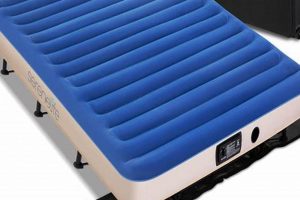

A portable sleeping solution designed for the cargo area of a truck, it provides a comfortable surface for rest during outdoor adventures or travel. This product typically utilizes air chambers that inflate to create a level and cushioned platform within the confines of the vehicle’s bed. Variations exist to accommodate different truck bed sizes and shapes.

The primary advantage of such a product lies in its convenience, enabling spontaneous camping or overnight stays without the need for a tent or lodging. It offers a cost-effective alternative to traditional accommodation while maximizing the utility of a vehicle. The concept has evolved from simple air mattresses to models with integrated air pumps, durable materials, and custom designs tailored to specific truck models, reflecting a growing demand for accessible and comfortable outdoor recreation solutions.

The following sections will explore the diverse types available, key features to consider when selecting one, practical applications for its use, and maintenance procedures to ensure longevity.

Essential Usage Considerations

Optimal utilization requires careful attention to detail and adherence to specific guidelines. The following recommendations promote safety, comfort, and the extended lifespan of the product.

Tip 1: Size Verification: Prior to purchase, meticulously measure the truck bed’s interior dimensions. Mismatched sizes can result in improper inflation, discomfort, and potential damage to both the product and the vehicle.

Tip 2: Surface Preparation: Before inflation, ensure the truck bed surface is clear of debris, sharp objects, or abrasive materials. These can puncture or damage the product’s exterior, compromising its integrity.

Tip 3: Inflation Control: Adhere strictly to the manufacturer’s inflation guidelines. Overinflation can lead to seam failure, while underinflation compromises support and comfort. Utilize a calibrated air pump with a pressure gauge for accurate inflation.

Tip 4: Temperature Considerations: Extreme temperatures can affect air pressure within the mattress. In hot conditions, release small amounts of air to prevent overexpansion. In cold conditions, add air to maintain desired firmness.

Tip 5: Weight Distribution: Distribute weight evenly across the surface. Concentrated pressure in one area can cause localized stress and potential failure of the internal structure. Avoid placing heavy objects on the product.

Tip 6: Storage Procedures: When not in use, deflate completely and store in a cool, dry place, away from direct sunlight and sharp objects. Proper storage prevents deterioration and extends the product’s lifespan.

Tip 7: Regular Inspection: Periodically inspect the product for signs of wear, leaks, or damage. Promptly repair minor issues using provided repair kits or professional services to prevent further degradation.

Adhering to these guidelines enhances the user experience and ensures long-term viability. Prioritizing responsible usage maximizes the inherent value of this mobile sleeping solution.

The concluding section provides an overview of common issues, troubleshooting steps, and repair techniques.

1. Material Durability

Material durability is a paramount factor directly influencing the longevity and utility of a pickup bed inflatable mattress. The inherent cause-and-effect relationship is evident: a more robust material composition results in greater resistance to punctures, abrasions, and environmental degradation. Conversely, inferior materials are susceptible to damage from sharp objects in the truck bed, prolonged exposure to sunlight, or repeated inflation and deflation cycles. The practical significance lies in the product’s ability to withstand real-world conditions, ensuring reliable performance and preventing premature failure.

For instance, mattresses constructed from heavy-gauge PVC or reinforced nylon demonstrate superior resistance to tearing and air leakage compared to those made from thinner, less durable materials. Field tests consistently show that mattresses utilizing multi-layered construction and protective coatings exhibit extended lifespans, even under rigorous usage. The consequences of inadequate material durability can range from inconvenient air leaks during use to complete product failure, rendering the mattress unusable and negating its intended benefits. Therefore, investment in a product with demonstrably durable materials translates directly into long-term cost savings and enhanced user satisfaction.

In conclusion, material durability is not merely a desirable attribute but a fundamental requirement for a functional and reliable pickup bed inflatable mattress. Understanding the material properties, construction methods, and protective features is crucial for informed purchasing decisions. Choosing a product with a proven track record of durability minimizes the risk of premature failure, maximizes the return on investment, and ensures a comfortable and dependable sleeping solution for outdoor adventures or travel. Challenges remain in balancing durability with affordability, but prioritizing material quality ultimately contributes to a superior user experience.

2. Inflation System

The inflation system represents a critical component directly impacting the usability and convenience of a pickup bed inflatable mattress. It dictates the ease and speed with which the mattress can be prepared for use, influencing the overall user experience and practical value of the product.

- Integrated Electric Pumps

Many models incorporate integrated electric pumps, simplifying the inflation process. These pumps, often powered by a 12V DC outlet or AC adapter, automatically inflate the mattress to a pre-determined pressure. An example is a built-in pump that fills the mattress in under five minutes with the push of a button. The implication is reduced effort and time investment for the user, making it ideal for spontaneous or frequent use scenarios.

- Manual Inflation Valves

Alternative systems utilize manual inflation valves, requiring an external pump or manual effort. While less convenient, these systems offer greater independence from electrical power sources. A common example is a two-way valve compatible with standard air mattress pumps. The implication is a lower reliance on external power, suitable for remote locations or situations where electricity is unavailable.

- Inflation Time and Efficiency

The inflation time and efficiency of the system directly correlate to user convenience. Shorter inflation times and efficient air distribution enhance the overall usability of the product. For instance, a dual-chamber design can inflate faster than a single-chamber model. The implication is a more rapid and convenient setup process, part

icularly beneficial in adverse weather conditions or time-sensitive situations. - Pressure Regulation and Control

Advanced systems feature pressure regulation and control mechanisms, allowing users to adjust the firmness of the mattress to their preference. This is achieved through adjustable valves or pressure sensors. The implication is enhanced comfort and customization, catering to individual needs and preferences for optimal sleep quality.

In summary, the inflation system is an integral design element. The choice between integrated pumps and manual valves, along with factors such as inflation time and pressure regulation, significantly influences the practicality and user satisfaction associated with a pickup bed inflatable mattress. Understanding these nuances enables informed purchasing decisions based on individual needs and anticipated usage scenarios.

3. Size Compatibility

The correct dimensions are paramount for effective utilization. A mis-sized product can lead to compromised comfort, stability, and even damage to both the mattress and the truck bed. Therefore, a detailed understanding of size variations and measurement techniques is crucial.

- Bed Length Variations

Truck beds are manufactured in various lengths, typically categorized as short, standard, and long. A mattress designed for a short bed will not properly fit a long bed, resulting in significant gaps and instability. Similarly, a mattress intended for a long bed cannot be effectively used in a short bed due to overhang and potential damage. A practical example includes a 5.5-foot mattress being incompatible with an 8-foot bed. The implication is that precise measurements are required prior to purchase to ensure compatibility.

- Wheel Well Interference

The internal dimensions of a truck bed are further complicated by the presence of wheel wells. These protrusions reduce the available flat surface area and can interfere with the mattress’s fit. A mattress that does not account for wheel well placement may be too wide or require modification for proper installation. A real-world scenario is a mattress designed for a flat-bed truck being unsuitable for a standard pickup with prominent wheel wells. The implication is the necessity of selecting a mattress specifically designed to accommodate the truck bed’s internal contours.

- Width and Height Constraints

The width and height of the truck bed also impose limitations. A mattress that is too wide may not fit between the bed walls, while one that is too tall can interfere with a tonneau cover or create discomfort. An example is a mattress exceeding the available height under a closed tonneau cover, rendering the cover unusable. The implication is a need to consider both width and height dimensions to ensure a secure and comfortable fit without compromising the vehicle’s functionality.

- Custom Fit Options

Recognizing the diversity of truck bed sizes and configurations, some manufacturers offer custom-fit mattresses. These products are specifically tailored to match the exact dimensions of a particular truck model. An example is a mattress custom-designed for a specific make and model year, ensuring a perfect fit and optimal comfort. The implication is the availability of solutions for unusual bed sizes or those requiring a precise fit.

These considerations underscore the critical importance of verifying product dimensions before purchase. Accurate measurements and a thorough understanding of truck bed characteristics are essential for selecting a size-compatible mattress that maximizes comfort, stability, and longevity.

4. Weight Capacity

Weight capacity, in the context of a pickup bed inflatable mattress, signifies the maximum load the product can safely support without compromising structural integrity or user safety. It is a critical specification that dictates the suitability of the mattress for single or multiple occupants and the potential for damage due to overloading.

- Material Stress and Deformation

Exceeding the designated weight limit causes undue stress on the mattress’s internal structure and outer material. This can lead to permanent deformation, seam failure, or even catastrophic rupture. For example, a mattress rated for 500 lbs subjected to a 700-lb load is likely to experience accelerated wear and potential air leaks. The implication is that adherence to weight limits is essential for preserving the mattress’s lifespan and preventing hazardous failures during use.

- Inflation Pressure Dynamics

Weight distribution directly influences the internal air pressure within the mattress. Concentrated loads exceeding the design parameters can create localized pressure spikes, resulting in uneven support and potential damage to the inflation system. A specific instance involves a single individual significantly exceeding the per-person weight limit causing localized stress on one section of the mattress. The implication is that even distribution of weight is critical, especially when approaching the maximum weight capacity, to maintain consistent support and prevent localized damage.

- Warranty Implications

Manufacturers typically specify weight limits as a condition of warranty coverage. Exceeding these limits voids the warranty, leaving the user responsible for any repairs or replacements necessitated by overloading. An example is a warranty clause explicitly excluding damage caused by exceeding the stated weight capacity. The implication is that respecting weight restrictions is not only a safety precaution but also a safeguard for the financial investment in the product.

- Safety Considerations

Overloading a mattress compromises stability and support, increasing the risk of falls or injuries, especially if the truck bed is not perfectly level. Furthermore, excessive weight can cause the mattress to shift during transit, potentially leading to accidents. A specific concern is a shifting mattress causing instability while the vehicle is in motion, jeopardizing vehicle control. The implication is that adherence to weight limits is a primary safety measure to protect occupants from potential harm.

The weight capacity specification of a pickup bed inflatable mattress is therefore not an arbitrary number but a crucial parameter that dictates the product’s safe and effective operation. Failure to observe this limit can result in reduced lifespan, voided warranties, and, most importantly, increased risk of injury. Consequently, careful consideration of weight limits is an indispensable part of selecting and utilizing this type of product.

5. Storage Compactness

Storage compactness represents a key attribute directly influencing the practicality and appeal of a pickup bed inflatable mattress. This characteristic defines the reduced volume the mattress occupies when deflated and packed for storage, thus affecting its portability and ease of management. The relationship between storage compactness and usability is inverse: a more compact storage volume cor

relates to greater convenience in transport and storage, while a bulky, difficult-to-manage package diminishes the overall value of the product. The significance lies in the limited storage space typically available in vehicles, especially during camping trips or long journeys where maximizing usable space is paramount. Examples include models designed to compress into a small duffel bag versus those requiring significant cargo area even when deflated. The practical significance underscores the importance of assessing storage dimensions prior to purchase, particularly for users with space constraints.

The implementation of advanced folding techniques and material science contributes to enhanced storage compactness. Mattress designs that utilize thinner, yet durable, materials and incorporate strategic folding patterns achieve smaller packed sizes. For instance, some models employ a multi-fold design and are constructed from lightweight ripstop nylon, enabling compression into a package comparable in size to a sleeping bag. This facilitates convenient storage behind the truck seat, in a toolbox, or within a roof-mounted cargo carrier, freeing up valuable space inside the vehicle. Furthermore, integrated compression straps and storage bags further contribute to secure and streamlined storage, preventing unwanted expansion and simplifying handling. These features enhance the overall portability and usability of the mattress, particularly for users who prioritize minimizing cargo volume.

In conclusion, storage compactness is a crucial consideration in the selection of a pickup bed inflatable mattress, directly influencing its portability and ease of management. Smaller storage volumes translate into enhanced convenience and maximized space utilization, particularly important for outdoor enthusiasts and travelers. While challenges remain in balancing durability with compressibility, prioritizing storage compactness ensures a more practical and user-friendly product. Future innovations in materials and design will likely further improve storage efficiency, solidifying this attribute as a key differentiator in the market.

Frequently Asked Questions

The following section addresses common inquiries related to pickup bed inflatable mattresses, providing detailed information to aid in informed decision-making.

Question 1: What factors influence the durability of a pickup bed inflatable mattress?

Material composition, construction methods, and usage conditions significantly impact durability. Heavy-gauge PVC or reinforced nylon offer superior resistance to punctures and abrasions compared to thinner materials. Proper inflation, avoiding overloading, and protecting the mattress from sharp objects are crucial for extending its lifespan.

Question 2: How critical is size compatibility when selecting a pickup bed inflatable mattress?

Accurate size matching is paramount. Mismatched dimensions can result in improper inflation, compromised comfort, and potential damage to the product or the truck bed. Measure the truck bed’s internal dimensions, accounting for wheel wells and other obstructions, before making a purchase.

Question 3: What types of inflation systems are commonly found in these mattresses?

Options include integrated electric pumps, manual inflation valves, and hybrid systems. Integrated pumps offer convenience, while manual valves provide independence from electrical power. Inflation time, efficiency, and pressure regulation capabilities vary among systems and should be considered based on user needs.

Question 4: Why is weight capacity a significant consideration when using a pickup bed inflatable mattress?

Exceeding the specified weight limit can cause material stress, deformation, and potential failure. It also voids the warranty and increases the risk of injury due to compromised support and stability. Adhering to weight restrictions is crucial for safety and product longevity.

Question 5: What steps can be taken to properly store a pickup bed inflatable mattress?

Deflate the mattress completely, clean it thoroughly, and store it in a cool, dry place away from direct sunlight and sharp objects. Use the provided storage bag and compression straps to minimize storage volume and prevent damage. Proper storage prevents deterioration and extends the product’s lifespan.

Question 6: How should minor punctures or air leaks in a pickup bed inflatable mattress be addressed?

Most mattresses include a repair kit containing patches and adhesive. Clean the affected area, apply the adhesive and patch according to the manufacturer’s instructions, and allow sufficient time for the adhesive to cure before reinflating. For larger or more complex repairs, professional repair services may be necessary.

Understanding these aspects of pickup bed inflatable mattresses ensures responsible usage and maximizes the product’s benefits.

The subsequent section covers potential issues, troubleshooting techniques, and maintenance practices.

Concluding Remarks

This exploration of the pickup bed inflatable mattress has underscored the importance of meticulous selection, responsible usage, and diligent maintenance. Key considerations encompass material durability, inflation system efficacy, accurate size compatibility, adherence to weight capacity limitations, and storage compactness. Understanding these factors is paramount for maximizing product lifespan, ensuring user safety, and optimizing the return on investment.

The informed consumer recognizes that a pickup bed inflatable mattress represents a significant investment, requiring careful consideration and proactive care. Failure to prioritize these elements can lead to diminished performance, premature failure, and potential safety hazards. Ongoing advancements in materials and design offer the potential for enhanced durability, comfort, and convenience. Therefore, continuous evaluation of product specifications and adherence to recommended practices are essential for realizing the full potential of this versatile mobile sleeping solution.

![Best Truck Bed Inflatable Mattress [Deals] for Comfortable Sleep Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Truck Bed Inflatable Mattress [Deals] for Comfortable Sleep | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7233-300x200.jpg)