A sleeping surface addition, designed for placement atop an infant’s bed, utilizes a viscoelastic material known for its conforming properties. This material responds to pressure and temperature, adapting to the shape of the body resting upon it. The intended application is within the confines of a baby’s sleeping environment, specifically tailored to fit standard-sized cots.

The inclusion of such an item can potentially enhance comfort for the infant, potentially promoting longer and more restful periods of sleep. The conforming nature may aid in evenly distributing pressure, reducing localized stress points. Historically, improvements in materials science have led to increased availability and affordability of viscoelastic foam, making it a more common component in bedding products designed for various age groups.

Subsequent sections will delve into aspects such as material composition, safety considerations regarding use with infants, available product variations, and best practices for maintenance and care. Furthermore, potential drawbacks and alternative bedding solutions will be addressed to provide a comprehensive overview.

Tips for Selecting and Using

Careful consideration should be given when selecting and implementing a viscoelastic foam addition to an infant’s sleeping environment. Prioritizing safety and suitability is paramount.

Tip 1: Verify Density and Firmness: Opt for a product specifically designed for infant use, prioritizing a higher density for adequate support and a firmness level recommended by pediatric sleep specialists. Excessive softness can pose a suffocation risk.

Tip 2: Assess Material Certifications: Scrutinize the product details for certifications from independent testing organizations (e.g., CertiPUR-US) confirming the absence of harmful chemicals, heavy metals, and volatile organic compounds (VOCs).

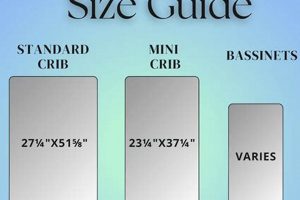

Tip 3: Ensure Proper Fit: Meticulously measure the crib dimensions and select a product that fits snugly within the cot, leaving no gaps around the perimeter. Gaps can create a potential entrapment hazard.

Tip 4: Use a Fitted Sheet: Always cover the surface with a tight-fitting sheet specifically designed for crib mattresses. This provides a barrier against spills and facilitates easier cleaning while maintaining a secure sleeping surface.

Tip 5: Monitor for Wear and Tear: Regularly inspect the foam for any signs of deterioration, such as cracking, crumbling, or indentation. Discontinue use immediately if any damage is detected.

Tip 6: Implement a Gradual Introduction: Consider introducing the addition gradually, allowing the infant to adjust to the change in sleeping surface. Monitor the infant’s comfort and sleep patterns closely during the initial period.

Tip 7: Adhere to Safe Sleep Guidelines: Always place the infant on their back to sleep, on a firm, flat surface, free of any loose bedding, pillows, or soft toys. These guidelines remain crucial, even with the addition of a viscoelastic foam layer.

By meticulously considering these factors, responsible selection and usage contribute to a safer and potentially more comfortable sleeping environment for the infant.

The subsequent section will elaborate on specific safety standards and regulations pertaining to infant bedding products.

1. Firmness

Firmness, in the context of infant bedding and, specifically, viscoelastic foam additions intended for cribs, assumes a paramount role due to its direct impact on infant safety and development. The degree of resistance to compression dictates the level of support provided and influences the potential for respiratory obstruction. An inadequate firmness level can pose a significant hazard.

- Suffocation Risk Mitigation

Insufficient firmness presents a suffocation hazard. Infants lack the motor skills to reposition themselves effectively if their face becomes pressed against a yielding surface. Overly soft viscoelastic foam can conform around the infant’s face, potentially obstructing airways and leading to respiratory distress or suffocation. Firmness levels should adhere to guidelines established by pediatric sleep safety organizations to minimize this risk.

- Spinal Support and Development

Proper spinal alignment is crucial for infant development. A sufficiently firm surface provides the necessary support to maintain a neutral spinal position during sleep. Excessive softness can cause the infant’s spine to curve unnaturally, potentially leading to discomfort or long-term musculoskeletal issues. The firmness level must strike a balance between comfort and adequate spinal support.

- Impact on Sleep Quality

While comfort is a consideration, excessive softness can paradoxically disrupt sleep. Infants may sink too deeply into a yielding surface, leading to discomfort and frequent awakenings. A firmer surface promotes more stable and consistent support, potentially contributing to longer and more restful sleep periods. Firmness affects sleep architecture and overall sleep quality.

- Relationship to Material Density

The firmness of viscoelastic foam is directly related to its density. Higher density foams generally exhibit greater firmness and provide more substantial support. Lower density foams tend to be softer and more yielding. When selecting a viscoelastic foam addition for an infant’s crib, it is crucial to prioritize higher density materials specifically designed and tested for infant use. Density is a key indicator of firmness and safety.

The interconnected nature of firmness, material density, and infant safety underscores the importance of making informed decisions regarding the selection of viscoelastic foam additions for crib environments. Prioritizing appropriate firmness levels, guided by established safety standards and recommendations, is essential for minimizing risks and promoting healthy infant development.

2. Safety certifications

Safety certifications serve as critical indicators of product compliance with established safety standards and regulations. In the context of viscoelastic foam additions designed for infant cribs, these certifications provide independent verification of a product’s composition, construction, and potential impact on infant health and well-being. Their presence or absence directly influences the suitability and safety of these bedding components.

- CertiPUR-US Certification

CertiPUR-US certification verifies that the viscoelastic foam has been independently tested and certified to meet specific standards for content, emissions, and durability. Certified foams are free from prohibited phthalates, ozone depleters, PBDE flame retardants, mercury, lead, and other heavy metals. Low VOC (Volatile Organic Compound) emissions are also a requirement for certification, minimizing potential indoor air pollution. The presence of this certification indicates a lower risk of exposure to harmful chemicals.

- OEKO-TEX Standard 100 Certification

OEKO-TEX Standard 100 certification focuses on the human ecology aspect of textile products. It tests for harmful substances in the materials at all stages of processing, from raw materials to finished product. This certification ensures that the product does not contain substances at levels known to be harmful to human health. The label provides assurance to consumers regarding the material’s safety for direct contact with skin, particularly important for infants.

- GREENGUARD Gold Certification

GREENGUARD Gold certification signifies that a product has been tested and certified to have low chemical emissions, specifically targeting VOCs, to improve indoor air quality. This certification is particularly relevant for products used in environments where children spend significant time, such as nurseries and bedrooms. Meeting the GREENGUARD Gold standard indicates that the viscoelastic foam addition contributes to a healthier indoor environment.

- JPMA Certification

JPMA (Juvenile Products Manufacturers Association) certification indicates that a product meets or exceeds the safety standards established by ASTM International (formerly known as the American Society for Testing and Materials). While not specific to foam composition, JPMA certification, when applied to a crib mattress or related product, demonstrates adherence to comprehensive safety requirements for juvenile products. It signifies a commitment to overall product safety and performance.

These certifications, while distinct in their focus, collectively provide a framework for assessing the safety and suitability of viscoelastic foam additions for infant cribs. Consumers should prioritize products with verifiable certifications from reputable organizations to minimize potential risks and ensure a safer sleeping environment for their infants. The absence of such certifications should raise concerns regarding the product’s composition and potential impact on infant health.

3. Proper Fit

The dimensional accuracy between a viscoelastic foam addition and the interior of a crib is critical for infant safety. An ill-fitting addition creates hazardous gaps. These gaps pose an entrapment risk where an infant can become wedged between the product and the crib’s side rails. Such entrapment can lead to suffocation. A proper fit ensures a snug and secure placement, minimizing this risk and contributing to a safer sleeping environment.

Conversely, an undersized addition presents similar dangers. Uneven surfaces or protruding edges can increase the risk of positional asphyxia. Infants may roll into the resulting depressions or against the exposed edges, obstructing their airways. A real-world example illustrates this: a recalled product demonstrated significant size discrepancies, leading to multiple reported instances of infants becoming trapped. The practical significance lies in meticulous measurement of the crib’s interior dimensions before selecting any aftermarket addition. Accurate measurements are crucial to ensuring compatibility and mitigating potential hazards.

In summation, the correlation between proper fit and safety cannot be overstated. The snugness and dimensional accuracy minimizes the risk of entrapment and positional asphyxia. Prioritizing precise measurements and selecting a product that adheres to these dimensions is paramount. The challenges associated with ill-fitting additions underscore the necessity of diligent product selection and responsible implementation within the infant’s sleeping environment. This understanding links directly to the broader theme of responsible infant care and the mitigation of preventable risks associated with bedding.

4. Breathability

Breathability, in the context of a viscoelastic foam addition for infant cribs, refers to the material’s capacity to permit the passage of air and moisture. This characteristic significantly influences the sleeping environment’s thermal regulation and overall safety. Reduced breathability can lead to heat retention, potentially causing overheating, a known risk factor for Sudden Infant Death Syndrome (SIDS). The closed-cell structure inherent in some viscoelastic foams can restrict airflow, exacerbating this issue. Conversely, enhanced breathability facilitates the dissipation of heat and moisture, promoting a more comfortable and safer sleeping surface. Real-life examples underscore the importance of this consideration; infants sleeping on less breathable surfaces have been observed to exhibit elevated body temperatures compared to those sleeping on more breathable alternatives. The practical significance lies in recognizing that material selection directly affects the microclimate within the crib and, consequently, the infant’s well-being.

Modifications to the foam’s structure or the incorporation of breathable materials can mitigate the breathability limitations of viscoelastic foam. Open-cell foam structures, for instance, allow for greater airflow compared to closed-cell structures. Additionally, some manufacturers incorporate breathable fabrics or ventilated designs to enhance air circulation. Consider a study where ventilated crib mattresses demonstrated a measurable reduction in surface temperature compared to non-ventilated counterparts. Practical applications include selecting products with open-cell construction or those incorporating breathable covers made from materials such as cotton or bamboo. Furthermore, maintaining a moderate room temperature and avoiding excessive swaddling can complement the effects of a breathable sleeping surface.

In summary, breathability represents a critical component in evaluating the suitability of viscoelastic foam additions for infant cribs. Reduced breathability can contribute to overheating, increasing the risk of SIDS, whereas enhanced breathability promotes a safer and more comfortable sleeping environment. Challenges remain in balancing the comfort and pressure-relieving properties of viscoelastic foam with the need for adequate airflow. Linking this understanding to the broader theme of infant sleep safety underscores the importance of informed product selection and the implementation of safe sleep practices. Prioritizing breathability, alongside other safety considerations, is paramount in creating an optimal sleeping environment for infants.

5. Cleaning ease

Maintaining hygiene within an infant’s sleeping environment is crucial for preventing the proliferation of bacteria, allergens, and other potential irritants. The ease with which a viscoelastic foam addition can be cleaned directly impacts the level of hygiene achievable, influencing the health and well-being of the infant. Spills, bodily fluids, and other contaminants are inevitable occurrences, necessitating efficient cleaning protocols.

- Material Composition and Absorbency

The inherent porosity of viscoelastic foam can make it susceptible to absorbing liquids. Certain foam densities and compositions are more absorbent than others, complicating the cleaning process. For instance, open-cell foam structures, while promoting breathability, tend to absorb liquids more readily than closed-cell structures. This necessitates the use of waterproof or water-resistant covers to prevent liquids from penetrating the foam. Failure to do so can result in persistent stains, odors, and the potential for microbial growth within the foam. Real-world observations confirm that viscoelastic foam additions without protective barriers are more prone to liquid absorption and subsequent cleaning challenges.

- Removable and Washable Covers

The presence of a removable and washable cover significantly enhances the ease of cleaning. These covers act as a primary barrier against spills and stains, preventing them from reaching the underlying foam. Washable covers can be easily removed and laundered according to manufacturer instructions, effectively eliminating most contaminants. However, the type of fabric used for the cover also influences its cleanability. Materials such as cotton or polyester blends are generally more stain-resistant and easier to clean than more delicate fabrics. Products lacking removable and washable covers necessitate more laborious and potentially less effective cleaning methods.

- Cleaning Protocols and Product Compatibility

The recommended cleaning protocols for viscoelastic foam vary depending on the material composition and construction. Some foams can be spot-cleaned with mild detergents and water, while others require more specialized cleaning solutions. Harsh chemicals or abrasive cleaners should be avoided, as they can damage the foam or leave behind harmful residues. The compatibility of cleaning agents with the foam material must be carefully considered to prevent degradation or discoloration. Product manuals and manufacturer guidelines provide essential information regarding appropriate cleaning methods. Failure to adhere to these guidelines can compromise the integrity and longevity of the viscoelastic foam addition.

- Drying Time and Ventilation

Adequate drying time and ventilation are critical after cleaning viscoelastic foam to prevent the growth of mold and mildew. Trapped moisture within the foam can create a favorable environment for microbial proliferation, posing a potential health hazard. Thoroughly drying the foam after cleaning is essential. This can be achieved by allowing it to air dry in a well-ventilated area or by using a low-heat setting on a hairdryer. Avoid placing the foam in direct sunlight or using high heat, as this can damage the material. Insufficient drying can lead to persistent odors and the potential for allergic reactions.

The ease of cleaning a viscoelastic foam addition for an infant crib is directly tied to its design, material composition, and the availability of appropriate cleaning protocols. Features such as removable and washable covers, combined with careful consideration of cleaning agents and drying methods, contribute to maintaining a hygienic sleeping environment. Products lacking these features present greater cleaning challenges and potentially increase the risk of exposure to allergens and contaminants. Therefore, evaluating cleaning ease is a crucial factor in selecting a viscoelastic foam addition that promotes infant health and well-being.

6. Durability

Durability, concerning a viscoelastic foam addition intended for a crib, signifies its capacity to maintain structural integrity and functional performance over an extended period of use. This attribute directly impacts the product’s cost-effectiveness, safety, and ability to provide consistent support for the infant. Degradation of the material can compromise its intended benefits and potentially introduce hazards.

- Material Density and Resistance to Deformation

The density of the viscoelastic foam directly correlates with its resistance to permanent deformation under sustained pressure. Higher density foams typically exhibit greater resilience and are less prone to sagging or indentation over time. This is particularly important in the context of a crib mattress addition, where the infant’s weight is concentrated over a relatively small surface area. Lower density foams may exhibit premature wear, resulting in uneven support and potential discomfort. Real-world examples demonstrate that higher density viscoelastic foam additions maintain their shape and support characteristics longer than their lower density counterparts, extending their lifespan and providing consistent performance.

- Resistance to Tearing and Abrasion

The foam’s resistance to tearing and abrasion is another critical aspect of durability. Repeated contact with crib sheets, blankets, and the infant’s movements can subject the foam to frictional forces. A foam that is prone to tearing or abrasion will degrade more rapidly, potentially releasing small particles that could pose a choking hazard or cause skin irritation. The presence of a durable outer cover can significantly enhance the foam’s resistance to tearing and abrasion. Products with reinforced seams and durable fabric choices offer greater protection against wear and tear, contributing to a longer lifespan. Cases of premature product failure often reveal deficiencies in the foam’s tear strength and abrasion resistance.

- Resistance to Degradation from Moisture and Cleaning

Exposure to moisture and cleaning agents can accelerate the degradation of viscoelastic foam. Spills, bodily fluids, and the use of cleaning solutions can compromise the foam’s structural integrity and performance. Certain cleaning agents can cause the foam to become brittle or lose its elasticity. The ability of the foam to withstand repeated cleaning cycles without significant degradation is an essential factor in durability. Waterproof or water-resistant covers play a crucial role in protecting the foam from moisture and facilitating easier cleaning. Products specifically designed for infant use should be tested for their resistance to common cleaning agents to ensure long-term durability.

- Long-Term Support and Comfort Retention

The ultimate measure of durability is the ability of the viscoelastic foam addition to maintain its support and comfort characteristics over time. A durable product will continue to provide adequate support for the infant’s spine and distribute pressure evenly, promoting restful sleep. Conversely, a product that degrades rapidly will lose its support capabilities, potentially leading to discomfort or musculoskeletal issues. Longitudinal studies that track the performance of viscoelastic foam additions over extended periods provide valuable insights into their long-term durability and ability to retain their intended benefits. Products that exhibit minimal loss of support and comfort over time are considered more durable and offer greater value to consumers.

The facets of material density, tear resistance, resistance to cleaning degradation, and long-term support all contribute to the overall durability of a viscoelastic foam addition for cribs. A durable product not only offers better value by lasting longer but also ensures the continued safety and comfort of the infant, aligning with the primary goals of responsible infant care. Focusing on these elements ensures both safety for the baby and a better investment over time.

7. Thickness

The dimension of thickness in viscoelastic foam additions for crib mattresses exerts a significant influence on both the safety and comfort aspects of the sleeping surface. A direct cause-and-effect relationship exists between this attribute and the support provided to the infant. Insufficient thickness may compromise spinal alignment and pressure distribution, whereas excessive thickness can create an unsafe sleeping environment. The importance of thickness stems from its direct role in modulating the firmness and overall sleeping surface characteristics. An example is a thin layer, perhaps less than one inch, offering minimal contouring and pressure relief, essentially negating the intended benefits of viscoelastic foam. In contrast, a layer exceeding three inches may create an overly soft surface, increasing the risk of suffocation. Understanding this connection is practically significant for selecting an appropriate product that balances comfort and safety.

Further analysis reveals that ideal thickness levels are contingent upon foam density and the overall construction of the crib mattress. Higher density foams may require less thickness to achieve adequate support compared to lower density alternatives. Consideration must also be given to the existing firmness of the underlying crib mattress. A firmer mattress may necessitate a thinner viscoelastic foam addition, while a softer mattress may benefit from a slightly thicker layer. Practical application involves consulting product guidelines and recommendations from pediatric sleep specialists to determine the appropriate thickness range for a given crib mattress and infant age. This targeted approach minimizes the potential for both inadequate support and excessive softness.

In summary, the thickness of a viscoelastic foam addition is a critical factor influencing its safety and effectiveness. Finding the correct balance is paramount. Challenges lie in the variability of foam densities and the absence of universal thickness guidelines. However, by carefully considering foam density, underlying mattress firmness, and expert recommendations, consumers can make informed decisions regarding product selection. The relationship between this dimension and infant safety underscores the responsibility in providing a safe environment.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding the use of viscoelastic foam additions intended for infant crib mattresses. Information presented is intended to provide clarity and promote informed decision-making.

Question 1: Are all viscoelastic foam additions safe for infants?

No. Safety hinges on several factors, including foam density, firmness, and the presence of safety certifications. Products lacking appropriate density or firmness levels may pose suffocation risks. The presence of CertiPUR-US or similar certifications indicates compliance with safety standards regarding harmful chemicals.

Question 2: Can a viscoelastic foam addition help with infant reflux?

While some anecdotal evidence suggests potential benefits, scientific evidence supporting this claim is limited. Elevating the head of the crib is the recommended approach for managing infant reflux, achieved through other means than solely relying on a topper.

Question 3: How often should a viscoelastic foam addition be cleaned?

Cleaning frequency depends on usage and potential spills. Removable and washable covers should be laundered regularly according to the manufacturer’s instructions. The foam itself should be spot-cleaned as needed with mild detergents, ensuring thorough drying to prevent mold growth.

Question 4: Does the thickness of the addition affect its safety?

Yes. Excessive thickness can create an overly soft surface, increasing the risk of suffocation. Insufficient thickness may not provide adequate support. It is essential to adhere to recommended thickness guidelines based on the foam’s density and the infant’s age and weight.

Question 5: How do I ensure a proper fit for the addition?

Accurate measurements of the crib’s interior dimensions are essential. Select a product that matches these measurements precisely, leaving no gaps around the perimeter. Gaps can create entrapment hazards.

Question 6: What are the potential drawbacks of using a viscoelastic foam addition?

Potential drawbacks include the risk of overheating due to reduced breathability, the potential for off-gassing of volatile organic compounds (VOCs), and the challenges associated with cleaning and maintaining hygiene. Careful product selection and adherence to safety guidelines can mitigate these risks.

In summary, the safe and effective utilization of viscoelastic foam additions for infant cribs requires diligent research, careful product selection, and adherence to recommended safety guidelines. The information presented herein serves as a starting point for informed decision-making.

Subsequent sections may delve into alternative bedding solutions or advanced topics related to infant sleep safety.

Conclusion

This exploration of the viscoelastic foam addition for infant cribs, often referred to as the memory foam topper crib mattress, has illuminated crucial factors for consideration. Aspects of firmness, safety certifications, proper fit, breathability, cleaning ease, durability, and thickness each impact its suitability. Furthermore, misconceptions have been clarified regarding its use and safety parameters.

Responsible parties are therefore urged to exercise diligence in evaluating options and aligning selections with established safety guidelines. Continuous vigilance is essential to promoting an optimal and secure sleeping environment for the infant.

![Best Babyletto Pure Core Mini Crib Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Pure Core Mini Crib Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1348-300x200.jpg)

![Best Babyletto Midi Crib Mattress [Guide] For Your Crib Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Midi Crib Mattress [Guide] For Your Crib | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1347-300x200.jpg)

![Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1346-300x200.jpg)