A large, airtight enclosure designed to compress and protect bedding, typically crafted from durable plastic, offers a method for reducing the volume of bulky items. For example, a product can accommodate and seal a sizable bed covering, enabling efficient storage or transportation.

The advantage of utilizing such storage solutions lies in the space savings and safeguarding against environmental factors like dust, moisture, and pests. Historically, methods to reduce the size of textiles have been employed, but modern materials and vacuum technology provide a more effective and convenient solution for preserving and managing large bedding items.

The subsequent sections will examine the characteristics, selection criteria, proper usage, and potential applications of these space-saving solutions, offering a detailed understanding of their functionality and benefits in various scenarios.

Essential Usage Guidance

The following guidance will ensure optimal performance and longevity when utilizing compression storage for substantial bedding items.

Tip 1: Material Preparation: Prior to placement, ensure the textile is thoroughly cleaned and completely dry. Residual moisture can foster mildew growth within the sealed environment, compromising the material’s integrity.

Tip 2: Proper Folding Technique: Employ a systematic folding approach to minimize wrinkles and distribute the material evenly within the enclosure. This facilitates efficient compression and reduces the potential for permanent creasing.

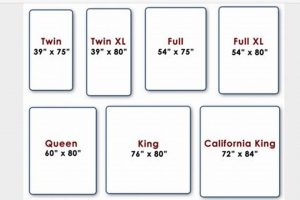

Tip 3: Appropriate Sizing Selection: Verify that the dimensions of the enclosure correspond precisely with the dimensions of the item being stored. Overfilling can compromise the seal and negate the intended space-saving benefits.

Tip 4: Vacuum Device Compatibility: Confirm that the vacuum cleaner or pump being used is compatible with the enclosure’s valve system. Incompatible devices may damage the valve or fail to achieve adequate compression.

Tip 5: Seal Integrity Verification: After vacuuming, meticulously inspect the seal to ensure it is airtight. Any breach in the seal will allow air to re-enter, diminishing the compressed state and potentially exposing the item to environmental contaminants.

Tip 6: Storage Environment Considerations: Store the compressed item in a cool, dry location away from direct sunlight and extreme temperature fluctuations. These conditions can degrade the plastic enclosure and impact the stored item.

Tip 7: Periodic Inspection Routine: Implement a schedule for regularly inspecting the stored item for any signs of air leakage, condensation, or material degradation. Early detection allows for timely intervention and prevents further damage.

Adhering to these guidelines will maximize the space-saving advantages and safeguard the integrity of the stored bedding item, ensuring its preservation for extended periods.

The concluding section will address common challenges and offer solutions for troubleshooting potential issues encountered during the usage of these storage solutions.

1. Dimensions

The dimensions of a compression storage solution are paramount to its effective use for bed coverings. Proper sizing ensures both adequate space for the item and the ability to achieve a significant volume reduction without damaging the material.

- Length and Width Considerations

These measurements must exceed the corresponding dimensions of the bed covering to allow for easy insertion and sealing. Insufficient length or width may result in tearing or prevent complete closure.

- Depth Allowance for Compression

This dimension represents the space available for the compressed item. A greater depth allowance facilitates a more substantial reduction in volume, optimizing storage efficiency.

- Valve Placement and Accessibility

The position of the valve influences the ease of air extraction. Strategically placed valves ensure uniform compression and accessibility for vacuum devices.

- Material Flexibility and Conformity

The material’s ability to conform to the shape of the bedding directly impacts the efficiency of compression. Flexible materials minimize air pockets and maximize volume reduction.

Careful consideration of these dimensional factors ensures that the storage solution provides optimal protection, space savings, and ease of use. Inadequate attention to these details can lead to compromised storage effectiveness and potential damage to the item being stored.

2. Material Durability

The longevity and protective efficacy of a compression storage solution designed for large bedding are intrinsically linked to the durability of its constituent material. The capacity of the enclosure to withstand repeated handling, resist punctures, and maintain an airtight seal dictates its suitability for long-term storage. Inferior materials are prone to tearing or seam failure, compromising the compressed state and exposing the contents to environmental contaminants. For instance, a bag constructed from thin, low-grade polyethylene may readily puncture during transport or storage, rendering it ineffective. In contrast, a product utilizing multi-layer, reinforced nylon offers superior resistance to physical stress and maintains its integrity over extended periods, safeguarding the bedding from moisture, dust, and pests.

Material durability also impacts the ability to withstand temperature fluctuations and UV exposure. Prolonged exposure to sunlight can degrade certain plastics, leading to brittleness and cracking. Selecting a material formulated with UV inhibitors extends the lifespan of the bag and preserves its protective qualities. Furthermore, the material’s resistance to abrasion is crucial, particularly when the compressed item is stored in areas with potential friction against other objects. Abrasive surfaces can gradually wear down thinner materials, eventually compromising the seal and requiring replacement of the storage solution. Higher-density polymers and reinforced laminates offer enhanced abrasion resistance, ensuring the continued effectiveness of the storage.

In summary, material durability is a non-negotiable attribute in a high-quality product designed for storing sizable bed coverings. Its impact extends beyond mere longevity, directly influencing the protection afforded to the stored item and the overall value proposition of the storage solution. Investment in products constructed from robust, resilient materials ensures long-term performance and mitigates the risks associated with material degradation and seal compromise.

3. Valve Efficiency

Valve efficiency within a product intended for compressing and storing bed coverings dictates the speed and effectiveness of air evacuation, directly impacting the achievable compression ratio and long-term seal integrity. A poorly designed valve restricts airflow, prolonging the vacuuming process and potentially causing the user to discontinue before optimal compression is achieved. Conversely, a high-efficiency valve, engineered for maximum airflow, facilitates rapid and thorough air removal, creating a significantly smaller and more manageable package. The resulting reduction in volume is critical for optimizing storage space, particularly in environments with limited square footage.

The valve’s ability to maintain a secure seal after air evacuation is equally important. A valve that leaks, even minimally, will gradually allow air to re-enter the enclosure, negating the initial compression efforts and exposing the bedding to potential environmental contaminants like moisture and dust. Engineering designs incorporating one-way valves with robust sealing mechanisms are therefore essential for preventing leakage and ensuring the long-term preservation of the compressed state. Consider, for example, a valve utilizing a double-seal configuration, which provides an additional layer of protection against air infiltration compared to simpler single-seal designs. The choice of valve material also contributes to long-term performance; durable, non-porous materials resist degradation and maintain their sealing properties over extended periods of storage.

Ultimately, valve efficiency represents a critical performance parameter for compression storage solutions. It directly influences the user experience, the achievable space savings, and the long-term protection of the stored bedding. Investing in products featuring high-efficiency valves, engineered for rapid air evacuation and long-term seal integrity, is therefore essential for maximizing the benefits of compression storage and ensuring the effective preservation of valuable bedding items.

4. Airtight Seal

The function of a compression storage bag for large bedding is fundamentally dependent on the integrity of its airtight seal. The presence of an imperfect seal directly negates the purpose of the device. A properly executed seal prevents the ingress of air and environmental contaminants such as moisture, dust, and pests. Without this seal, the reduced volume achieved through vacuum compression is lost, rendering the bag ineffective for space saving. For instance, the benefit of storing a bed covering, a compressed item, is substantially diminished if the seal allows humid air to enter, fostering mold growth. The seal maintains a consistent environment.

The design and materials of the sealing mechanism are critical determinants of its effectiveness. Zippers with multiple interlocking tracks, combined with robust sealing clips, are commonly employed to create an airtight barrier. The materials used in the seal construction, such as specialized polymers, must exhibit resilience to repeated opening and closing without compromising their ability to prevent air leakage. Proper usage, including ensuring the seal is free of debris and fully closed, is essential for maximizing its performance. Real-world applications demonstrate that bags with inferior seals often exhibit gradual reinflation over time, indicating a breach in the airtight barrier. To contrast, bed coverings protected by vacuum seal bags guarantee protection of items.

In summary, the airtight seal constitutes a critical component of a compression storage solution designed for bed coverings. It represents the primary mechanism for preserving the reduced volume and protecting the stored item from environmental factors. Challenges in achieving a reliable seal often stem from design flaws or material limitations. The quality and reliability of this element directly correlate with the overall effectiveness and long-term utility of the storage solution and vacuum compression, ensuring protection and cleanliness for the bedding. The seal’s integrity ensures proper storage.

5. Puncture Resistance

Puncture resistance represents a critical attribute in products designed for compressing and storing sizable bedding items, directly influencing the product’s ability to protect its contents and maintain its functionality over extended periods of use. The inherent vulnerability of plastic films to breaches necessitates robust material selection and construction techniques to mitigate the risk of punctures, tears, and subsequent air leakage.

- Material Composition and Layering

The type and arrangement of materials used in manufacturing a bed covering influence puncture resistance. Multi-layered films, incorporating high-density polyethylene or nylon, offer increased protection compared to single-layer alternatives. The inclusion of reinforcing agents or woven fabrics further enhances the material’s ability to withstand sharp objects and abrasive surfaces. For example, a vacuum bag composed of several layers provides increased protection against punctures from sharp edges.

- Thickness and Gauge

The thickness of the plastic film directly correlates with its resistance to punctures. Thicker films, measured in gauge or mils, offer greater protection against penetration by sharp objects. While increasing thickness adds to the material cost, it provides a tangible benefit in terms of durability and long-term performance. A thicker, better manufactured vacuum seal bag creates longer and safer storage.

- Seam Strength and Integrity

The seams represent a vulnerable point in any sealed enclosure. Weak or poorly constructed seams are susceptible to tearing under stress, compromising the airtight seal and exposing the contents to environmental factors. Reinforced seams, utilizing heat sealing or adhesive bonding techniques, enhance the overall puncture resistance of the bag. Reinforced seams ensure protection.

- Environmental Factors and Storage Conditions

The storage environment significantly impacts the long-term puncture resistance of a compression storage solution. Exposure to extreme temperatures, direct sunlight, or abrasive surfaces can degrade the plastic film and increase its susceptibility to punctures and tears. Proper storage practices, such as placing the compressed bed covering on a smooth, clean surface, mitigate the risk of damage. Ensuring the storage environment is appropriate protects the bags.

The discussed aspects emphasize the connection to their performance of vacuum storage bags. Selecting products with high puncture resistance, demonstrated through robust materials, reinforced construction, and careful handling, ensures long-term protection and effective space-saving capabilities.

6. Storage Space

The primary function of a compression storage solution for bed coverings is to reduce the amount of storage space required. These bags, when used correctly, compress bulky items, such as bedding, to a fraction of their original volume. The degree to which storage space is conserved is directly proportional to the bag’s design, the efficiency of the vacuum seal, and the initial volume of the bedding. For example, a bed covering, when decompressed, requires a considerable area within a closet or storage unit. The utilization of a compression bag and volume reduction allows a user to store more within the same area.

The efficient use of storage space has practical implications for various living situations. In apartments or smaller homes with limited closet space, compression bags enable residents to neatly store seasonal bedding or extra linens. In moving situations, the ability to compress bulky items reduces the overall volume of possessions, potentially lowering moving costs. Furthermore, the protection provided by the airtight seal preserves the quality of the stored bedding, preventing damage from moisture, pests, or dust. This is especially beneficial for valuable or sentimental items. Compression storage bags offer greater protection when the bedding is stored long-term.

Understanding the interplay between storage space and the functionality of compression bags is crucial for maximizing their utility. Challenges in achieving optimal space savings often stem from improper bag usage, such as overfilling or failure to create a complete seal. Realizing the full benefits of volume reduction depends on selecting bags appropriate for the size and type of bedding being stored, and adhering to the manufacturer’s instructions. These considerations ensure that such products function effectively, creating more storage. Therefore, they are practical solutions for homes and small apartments.

7. Reusable Design

The concept of reusable design applied to vacuum storage solutions for large bed coverings represents a significant determinant of both economic value and environmental impact. Initial material costs, while often higher for more durable, reusable solutions, are amortized over multiple uses. Conversely, single-use products necessitate repeated purchases, ultimately increasing expenditure. From an ecological perspective, products engineered for repeated use reduce the volume of plastic waste entering landfills, mitigating the environmental consequences associated with disposable consumer goods. Example: purchasing a thicker, multi-layered bag, designed for at least five reuses, would save more over the long-term than using disposable, thin bags that end up breaking. Reusability also reduces plastic consumption.

The practicality of reusable vacuum bags extends to the consistency of their performance. High-quality, reusable bags maintain their airtight seal and structural integrity over numerous compression cycles. Disposable alternatives, often constructed from thinner materials, are more prone to tearing or seal failure after only a few uses, compromising their effectiveness and necessitating premature replacement. Furthermore, reusable designs frequently incorporate features that enhance usability, such as reinforced zippers or improved valve mechanisms, contributing to a more reliable and user-friendly storage experience. A zipper on a vacuum storage bag helps the bag stay open while the product is inserted.

In summary, the reusable design of a product to compress and store bed coverings presents a compelling argument for long-term value and ecological responsibility. While upfront costs may be slightly elevated, the durable construction, consistent performance, and reduced environmental impact of reusable designs offer a superior alternative to disposable options. Challenges remain in educating consumers about the long-term benefits of reusable products and developing recycling programs for end-of-life disposal of reusable bags. Reusable vacuum storage bags are environmentally friendly and better than their single-use alternatives.

Frequently Asked Questions about Queen Size Mattress Vacuum Bags

The following addresses common inquiries concerning the application, advantages, and optimal utilization of vacuum compression solutions designed for queen-size bedding.

Question 1: What distinguishes a “queen size mattress vacuum bag” from standard storage bags?

These bags are specifically dimensioned to accommodate a queen-size mattress. Standard storage bags may lack the necessary volume or structural integrity.

Question 2: Can any vacuum cleaner be used to evacuate air from a “queen size mattress vacuum bag?”

Most standard vacuum cleaners with a hose attachment are compatible. However, confirming the nozzle’s compatibility with the bag’s valve is advisable.

Question 3: Does using a “queen size mattress vacuum bag” risk damaging the mattress’s internal structure?

Prolonged compression may potentially affect the mattress’s form. Removing the mattress from the bag periodically is advisable to allow it to regain its shape.

Question 4: How long can a mattress remain compressed within a “queen size mattress vacuum bag” without adverse effects?

This depends on the mattress type and bag quality. Monitoring the mattress’s condition during storage and allowing it to air out regularly is recommended.

Question 5: Are all “queen size mattress vacuum bags” reusable?

Reusability depends on the bag’s construction and materials. Bags constructed from thicker, more durable plastics offer greater reusability.

Question 6: What measures should be taken to prevent mold or mildew growth within a “queen size mattress vacuum bag?”

Ensuring the mattress is completely dry before storage and incorporating desiccant packs within the bag are essential preventative measures.

The answers clarify aspects that affect the usability and considerations that must be made before, during, and after vacuum-sealing a mattress. The material that is used must be considered along with the humidity.

The following section will present case studies illustrating the practical application and benefits of vacuum compression solutions in various scenarios.

Concluding Remarks

This exploration has detailed the functionality, benefits, and considerations relevant to selecting and utilizing a product for compressing bed coverings. The importance of material durability, airtight seal, valve efficiency, and appropriate dimensions has been emphasized. These features directly impact the effectiveness of space saving, protection from environmental factors, and the longevity of the storage solution.

The responsible application of compression storage contributes to efficient resource management and waste reduction. Careful assessment of individual storage needs, combined with informed product selection, ensures optimal utilization and maximizes the benefits of this storage methodology.