A vehicle-specific inflatable sleeping surface designed for use within the bed of a Toyota Tacoma pickup truck offers a portable and comfortable solution for rest and relaxation during outdoor activities or travel. These mattresses are typically constructed from durable, puncture-resistant materials and are shaped to conform to the dimensions of the truck bed, often accommodating wheel well cutouts and other features. Such a product provides an alternative to traditional camping setups for individuals who own a Tacoma.

The advantage of using an inflatable bed inside a pickup truck lies in its convenience and elevated sleeping platform. It keeps the user off the ground, providing insulation and protection from uneven terrain, insects, and moisture. The integration with the vehicle allows for spontaneous camping trips and eliminates the need to transport and set up separate tents and sleeping arrangements. Historically, individuals have sought methods to adapt their vehicles for recreational use, with this type of accessory representing an evolution in mobile comfort solutions.

Understanding the specifications, materials, inflation methods, and storage options associated with truck bed sleeping systems is essential for prospective buyers. Subsequent sections will delve into the various features available and factors to consider when choosing a suitable model to maximize comfort and durability during use.

Tips for Selecting and Using a Truck Bed Inflatable Sleeping Surface

Optimizing the experience with a vehicle-specific inflatable bed requires careful consideration of several factors. These tips aim to provide users with practical guidance on selection, setup, and maintenance.

Tip 1: Assess Bed Dimensions and Vehicle Compatibility: Prior to purchase, verify the exact dimensions of the Toyota Tacoma truck bed. Ensure the chosen inflatable product corresponds precisely to the bed’s length, width, and depth to avoid ill-fitting or unstable setups. Consider the short bed versus long bed configurations.

Tip 2: Prioritize Durable Material Composition: Examine the material used in the inflatables construction. Reinforced PVC or similar heavy-duty polymers offer increased resistance to punctures and abrasion, prolonging the product’s lifespan and ensuring reliability in outdoor environments.

Tip 3: Evaluate Inflation Mechanism and Portability: Assess the type of pump required for inflation. Integrated electric pumps provide convenient inflation, while manual pumps offer portability in situations where power is unavailable. The ability to deflate and compactly store the product is also crucial for efficient storage.

Tip 4: Consider Surface Texture and Comfort: The surface texture impacts comfort during sleep. Flocked or velvet-like surfaces enhance comfort and prevent sleeping bags or blankets from slipping. Evaluate the texture based on intended usage and personal preferences.

Tip 5: Ensure Adequate Support and Weight Capacity: Verify the maximum weight capacity of the inflatable structure. Exceeding the specified limit can compromise structural integrity and lead to deflation or damage. Distribute weight evenly across the surface during use.

Tip 6: Implement Protective Layering: Use a fitted sheet or mattress protector to safeguard the inflatable surface from dirt, moisture, and potential abrasion. This practice extends the product’s longevity and maintains cleanliness.

Tip 7: Practice Responsible Storage and Maintenance: After each use, thoroughly clean and dry the inflatable surface before deflating and storing it. Store the product in a cool, dry place away from direct sunlight and sharp objects to prevent damage.

Adhering to these guidelines will enhance the comfort, durability, and overall satisfaction when utilizing a bed-integrated inflatable sleep system. Proper selection and maintenance contribute to a reliable and enjoyable outdoor experience.

The following sections will address common issues and troubleshooting techniques to further optimize usage.

1. Vehicle Bed Compatibility

Vehicle bed compatibility is a foundational element in the effective utilization of a sleeping platform designed for the Toyota Tacoma. The precise fit of the inflatable surface within the truck bed directly influences its stability, comfort, and overall usability. A mismatch between the dimensions of the bed and the inflatable product will lead to instability, uneven weight distribution, and potential damage to the product itself. For instance, an excessively large mattress may buckle or overhang, while a smaller unit will shift during use, diminishing comfort and posing a potential safety hazard. The Tacoma’s bed shape, including wheel well contours and bed rail design, necessitates tailored designs to avoid interference and ensure a level sleeping surface. Failure to address this compatibility can render the mattress unusable or create an unsafe sleeping environment.

Specific examples of incompatibility issues include products designed for full-size trucks being inappropriately used in the mid-size Tacoma bed. The resulting excess length or width interferes with tailgate closure or proper bed space utilization. Conversely, a generic air mattress placed in the Tacoma bed lacks the necessary cutouts and tailored fit, leading to an unstable and uncomfortable sleeping arrangement. The practical implications involve wasted investment, compromised sleep quality, and the potential for injury due to instability. Manufacturers addressing this concern offer models specifically engineered for the Tacoma short or long bed configurations, ensuring optimal integration.

In summary, vehicle bed compatibility is not merely a matter of convenience; it’s a critical performance factor affecting the safe and comfortable use of an inflatable bed within a Toyota Tacoma. Neglecting this aspect can lead to product damage, user discomfort, and potentially unsafe sleeping conditions. A precise, vehicle-specific fit ensures stability, optimal space utilization, and a positive overall experience. It links directly to customer satisfaction and the intended functionality of the mobile sleeping platform.

2. Material Puncture Resistance

The durability of a vehicle-specific inflatable sleeping surface is intrinsically linked to the material’s ability to withstand punctures. Given the intended use of such a product in outdoor environments, where exposure to sharp objects and abrasive surfaces is likely, material puncture resistance is a critical performance characteristic directly affecting its longevity and reliability.

- Reinforced Polymer Composition

Reinforced polymers, such as PVC with added nylon or polyester fibers, enhance the material’s tensile strength and resistance to tearing. These materials withstand the stresses imposed by uneven surfaces or acc

idental contact with sharp objects within the truck bed. For example, a standard PVC air mattress might puncture upon contact with a stray pebble, whereas a reinforced version would resist the damage, maintaining its inflation and functionality. This reinforcement is fundamental for maintaining the mattress’s integrity and usability over extended periods. - Thickness and Denier Rating

The thickness of the material, often measured in millimeters or gauges, and the denier rating, which indicates the fiber density of the material, both contribute to its puncture resistance. A higher denier rating signifies a tighter weave and greater material density, offering increased protection against penetration. Similarly, a thicker material layer presents a greater barrier against punctures. Consequently, opting for an inflatable bed with a higher thickness and denier rating directly correlates to increased resistance to damage from sharp objects encountered during use.

- Seam Construction and Reinforcement

The seams where separate material panels are joined are particularly vulnerable points for puncture or tearing. Reinforced seams, often achieved through welding or multiple stitching lines, distribute stress and prevent seam separation. For instance, poorly constructed seams may burst under pressure or easily tear if snagged on a sharp edge. Robust seam construction is therefore crucial for preventing air leaks and ensuring the overall structural integrity of the sleeping surface, especially along the edges and corners.

- Protective Coatings and Treatments

Certain manufacturers apply protective coatings or treatments to the surface of the material to further enhance its puncture resistance. These coatings may provide an additional layer of protection against abrasion or chemical degradation, increasing the material’s lifespan and resilience in harsh environments. Examples include UV-resistant coatings or waterproof treatments that also contribute to puncture resistance by maintaining the material’s pliability and preventing it from becoming brittle and prone to cracking.

In conclusion, the selection of a material with high puncture resistance is a vital factor when considering a truck bed sleeping solution. Reinforced polymer composition, thickness, seam construction, and protective coatings all contribute to the overall durability and reliability of the product, enabling it to withstand the rigors of outdoor use within the Toyota Tacoma bed. Investing in a product with superior material characteristics translates to a longer lifespan, improved comfort, and a greater return on investment.

3. Inflation/Deflation Ease

The ease with which a vehicle-specific inflatable sleeping platform can be inflated and deflated is a primary determinant of its convenience and practicality for use within a Toyota Tacoma truck bed. Efficient inflation and deflation mechanisms directly affect the time investment required for setup and takedown, influencing the overall user experience. A complex or cumbersome system diminishes the spontaneity and ease of use typically associated with mobile sleeping solutions.

- Pump Type and Power Source

The type of pump utilized significantly impacts inflation speed and effort. Integrated electric pumps, powered by the vehicle’s 12V outlet or a portable power station, offer rapid and effortless inflation. Manual pumps, while eliminating the need for an external power source, necessitate physical exertion and generally require a longer inflation time. The power source dictates the pump’s portability and availability in remote locations. An integrated system powered by the vehicle provides inherent convenience, while a manually powered pump allows operation independent of vehicle proximity.

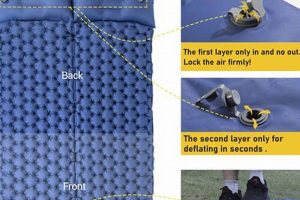

- Valve Design and Airflow Capacity

The valve design directly affects the rate of airflow into and out of the inflatable structure. Large-diameter valves with unobstructed airflow channels facilitate faster inflation and deflation. Conversely, smaller valves or those with intricate internal mechanisms restrict airflow, prolonging the inflation/deflation process. Valve materials and sealing effectiveness also influence air retention and prevent leakage, which can compromise inflation efficiency and sleeping comfort.

- Inflation/Deflation Time and Automation

The total time required for full inflation and deflation is a key metric of convenience. Automated systems, often coupled with electric pumps, inflate the mattress to a preset pressure level, eliminating the need for manual monitoring. Similarly, rapid deflation mechanisms, such as large-diameter valves or integrated deflation pumps, expedite the takedown process. Inflatable beds with shorter inflation/deflation times allow for quicker setup and breakdown, maximizing usability and minimizing time spent on logistical tasks.

- Storage and Portability Considerations

The ease of deflation directly influences the compactness of the deflated mattress for storage and transport. Products that deflate completely and can be tightly rolled or folded into a small package are more convenient to store within the vehicle or camping gear. The inclusion of a dedicated storage bag or compression straps further enhances portability and protects the deflated mattress from damage during transport. Optimizing deflation and storage efficiency minimizes space consumption and simplifies packing procedures.

Efficient inflation and deflation are not merely conveniences but are integral to the overall user experience when using a sleeping surface within a Toyota Tacoma. A system that inflates and deflates rapidly, utilizes readily available power sources, and packs down compactly enhances the spontaneity and practicality of the mobile sleeping solution, aligning with the intended use case of convenient and readily available rest during outdoor activities.

4. Supportive Design Features

Supportive design features are paramount to the functionality and user satisfaction of any inflatable sleeping surface, particularly when integrated within the constrained dimensions of a Toyota Tacoma truck bed. These features directly influence comfort, stability, and the prevention of pressure point discomfort during sleep.

- Internal Baffle Construction

Internal baffle construction refers to the internal structure of the air mattress, typically composed of vertical or horizontal partitions that distribute air pressure evenly. Without baffles, the mattress can develop bulges or sags, leading to uneven support. The presence of robust baffle systems, particularly in vehicle-specific models, ensures consistent firmness and prevents the “rolling” effect common in simpler air mattresses. This even distribution is crucial for maintaining spinal alignment and preventing pressure sores during extended use.

- Zonal Support Systems

Zonal support systems involve varying the firmness across different sections of the mattress to accommodate the varying weight distribution of the human body. For example, a firmer central zone can provide additional lumbar support, while softer zones at the shoulders and hips allow for greater pressure relief. Implementing zonal support within a truck bed air mattress optimizes comfort by tailoring

the support to the specific needs of the sleeper’s anatomy. This can be achieved through variations in baffle density or material thickness within different mattress sections. - Edge Support Reinforcements

Edge support reinforcements refer to structural enhancements along the perimeter of the mattress, preventing edge collapse when the sleeper sits or lies near the edge. Reinforced edges maximize the usable sleeping surface and prevent the sensation of rolling off the mattress. In the context of a Tacoma truck bed, where space is limited, strong edge support is essential for maximizing the available sleeping area and ensuring a stable sleeping platform. These reinforcements often consist of thicker material or additional support structures along the mattress’s edges.

- Integrated Pillow Structures

Integrated pillow structures are built-in raised sections at the head of the mattress, providing neck and head support without the need for separate pillows. These structures maintain proper spinal alignment in the cervical region, enhancing sleep quality and preventing neck strain. While separate pillows can shift and become displaced during sleep, an integrated pillow structure remains fixed in position, providing consistent support throughout the night. These structures are often contoured to cradle the head and neck, further enhancing comfort and support.

The integration of these supportive design features significantly enhances the comfort and usability of a sleeping surface within a Toyota Tacoma. By addressing the specific challenges posed by the limited space and uneven terrain often encountered in outdoor environments, these features ensure a more restful and supportive sleeping experience, transforming the truck bed into a viable and comfortable sleeping solution.

5. Storage Space Optimization

Storage space optimization is a critical consideration when incorporating an inflatable sleeping surface into a Toyota Tacoma. The limited cargo capacity of the truck bed necessitates careful planning to maximize available space while accommodating both the sleeping surface and other essential gear. The efficient management of storage space directly impacts the practicality and convenience of using a sleeping platform within the vehicle.

- Compressed Mattress Dimensions

The dimensions of the sleeping surface when fully deflated and compressed significantly influence storage efficiency. Models that fold or roll into compact packages minimize the space occupied during transport and storage, allowing for the accommodation of other essential equipment. Excessively bulky mattresses, even when deflated, can impede access to the truck bed and reduce the overall utility of the vehicle. Choosing a model prioritizing compressed size allows for a more organized and functional use of the Tacoma’s limited space.

- Integrated Storage Solutions

Some vehicle-specific air mattresses incorporate integrated storage solutions, such as built-in pockets or compartments. These features provide designated spaces for storing smaller items, such as phones, keys, or books, eliminating the need for separate storage containers and further optimizing space utilization within the truck bed. The presence of integrated storage contributes to a more organized and clutter-free sleeping environment, enhancing overall comfort and convenience.

- Compatibility with Existing Bed Storage Systems

The ability of the air mattress to integrate with existing truck bed storage systems, such as toolboxes or bed organizers, is essential for maximizing space efficiency. A well-designed mattress should not interfere with the functionality of these systems, allowing for the simultaneous storage of camping gear, tools, and other equipment. Compatibility ensures that the addition of the sleeping surface does not compromise the existing storage capabilities of the Toyota Tacoma.

- Weight Considerations

While not directly related to volume, the weight of the deflated mattress also contributes to storage space optimization. Excessively heavy mattresses can be difficult to maneuver and store, potentially requiring assistance or specialized equipment. Lighter models are easier to handle and can be stowed in overhead compartments or other tight spaces, further contributing to efficient space utilization. Choosing a lightweight mattress facilitates easier storage and transportation, enhancing the overall practicality of the sleeping solution.

In conclusion, storage space optimization is an indispensable aspect of incorporating an inflatable sleeping surface into a Toyota Tacoma. The dimensions of the compressed mattress, integrated storage solutions, compatibility with existing bed storage systems, and weight considerations all play a role in maximizing the available space and ensuring the practicality of the mobile sleeping solution. Prioritizing these factors allows for a more organized, functional, and enjoyable camping or travel experience.

6. Cleanliness/Maintenance Requirements

Maintaining a vehicle-specific inflatable sleeping surface within a Toyota Tacoma necessitates adherence to specific cleanliness and maintenance protocols. These procedures directly influence the product’s longevity, hygiene, and overall performance, ensuring continued usability and minimizing the risk of damage or degradation.

- Surface Cleaning and Sanitization

Regular cleaning of the mattress surface is essential to remove dirt, debris, and bodily fluids that accumulate during use. A mild soap solution and a soft cloth are suitable for routine cleaning. More rigorous cleaning may be required after exposure to mud or other contaminants. Sanitization with an appropriate disinfectant helps to minimize the growth of bacteria and fungi, ensuring a hygienic sleeping environment. Neglecting surface cleaning can lead to material degradation, unpleasant odors, and the potential for skin irritation or infection.

- Moisture Control and Drying Procedures

Moisture accumulation, whether from condensation, spills, or humid conditions, can promote mold and mildew growth within the mattress. Thorough drying after each use is critical to prevent this. Allowing the mattress to air dry in a well-ventilated area, away from direct sunlight, is recommended. In humid climates, the use of a dehumidifier may be necessary to ensure complete drying. Storing a damp mattress can lead to irreversible damage and render it unusable.

- Puncture Prevention and Repair

Preventing punctures is essential to maintaining the mattress’s inflation and structural integrity. Inspecting the truck bed for sharp objects prior to inflation and using a protective ground cover can minimize the risk of punctures. In the event of a puncture, prompt repair is necessary to prevent further air loss. Repair kits typically include patches and adhesive suitable for repairing small holes. Larger punctures may require professional repair or replacement of the mattress. Regular inspection and timely repair are crucial for extending the mattress’s lifespan.

- Storage Practices and Environmental Protection

Proper storage practices are essential to protecting the mattress from damage when not in use

. Deflating the mattress completely and storing it in a dry, cool place away from direct sunlight and extreme temperatures is recommended. Folding or rolling the mattress according to the manufacturer’s instructions minimizes creases and stress on the material. Storing the mattress in its original storage bag or a similar protective container prevents abrasion and other damage. Protecting the mattress from environmental factors ensures its long-term durability and performance.

Adherence to these cleanliness and maintenance requirements is paramount for ensuring the continued functionality and hygiene of a vehicle-specific inflatable sleeping surface within a Toyota Tacoma. Regular cleaning, moisture control, puncture prevention, and proper storage practices contribute to a longer lifespan, improved user experience, and a more hygienic sleeping environment. Neglecting these procedures can lead to material degradation, mold growth, and premature failure of the product.

7. Environmental Temperature Impact

Ambient temperature exerts a significant influence on the performance and longevity of an inflatable sleeping surface used within the bed of a Toyota Tacoma. The physical properties of the materials used in the construction of the “tacoma air mattress” are susceptible to temperature fluctuations, affecting air pressure, material flexibility, and overall structural integrity. The following considerations outline specific facets of this interaction.

- Air Pressure Fluctuations

Gases expand when heated and contract when cooled. This principle directly affects the air pressure within the confines of a sealed “tacoma air mattress”. During periods of high ambient temperature, the internal air pressure will increase, potentially exceeding the mattress’s capacity and leading to seam stress or even rupture. Conversely, in colder temperatures, the air pressure will decrease, resulting in a loss of firmness and diminished support. Regular monitoring and adjustment of the air pressure are essential to compensate for these temperature-induced fluctuations. A practical example is inflating the mattress to optimal firmness during the cool evening hours, only to find it over-inflated and rigid under the midday sun.

- Material Flexibility and Elasticity

The flexibility and elasticity of the materials used in the “tacoma air mattress” are also temperature-dependent. At lower temperatures, polymers such as PVC or TPU tend to become more rigid and less pliable, increasing the risk of cracking or tearing if subjected to stress or sharp bending. Higher temperatures, on the other hand, can cause the materials to soften and become more susceptible to stretching or deformation. These effects can compromise the mattress’s structural integrity and reduce its resistance to punctures or abrasion. Therefore, storing the mattress in a temperature-controlled environment and avoiding extreme temperature exposure can prolong its lifespan.

- Condensation and Moisture Accumulation

Temperature differentials between the air inside the “tacoma air mattress” and the surrounding environment can lead to condensation. When warm, moist air inside the mattress comes into contact with a cooler surface, water vapor condenses, creating moisture buildup. This moisture can promote the growth of mold and mildew, leading to unpleasant odors, material degradation, and potential health risks. Proper ventilation and the use of moisture-absorbing materials can help to mitigate condensation. For example, regularly airing out the mattress in a dry environment can prevent moisture accumulation and maintain a hygienic sleeping surface.

- Seam Integrity and Adhesive Performance

The seams and adhesive bonds used to construct the “tacoma air mattress” are vulnerable to temperature-related stress. Extreme temperature fluctuations can cause expansion and contraction of the materials, placing stress on the seams and potentially weakening the adhesive bonds. This can lead to air leaks or seam separation, compromising the mattress’s ability to retain air pressure. Choosing a mattress with reinforced seams and high-quality adhesives can enhance its resistance to temperature-induced stress. Moreover, avoiding prolonged exposure to extreme temperatures can help to maintain the integrity of the seams and adhesive bonds.

The interrelationship between environmental temperature and the “tacoma air mattress” necessitates a proactive approach to mitigate potential adverse effects. Monitoring air pressure, protecting the material from extreme temperature exposure, preventing condensation, and selecting durable construction materials are crucial steps in ensuring the longevity, performance, and safety of the inflatable sleeping surface. These considerations emphasize the importance of understanding environmental factors when utilizing such a product in varying climate conditions.

Frequently Asked Questions

This section addresses common inquiries regarding vehicle-specific inflatable sleeping surfaces designed for use within the bed of a Toyota Tacoma pickup truck. The information provided aims to clarify typical concerns and provide factual guidance for prospective purchasers and users.

Question 1: What are the primary benefits of using a “Tacoma air mattress” compared to traditional camping setups?

A “Tacoma air mattress” offers convenience by eliminating the need for a separate tent. It provides an elevated sleeping surface, protecting against ground moisture, insects, and uneven terrain. Setup and takedown are typically faster than with conventional camping arrangements.

Question 2: How does one determine the correct size “Tacoma air mattress” for a specific vehicle?

The truck bed’s length, width, and depth must be accurately measured. Short bed and long bed Tacoma models require different sized mattresses. The manufacturers specifications should be consulted to ensure compatibility with the vehicle.

Question 3: What materials provide the best puncture resistance for a “Tacoma air mattress”?

Reinforced PVC or heavy-duty polymers with high denier ratings offer increased resistance to punctures and abrasion. These materials enhance the product’s lifespan, particularly in outdoor environments where contact with sharp objects is possible.

Question 4: What methods are available for inflating a “Tacoma air mattress,” and what are the advantages of each?

Integrated electric pumps offer convenient inflation using the vehicle’s 12V outlet. Manual pumps provide portability in situations where power is unavailable. The choice depends on the user’s preference for convenience versus portability.

Question 5: How should a “Tacoma air mattress” be properly stored to prevent damage and extend its lifespan?

The mattress should be thoroughly cleaned and dried before deflation. It should be stored in a cool, dry place away from direct sunlight and sharp objects. Following the manufacturers folding or rolling instructions minimizes stress on the material.

Question 6: What factors influence the air pressure within a “Tacoma air mattress,” and how can adjustments be made to compensate?

Ambient temperature fluctuations affect air pressure. Increases in temperature cause expansion, potentially leading to over-inflation, while decreases in temperature cause contraction, reducing firmness. Regular monitoring and adjustment of the air pressure are necessary to maintain optimal support.

Proper selection, maintenance, and understanding of environmental factors are crucial for maximizing the utility and longevity of a “Tacoma air mattress.”

The subsequent section provides insights into potential challenges and troubleshooting techniques associated with “Tacoma air mattress” usage.

In Conclusion

This exploration has outlined critical facets of integrating an inflatable sleeping surface within a Toyota Tacoma. Factors ranging from vehicle compatibility and material durability to inflation mechanisms, support features, and environmental influences significantly impact the utility and longevity of a “tacoma air mattress”. The assessment of these elements is essential for informed purchasing decisions and responsible usage.

The suitability of a “tacoma air mattress” hinges on a comprehensive evaluation of individual needs and environmental contexts. Prioritizing meticulous product selection and conscientious maintenance will optimize user satisfaction and ensure the reliable performance of this vehicular sleeping solution. A commitment to these principles facilitates a functional and comfortable extension of the mobile lifestyle.