A large-sized bed featuring an additional layer of cushioning sewn onto the top surface constitutes a specific bedding configuration. This design aims to enhance comfort by providing a softer initial feel for the sleeper. Such a sleeping arrangement is frequently sought after for its luxuriousness and potential to improve sleep quality through enhanced pressure relief.

The appeal of these large, cushioned sleeping surfaces stems from their capacity to offer both support and a plush sleeping experience. Historically, mattresses prioritized firm support. The introduction of enhanced comfort layers represents a shift towards accommodating preferences for a gentler sleep surface. Benefits often cited include reduced pressure on joints, potential alleviation of back pain, and an overall perception of increased sleep quality due to the enhanced comfort.

The following sections will delve into the construction specifics, material composition, maintenance guidelines, and factors to consider when selecting a mattress of this type. Further discussion will explore common issues, warranty considerations, and price points associated with this specific bed size and comfort feature.

Selection and Care Tips for Enhanced Comfort Mattresses

Optimizing the longevity and comfort of a specific large-dimension, cushioned mattress requires careful consideration during selection and adherence to appropriate maintenance practices. The following tips provide guidance for prospective purchasers and current owners.

Tip 1: Evaluate Support System Integrity: Assess the quality of the underlying support core. The top layer’s comfort is contingent on a stable and durable foundation. Inquire about coil count, gauge, and construction type (e.g., pocketed coils, continuous coils) as these factors directly influence the support system’s ability to provide proper spinal alignment.

Tip 2: Consider Material Composition: Investigate the materials used in both the comfort layer and the support core. High-density foams, natural latex, or memory foam often offer superior pressure relief and durability compared to lower-quality alternatives. Examine certifications, such as CertiPUR-US, to ensure materials are free from harmful chemicals.

Tip 3: Account for Sleep Position: Different sleep positions necessitate varying degrees of support and cushioning. Side sleepers may benefit from a thicker comfort layer to alleviate pressure on hips and shoulders. Back sleepers often require a firmer foundation with moderate cushioning for optimal spinal alignment. Stomach sleepers typically need the firmest support to prevent excessive sinking.

Tip 4: Inquire About Warranty Coverage: Thoroughly review the manufacturer’s warranty. Pay close attention to covered defects, duration of coverage, and any specific exclusions. A comprehensive warranty indicates the manufacturer’s confidence in the product’s durability and can provide recourse in case of premature failure.

Tip 5: Utilize a Mattress Protector: Employ a high-quality mattress protector to safeguard against spills, stains, and dust mites. A waterproof and breathable protector can significantly extend the lifespan of the mattress and maintain a hygienic sleep environment.

Tip 6: Rotate Regularly: Rotate the mattress every 3-6 months to promote even wear and prevent localized sagging. This practice helps distribute weight more uniformly across the surface and can prolong the overall comfort and support provided.

Tip 7: Ensure Proper Bed Frame Support: Verify that the bed frame adequately supports the mattress. Insufficient support can compromise the mattress’s structure and void the warranty. A center support beam is crucial for mattresses of this size to prevent sagging in the middle.

Following these guidelines will help to ensure the selection of a high-quality mattress that provides lasting comfort and support, ultimately contributing to improved sleep quality and overall well-being.

The subsequent sections will address common concerns regarding maintenance, cleaning, and troubleshooting potential issues to further extend the life and performance of the chosen mattress.

1. Size and Dimensions

The physical dimensions of a sleeping surface are of fundamental importance, especially when considering a large configuration with an integrated comfort layer. The specified size impacts bedroom space requirements, suitability for multiple occupants, and the overall sleep experience.

- Standard Dimensions and Spatial Requirements

The standard size measures approximately 76 inches in width and 80 inches in length. This sizable footprint necessitates adequate bedroom square footage to ensure comfortable movement around the bed. A room too small for such a bed can feel cramped and limit accessibility. Measuring the intended space prior to purchase is critical.

- Impact on Co-Sleeping

These sleeping surfaces offer ample space for two adults, minimizing sleep disturbance from partner movement. The width allows each sleeper sufficient personal space, reducing the likelihood of accidental contact and promoting individual sleep quality. Couples who value personal space during sleep often find a large sleeping configuration beneficial.

- Sheet and Bedding Compatibility

The dimensions necessitate the use of appropriately sized sheets, blankets, and comforters. Standard-sized bedding is designed to fit these mattresses. Using undersized bedding can result in inadequate coverage, discomfort, and potential damage to the mattress.

- Weight and Handling Considerations

Mattresses of this type tend to be heavy and cumbersome, due to their size and construction. This can complicate transportation, installation, and rotation. Proper lifting techniques and potentially professional assistance may be required to avoid injury or damage.

The interplay between the precise dimensions, bedroom space, co-sleeping needs, bedding requirements, and logistical considerations associated with handling collectively define the practical suitability of such a mattress. Prioritizing careful measurement and assessment of individual needs ensures a well-informed purchase decision.

2. Comfort Layer Material

The materials comprising the uppermost cushioning section represent a critical determinant of the overall comfort and performance characteristics of a large mattress featuring a sewn-on layer. The selection of these materials profoundly influences pressure relief, temperature regulation, and durability, thereby impacting the sleeper’s experience.

- Memory Foam: Viscoelastic Properties and Conformity

Memory foam is renowned for its ability to conform closely to the body’s contours, distributing weight evenly and reducing pressure

points. This characteristic can provide significant relief for individuals experiencing joint pain or seeking enhanced spinal alignment. However, its density can sometimes lead to heat retention, potentially causing discomfort for sleepers prone to overheating. Advancements in memory foam technology, such as gel infusions and open-cell structures, attempt to mitigate this issue. - Latex: Natural Resilience and Breathability

Latex, derived from rubber trees, offers a naturally resilient and supportive feel. It possesses inherent breathability, promoting airflow and minimizing heat buildup. Latex is available in two primary forms: Dunlop and Talalay. Dunlop is denser and firmer, while Talalay is softer and more consistent. Latex is often favored for its durability and resistance to dust mites and allergens.

- Polyurethane Foam: Versatility and Cost-Effectiveness

Polyurethane foam is a synthetic material widely used in mattresses due to its versatility and relatively low cost. It can be manufactured in varying densities and firmness levels to achieve different comfort characteristics. While polyurethane foam can provide adequate cushioning, it typically lacks the durability and pressure-relieving properties of memory foam or latex. Higher-density polyurethane foams offer improved performance compared to lower-density options.

- Fiberfill Blends: Softness and Enhanced Surface Feel

Fiberfill blends, often incorporating materials such as polyester or cotton, are frequently used to create a plush surface feel in large mattresses with added comfort layers. These blends contribute to initial softness but may compress over time, potentially reducing long-term support. Fiberfill blends are typically more affordable than foam or latex and can enhance breathability, but they generally offer less pressure relief.

The choice of material for the comfort layer directly dictates the perceived comfort level, support characteristics, and longevity of the mattress. A comprehensive understanding of these materials’ properties enables consumers to make informed decisions aligned with their individual needs and preferences, ensuring a satisfactory sleeping experience on their large enhanced-comfort bed.

3. Support Core Construction

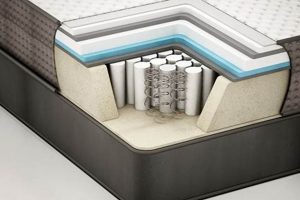

The support core within a large mattress with a sewn-on cushioning layer constitutes the primary structural element dictating overall stability, spinal alignment, and longevity. The design and materials employed in this core directly counteract the potential for sagging or uneven wear, which can be exacerbated by the added plushness of the uppermost layer. Inadequate support core construction renders the additional cushioning ineffective and may lead to premature degradation of the mattress’s comfort properties. For instance, a coil system with insufficient gauge steel may deform under the weight of sleepers, resulting in a hammock-like sleeping surface that negates the intended pressure relief provided by the top layer. Conversely, a high-density foam core can maintain its shape and integrity for an extended period, preserving the intended comfort and support balance.

Practical examples highlight the significance of the support core. Consider two mattresses: one with a low-density foam core and another with individually pocketed coils. The former, while initially comfortable, may develop body impressions within a year or two, causing uneven support and discomfort. The latter, with its independent coil movement, can conform to the sleeper’s body while maintaining consistent support across the entire surface. This is particularly important for couples with differing body weights, as the independent coils minimize motion transfer and prevent one sleeper from rolling towards the other. The number of coils, the coil gauge (thickness), and the zoning (varying firmness in different areas) are all crucial factors influencing the core’s performance.

In summary, the support core’s construction represents the foundational element underpinning the comfort provided by a large mattress with an integrated cushioning layer. Its design directly influences the mattress’s ability to provide sustained support, proper spinal alignment, and long-term durability. Understanding the intricacies of coil systems, foam densities, and zoning configurations empowers consumers to make informed choices, ensuring that the mattress delivers the intended benefits throughout its lifespan and prevents premature degradation of the comfort layers. The core ensures that all the benefits of the pillow top can be fully realized.

4. Edge Support Systems

Edge support systems are integral to the functionality and longevity of a large mattress with an integrated cushioning layer. The perimeter of a mattress often experiences concentrated pressure from individuals sitting on the edge or sleeping near it. Without adequate reinforcement, the edges of the mattress are prone to sagging and compression, reducing the usable sleeping surface and compromising overall support. In a large, cushioned mattress, this issue is amplified due to the increased weight and plushness of the top layer, which can exacerbate edge deformation if not properly addressed. The presence of a robust edge support system is, therefore, not merely a comfort enhancement but a structural necessity for maintaining the mattress’s integrity and usable area over time.

Several edge support technologies are available, each offering varying degrees of effectiveness. Reinforced foam encasements, steel perimeter wires, and strategically placed high-density coils are common solutions. A foam encasement surrounds the spring unit, providing a firm, supportive edge that resists compression. Steel perimeter wires, typically clipped to the outer coils, create a rigid boundary that prevents the edges from collapsing. High-density coils placed along the perimeter offer targeted support to withstand edge pressure. For instance, consider two identical mattresses, one with reinforced foam encasement and one without. Over time, the mattress without edge support is likely to exhibit noticeable sagging along the perimeter, reducing the effective sleeping surface and potentially causing individuals to roll off the edge during sleep. In contrast, the mattress with a foam encasement will maintain its shape and provide consistent support across the entire surface, maximizing usable space and promoting a more secure sleep experience.

The integration of effective edge support in a large mattress with a sewn-on comfort layer is crucial for sustained comfort, structural integrity, and optimal utilization of the entire sleeping surface. The selection of an appropriate edge support system mitigates the risk of edge sagging, extends the mattress’s lifespan, and enhances the overall sleep experience by providing a consistent and supportive sleeping surface from edge to edge. In conclusion, the presence and quality of edge support constitute a significant factor in evaluating the long-term performance and value of a mattress of this type, transforming it from a potentially problematic weakness into a valued strength.

5. Temperature Regulation

Temperature regulation within

a large mattress featuring an integrated comfort layer is a critical factor influencing sleep quality and overall comfort. The materials utilized in the construction of the added layer, as well as the mattress’s core, directly impact its capacity to dissipate heat and maintain a stable sleep environment. Inadequate temperature regulation can lead to overheating, night sweats, and disrupted sleep patterns, thereby negating the intended benefits of enhanced cushioning. The increased surface area and potentially denser materials of such mattresses can exacerbate heat retention issues, making material selection and design features that promote airflow particularly important.

Specific materials and construction techniques play a significant role in managing temperature. Traditional memory foam, for instance, is known for its heat-retentive properties, often trapping body heat and leading to discomfort. In contrast, latex, particularly Talalay latex, exhibits greater breathability due to its open-cell structure, facilitating airflow and reducing heat buildup. Similarly, mattresses incorporating gel-infused memory foam or those designed with ventilated channels aim to improve airflow and dissipate heat more effectively. Furthermore, the type of cover material used can influence temperature regulation. Breathable fabrics like cotton or bamboo allow for better air circulation compared to synthetic materials, contributing to a cooler sleeping surface. A practical example involves two individuals sleeping on similar mattresses, one constructed with traditional memory foam and the other with gel-infused memory foam and a breathable cover. The individual on the former mattress may experience overheating and discomfort, while the individual on the latter mattress is more likely to maintain a comfortable sleep temperature throughout the night.

In summary, the ability of a large mattress with an added comfort layer to effectively regulate temperature is crucial for optimizing sleep quality. Material selection, construction techniques, and cover fabric all contribute to the mattress’s thermal performance. Prioritizing mattresses designed with breathable materials and ventilation features mitigates the risk of overheating, ensuring a more comfortable and restorative sleep experience. The optimization of temperature regulation ensures that the enhanced comfort features of a large, cushioned mattress contribute to a more restful night, as intended.

6. Motion Isolation Properties

The capacity to minimize the transfer of movement across the surface represents a significant attribute, particularly in large-sized mattresses featuring an added comfort layer. Enhanced cushioning can, paradoxically, either amplify or dampen motion transfer depending on the underlying construction and materials employed. Therefore, the effective isolation of movement is a crucial consideration for co-sleepers seeking undisturbed rest.

- Role of Independent Coil Systems

Individually pocketed coils, wherein each spring operates independently, constitute a primary mechanism for reducing motion transfer. These systems allow localized compression and support without affecting the surrounding areas of the mattress. For instance, if one sleeper shifts position, the corresponding movement is largely absorbed by the individual coils beneath them, minimizing disturbance to their partner. This contrasts with interconnected coil systems, where movement in one area can propagate across the entire mattress surface.

- Influence of Foam Density and Composition

The density and composition of the foam layers, particularly the comfort layer, also play a significant role in motion isolation. High-density memory foam, due to its viscoelastic properties, tends to absorb movement more effectively than lower-density polyurethane foams. The close conformity of memory foam to the body minimizes the potential for movement to ripple across the mattress. Latex foam, while offering excellent support and responsiveness, may exhibit slightly less motion isolation compared to high-density memory foam, depending on its specific density and construction.

- Impact of Mattress Construction and Layering

The overall construction of the mattress, including the layering of different materials, contributes to its motion isolation capabilities. A well-designed mattress typically incorporates a combination of materials optimized for both comfort and motion reduction. For example, a mattress might feature a top layer of high-density memory foam for motion absorption, followed by a layer of supportive latex for responsiveness, and an independent coil system for targeted support and minimized transfer. The synergistic effect of these combined elements enhances the overall effectiveness of motion isolation.

- Considerations for Co-Sleeping Dynamics

The effectiveness of motion isolation directly correlates to the dynamics of co-sleeping. Factors such as the weight difference between sleepers, their individual sleep habits, and the frequency of nighttime movements influence the perceived level of disturbance. A mattress with superior motion isolation is particularly beneficial for couples with significant weight disparities or those who are light sleepers easily awakened by movement. Proper mattress selection, considering these factors, promotes a more harmonious and restful sleep environment for both partners.

The selection of a king-sized mattress featuring a top layer necessitates a careful evaluation of its motion isolation properties. The interplay of independent coil systems, foam density, mattress construction, and co-sleeping dynamics collectively determines the extent to which movement is minimized and sleep disturbance is prevented. Prioritizing these factors ensures that the expanded sleep surface does not compromise individual sleep quality, thereby maximizing the benefits of the chosen mattress configuration.

7. Durability and Longevity

The inherent construction and materials of a mattress directly influence its capacity to withstand prolonged use and maintain its intended comfort and support characteristics. This consideration assumes heightened importance with the purchase of a large, cushioned mattress, given the associated investment and expectation of extended performance.

- Material Quality and Density

The density and quality of materials used in both the support core and the comfort layer critically impact a mattress’s lifespan. High-density foams, robust coil systems, and resilient fabrics are less prone to degradation and compression over time. Lower-quality materials are more susceptible to sagging, body impressions, and loss of support, thereby diminishing the mattress’s comfort and structural integrity. For example, a high-density memory foam with an ILD (Indentation Load Deflection) rating above a certain threshold, or a coil system constructed with heavy-gauge steel, will predictably maintain its shape and support characteristics longer than less robust alternatives.

- Construction Techniques and Reinforcement

The methods employed in constructing the mattress, including stitching patterns, edge reinforcement, and layering techniques, contribute significantly to its overall durability. Reinforced edges prevent sagging and increase the usable sleep surface, while robust stitching prevents

seams from unraveling. Proper layering ensures even weight distribution and minimizes stress on individual components. Mattresses that incorporate these advanced construction techniques tend to exhibit greater resilience and resistance to wear and tear, extending their functional lifespan. - Maintenance and Care Practices

Adhering to recommended maintenance and care practices can significantly extend the longevity of a mattress. Regular rotation, the use of a mattress protector, and proper support from the bed frame are essential for preventing premature wear and tear. Failure to follow these guidelines can accelerate the degradation of the mattress and void warranty coverage. For instance, a mattress that is not rotated regularly may develop localized sagging, while one exposed to spills and stains may experience material breakdown and reduced hygiene.

- Warranty Coverage and Expected Lifespan

The terms of the manufacturer’s warranty and the expected lifespan of the mattress provide insights into its anticipated durability. A comprehensive warranty, covering a range of potential defects, indicates the manufacturer’s confidence in the product’s quality. However, the warranty should be carefully reviewed, as it typically excludes normal wear and tear. The expected lifespan, based on industry standards and consumer reviews, offers a benchmark for assessing the mattress’s long-term value. While individual experiences may vary, a mattress with a documented history of longevity generally represents a more durable and reliable investment.

The interplay of material quality, construction techniques, maintenance practices, and warranty coverage collectively determines the long-term performance and value proposition of a large cushioned mattress. Prioritizing mattresses designed with durable materials and robust construction, coupled with diligent care, ensures a prolonged and satisfactory sleep experience. Ultimately, carefully considering these elements ensures that the substantial investment associated with such a mattress yields enduring comfort, support, and value over its intended lifespan.

Frequently Asked Questions

The following addresses commonly posed inquiries regarding mattresses with a sewn-on comfort layer in the specified size. The responses aim to provide objective and informative guidance to prospective purchasers and current owners.

Question 1: What is the expected lifespan of a pillow top mattress king, and how does it compare to other mattress types?

The anticipated lifespan typically ranges from 7 to 10 years, contingent upon material quality, construction, and maintenance. This lifespan aligns with that of other mattress types. However, the uppermost layer may exhibit compression or degradation earlier than the core, potentially impacting overall comfort.

Question 2: Are there specific weight restrictions associated with a mattress of this type?

While not explicitly restrictive, exceeding the manufacturer’s recommended weight capacity may accelerate wear and tear. Consult the product specifications for detailed information regarding weight limitations. Distributing weight evenly across the surface mitigates the risk of premature degradation.

Question 3: Does the comfort layer affect the suitability of the mattress for individuals with back pain?

The appropriateness for individuals with back pain hinges on the balance between support and cushioning. Excessive cushioning can compromise spinal alignment, exacerbating discomfort. Conversely, adequate cushioning can alleviate pressure points, promoting relief. A medium-firm support core coupled with a moderate comfort layer is generally recommended.

Question 4: How does the mattress’s height impact the choice of bedding and bed frames?

The increased height necessitates the acquisition of deep-pocketed sheets to ensure adequate coverage. Bed frames must provide sufficient support to accommodate the added weight and thickness. Adjustable bed frames may require specific compatibility verification to ensure proper functionality.

Question 5: What are the recommended cleaning and maintenance procedures to preserve its condition?

Regular vacuuming, the use of a mattress protector, and periodic rotation are recommended. Spot cleaning with a mild detergent is advisable for spills. Avoid prolonged exposure to moisture. Professional cleaning services may be necessary for deep stains or persistent odors.

Question 6: How does the price point compare to other king-size mattresses, and what factors influence the cost?

The price typically exceeds that of standard king-size mattresses due to the added comfort layer. Factors influencing cost include material quality, brand reputation, construction complexity, and features such as enhanced edge support or temperature regulation.

In summary, understanding the nuances of lifespan, weight restrictions, suitability for specific conditions, bedding compatibility, maintenance requirements, and pricing dynamics enables informed decision-making when considering a mattress with a sewn-on comfort layer in a large size.

The following sections will address warranty considerations and troubleshooting common issues to provide further guidance regarding the long-term care and performance of the chosen mattress.

Conclusion

The preceding analysis has detailed the multifaceted considerations inherent in selecting a large mattress with an integrated comfort layer. Factors ranging from material composition and support core construction to edge support systems and temperature regulation profoundly influence the sleeping experience. A comprehensive understanding of these elements is essential for informed decision-making.

The ultimate value proposition of a pillow top mattress king rests on its capacity to deliver sustained comfort, support, and durability. Prospective purchasers are encouraged to meticulously evaluate their individual needs and preferences, aligning their selection with mattresses that embody the characteristics outlined herein. The investment in quality bedding directly impacts sleep quality and overall well-being.

![Best King Mattress: Sealy Posturepedic [Guide & Review] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best King Mattress: Sealy Posturepedic [Guide & Review] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-8280-300x200.jpg)