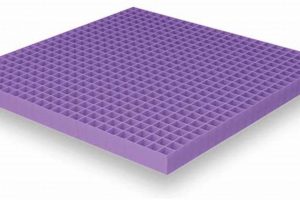

This bedding accessory is designed to prevent movement of the mattress on the bed frame or the mattress protector on the mattress. These pads typically employ materials or coatings that increase friction, effectively anchoring the layers and minimizing shifting. For example, a common application is to place this product between a memory foam mattress and a metal bed frame to prevent the mattress from sliding off during sleep.

The utilization of this product contributes to a more stable and comfortable sleep environment. Reduced mattress movement can minimize sleep disturbances, improving overall rest quality. Historically, solutions to address mattress slippage have ranged from makeshift remedies to professionally manufactured products, reflecting an ongoing need for secure bedding arrangements. The benefits extend to preserving the longevity of both the mattress and the protector by minimizing friction-related wear and tear.

Subsequent sections will explore the different materials used in manufacturing these pads, their effectiveness based on mattress type, and considerations for choosing the appropriate option.

Effective Use Strategies

The following guidelines are presented to optimize the functionality of a bedding stability solution.

Tip 1: Correct Placement: Ensure proper positioning between the mattress and the bed frame, or between the mattress and mattress protector, depending on the intended purpose. A partial application may compromise overall effectiveness.

Tip 2: Size Appropriateness: Select a pad that corresponds with the dimensions of the mattress. An undersized pad offers diminished grip, while an oversized pad might require trimming for a proper fit.

Tip 3: Material Compatibility: Consider the materials of both the mattress and the bed frame when selecting the pad. Certain surfaces may interact more favorably with specific materials used in the pad’s construction. For example, rubberized options often work well with metal frames.

Tip 4: Regular Inspection: Periodically assess the condition of the pad for signs of wear or damage. Replacement may be necessary to maintain optimal performance.

Tip 5: Cleaning Maintenance: Follow manufacturer instructions for cleaning the pad. Improper cleaning can degrade the friction-enhancing properties of the material.

Tip 6: Evaluate Mattress Type: Different mattress types (e.g., memory foam, innerspring) may require different levels of grip. A heavier mattress may necessitate a more robust solution.

Tip 7: Consider Bed Frame Construction: The design of the bed frame (e.g., slatted, solid platform) can impact the effectiveness of the pad. A slatted frame may require additional measures to prevent movement between slats.

Adhering to these recommendations will enhance the stability of the mattress and improve the overall sleep experience.

The subsequent section will summarize common concerns and frequently asked questions about these stability solutions.

1. Grip Strength

Grip strength, in the context of a bedding stability solution, directly correlates with its ability to inhibit mattress movement. This parameter is a primary determinant of the product’s efficacy, influencing both sleep quality and mattress longevity.

- Coefficient of Friction

The coefficient of friction quantifies the resistive force between the pad and the surfaces it contacts (mattress and bed frame or mattress protector). A higher coefficient indicates a greater force required to initiate movement, thereby enhancing stability. Materials with inherent surface textures or adhesive coatings contribute to an elevated coefficient. For instance, pads utilizing rubber or silicone often exhibit superior coefficients compared to those composed of smooth fabrics.

- Material Composition

The inherent characteristics of the materials used in construction dictate the potential grip. Certain materials, such as open-cell foam or polymers with a high degree of tackiness, possess naturally higher friction. Furthermore, the manufacturing process, including surface treatments and texturing, can augment grip strength. Variations in material sourcing and processing methods can lead to significant differences in performance between seemingly similar products.

- Surface Contact Area

The extent of contact between the pad and the mattress/bed frame influences overall grip strength. A larger contact area distributes the resistive force, minimizing localized slippage. Pads designed with full mattress coverage provide greater stability compared to those with a smaller footprint. Additionally, the conformity of the pad to surface irregularities enhances contact and improves grip.

- Load Bearing Capacity

A solution’s ability to maintain its grip strength under the load of a mattress and occupant is critical. Compression or deformation under load can reduce the contact area and diminish the coefficient of friction. Materials with high density and resistance to compression exhibit superior load-bearing capacity, ensuring consistent performance over time. Regular inspection for signs of compression or degradation is recommended to maintain optimal functionality.

The interplay of these facets determines the overall grip strength. Pads exhibiting a high coefficient of friction, constructed from durable materials, providing full surface coverage, and possessing sufficient load-bearing capacity offer the most effective solution for mitigating mattress movement and enhancing the sleeping experience. The selection process should prioritize these attributes based on the specific characteristics of the mattress and bed frame.

2. Material Durability

Material durability is a critical attribute directly affecting the lifespan and sustained performance of a bedding stability solution. The materials used in its construction must withstand repeated compression, friction, and potential exposure to moisture or temperature fluctuations. Insufficient durability manifests as diminished grip strength, tearing, or disintegration, rendering the product ineffective. For example, a pad constructed from low-grade foam may quickly compress and lose its ability to prevent mattress slippage, necessitating premature replacement.

The composition of the pad dictates its resistance to wear. Polymers with high tensile strength and abrasion resistance, such as certain grades of silicone or reinforced fabrics, offer enhanced durability compared to less robust alternatives. Furthermore, the manufacturing process plays a crucial role; proper bonding and sealing techniques contribute to structural integrity. Regular washing or exposure to body fluids can accelerate degradation, highlighting the importance of selecting materials that are resistant to these factors. A pad designe

d for heavy-duty use, such as in a hospitality setting, requires more durable materials than one intended for light residential use.

In summary, the material durability of a bedding stability solution directly influences its cost-effectiveness and long-term performance. Selecting a product constructed from high-quality, resilient materials ensures consistent grip strength and resistance to wear, ultimately contributing to a more stable and comfortable sleep environment. While initial cost may be higher for more durable options, the extended lifespan and sustained effectiveness justify the investment. Failure to consider material durability results in frequent replacements and diminished performance.

3. Size Appropriateness

Size appropriateness is paramount to the functionality of a bedding stability solution. A pad that does not correspond to the dimensions of the mattress compromises its ability to effectively prevent slippage. Incorrect sizing negates the intended benefits and may introduce new stability issues.

- Coverage Area

Insufficient coverage area resulting from an undersized pad leaves portions of the mattress vulnerable to movement. The uncovered sections are free to slide, undermining the stabilizing effect of the pad. Conversely, an oversized pad necessitates trimming, which may compromise the integrity of the material and create uneven edges that detract from its performance. Full coverage maximizes the frictional force resisting movement.

- Edge Alignment

Proper edge alignment ensures consistent contact between the pad and the mattress/bed frame surfaces. Misalignment, stemming from an incorrectly sized pad, creates gaps or overlaps that reduce surface contact and diminish grip strength. A pad that is too small will leave edges of the mattress exposed, while one that is too large may bunch or fold, leading to instability.

- Weight Distribution

An appropriately sized pad ensures uniform weight distribution across its surface. Uneven weight distribution, caused by an incorrectly sized pad, can lead to localized compression or deformation, reducing its ability to prevent slippage. The weight of the mattress and occupants must be evenly supported to maintain consistent frictional force across the entire contact area.

- Material Strain

An ill-fitting pad induces material strain. An oversized pad, when forced to fit, may stretch or wrinkle, reducing its grip strength. An undersized pad experiences concentrated stress at its edges, accelerating wear. Matching the pad size to the mattress dimensions prevents undue strain and prolongs the lifespan.

The congruence between pad dimensions and mattress size is a fundamental requirement. Deviations from the ideal size compromise stability, reduce lifespan, and negate intended benefits. The effectiveness is contingent upon selecting a pad that precisely matches the mattress dimensions.

4. Ease of Cleaning

Ease of cleaning is a significant attribute for a bedding stability solution, directly affecting hygiene and longevity. These pads, positioned between the mattress and bed frame or protector, are susceptible to accumulating dust, spills, and body fluids. Failure to maintain cleanliness diminishes the product’s functionality and promotes an unsanitary sleep environment. A pad saturated with contaminants loses its grip and becomes a breeding ground for allergens and bacteria. For example, consider a scenario where a beverage is spilled on the bed; a pad that is easily cleaned can be quickly sanitized, preventing stains, odors, and microbial growth. Conversely, a pad that is difficult to clean may require professional cleaning or premature replacement, increasing maintenance costs and compromising hygiene.

The materials used in the construction influence cleanability. Pads constructed from closed-cell foams or coated fabrics are inherently easier to clean compared to those made from open-cell materials or untreated fabrics. These materials resist the absorption of liquids and facilitate wiping or washing. Furthermore, the design of the pad affects its cleanability. Pads with simple, flat surfaces are easier to clean than those with intricate textures or seams, which trap dirt and debris. For example, a smooth silicone pad can be easily wiped clean with a damp cloth, while a quilted fabric pad may require vacuuming or machine washing. The cleaning method must be compatible with the material; harsh chemicals can degrade certain materials, reducing grip and lifespan. Adherence to manufacturer instructions for cleaning ensures effective sanitation without compromising the product’s integrity.

In summary, ease of cleaning is a crucial aspect of a bedding stability solution, impacting hygiene, longevity, and overall user satisfaction. Selection criteria should prioritize materials and designs that facilitate simple and effective cleaning. Regular maintenance prevents the accumulation of contaminants, preserves grip strength, and prolongs the pad’s lifespan, contributing to a healthier and more comfortable sleep environment. Neglecting this aspect can result in unsanitary conditions, reduced performance, and premature product failure.

5. Mattress Compatibility

The effectiveness of a bedding stability solution is inextricably linked to its compatibility with the specific mattress type. Material composition, weight, and surface characteristics of mattresses vary considerably, impacting the performance of the accessory designed to mitigate movement. Selection without considering these factors can result in diminished efficacy or damage to the mattress.

- Memory Foam Interaction

Memory foam mattresses, known for their conforming properties, often exhibit a smooth surface that can readily slide on various bed frames. Solutions with a high coefficient of friction are essential to prevent movement. However, certain materials used in these pads may trap heat, counteracting the cooling properties often sought in memory foam mattresses. For example, a thick rubber pad, while providing excellent grip, could restrict airflow and increase sleeping temperature. The solution should be breathable to maintain comfort.

- Innerspring Considerations

Innerspring mattresses, characterized by their coil support systems, typically possess a more textured surface compared to memory foam. While this texture provides some inherent grip, the weight and potential for shifting remain concerns. The chosen solution should distribute weight evenly to prevent localized pressure points on the coils. Pads that are too thin may not provide adequate support, leading to uneven wear on the mattress. Reinforced materials are recommended to withstand the rigors of innerspring mattresses.

- Latex Responsiveness

Latex mattresses, known for their responsiveness and breathability, can also present slippage challenges. Natural latex often has a slightly tacky surface, but this may not be sufficient to prevent movement on certain bed frames. Furthermore, the open-cell structure of latex makes it vulnerable to damage from abrasive materials. The solutio

n should be non-abrasive and allow for airflow. A finely textured pad constructed from a soft, breathable material is well-suited for latex mattresses. - Hybrid Adaptability

Hybrid mattresses, combining elements of multiple mattress types (e.g., memory foam and innerspring), present unique compatibility considerations. The surface characteristics and weight distribution can vary significantly depending on the specific construction. A versatile solution is needed that addresses both the smooth surface of memory foam and the weight of innerspring coils. Adjustable grip strength and breathable materials are advantageous in accommodating the diverse needs of hybrid mattresses. The compatibility should be carefully assessed based on the specific materials used in the hybrid mattress.

The selection of a bedding stability solution should be informed by a thorough understanding of the mattress characteristics. Incompatibility can lead to diminished performance, reduced comfort, and potential damage to the mattress. A comprehensive assessment ensures optimal stability and prolongs the lifespan of both the mattress and the accessory.

6. Frame Interaction

Frame interaction, in the context of bedding stability, denotes the interface between the bed frame and the chosen stability solution. The design and material of the bed frame exert a direct influence on the efficacy. For instance, a metal frame with a smooth, powder-coated surface presents a different challenge compared to a wooden frame with a textured or unfinished surface. The solution must effectively grip the frame material to prevent mattress slippage. An improperly matched system yields instability, compromising sleep quality and potentially damaging the mattress.

The construction of the bed frame also plays a vital role. Slatted frames, common in modern designs, require a solution that can effectively grip individual slats, preventing the mattress from shifting between them. Solid platform frames offer a more uniform surface, but the material of the platform (e.g., wood, metal, fabric) still impacts the grip. An example is a platform covered in a slick fabric, which increases the likelihood of mattress movement. The solution should be compatible with the frame’s architecture, providing consistent contact and preventing localized slippage. The presence of side rails or headboards may further constrain mattress movement, but the core principle of secure frame interaction remains paramount.

Effective frame interaction requires considering the frame material, construction, and the potential for abrasion or damage. Abrasive solutions can mar the finish of the frame, while incompatible materials may degrade over time, reducing grip. The solution should be chosen to complement the frame, providing secure contact without compromising its structural integrity or aesthetic appeal. Failure to address frame interaction undermines the overall stability, regardless of the solution’s other attributes.

Frequently Asked Questions

The following section addresses common inquiries regarding bedding stability solutions. The information presented aims to clarify functionality and proper usage.

Question 1: What is the expected lifespan?

The longevity depends on material composition, usage frequency, and maintenance. High-quality materials, coupled with proper cleaning, can extend the lifespan to several years. Conversely, frequent washing, exposure to harsh chemicals, or excessive weight may shorten the lifespan.

Question 2: Are all pads machine washable?

No. The washability is contingent on the materials used in its construction. Refer to the manufacturer’s instructions for specific cleaning guidelines. Washing a non-washable pad can lead to shrinkage, deformation, or disintegration.

Question 3: Can it damage my mattress?

When used correctly, it should not damage the mattress. However, abrasive materials or improper placement can cause wear or indentation. Select a solution with a smooth surface and ensure proper alignment to minimize potential for damage.

Question 4: Is it suitable for adjustable beds?

Suitability depends on the flexibility and grip. Solutions that are too rigid may not conform to the adjustable bed’s contours, reducing effectiveness. Opt for a flexible pad with a strong grip to accommodate the bed’s movements.

Question 5: Will it eliminate all mattress movement?

While designed to minimize movement, it may not entirely eliminate it, particularly with heavier mattresses or active sleepers. The level of stability achieved depends on factors such as mattress weight, bed frame construction, and the pad’s grip strength.

Question 6: Can it be used with a mattress protector?

Yes, it can be used in conjunction with a mattress protector. The pad is typically placed between the mattress and the protector to prevent both mattress and protector slippage. Ensure the protector is compatible with the pad’s material to maintain breathability and prevent moisture buildup.

Understanding the proper application and limitations is crucial for realizing the intended benefits.

The subsequent section will provide a concluding summary of the key considerations.

Conclusion

This exploration of the non slip mattress pad reveals its importance as a bedding accessory designed to mitigate mattress movement. Key considerations include grip strength, material durability, size appropriateness, ease of cleaning, mattress compatibility, and frame interaction. Understanding these attributes is essential for selecting a product that effectively enhances sleep quality and preserves mattress longevity.

The careful selection and proper maintenance of a non slip mattress pad represents a proactive investment in sleep hygiene. As bedding technology evolves, continued innovation in materials and design will likely yield further advancements in mattress stabilization, reinforcing its significance in creating a stable and comfortable sleep environment. Consumers are encouraged to diligently evaluate these factors when choosing solutions tailored to their specific needs.

![Top-Rated Best Mattress Pad Warmer of [Year] Stay Cozy! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top-Rated Best Mattress Pad Warmer of [Year] Stay Cozy! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-4744-300x200.jpg)