A sleeping surface designed for placement within the cargo area of a pickup truck provides a mobile and adaptable solution for rest. These surfaces often consist of foam or inflatable materials, tailored to conform to the contours of a truck bed. An example includes a custom-cut foam pad fitting snugly between the wheel wells of a standard pickup, allowing for comfortable overnight stays during camping trips or long drives.

The importance of a comfortable sleeping arrangement in a truck bed stems from the increasing popularity of vehicle-based adventures and cost-effective travel. Such a setup allows for spontaneous lodging, eliminating the need for pre-booked accommodations. Historically, travelers have relied on rudimentary bedding in vehicles; however, modern iterations prioritize ergonomics and convenience, offering enhanced comfort and protection from the elements.

This article will explore the various types of sleeping solutions for truck beds, discussing their materials, dimensions, installation, and maintenance. Furthermore, it will examine the factors to consider when selecting a truck bed sleeping surface, including cost, durability, and compatibility with different truck models.

Tips for Selecting and Maintaining a Truck Bed Sleeping Surface

Optimal utilization and longevity of a sleeping surface within a pickup truck bed require careful consideration of several factors. These tips provide guidance on selection, installation, and maintenance practices.

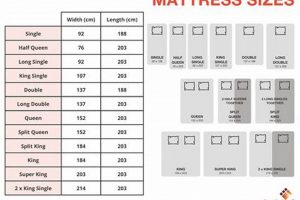

Tip 1: Measure the Truck Bed Accurately: Prior to purchasing a sleeping surface, precise measurements of the truck bed are essential. This includes length, width (between wheel wells), and depth. Accurate measurements ensure a proper fit, preventing slippage and maximizing available space.

Tip 2: Consider Material Properties: Sleeping surfaces are available in various materials, including foam, air mattresses, and combinations thereof. Foam offers consistent support and durability, while air mattresses provide adjustable firmness. The intended use (e.g., frequent camping vs. occasional use) should inform the material selection.

Tip 3: Evaluate Thickness and Density: For foam mattresses, higher density translates to greater support and longevity. A thicker mattress generally provides increased comfort, especially for individuals with joint pain or back problems. Balance thickness with available headroom within the truck bed.

Tip 4: Assess Weather Resistance: If the sleeping surface will be exposed to the elements, prioritize water-resistant or waterproof materials. This prevents moisture absorption, which can lead to mold growth and material degradation. Consider a waterproof cover for added protection.

Tip 5: Prioritize Proper Ventilation: Enclosed truck beds can trap moisture, leading to condensation and discomfort. Employ ventilation strategies such as slightly opening the truck bed cover or utilizing a moisture-wicking mattress pad to promote airflow.

Tip 6: Secure the Sleeping Surface: Prevent shifting during travel by securing the sleeping surface. Options include non-slip mats, straps, or custom-fitted designs that conform to the truck bed contours. A secure surface enhances safety and prevents damage.

Tip 7: Clean Regularly: Periodic cleaning prevents the accumulation of dirt, debris, and moisture. Vacuuming or wiping down the surface with a mild cleaning solution is recommended. Follow the manufacturer’s instructions for specific cleaning procedures.

Adherence to these tips enhances the comfort, durability, and safety of a truck bed sleeping surface, ensuring a more enjoyable and cost-effective experience. Proper selection and maintenance translate to long-term value.

The following sections will delve into common issues and troubleshooting techniques related to truck bed sleeping surfaces.

1. Dimensions

The dimensions of a sleeping surface intended for a truck bed directly influence its usability and comfort. Inaccurate measurements can render the item unusable, either by being too large to fit or too small, resulting in wasted space and potential instability. For example, a standard full-size truck bed often features a length of approximately 8 feet, while short beds measure around 5.5 to 6.5 feet. A sleeping surface designed for the former will not adequately fit the latter, creating a hazardous and uncomfortable sleeping environment. Thus, precise dimensional compatibility is paramount for safe and effective use.

Variations in truck bed design, such as the presence of wheel wells, also necessitate careful consideration of dimensions. A rectangular mattress, for instance, might not fully utilize the available space due to the intrusion of wheel wells. Custom-designed surfaces, tailored to the specific contours of the truck bed, maximize usable sleeping area. Furthermore, the height or thickness of the mattress impacts headroom within the truck bed, particularly when used with a truck bed cover or camper shell. Optimizing dimensions, therefore, balances available space, comfort, and practicality.

In summary, the dimensions of a sleeping surface are a critical determinant of its suitability for a truck bed. Ensuring dimensional accuracy promotes safety, comfort, and efficient use of available space. Failure to account for these dimensional constraints can lead to discomfort, instability, and ultimately, the ineffectiveness of the intended sleeping arrangement. The connection between truck bed dimensions and sleeping surface dimensions is therefore a fundamental consideration when selecting or designing such a product.

2. Materials

The choice of materials fundamentally dictates the performance characteristics and longevity of a sleeping surface intended for a truck bed. This selection process directly influences comfort, durability, water resistance, and overall suitability for its intended purpose. For example, open-cell foam mattresses, while offering excellent breathability, are susceptible to moisture absorption, making them less suitable for environments with high humidity or potential exposure to rain. Conversely, closed-cell foam provides superior water resistance but may lack the breathability necessary for comfortable sleep in warmer conditions. The material, therefore, is not merely a component; it is the defining factor in the sleeping surface’s utility.

Real-world applications demonstrate the practical significance of understanding material properties. Consider the use of high-density memory foam, known for its ability to conform to body contours and distribute weight evenly. While providing exceptional comfort for individuals with back pain, memory foam can be heavier and less compressible than other options, potentially impacting portability and ease of storage. Alternatively, inflatable air mattresses offer adjustable firmness and portability, but are vulnerable to punctures and require a power source for inflation, t

hus limiting their applicability in remote locations without access to electricity. The selection of material thus involves a trade-off between various performance attributes, necessitating careful consideration of individual needs and environmental conditions.

In conclusion, the materials used in constructing a truck bed sleeping surface are critical to its overall performance and suitability. Understanding the properties of different materials allows for informed decision-making, balancing factors such as comfort, durability, water resistance, and portability. Challenges arise in identifying materials that offer a comprehensive blend of desirable characteristics, often requiring compromises based on specific use cases. However, a thorough understanding of material science remains paramount for optimizing the design and functionality of sleeping solutions for truck beds.

3. Comfort

Comfort, in the context of a sleeping surface intended for a truck bed, directly impacts the quality of rest and overall user experience. A lack of adequate comfort can result in restless sleep, muscle stiffness, and fatigue, negating the primary purpose of such a provision. The quality of the mattress directly affects spinal alignment and pressure point relief, thus determining whether the user wakes refreshed or experiences discomfort. For example, a thin, unsupportive mattress placed directly on the corrugated surface of a truck bed provides inadequate cushioning, leading to pressure on hips, shoulders, and the spine. The correlation between the quality of the sleeping surface and the resulting comfort level is therefore a direct and influential relationship.

Real-world applications illustrate the practical significance of prioritizing comfort. Truck drivers, for instance, often rely on truck bed mattresses for rest during long hauls. A properly designed mattress can mitigate the physical strain associated with extended driving, improving alertness and reducing the risk of accidents. Conversely, an uncomfortable mattress can exacerbate fatigue, impairing cognitive function and increasing the likelihood of errors. Similarly, outdoor enthusiasts who utilize truck bed setups for camping benefit from the restorative effects of a comfortable sleep environment, enhancing their overall enjoyment of the experience. The ergonomic design, material composition, and dimensional fit of the mattress are critical factors that collectively contribute to the overall sense of comfort.

In conclusion, comfort is not merely a luxury but an essential attribute of a sleeping surface within a truck bed. It directly affects the user’s physical well-being and ability to perform tasks requiring focus and stamina. Challenges arise in balancing comfort with other desirable qualities such as durability, portability, and affordability. However, the prioritization of comfort, achieved through careful design and material selection, remains a fundamental consideration for ensuring a satisfactory and beneficial user experience.

4. Durability

Durability is a paramount consideration in the context of a sleeping surface designed for placement within a pickup truck bed. The inherent exposure to environmental factors and the demands of frequent use necessitate a robust construction capable of withstanding wear and tear. The lifespan and performance of the mattress are directly contingent upon its ability to resist degradation under such conditions.

- Material Resistance to Abrasion and Tearing

The composition of the outer shell material significantly impacts resistance to abrasion from the truck bed surface and potential tearing caused by sharp objects or repeated compression. High-denier fabrics, reinforced seams, and durable coatings enhance the material’s ability to withstand physical stresses, extending the usable life of the sleeping surface. For example, a vinyl-coated nylon material provides better abrasion resistance than a standard cotton fabric.

- Resistance to Environmental Degradation

Exposure to sunlight, moisture, and temperature fluctuations can accelerate the degradation of mattress materials. Ultraviolet radiation can cause fading and weakening of fabrics, while moisture promotes mold growth and material breakdown. Materials treated with UV inhibitors and waterproof coatings offer increased protection against environmental damage. Consider the effects of prolonged sun exposure on an untreated foam mattress versus one designed with UV resistant materials.

- Structural Integrity of Seams and Fastenings

The strength and construction of seams and fastenings are critical to maintaining the structural integrity of the mattress. Weak seams are prone to splitting under stress, while poorly attached fasteners can detach, compromising the mattress’s functionality. Reinforced stitching, durable zippers, and robust buckles contribute to a more resilient and long-lasting design. The quality of seams is immediately apparent when comparing mattresses with single- versus double-stitched construction.

- Compression Resistance of Filling Materials

The filling material’s ability to resist compression over time directly influences the mattress’s comfort and support. Low-quality foams can compress permanently, resulting in a loss of cushioning and a reduction in the overall sleeping quality. High-density foams and resilient air chambers maintain their shape and support, even after repeated use. The firmness of a new mattress versus one that has been heavily used highlights the effects of compression on the internal filling.

In conclusion, the durability of a sleeping surface for a pickup truck bed is a multifaceted attribute influenced by material selection, construction techniques, and resistance to environmental factors. Prioritizing durable materials and robust construction methods ensures a longer lifespan, improved performance, and a more cost-effective solution over time. A mattress designed with durability in mind provides a reliable and comfortable sleeping environment, regardless of the conditions encountered within the truck bed.

5. Water Resistance

Water resistance is a critical performance characteristic of any sleeping surface intended for use in the bed of a pickup truck. The open cargo area exposes the mattress to potential precipitation, humidity, and spills, necessitating a design that mitigates water absorption and damage. Effective water resistance preserves the integrity of the mattress, preventing mold growth, material degradation, and discomfort.

- Material Impermeability

The inherent water resistance of the surface material directly impacts its ability to repel moisture. Tightly woven synthetic fabrics like polyester or nylon, often coated with polyurethane or vinyl, provide a barrier against water penetration. Natural fibers, such as cotton, are highly absorbent and unsuitable without significant treatment. Consider the difference in water repellency between a canvas tarp and a coated nylon tent; the principle applies directly to mattress materials.

- Seam Sealing

Sewn seams represent a potential entry point for water, compromising the overall water resistance of the mattress.

Seam sealing, through the application of waterproof tape or liquid sealant, effectively closes these gaps, preventing moisture from wicking into the mattress core. The absence of seam sealing can negate the water-resistant properties of the surface material, rendering the mattress vulnerable to water damage despite its external protection. - Core Material Properties

Even with a water-resistant outer layer, the core material’s susceptibility to moisture is a significant factor. Open-cell foam readily absorbs water, leading to mold and mildew growth. Closed-cell foam, air chambers, or treated synthetic fillings offer better resistance to moisture absorption. A waterlogged mattress loses its structural integrity, becomes heavier, and provides a breeding ground for microorganisms, making the selection of appropriate core materials essential.

- Protective Covers and Treatments

The application of a waterproof or water-resistant cover provides an additional layer of protection against moisture. These covers, typically constructed from coated fabrics or waterproof membranes, encase the mattress, preventing water from reaching the core material. Regular application of water-repellent treatments can further enhance the surface’s ability to shed water. A simple cover can significantly extend the life of a mattress exposed to unpredictable weather conditions.

The integration of these water-resistant facets is essential for ensuring the longevity and usability of a sleeping surface within the demanding environment of a pickup truck bed. Prioritizing water resistance through material selection, seam sealing, core material properties, and protective covers safeguards the mattress from moisture damage, promoting comfort and preventing the growth of harmful microorganisms.

6. Portability

Portability, in the context of a sleeping surface designed for a pickup truck bed, denotes the ease with which the item can be transported, stored, and deployed. The limited cargo space often available within a truck, coupled with the potential need for frequent relocation, underscores the significance of this characteristic. A lack of portability can negate the benefits of having a dedicated sleeping arrangement, rendering it impractical for many users.

- Weight and Volume

The weight and packed volume of a sleeping surface are primary determinants of its portability. Lighter and more compact options are inherently easier to transport and store, particularly when other cargo occupies the truck bed. High-density foam mattresses, while offering superior comfort, often exhibit substantial weight and volume, posing challenges for single-person handling and storage. Conversely, inflatable air mattresses, when deflated, occupy minimal space and weigh significantly less, enhancing their portability despite potential compromises in comfort.

- Integrated Carry Systems

The presence of integrated carry systems, such as handles, straps, or dedicated carrying bags, directly facilitates the transportation of the sleeping surface. These features enhance the ease of handling and prevent damage during transit. A bulky mattress lacking integrated carry options can be unwieldy and susceptible to tearing or contamination during handling. Conversely, a mattress equipped with robust handles and a protective carrying case can be transported with minimal effort and risk of damage.

- Ease of Inflation/Deflation

For inflatable mattresses, the speed and ease of inflation and deflation significantly impact their overall portability. Mattresses requiring manual inflation or deflation processes are less convenient and more time-consuming to set up or pack away. Electric pumps or integrated inflation systems streamline the process, enhancing portability and user convenience. The difference in setup time between a self-inflating mattress and one requiring manual pumping underscores the practical significance of this facet.

- Storage Requirements

The storage requirements of a sleeping surface, when not in use, directly influence its practicality. Mattresses that can be tightly rolled or folded into a compact form factor minimize storage space. Rigid or bulky mattresses may require dedicated storage areas, potentially limiting their suitability for individuals with limited storage capacity. The ability to store a deflated air mattress in a small compartment versus the need to dedicate a large storage area for a bulky foam mattress highlights the differential impact of storage requirements on portability.

Collectively, these facets contribute to the overall portability of a sleeping surface intended for a pickup truck bed. A balanced consideration of weight, volume, carry systems, inflation/deflation mechanisms, and storage requirements enables users to select a mattress that aligns with their specific transportation and storage constraints. The prioritization of portability enhances the practicality and convenience of a sleeping arrangement, maximizing its utility for a wide range of applications.

7. Security

Security, when considered in conjunction with a sleeping surface placed within a pickup truck bed, encompasses both the protection of the mattress itself from theft or damage and the safety of the occupant utilizing the sleeping arrangement. The open nature of a truck bed introduces vulnerabilities that must be addressed to ensure a secure and comfortable experience.

- Theft Prevention Measures

The risk of theft necessitates measures to secure the sleeping surface when the vehicle is unattended. Unsecured mattresses are easily removed, representing a significant loss to the owner. Solutions include locking truck bed covers, cable locks threaded through the mattress and anchored to the truck bed, or storing the mattress within the cab when not in use. A visible deterrent, such as a locked cover, can discourage potential thieves, mitigating the risk of theft.

- Secure Mounting and Restraint Systems

An improperly secured mattress can shift during transit, posing a hazard to the occupant and potentially causing damage to the truck bed or mattress. Restraint systems, such as straps, nets, or custom-fitted designs, prevent movement and maintain the stability of the sleeping surface. A secure mounting system also prevents the mattress from being ejected from the truck bed in the event of an accident, enhancing safety for both the occupant and other drivers.

- Privacy and Concealment

For individuals utilizing a truck bed mattress for overnight stays, privacy is a primary security concern. Truck bed covers, camper shells, or window coverings offer concealment from public view, reducing the risk of unwanted attention or intrusion. Tinted windows and opaque covers provide a visual barrier, enhancing the occupant’s sense of security and deterring potential disturbances.

- Protection Against the Elements

Environmental factors, such as severe weather, can compromise both the mattress and the occupant’s safety. A waterproof truck bed cover shields the sleeping surface from rain, snow, and wind, preventing damage and maintaining a dry, comfortable environment. In extreme conditions, relocation to a more secure location may be necessary, but a robust cover provides a critical layer of protection.

These

facets underscore the multifaceted nature of security in the context of a truck bed sleeping surface. Addressing concerns related to theft, secure mounting, privacy, and environmental protection is essential for ensuring a safe, comfortable, and reliable sleeping arrangement within a pickup truck bed. Integrating these security measures enhances the practicality and peace of mind for individuals utilizing this mobile sleeping solution.

Frequently Asked Questions

This section addresses common inquiries regarding sleeping surfaces intended for pickup truck beds. The aim is to provide clear and concise answers to facilitate informed decision-making.

Question 1: What mattress dimensions are appropriate for a standard pickup truck bed?

Appropriate dimensions vary depending on the specific truck model and bed length. Measuring the truck bed’s interior dimensions, particularly between the wheel wells, is essential prior to selecting a mattress. Short beds typically require mattresses around 75 inches in length, while long beds may accommodate mattresses up to 80 inches or more. Custom-cut mattresses ensure optimal fit and space utilization.

Question 2: What materials are best suited for a pickup bed mattress, considering outdoor exposure?

Materials with inherent water resistance and durability are preferable. Closed-cell foam, coated nylon fabrics, and vinyl offer protection against moisture and abrasion. Cotton and open-cell foam are generally unsuitable due to their absorbent properties. UV-resistant treatments can further extend the lifespan of the mattress material.

Question 3: How can the comfort of a pickup bed mattress be maximized?

Comfort can be enhanced through the selection of high-density foam, the incorporation of memory foam layers, or the use of adjustable air chambers. A sufficient mattress thickness (at least 4 inches) provides adequate cushioning and support. A smooth, non-abrasive surface material further contributes to a comfortable sleeping experience.

Question 4: What measures can be taken to secure a pickup bed mattress and prevent theft?

Security measures include the use of locking truck bed covers, cable locks threaded through the mattress and secured to the truck bed, and storing the mattress within the cab when not in use. Visible deterrents, such as alarms or security cameras, can further discourage potential thieves.

Question 5: How should a pickup bed mattress be cleaned and maintained to prolong its lifespan?

Regular cleaning with a mild detergent and water is recommended to remove dirt and debris. Thorough drying prevents mold and mildew growth. Protective covers should be used to minimize exposure to moisture and sunlight. Following the manufacturer’s instructions for specific cleaning procedures is crucial.

Question 6: Are there specific regulations or guidelines regarding sleeping in a pickup truck bed?

Regulations vary depending on local laws and jurisdictions. It is advisable to research local ordinances regarding camping or sleeping in vehicles within specific areas. Adhering to established safety guidelines, such as avoiding carbon monoxide exposure and ensuring proper ventilation, is essential for occupant safety.

These FAQs provide a fundamental understanding of considerations pertaining to sleeping surfaces within pickup truck beds. Careful attention to dimensions, materials, comfort, security, maintenance, and regulations ensures a safe and satisfactory experience.

The subsequent section will address troubleshooting common issues associated with truck bed sleeping arrangements.

Conclusion

This exploration has presented various facets of the pickup bed mattress, ranging from material composition and dimensional considerations to crucial aspects of security and maintenance. The analysis underscores the necessity of informed decision-making when selecting and utilizing such a sleeping arrangement. Factors such as comfort, durability, and water resistance are not merely desirable features, but rather essential attributes that directly impact the user’s well-being and the longevity of the product.

The efficacy of a pickup bed mattress is contingent upon a comprehensive understanding of its limitations and potential. Prudent selection and responsible use remain paramount. Further research and development in materials and design may yield enhancements in comfort, security, and environmental resilience, expanding the utility and adoption of this mobile sleeping solution. Prioritizing safety and practicality will define the future of the pickup bed mattress as a viable alternative for rest and recreation.

![Best Toyota Tacoma Bed Air Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Toyota Tacoma Bed Air Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7271-300x200.jpg)