The combination of a fold-down bed frame and a standard 54-inch wide mattress presents a space-saving sleeping solution. This configuration is designed to maximize floor area in smaller living spaces such as apartments, studios, or guest rooms. The bed remains concealed within a cabinet or wall structure when not in use, effectively repurposing the room for other activities.

This particular bed configuration offers a compelling balance between comfort and practicality. It provides ample sleeping space for one or two adults while minimizing the bed’s footprint when stowed away. This is especially advantageous in urban environments where square footage is at a premium. Historically, these beds have been utilized to address space limitations and offer flexible living arrangements.

The subsequent sections will delve into the specific attributes of mattresses designed for these beds, considerations for selecting the appropriate type, and installation guidelines to ensure optimal functionality and longevity.

Essential Considerations

This section offers crucial guidance for selecting and maintaining a sleeping arrangement where a full-size mattress is integrated into a folding bed frame, ensuring optimal performance and longevity.

Tip 1: Mattress Thickness: Limit mattress thickness to the manufacturer’s specified maximum to ensure proper closure and prevent damage to the folding mechanism. Exceeding the recommended thickness can hinder operation and compromise the bed’s structural integrity.

Tip 2: Mattress Weight: Adhere to the weight restrictions outlined in the bed frame’s documentation. An excessively heavy mattress can strain the lifting mechanism, leading to premature wear or failure.

Tip 3: Mattress Type Compatibility: Confirm that the chosen mattress type (e.g., memory foam, innerspring, latex) is compatible with the bed’s design. Some frames may not adequately support certain mattress types, impacting comfort and support.

Tip 4: Securing Straps Usage: Always utilize the provided mattress securing straps when stowing the bed. These straps prevent the mattress from shifting during folding, maintaining its position and preventing damage to the frame or surrounding cabinetry.

Tip 5: Regular Mechanism Inspection: Conduct routine inspections of the folding mechanism for any signs of wear, looseness, or damage. Promptly address any issues to ensure safe and reliable operation.

Tip 6: Proper Ventilation: Allow for adequate ventilation around the stowed bed to prevent moisture buildup and mildew growth. Ensure the surrounding area is free from obstructions that could impede airflow.

Tip 7: Professional Installation: Consider professional installation to guarantee proper assembly and alignment. Incorrect installation can compromise the bed’s stability and functionality.

Implementing these guidelines will help maintain the functionality, safety, and lifespan of this space-saving sleeping solution, providing consistent comfort and efficient use of available space.

The subsequent sections will delve into troubleshooting common issues and exploring alternative configurations.

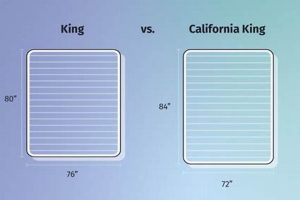

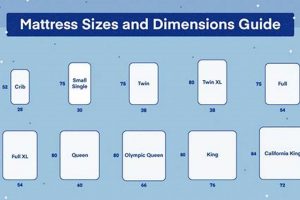

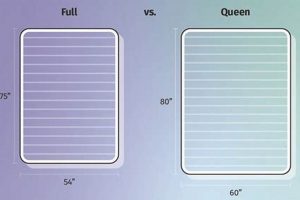

1. Dimensions

The dimensions of a full-size mattress significantly dictate the overall footprint and functionality of a Murphy bed system. The standard full-size mattress, typically measuring 54 inches in width and 75 inches in length, dictates the minimum cabinet size required to house the stowed bed. Failing to account for these dimensions during the design or selection process can result in the Murphy bed failing to fully retract, obstructing movement within the room, or even preventing the bed from closing altogether. A common example involves selecting a cabinet depth insufficient to accommodate the mattress’s thickness in addition to the frame’s mechanism, a factor often overlooked.

Furthermore, accurate dimensional understanding is critical during installation. If the wall space designated for the Murphy bed is not properly measured and prepared, the entire unit may be misaligned. This misalignment can lead to uneven weight distribution, stressing the bed’s folding mechanism and potentially reducing its lifespan. In situations where customized cabinetry is integrated around the Murphy bed, precise dimensions are crucial to ensure a seamless and aesthetically pleasing fit. Discrepancies, even minor ones, can result in gaps, overlaps, or an overall unbalanced visual aesthetic.

In summary, the dimensions of a full-size mattress are a non-negotiable factor when considering a Murphy bed. Accurate measurement, careful planning, and precise installation are all essential to ensure optimal functionality, longevity, and aesthetic integration within the intended space. Ignoring these dimensional considerations can lead to practical challenges and diminish the value and utility of the Murphy bed system.

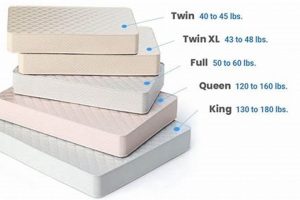

2. Weight

The weight of a full-size mattress is a critical factor in the design and functionality of a Murphy bed system. It directly impacts the bed’s lifting mechanism, structural integrity, and overall safety. Selecting a mattress without considering its weight can lead to operational difficulties, premature wear, or even system failure.

- Mechanism Strain

Exceeding the weight capacity of a Murphy bed’s lifting mechanism places undue stress on its components, such as springs, pistons, or hinges. Over time, this can result in the mechanism becoming less effective, requiring increased effort to raise or lower the bed, or even leading to complete failure. For instance, a spring-loaded mechanism rated for a 60 lb mattress will quickly degrade if consistently used with an 80 lb mattress.

- Frame Integrity

The bed frame itself must be capable of supporting both the mattress’s weight and the weight of any occupants. Using a too-heavy mattress can cause the frame to bend or warp, compromising the bed’s stability and safety. This is especially true for frames constructed from lighter materials or those with weaker joints. An example would be a frame made with thin particleboard buckling under the combined weight of a heavy memory foam mattress and two adults.

- Operational Safety

An overloaded Murphy bed system can pose significant safety risks. A weakened lifting mechanism may fail unexpectedly, causing the bed to slam down with considerable force. This poses a danger of injury to anyone nearby. Furthermore, a compromised frame may collapse during use, potentially causing serious harm to occupants. For example, a broken piston on a spring-loaded system could cause the bed to suddenly drop, trapping a user.

- Mattress Type Limitations

The weight restrictions of a Murphy bed often limit the types of full-size mattresses that can be used. Heavier mattress types, such as certain memory foam or hybrid models, may exceed the bed’s weight capacity. This necessitates careful consideration of mattress materials and construction to ensure compatibility. A thick, all-latex mattress, for example, can easily exceed the weight limit of many standard Murphy bed systems.

In conclusion, carefully considering the weight of the full-size mattress is paramount when selecting a Murphy bed system. Adhering to the manufacturer’s weight recommendations will ensure optimal performance, longevity, and, most importantly, the safety of the bed’s occupants. Ignoring these weight limitations can lead to costly repairs, reduced functionality, and potential safety hazards. Understanding weight’s importance and acting according to it, provides the best solution for a full sized murphy bed.

3. Thickness

The thickness of a full-size mattress is a critical specification that directly influences the functionality and practicality of its integration within a Murphy bed system. Careful consideration of this dimension is essential to ensure smooth operation and prevent potential damage to both the mattress and the bed frame.

- Cabinet Closure

Mattress thickness directly impacts the ability of the Murphy bed cabinet to close completely and securely. Exceeding the recommended maximum thickness specified by the manufacturer prevents the cabinet door from latching properly. This can create an unsafe condition, leaving the bed partially exposed and potentially damaging the cabinet door hinges or locking mechanism. For example, if a Murphy bed is designed for a maximum 10-inch thick mattress, attempting to use a 12-inch mattress will likely prevent the cabinet from fully closing.

- Folding Mechanism Stress

Using a mattress that is too thick can place undue stress on the Murphy bed’s folding mechanism. The added compression can strain the springs, pistons, or hinges, leading to premature wear and potential failure. This can manifest as increased difficulty in raising or lowering the bed, or even as a complete breakdown of the mechanism. For instance, a hydraulic lift system designed for a 10-inch mattress might struggle to lift and support a significantly thicker mattress, shortening its lifespan.

- Aesthetic Integration

The thickness of the mattress affects the overall aesthetic appearance of the Murphy bed system when stowed. A mattress that is too thick can protrude beyond the cabinet frame, creating an unsightly and unbalanced look. This can detract from the intended clean lines and space-saving design of the Murphy bed. An example might be a Murphy bed designed to blend seamlessly into a wall, but a mattress exceeding the recommended thickness disrupts the flush appearance.

- Sleeping Comfort and Support

While thickness is crucial for functionality, it should not compromise sleeping comfort and support. A thinner mattress might allow the Murphy bed to close properly but fail to provide adequate cushioning and spinal support, leading to discomfort and potential health issues. Conversely, a thicker mattress exceeding recommendations might offer excellent comfort but render the Murphy bed unusable. Therefore, finding the optimal balance between thickness, support, and comfort is paramount. An example is selecting a thinner memory foam mattress that provides sufficient support while adhering to the thickness constraints of the bed frame.

In summary, the thickness of a full-size mattress in a Murphy bed context is a multifaceted consideration that balances mechanical requirements with user comfort. A well-informed decision, based on manufacturer specifications and individual needs, is crucial for a functional, aesthetically pleasing, and comfortable sleeping solution. Ignoring the thickness can be harmful.

4. Compatibility

The concept of compatibility is paramount in the successful integration of a full-size mattress into a Murphy bed system. This encompasses multiple factors, including mattress type, dimensions, weight, and flexibility, each interacting to ensure the safe and efficient operation of the bed. Incompatibility in any of these areas can lead to mechanical issues, reduced lifespan of the system, and compromised user safety. The selection of a suitable mattress, therefore, is not merely a matter of personal preference but a critical element in the overall functionality of the Murphy bed.

Different mattress types, such as innerspring, memory foam, and latex, exhibit varying degrees of compatibility with Murphy bed mechanisms. For example, a heavy, rigid innerspring mattress may place undue stress on the lifting mechanism, particularly in systems designed for lighter, more flexible materials like memory foam. Furthermore, the mattress’s edge support characteristics influence its ability to maintain its shape when stowed vertically, impacting the ease of folding and unfolding. Incompatible combinations can result in the mattress deforming over time, affecting its comfort and longevity. Real-world examples include reports of spring mechanisms failing prematurely due to the excessive weight of an inappropriate mattress or mattresses becoming permanently bent from prolonged vertical storage.

Understanding compatibility is, therefore, not just theoretical but of practical significance. By carefully considering the manufacturer’s specifications for both the Murphy bed frame and potential mattresses, consumers can avoid costly errors and ensure long-term satisfaction with their purchase. Challenges remain in accurately assessing mattress properties prior to purchase, as manufacturers’ specifications may not always fully address the unique demands of Murphy bed systems. Further research and consultation with experienced retailers or installers are recommended to mitigate these risks and ensure a harmonious and functional integration of the full-size mattress into the Murphy bed.

5. Support

Adequate support is paramount when selecting a full-size mattress for a Murphy bed, directly influencing user comfort, spinal health, and the long-term integrity of the mattress itself. Improper support can lead to discomfort, pain, and premature wear, negating the space-saving benefits of the Murphy bed design.

- Spinal Alignment

A supportive mattress ensures proper spinal alignment during sleep. Lack of support can result in the spine curving unnaturally, leading to back pain, neck stiffness, and potentially long-term musculoskeletal issues. In the context of a Murphy bed, where the mattress is frequently stored vertically, consistent support is even more critical to prevent sagging or uneven compression that exacerbates these problems.

- Pressure Distribution

Effective support distributes body weight evenly across the mattress surface, minimizing pressure points. Inadequate support concentrates pressure on areas like the hips and shoulders, leading to discomfort and disrupted sleep. This is particularly important for full-size mattresses, which may accommodate two sleepers, requiring consistent and even support across the entire surface.

- Edge Support

Edge support refers to the stability of the mattress perimeter. Strong edge support prevents the sleeper from rolling off the bed and maximizes the usable sleeping surface. In a Murphy bed context, robust edge support is also essential to maintain the mattress’s shape during vertical storage and prevent edge sagging over time. Weak edge support can lead to premature wear and a compromised sleeping experience.

- Mattress Longevity

Appropriate support contributes to the overall lifespan of the mattress. A mattress that is not adequately supported is more likely to sag, develop indentations, or experience structural damage. This is exacerbated in a Murphy bed due to the stresses of frequent folding and unfolding. Proper support distributes weight evenly, reducing stress on individual components and extending the mattress’s useful life. For instance, a platform base with evenly spaced slats will generally provide better support and extend a mattresss life compared to a base with wide gaps.

In conclusion, the level and consistency of support offered by a full-size mattress are key determinants of its suitability for use in a Murphy bed system. Prioritizing mattresses with features designed to promote spinal alignment, distribute pressure, and maintain structural integrity will ensure both a comfortable sleeping experience and the long-term functionality of the Murphy bed itself.

6. Durability

Durability, in the context of a full-size mattress integrated within a Murphy bed system, extends beyond the mattress itself to encompass the entire assembly. The frequent folding and unfolding inherent in Murphy bed operation place unique demands on the mattress’s construction and materials, as well as on the bed frame and supporting mechanisms. A mattress with poor durability may exhibit premature sagging, loss of support, and fabric degradation, impacting sleep quality and requiring replacement. The Murphy bed frame, similarly, must withstand repeated stress without warping, bending, or experiencing component failure. The interaction between these elements determines the overall lifespan and utility of the system. The effect of lacking durability is huge.

Consider, for instance, a scenario where a high-density memory foam mattress is paired with a low-gauge steel frame. While the mattress may initially provide adequate comfort, the frame’s inability to consistently support its weight during both stowed and deployed positions will likely lead to frame deformation over time. Conversely, a robust frame combined with a low-quality innerspring mattress may result in the mattress springs losing their tension and providing inadequate support. These examples underscore the importance of evaluating the durability of all components, considering the stresses imposed by the Murphy bed’s operational cycle. Therefore we need to think for durability as a component to a full size murphy bed.

Therefore, selecting a full-size mattress and Murphy bed frame requires careful consideration of material quality, construction techniques, and weight capacity. Investing in components known for their robustness and resistance to wear is essential for maximizing the system’s lifespan and ensuring consistent performance. This understanding highlights the practical significance of prioritizing durability to achieve a cost-effective and satisfactory long-term solution for space-saving sleeping arrangements.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, use, and maintenance of full-size mattresses designed for Murphy bed systems. The information provided aims to offer clarity and guidance for maximizing the performance and longevity of this space-saving sleeping solution.

Question 1: What is the standard thickness for a full-size mattress used in a Murphy bed?

The optimal thickness varies depending on the specific Murphy bed frame design. Generally, a range of 8 to 12 inches is recommended to ensure proper cabinet closure and prevent undue stress on the folding mechanism. Consult the manufacturer’s specifications for the precise recommended thickness for each individual bed frame.

Question 2: Can any type of full-size mattress be used in a Murphy bed?

No. The mattress type must be compatible with the Murphy bed frame’s weight and flexibility limitations. Heavy innerspring mattresses may not be suitable for frames designed for lighter memory foam or latex options. Refer to the manufacturer’s guidelines for approved mattress types.

Question 3: How does the weight of the mattress affect the operation of a Murphy bed?

Excessive mattress weight places undue stress on the bed’s lifting mechanism, potentially leading to premature wear and failure. It is imperative to adhere to the weight capacity specified by the Murphy bed manufacturer. Exceeding this limit can compromise the system’s functionality and safety.

Question 4: Are special straps required to secure the mattress within a Murphy bed?

Yes. Most Murphy bed systems include straps designed to secure the mattress during folding and storage. These straps prevent the mattress from shifting, maintaining its position, and preventing damage to the frame or surrounding cabinetry. Proper use of these straps is crucial for safe and reliable operation.

Question 5: How often should the lifting mechanism of a Murphy bed be inspected?

The lifting mechanism should be inspected at least annually, or more frequently with regular use. Look for signs of wear, looseness, or damage to springs, pistons, or hinges. Address any issues promptly to prevent system failure and ensure user safety.

Question 6: Does the type of foundation or support system beneath the mattress matter in a Murphy bed?

Yes. The support system plays a crucial role in distributing weight evenly and preventing mattress sagging. A solid platform or a slatted foundation with appropriately spaced slats is generally recommended. Ensure that the support system is compatible with both the mattress type and the Murphy bed frame design.

In summary, careful consideration of mattress thickness, weight, type, and the proper use of securing straps are paramount for ensuring the safe and efficient operation of a full-size Murphy bed. Regular inspection and maintenance of the lifting mechanism are also essential for long-term reliability.

The next section will address troubleshooting common issues encountered with full-size Murphy bed mattress systems.

Conclusion

The preceding analysis has underscored the multifaceted considerations inherent in selecting a “murphy bed full size mattress.” Dimensions, weight, thickness, compatibility, support, and durability each contribute to the functional integrity and longevity of the system. Failure to adequately address these factors can compromise the bed’s operation, reduce its lifespan, and potentially create safety hazards. Therefore a murphy bed full size mattress is a good thing to install.

As urban living spaces continue to shrink, the demand for efficient space-saving solutions will likely increase. A thorough understanding of the specifications and limitations associated with this configuration remains crucial for consumers seeking to maximize their living space without sacrificing comfort or safety. Continued research and adherence to manufacturer guidelines will ensure that this space-saving solution remains a viable and effective option for years to come. Making a good choice is your responsibility.