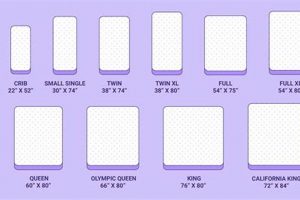

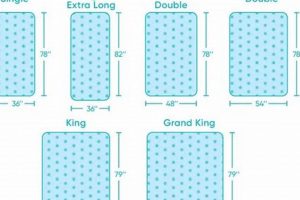

Mattress dimensions that deviate from established industry norms for lengths and widths are considered unconventional. Examples include sizes tailored for antique bed frames, custom-built sleeping platforms, or specialized needs such as accommodating taller individuals or fitting into recreational vehicles.

Selecting a mattress outside of standard dimensions provides solutions where pre-defined sizes are unsuitable. This adaptability is particularly advantageous for optimizing space in compact environments, replicating historical accuracy in restoration projects, or ensuring maximum comfort for individuals with specific height requirements. Historically, custom sizes were more common before mass production standardized dimensions.

The following sections will delve into the specific applications, common custom measurements, and purchasing considerations associated with mattresses made to order. Factors such as material options, support system variations, and the process of procuring a non-standard mattress will be addressed.

Guidance on Unconventional Mattress Dimensions

The pursuit of a sleep surface outside of typical industry measurements necessitates careful consideration to ensure satisfaction and value. This section provides guidance for those navigating the options and challenges associated with bespoke mattress sizing.

Tip 1: Precise Measurement is Critical:Accurately measure the intended sleeping space or bed frame. Double-check all dimensions, accounting for any internal frame allowances. Inaccurate measurements can lead to a mattress that does not fit properly.

Tip 2: Material Selection Impacts Cost: Certain mattress materials, such as natural latex or high-density memory foam, are inherently more expensive to customize. Explore alternative material combinations to manage budgetary constraints.

Tip 3: Support Core Considerations: The internal support system, be it innerspring, foam, or a hybrid, should be proportionate to the overall dimensions of the mattress. A poorly designed support core can compromise comfort and longevity.

Tip 4: Foundation Compatibility: Ensure the bed foundation or platform is suitable for the dimensions and weight of the chosen mattress. Inadequate support can void warranties and contribute to premature wear.

Tip 5: Customization Lead Times Vary: Be prepared for longer production times. Fabrication processes for non-standard items are inherently more involved than those for standard inventory.

Tip 6: Return Policies are Limited: Custom-made items typically have restricted or non-existent return policies. Clarify the terms of sale with the vendor prior to finalizing the order.

Tip 7: Verify Vendor Reputation: Select a mattress manufacturer or retailer with a proven track record of producing high-quality, custom-sized bedding. Check independent reviews and testimonials.

In summation, successful procurement relies on meticulous preparation, thorough vendor research, and a clear understanding of the trade-offs inherent in deviating from industry standard measurements.

The concluding section will provide a succinct recap of the key considerations discussed throughout this article and offer final advice for obtaining a tailored sleep solution.

1. Custom Length

The requirement for mattresses of non-standard length arises primarily to accommodate individuals whose height exceeds the dimensions of commercially available options. This need directly influences the specification and manufacture of bedding designed for specialized applications.

- Enhanced Ergonomics

Custom length mattresses ensure proper spinal alignment and support for taller individuals. A mattress that is too short can lead to discomfort, disrupted sleep, and potential musculoskeletal strain. By extending the sleep surface, these mattresses promote a more natural and comfortable sleeping posture.

- Antique Bed Restoration

Many antique bed frames were constructed with dimensions that differ from modern standards. Replicating or restoring these beds often necessitates a custom-length mattress to achieve an authentic fit. Standard sizing would compromise the aesthetic and functional integrity of the antique piece.

- Specialized Medical Applications

Certain medical conditions or physical limitations may require customized mattress lengths. For example, patients recovering from surgery or those with mobility challenges may benefit from a longer mattress to facilitate easier ingress and egress from the bed.

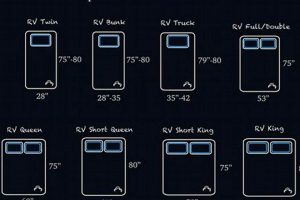

- Recreational Vehicle (RV) and Marine Bedding

Limited space within RVs and boats often dictates the need for shorter or longer mattresses to maximize usable area. These applications frequently demand unique lengths that deviate significantly from conventional sizes to conform to the internal dimensions of the sleeping quarters.

In summary, the specification of custom length in mattress manufacturing addresses a range of needs beyond simple aesthetics. It is driven by considerations of ergonomic comfort, historical preservation, medical necessity, and space optimization. The divergence from standard sizes underscores the demand for specialized solutions within the bedding industry.

2. Unique Width

Variations in mattress width, diverging from conventional industry dimensions, constitute a significant subset within the realm of non-standard mattress sizes. These deviations address specific needs and spatial constraints not met by standard offerings.

- Space Optimization in Compact Environments

Reduced width mattresses serve a crucial function in optimizing limited spaces, such as guest rooms, urban apartments, or recreational vehicles. For instance, a narrow twin mattress, shorter than the standard 38 inches, can allow for dual occupancy in a smaller room without compromising functionality. This allows for more floor space.

- Accommodation of Bariatric or Pediatric Needs

Conversely, increased width mattresses can cater to bariatric patients requiring a larger sleeping surface for comfort and support or pediatric patients with specific medical requirements needing extra space for care within the bed. Wider surfaces accommodate movement and caregiver access.

- Restoration of Antique Bed Frames

Historical bed frames often feature widths that do not align with modern mattress standards. A custom-width mattress is essential for maintaining the authenticity and aesthetic integrity of these pieces. The replication of period-accurate dimensions preserves historical context.

- Addressing Sensory Processing Sensitivity

Individuals with sensory processing sensitivity may benefit from a wider mattress, even in a single occupancy setting. The extra space reduces feelings of confinement and provides a greater sense of security, leading to improved sleep quality. This enhanced personal space promotes relaxation.

The divergence in mattress width underscores the demand for individualized sleep solutions. The examples provided illustrate that unique widths address specific constraints from spatial limitations to medical necessities or sensory sensitivities. The variations reflect a targeted approach to meeting user-specific needs within the broader context of non-standard mattress sizes.

3. Uncommon Thickness

Mattress thickness, when deviating from standard measurements, constitutes a significant aspect of non-standard mattress sizes. Uncommon thickness is not merely an aesthetic attribute; it directly influences support, comfort, and compatibility with bed frames. Instances of increased thickness may arise from incorporating multiple comfort layers, accommodating advanced support systems, or adhering to specific design requirements in high-end mattresses. Conversely, decreased thickness may serve space-saving objectives or cater to specialized needs, such as low-profile platforms or medical beds. This deviation from standard profiles directly affects the overall sleeping experience and requires careful consideration during selection and manufacturing.

Consider the practical implications of incompatible thickness. A mattress that is too thick for a bed frame can compromise safety and aesthetics, potentially obstructing headboards or creating an unstable sleeping surface. A too-thin mattress, on the other hand, may fail to provide adequate support, leading to discomfort and potential musculoskeletal issues. Furthermore, unusual thickness often necessitates custom-sized bedding, including sheets and mattress protectors, increasing the overall cost of ownership. A prime example is a mattress designed for historical accuracy in antique bed frames. These restorations may demand a specific, often thinner, profile to maintain the authenticity of the piece. RV and boat mattresses may also require reduced thickness to maximize headroom and usable space within confined environments.

In conclusion, uncommon thickness represents a critical dimension within the broader category of non-standard mattress sizes. It influences not only comfort and support but also compatibility and cost. A thorough understanding of its implications is essential for ensuring a proper fit and optimal performance. Selecting the correct thickness is a crucial step, and the final overall consideration in buying decisions. Choosing appropriate bedding solutions based on individual needs within unconventional parameters requires careful assessment.

4. Antique Frame Fitting

The intersection of antique bed frames and non-standard mattress sizes represents a distinct challenge within the bedding industry. Antique bed frames, constructed prior to the standardization of mattress dimensions, often exhibit unique internal measurements that preclude the use of modern, mass-produced mattresses. This discrepancy necessitates the production of custom-sized mattresses to ensure a proper fit and preserve the integrity of the antique frame. The absence of a correctly sized mattress can lead to instability, damage to the frame, and a compromised sleeping surface. Therefore, accurate measurement of the antique frame’s internal dimensions is paramount in determining the required mattress size.

Consider, for example, a Victorian-era bed frame with a length and width that deviate by several inches from standard queen or king sizes. Forcing a standard mattress into such a frame could result in buckling, uneven support, and eventual structural damage to both the mattress and the bed frame. A custom-made mattress, tailored to the precise dimensions of the antique frame, provides optimal support and prevents undue stress on the frame’s joints. This approach ensures the longevity of the antique furniture piece and provides a comfortable sleeping surface. Furthermore, the choice of mattress materials and construction methods can be adapted to complement the design and era of the antique frame.

In conclusion, antique frame fitting is a significant driver in the demand for non-standard mattress sizes. The successful integration of a mattress with an antique frame requires meticulous measurement, custom fabrication, and a thorough understanding of the frame’s structural limitations. Addressing this specialized need not only preserves historical artifacts but also provides a functional and comfortable sleeping solution that respects the unique characteristics of antique furniture.

5. RV/Boat Specific

The confined spaces within recreational vehicles and boats frequently necessitate bedding solutions that deviate significantly from standard mattress dimensions. This requirement for space optimization drives the demand for mattresses of non-standard sizes, designed to maximize comfort and functionality within limited areas.

- Contoured Shapes for Hull Conformance

Boat mattresses often require custom contours to conform to the curvature of the hull. Standard rectangular mattresses are unsuitable for these applications, necessitating specialized shapes such as trapezoids, triangles, or rounded edges to ensure a proper fit. This contouring maximizes usable space and prevents gaps between the mattress and the interior structure.

- Reduced Thickness for Headroom Optimization

Low headroom is a common constraint in both RVs and boats. Reducing mattress thickness is a primary strategy for increasing headroom and improving overall comfort. Standard mattress thicknesses can be excessive in these environments, leading to cramped conditions and reduced mobility. Thin profile mattresses, while potentially compromising some aspects of comfort, provide a practical solution for maximizing vertical space.

- Lightweight Materials for Load Management

Weight is a critical consideration in RV and boat design. Traditional innerspring mattresses can be excessively heavy, impacting fuel efficiency and vehicle handling. Lightweight materials, such as memory foam or latex, are often preferred in non-standard RV and boat mattresses to minimize weight and improve overall performance.

- Durable, Moisture-Resistant Construction

The marine environment presents unique challenges for bedding, including exposure to humidity, saltwater, and mold. RV mattresses may also be exposed to fluctuating temperatures and humidity levels. Non-standard RV and boat mattresses often incorporate durable, moisture-resistant materials to withstand these conditions and extend the lifespan of the product.

These factors collectively underscore the vital link between the spatial and environmental constraints of RV and boat environments and the demand for non-standard mattress sizes. Addressing these specific needs requires specialized design and manufacturing techniques to ensure comfort, durability, and optimal space utilization.

6. Special Needs Accommodation

The intersection of special needs accommodation and non-standard mattress sizes is critical for ensuring comfort, safety, and therapeutic efficacy for individuals with specific medical or physical requirements. Deviations from standard mattress dimensions are often necessary to address unique needs that cannot be met by conventional bedding solutions. This customization can involve alterations in length, width, thickness, material composition, or structural design. Failing to provide appropriate mattress sizing can directly impact the individual’s quality of sleep, physical well-being, and overall care.

A practical example is the provision of bariatric mattresses. Standard mattress sizes may lack the necessary width and support to comfortably and safely accommodate individuals with obesity. Non-standard, wider mattresses with reinforced support systems are crucial to prevent pressure sores, facilitate mobility, and ensure proper spinal alignment. Another application lies in pediatric care, where custom-sized mattresses can be designed to fit specialized cribs or hospital beds, accommodating medical equipment or providing additional space for caregivers to assist with treatment. Furthermore, individuals with mobility impairments may require non-standard mattress heights to facilitate easier transfers to and from wheelchairs or other mobility aids. Custom designs can also integrate features such as adjustable firmness, pressure redistribution technologies, and moisture-resistant materials to address specific therapeutic needs.

In summary, the demand for non-standard mattress sizes driven by special needs accommodation highlights the importance of personalized bedding solutions. These custom designs are not merely aesthetic preferences but essential components of medical and therapeutic care. Addressing the unique needs of individuals with specific physical or medical conditions requires a comprehensive understanding of mattress design principles, material properties, and therapeutic requirements. The availability and accessibility of custom mattress options are crucial for improving the quality of life and overall well-being of individuals with special needs.

7. Custom Shapes

Custom shapes represent a significant facet of non-standard mattress sizes, extending beyond simple variations in length, width, or thickness. The deviation from conventional rectangular forms arises from specific spatial constraints, design requirements, or functional needs. These uniquely shaped mattresses are not merely aesthetic choices but pragmatic solutions dictated by the intended application and environment.

The demand for custom shapes manifests across diverse scenarios. Boat mattresses, for instance, often require trapezoidal or rounded configurations to conform to the hull’s curvature. Similarly, antique beds may exhibit non-rectangular frames necessitating corresponding mattress shapes to ensure a proper fit and maintain historical accuracy. In specialized medical settings, custom shapes can enhance patient comfort and facilitate treatment. A semi-circular mattress, for example, may be required for a specific medical device. Custom shapes are also employed in recreational vehicles (RVs) to maximize space utilization within confined quarters. Consequently, understanding the principles and manufacturing techniques associated with shaped mattresses is crucial for addressing diverse needs within the non-standard bedding market.

In conclusion, the integration of custom shapes within the realm of non-standard mattress sizes underscores the bedding industry’s capacity to adapt to diverse demands. These solutions are crucial for optimizing comfort and usability across varied environments and applications. While challenges related to manufacturing complexity and cost may arise, the ability to provide shaped mattresses is a cornerstone of comprehensive non-standard bedding offerings, enabling tailored solutions for specialized needs.

Frequently Asked Questions

The following questions address common inquiries regarding mattress dimensions that deviate from industry standards. This section aims to provide clarity and informed guidance on selecting appropriate non-standard options.

Question 1: What constitutes a “non-standard” mattress size?

A non-standard mattress size refers to any length, width, or thickness dimension that does not conform to established industry norms for mattress production. These sizes are typically custom-made to fit specific bed frames or spatial constraints.

Question 2: Why might an individual require a non-standard mattress size?

Reasons for requiring a non-standard mattress include accommodating antique bed frames, optimizing space in recreational vehicles or boats, meeting specific medical needs (e.g., bariatric patients), or providing enhanced comfort for taller individuals.

Question 3: Are non-standard mattresses more expensive than standard sizes?

Generally, custom-made mattresses are more expensive due to the individualized manufacturing process, specialized materials, and limited production volume. The exact cost depends on factors such as dimensions, materials, and vendor pricing policies.

Question 4: What are the typical limitations associated with purchasing a non-standard mattress?

Limitations may include longer lead times for production, restricted or non-existent return policies, increased shipping costs, and difficulty in finding appropriately sized bedding (e.g., sheets, mattress protectors).

Question 5: How should one accurately measure a bed frame for a non-standard mattress?

Precise measurement is critical. Measure the internal length and width of the bed frame at multiple points, accounting for any structural obstructions or inconsistencies. Consult with the mattress manufacturer to confirm measurement accuracy and determine appropriate allowances.

Question 6: What types of materials are suitable for non-standard mattresses?

A wide range of materials can be used, including innerspring, memory foam, latex, and hybrid constructions. The selection depends on individual preferences, support requirements, and budgetary constraints. It is crucial to consider material durability and suitability for the intended application.

In summary, procuring a suitable mattress solution requires careful consideration and rigorous methodology. A well-informed approach ensures a positive outcome.

The next section will discuss emerging technologies in sleep solutions.

Conclusion

This exploration of non standard mattress sizes underscores their critical role in addressing diverse and specific needs. From accommodating antique bed frames and optimizing space in recreational vehicles to providing customized support for individuals with unique medical requirements, dimensions outside established norms offer solutions where standardized products fail. The process of selecting and procuring such mattresses demands meticulous measurement, careful material consideration, and a thorough understanding of the inherent limitations and potential cost implications.

The continued demand for non standard mattress sizes highlights the importance of specialized manufacturing processes and knowledgeable vendor support. Individuals seeking bespoke bedding solutions must prioritize accuracy and due diligence to ensure a comfortable, supportive, and enduring sleep surface that precisely meets their individual needs, now and in the future.

![Best Pillow Top Queen Size Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Pillow Top Queen Size Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-2308-300x200.jpg)