions, aim to mitigate heat retention. Spring models generally exhibit greater breathability, but the overall temperature regulation depends on the materials used in the comfort layers and cover.

Question 3: Which type offers better motion isolation for couples?

Foam-based designs generally excel in minimizing motion transfer. The conforming nature of memory foam absorbs and dissipates movement, preventing it from traveling across the surface. Spring models, particularly those with interconnected coils, may transmit movement more readily.

Question 4: What factors influence the lifespan?

Durability depends on material quality and construction techniques. Higher-density foams and thicker-gauge coils typically exhibit greater resistance to sagging and degradation over time. Edge support systems and proper maintenance also contribute to longevity.

Question 5: Is a higher price point always indicative of superior quality?

Price does not guarantee quality. While premium materials and advanced technologies often command a higher price, careful evaluation of material composition, construction methods, and warranty terms is crucial for assessing true value.

Question 6: Are there certifications to look for when evaluating a sleep surface?

Certifications such as CertiPUR-US for foam and Oeko-Tex Standard 100 for textiles provide assurance regarding the safety and environmental responsibility of materials. These certifications indicate compliance with specific standards for content, emissions, and durability.

Understanding these frequently asked questions aids in navigating the complexities of sleep surface selection. Individual needs, preferences, and specific health conditions should guide the decision-making process.

The concluding section of this article offers a synthesis of key considerations, providing a comprehensive overview to facilitate informed decision-making.

Memory Foam Mattress vs Spring Mattress

The preceding analysis has delineated key distinctions between visco-elastic foam and spring-based sleep surfaces, examining their respective attributes in terms of support, pressure relief, motion isolation, temperature regulation, durability, cost, and material composition. Each technology presents inherent advantages and disadvantages, demanding a personalized approach to selection.

Ultimately, the optimal choice hinges on individual sleep preferences, physical requirements, and budgetary constraints. A careful consideration of the factors outlined herein, coupled with thorough product research and, where possible, in-person evaluation, will contribute to a more informed purchasing decision, fostering improved sleep quality and long-term well-being.