A durable, inflatable sleeping surface designed to resist penetration by sharp objects characterizes a type of bedding suitable for both indoor and outdoor use. Constructed from reinforced materials, these items provide a portable and comfortable alternative to traditional beds, even in environments where sharp debris may be present. For example, such an item might be used in a camping setting where thorns or small rocks could potentially damage a conventional air mattress.

The inherent value lies in its extended lifespan and reduced maintenance. The minimization of air leakage translates to consistent support throughout the night and decreases the likelihood of needing repairs or replacements. Historically, advancements in polymer technology have contributed significantly to the development of increasingly resilient materials used in their manufacture, enabling a more reliable experience for users in varied contexts, including guest accommodations and temporary living spaces.

The following sections will delve into the specific materials used in construction, the testing procedures employed to ensure resistance, and the different models available, as well as provide guidance on selection and proper care.

Optimizing the Performance of Durable Air Mattresses

The effective utilization of a resilient inflatable sleeping surface necessitates adherence to specific guidelines. These tips aim to maximize longevity and ensure consistent performance.

Tip 1: Select Appropriate Location: Prior to inflation, carefully assess the surrounding area. Remove any sharp objects, such as rocks, twigs, or glass shards, from the intended placement site. Failure to do so may compromise the integrity of the protective layers.

Tip 2: Employ a Protective Layer: Even with reinforced construction, the addition of a ground cloth or blanket beneath the item provides an extra barrier against potential abrasions from the underlying surface. This is particularly important during outdoor use.

Tip 3: Avoid Over-Inflation: While rigidity is desirable, excessive inflation increases the stress on the seams and material. Consult the manufacturer’s instructions for recommended inflation levels and utilize a pressure gauge when possible.

Tip 4: Regulate Temperature Exposure: Extreme temperatures can affect the material’s properties. Direct sunlight or prolonged exposure to freezing conditions may lead to degradation over time. Store in a temperature-controlled environment when not in use.

Tip 5: Implement Proper Cleaning Procedures: Use a mild soap and water solution to clean the surface. Avoid harsh chemicals or abrasive cleaners, as these can damage the protective coating. Ensure the surface is thoroughly dry before storing.

Tip 6: Store Correctly: When deflated, fold the mattress neatly to minimize creases and stress points. Store in a dedicated bag or container to protect it from dust, pests, and physical damage.

Adhering to these measures can significantly extend the usable lifespan, maintaining a reliable sleeping surface. Preventative measures enhance long-term value.

The subsequent section offers a detailed examination of available models and their specific characteristics, enabling informed purchasing decisions.

1. Material Durability

Material durability is intrinsically linked to the functionality of resistant inflatable sleeping surfaces. The selection of materials directly influences the item’s ability to withstand sharp objects and abrasions. For instance, a mattress constructed from thin, non-reinforced PVC is significantly more susceptible to punctures than one fabricated with multiple layers of high-denier nylon or composite materials incorporating puncture-resistant additives. The correlation between material strength and penetration resistance is direct: stronger materials provide a more effective barrier against potential damage. Real-world applications exemplify this: a standard air mattress might fail quickly on a rocky campsite, whereas a model constructed with reinforced materials would likely remain functional.

Further illustrating this connection, consider the specific attributes of different materials. Thermoplastic polyurethanes (TPU) offer enhanced abrasion resistance compared to traditional PVC. Lamination techniques, where multiple layers of different materials are bonded together, can combine the benefits of each, creating a composite material superior to any single component. For example, a mattress with a TPU outer layer for abrasion resistance and a high-density polyethylene (HDPE) inner layer for puncture resistance offers a synergistic combination. The practical significance lies in the extended lifespan and enhanced reliability of the resulting product, reducing the frequency of repairs or replacements.

In conclusion, material durability is a critical determinant of the effectiveness. The choice of appropriate materials is paramount in achieving a puncture-resistant design, directly impacting its suitability for challenging environments and influencing its overall value proposition. While challenges exist in balancing material strength with weight and cost considerations, the pursuit of enhanced durability remains a central focus in the development of improved resilient inflatable bedding solutions.

2. Seam Strength

Seam integrity represents a critical factor in the overall performance of a resilient inflatable sleeping surface. The strength and construction of the seams dictate the structure’s ability to maintain inflation and withstand stress, particularly when subjected to weight and pressure after potential surface punctures. Its relevance should be highly addressed to make “puncture proof air mattress” has high quality.

- Welding Technique

Radio frequency (RF) welding or thermal welding methods are frequently employed to fuse the material layers together. The efficacy of the welding process directly influences the bond strength. Inadequate welding can lead to seam separation under load, negating the benefits of a puncture-resistant material. For instance, a mattress constructed from robust material but featuring poorly welded seams will likely fail prematurely.

- Seam Reinforcement

Reinforcement techniques, such as the addition of seam tape or fabric overlays, can significantly bolster seam strength. These reinforcements distribute stress and minimize the risk of tearing. High-stress areas, such as corners and edges, often benefit from additional reinforcement to prevent failure. This is particularly applicable in situations where the inflated item is used on uneven surfaces, increasing stress on specific seams.

- Seam Design

The geometrical design of the seam can also contribute to its strength. Overlapping seams or multi-stitched seams provide increased

resistance to tearing compared to simple butt seams. Interlocking seam designs enhance structural integrity by distributing pressure across a wider area, minimizing stress concentrations that could lead to failure. These designs mitigate the risk of seam failure even if the surrounding material sustains minor damage. - Material Compatibility

The compatibility of the materials being joined is a crucial consideration. Different materials may exhibit varying degrees of adhesion when subjected to welding or bonding processes. Incompatible materials can result in weak seams that are prone to separation. Selecting compatible materials and employing appropriate bonding agents or welding parameters are essential for ensuring optimal seam strength.

In conclusion, seam robustness plays a vital role in overall effectiveness and the durability of resistant inflatable bedding. The factors detailed abovewelding method, seam reinforcement, design, and material compatibilitycollectively determine the capacity to withstand sustained pressure. Ensuring that these seam-related aspects are thoroughly addressed is essential for producing inflatable structures capable of performing effectively in demanding environments.

3. Weight Capacity

Weight capacity is an important specification that directly affects performance and longevity, and must be evaluated in the context of an item resistant to punctures. The maximum supported load significantly influences the overall structural integrity and resistance to damage.

- Material Stress and Distribution

Weight applied to the surface of an inflatable item creates stress on the material and seams. Exceeding the designated weight capacity can lead to over-extension, material fatigue, and eventual failure. In a camping scenario, where two adults exceed the capacity, increased likelihood of seam rupture or material tearing is increased. Proper weight distribution also plays a role; concentrated loads increase stress in specific areas, while evenly distributed weight is less likely to cause damage.

- Impact on Puncture Resistance

While a material may be inherently resistant to punctures, exceeding the weight capacity compromises this resistance. Increased internal pressure from excessive weight stretches the material, making it thinner and more vulnerable to sharp objects. If the mattress is rated for 300 lbs and supports 400 lbs, the material becomes more susceptible to punctures from small rocks or debris underneath.

- Seam Integrity Under Load

The seams are often the weakest point in any inflatable structure. Exceeding the weight limit places undue stress on these seams, increasing the probability of separation or leakage. A reinforced seam design can mitigate this risk, but it cannot compensate for extreme overloading. A user close to the weight capacity should periodically check seams for signs of stress or separation.

- Long-Term Durability Implications

Consistently exceeding the weight capacity, even by a small margin, reduces the lifespan of the item. Repeated stress cycles lead to gradual material degradation and seam weakening, eventually compromising the items overall structural integrity. Regular use within the specified weight limits promotes longevity and consistent performance. Careful adherence to the manufacturer’s recommendations ensures continued reliability and minimizes the risk of premature failure.

Therefore, understanding and adhering to the designated weight capacity is crucial for maintaining functionality and prolonging the lifespan of these inflatable surfaces. Ignoring this specification can negate even the most puncture-resistant designs, leading to premature failure and compromised performance.

4. Inflation Method

The inflation method employed for a resilient inflatable sleeping surface is a crucial determinant of its convenience, efficiency, and overall user experience. It directly influences the speed and ease with which the item can be readied for use. The selected method must harmonize with its design and intended application.

- Integrated Electric Pumps

Certain models feature built-in electric pumps, simplifying the inflation process. These pumps typically operate on either AC power or rechargeable batteries, enabling rapid inflation without external equipment. The convenience of an integrated pump is particularly beneficial for indoor use or situations where access to power is readily available. The inflation speed and ease of use enhance overall user satisfaction and reduce setup time. In an emergency situation, an integrated pump can quickly deploy a comfortable sleeping surface.

- External Electric Pumps

External electric pumps offer greater versatility, as they can be used with various inflatable items, including those not specifically designed for electric inflation. These pumps are available in a range of sizes and power options, including models that operate on 12V DC power, making them suitable for camping and automotive applications. The ability to use an external pump expands the usage scenarios and provides a backup inflation method in case the primary pump malfunctions. An external pump is crucial if the air mattress faces leakage or if it needed to be inflated often due to personal needs.

- Manual Pumps

Manual pumps, such as foot pumps or hand pumps, provide a portable and independent inflation solution. These pumps require physical effort but offer a reliable means of inflation in locations without access to electricity. Manual pumps are particularly useful for backpacking or remote camping trips where weight and space are critical considerations. While inflation may take longer and require more effort compared to electric pumps, manual options ensure functionality regardless of power availability. Some manual pumps are more effective than others, so research is required before purchasing.

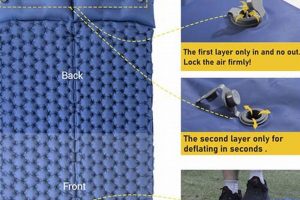

- Self-Inflation Valves

Some models incorporate self-inflation valves that allow the mattress to partially inflate automatically. These valves utilize open-cell foam within the mattress, which expands and draws in air when the valve is opened. While self-inflation is not typically sufficient to fully inflate the mattress, it significantly reduces the effort required to reach the desired firmness. Self-inflation valves are often combined with a small manual pump to achieve complete inflation and fine-tune the comfort level. For example, a self-inflating mattress can be quickly prepared for use with minimal effort, making it suitable for spontaneous camping trips.

The choice of inflation method is integral to the overall usability and convenience of a puncture-resistant inflatable sleeping surface. Considering the intended application, power availability, and personal preferences is essential when selecting a model. The optimal inflation method balances efficiency, portability, and ease of use, contributing to a positive user experience and maximizing the value of the purchase. Hybrid solutions that combine multiple inflation methods offer the greatest flexibility and adaptability to varying circumstances.

5. Portability

The characteristic of portability significantly enhances the utility of a puncture-resistant inflatable sleeping surface. The capacity to transport the item easily expands its applicability to diverse scenarios, including camping, guest accommodations, and emergency situations. The design attributes that contribute to puncture resistance often influence portability, creating trade-offs that manufacturers must address.

The use of heavier, more durable materials, while improving resistance to punctures, increases the overall weight and bulk of the deflated item. Consequently, models constructed with reinforced fabrics may be less convenient to transport than those made from lighter, less robust materials. The method of deflation and storage also affects portability. Mattresses with efficient air expulsion systems can be compressed into a smaller volume, simplifying packing and carrying. Examples of this can be seen in lightweight backpacking models with integrated compression straps.

Ultimately, portability represents a key attribute of inflatable surfaces that offer resistance to punctures, particularly for applications where convenience and ease of transport are paramount. Balancing the need for durability with weight and size considerations is a crucial aspect of the design process. Manufacturers often employ innovative materials and construction techniques to optimize both puncture resistance and portability, catering to the varied needs of users in different contexts. Therefore, when assessing a model, careful consideration of material weight versus resistance based on the intended use is recommended.

6. Repair Options

Although designed for resilience, even a “puncture proof air mattress” may sustain damage requiring repair. Therefore, the availability and efficacy of repair options are essential considerations for prolonged use and value retention.

- Patch Kits and Adhesives

Most resilient inflatable sleeping surfaces include or offer compatible patch kits consisting of adhesive patches and sometimes a specialized adhesive. The success of this repair method depends on the nature and extent of the damage, as well as the quality of the adhesive. Small punctures or tears can often be effectively sealed with a patch, restoring air retention. However, larger tears or seam separations may require more extensive repair or professional intervention. The type of adhesive is crucial; it must be compatible with the material of the mattress and able to maintain a strong bond under pressure and temperature fluctuations. Proper surface preparation, including cleaning and roughening the area around the puncture, is vital for ensuring a durable repair.

- Professional Repair Services

For significant damage, such as large tears, seam failures, or valve malfunctions, professional repair services offer a more comprehensive solution. These services typically employ specialized equipment and techniques to restore the structural integrity and air tightness. The cost of professional repair may vary depending on the extent of the damage and the complexity of the repair process. However, for high-value mattresses, professional repair can be a cost-effective alternative to replacement. Professional services have the expertise to handle complex repairs that are beyond the scope of DIY patch kits, thus extending the life of the product.

- Material Compatibility and Repair Limitations

The success of any repair hinges on the compatibility of the repair materials with the mattress material. Using incompatible adhesives or patches can result in a weak or temporary bond that fails under pressure. Certain materials, such as specialized coatings or laminates, may be difficult or impossible to repair effectively. Understanding the limitations of repair options is crucial for making informed decisions about whether to attempt a repair or seek a replacement. The product information typically specifies the material composition, which provides guidance in selecting appropriate repair materials.

- Preventative Measures and Maintenance

While repair options are important, preventative measures and proper maintenance play a critical role in minimizing the need for repairs. Avoiding sharp objects, using a protective ground cloth, and storing the mattress properly can significantly reduce the risk of punctures or tears. Regular inspection for signs of wear or damage allows for early detection and prompt repair, preventing small issues from escalating into major problems. Following the manufacturer’s recommendations for inflation pressure and cleaning further contributes to the longevity and reduces the likelihood of damage.

Therefore, while “puncture proof air mattress” designs aim to minimize damage, viable repair options are still essential for ensuring long-term usability and maximizing the investment. Evaluating available methods and materials and following proper maintenance practices will contribute to the continued utility.

7. Storage Needs

Storage considerations are integral to the long-term maintenance and usability of inflatable sleeping surfaces designed for puncture resistance. Proper storage safeguards against degradation and extends the functional lifespan.

- Environmental Protection

The storage environment significantly impacts the structural integrity. Exposure to extreme temperatures, direct sunlight, and humidity can degrade the material, leading to reduced puncture resistance and seam weakness. For example, prolonged storage in a hot attic can cause the material to become brittle and prone to cracking, negating the inherent puncture-resistant properties. A cool, dry, and dark storage space is optimal for preserving material integrity.

- Physical Protection

Protection from physical damage is equally crucial. When deflated, the item is still susceptible to punctures from sharp objects or abrasions from rough surfaces. Storing it in a dedicated storage bag or container shields it from these hazards. This is especially important when storing in shared spaces where other items may pose a threat. A puncture-resistant mattress stored carelessly amidst tools in a garage is still vulnerable to damage.

- Space Optimization

The deflated size and shape influence storage convenience. Models that can be tightly compressed and compactly folded are easier to store, particularly in limited spaces. Integrated compression straps or dedicated storage bags facilitate this process. An overly bulky deflated mattress can be difficult to store and may require a significant amount of space, making it less practical for certain users.

- Pest Control

Pests such as rodents and insects can damage stored inflatable items. Rodents may gnaw on the material, while insects can create small holes or weaken seams. Storing the mattress in a sealed container or using pest repellent measures can prevent this type of damage. A storage area with evidence of pest activity poses a significant risk to the integrity, potentially compromising its puncture resistance. Regular inspection can help determine this.

Therefore, understanding and addressing storage requirements is crucial for preserving the functionality and longevity of such mattresses. Adequate protection from envi

ronmental factors, physical damage, space constraints, and pests ensures that it remains in optimal condition for extended use. Proper storage enhances the value and reliability of the item.

Frequently Asked Questions

The following questions address common inquiries regarding the characteristics, usage, and maintenance of inflatable sleeping surfaces designed for puncture resistance. The information provided aims to clarify misconceptions and offer practical guidance.

Question 1: Are these surfaces completely impervious to punctures?

While designed to resist penetration, no material is entirely immune to punctures. The term “puncture-resistant” indicates a heightened level of protection compared to standard inflatable items, but sharp objects or extreme forces can still cause damage.

Question 2: How does weight capacity affect the surface’s resistance to punctures?

Exceeding the specified weight limit increases stress on the material and seams, compromising its inherent puncture resistance. Overloading stretches the material, making it thinner and more vulnerable to sharp objects. Adherence to the weight recommendations is crucial for maintaining functionality.

Question 3: What types of materials offer the best puncture protection?

Reinforced PVC, high-denier nylon, and composite materials incorporating puncture-resistant additives provide enhanced protection. Thermoplastic polyurethanes (TPU) offer improved abrasion resistance. Multiple layers of different materials can offer a combination of benefits.

Question 4: How should these surfaces be stored to prevent damage?

Storage in a cool, dry, and dark environment is recommended. Avoid exposure to extreme temperatures, direct sunlight, and humidity. Store the item in a dedicated bag or container to protect it from physical damage and pests.

Question 5: Can punctures be repaired effectively?

Small punctures can often be repaired with adhesive patches. Larger tears or seam separations may require professional repair services. The success of the repair depends on the compatibility of the repair materials with the mattress material.

Question 6: What is the expected lifespan of an inflatable sleeping surface resistant to punctures?

Lifespan depends on usage frequency, environmental conditions, and adherence to maintenance guidelines. With proper care and storage, a high-quality model can provide several years of reliable service.

In summary, such inflatable mattresses offer a degree of protection against punctures, but proper usage, maintenance, and storage are essential for maximizing its durability and overall lifespan.

The subsequent section will offer a buying guide.

Resilient Air Mattresses

The preceding discussion has thoroughly examined various facets of “puncture proof air mattress” design and utilization. Material composition, seam integrity, weight capacity, inflation methods, portability, repair options, and storage needs have each been scrutinized. These elements collectively determine the effectiveness and longevity of such items, influencing their suitability for diverse applications. The importance of selecting a model aligned with specific requirements and adhering to proper maintenance protocols cannot be overstated.

Ultimately, the utility of a “puncture proof air mattress” rests on a balance between its inherent design characteristics and the user’s diligence in its care. Continued advancements in material science and manufacturing techniques promise further enhancements in both durability and user experience. Consumers are encouraged to carefully evaluate their needs and prioritize long-term value over short-term cost savings when making a purchase decision. A well-chosen and properly maintained model offers a reliable and comfortable sleeping solution for years to come.