A sleeping surface specifically designed for the enclosed sleeping compartment of a large commercial vehicle is essential for drivers undertaking long-haul routes. This component provides a designated rest area within the truck’s cab, allowing drivers to adhere to mandated rest periods and manage fatigue effectively while on the road. The size and construction typically adhere to standards to maximize available space inside the sleeper berth.

The availability of a comfortable in-cab rest area is critical for driver well-being and alertness. Regular rest and adequate sleep contribute significantly to safety by mitigating the risks associated with drowsy driving. Furthermore, a properly supportive area helps drivers maintain physical health and reduces strain from prolonged periods spent behind the wheel. This feature represents an investment in the operational efficiency and the welfare of professional drivers.

The following sections will delve into specific features, materials, dimensions, and considerations when selecting the right sleeping arrangement for heavy-duty trucks, ensuring optimal comfort and compliance with industry standards.

Selection and Maintenance Guidance

The selection and proper care of a durable sleeping surface within a commercial vehicle is paramount for driver health and regulatory compliance. The following guidelines offer key considerations for procurement and upkeep.

Tip 1: Material Composition: Prioritize materials designed for durability and support. High-density foam or innerspring construction can withstand constant use. Consider fire-retardant fabrics to enhance safety and adhere to federal regulations.

Tip 2: Size and Fit: Accurately measure the interior dimensions of the sleeper berth before purchasing. Confirm compatibility with available space to ensure ease of movement within the cab and prevent damage to surrounding components.

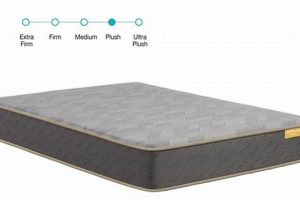

Tip 3: Firmness and Support: Select a firmness level appropriate for individual preferences and spinal support requirements. Consider consulting with a healthcare professional to identify an option that promotes proper posture and reduces back strain.

Tip 4: Breathability and Temperature Regulation: Opt for materials that promote air circulation to minimize heat retention during warmer months. Features such as gel-infused foam or breathable fabric covers contribute to a more comfortable sleep environment.

Tip 5: Regular Cleaning and Maintenance: Implement a routine cleaning schedule to prevent the accumulation of dust, allergens, and bacteria. Use appropriate cleaning products and techniques based on the manufacturers instructions. Consider a protective cover to extend the lifespan of the product.

Tip 6: Replacement Timing: Monitor the sleeping surface for signs of wear, sagging, or diminished support. Replacement should be considered when the product no longer provides adequate comfort or meets required hygiene standards.

Adhering to these recommendations will contribute to improved driver well-being, reduced fatigue, and enhanced operational safety. A well-maintained, appropriately selected sleeping surface is a fundamental aspect of responsible fleet management.

The subsequent sections will provide a detailed examination of specific product options and relevant industry standards.

1. Dimensions

The dimensional specifications of a sleeping surface designed for a commercial vehicle sleeper berth are a primary consideration during selection. The available space within the sleeper compartment directly dictates the acceptable range of measurements to ensure proper fit and functionality.

- Length and Width Compatibility

The length and width must correspond to the interior dimensions of the sleeper berth. Discrepancies can lead to inadequate support, damage to the surrounding interior, and compromised ease of movement within the cab. Standard dimensions exist, but variations are common, necessitating precise measurement before purchase.

- Thickness and Profile

The thickness affects overall comfort and support while also influencing available headroom within the sleeper berth. An excessively thick sleeping surface may reduce headroom, impacting driver comfort during periods of rest or non-driving activities. A thinner profile may compromise support.

- Customization Options

Manufacturers may offer customization options to accommodate non-standard sleeper berth sizes. Tailoring length, width, and thickness can address unique spatial constraints and optimize driver comfort within a specific commercial vehicle model. However, customization can impact cost and availability.

- Weight Considerations

Dimensions impact weight, which is relevant due to commercial vehicle weight regulations. Excessively heavy sleeping surfaces contribute to overall vehicle weight, potentially affecting fuel efficiency and compliance with weight limits. Lightweight materials combined with appropriate dimensions can mitigate this issue.

The dimensional aspects of a sleeper berth component are integrally connected to driver comfort, safety, and regulatory compliance. Careful consideration of these factors ensures that the selected product optimizes the available space, promotes driver well-being, and aligns with operational requirements.

2. Material Durability

The long-term performance and lifespan of a sleeping surface within a commercial vehicle are directly correlated with the inherent qualities of the materials used in its construction. Consequently, material durability is a crucial consideration when evaluating options for use in heavy-duty trucking applications.

- Core Material Integrity

The composition of the internal structure, be it foam, innerspring, or a hybrid system, dictates its resistance to compression and deformation over time. High-density foams, for example, exhibit superior resilience compared to lower-density counterparts, mitigating sagging and maintaining support over extended use. Innerspring systems should utilize tempered steel coils to prevent premature weakening and maintain consistent firmness.

- Fabric Resistance to Wear

The outer fabric layer is subject to constant abrasion from movement and contact with clothing. Heavy-duty fabrics such as reinforced polyester or vinyl exhibit enhanced resistance to tearing, puncture, and abrasion. Seam construction also contributes significantly; reinforced stitching and durable thread minimize seam failure, particularly in high-stress areas.

- Resistance to Environmental Degradation

The interior environment of a commercial vehicle sleeper berth can experience fluctuations in temperature and humidity, along with exposure to potential contaminants like spills or cleaning agents. Materials must demonstrate resistance to degradation caused by these factors. Waterproof or water-resistant fabric treatments can protect against moisture damage, while antimicrobial properties inhibit the growth of mold and mildew.

- Flame Retardancy Compliance

Federal Motor Vehicle Safety Standards mandate specific flame resistance requirements for materials used in commercial vehicle interiors. Durable materials that meet or exceed these standards are critical for minimizing fire hazards. Flame retardancy should be inherent in the material composition and not solely reliant on surface treatments, which may degrade over time.

The longevity and cost-effectiveness of a heavy-duty sleeping surface are intrinsically linked to its material durability. A durable product, constructed from resilient components and resistant to wear, environmental factors, and fire hazards, provides sustained comfort and safety for professional drivers, contributing to improved well-being and operational efficiency. Careful consideration of material specifications is therefore paramount when selecting a sleeper berth sleeping surface.

3. Comfort Support

The level of comfort and support afforded by a commercial vehicle sleeping surface directly impacts driver well-being and operational safety. Adequate comfort support mitigates fatigue, promotes restorative rest, and reduces the risk of musculoskeletal disorders. The relationship between these factors is integral to the selection and maintenance of appropriate sleeping arrangements.

- Spinal Alignment and Posture

A critical aspect of comfort support is the maintenance of proper spinal alignment during rest. The sleeping surface should provide adequate support to the natural curvature of the spine, preventing excessive pressure on specific vertebrae. Poor spinal alignment can contribute to back pain, neck stiffness, and chronic musculoskeletal issues. Examples include mattresses with zoned support, offering firmer resistance in the lumbar region and softer support for the shoulders and hips. The implications are reduced discomfort, improved posture, and enhanced long-term spinal health.

- Pressure Point Relief

Prolonged periods of immobility can result in concentrated pressure on specific areas of the body, potentially leading to discomfort, numbness, and impaired circulation. An effective support system redistributes body weight to minimize pressure points. Materials like memory foam or gel-infused foam conform to the body’s contours, alleviating pressure on areas such as the hips, shoulders, and heels. Reducing pressure points fosters improved circulation and minimizes sleep disturbances.

- Vibration Dampening

The operation of a commercial vehicle generates vibrations that can transmit to the sleeper berth, disrupting sleep and contributing to fatigue. Sleeping surfaces incorporating vibration-dampening materials or design features can mitigate the effects of these vibrations. Specialized foam or innerspring systems designed to absorb and dissipate vibrational energy contribute to a more stable and restful sleep environment. By minimizing vibration, drivers experience more undisturbed sleep and wake feeling more refreshed.

- Temperature Regulation

Temperature regulation refers to how well the mattress maintains a comfortable sleeping temperature. It is impacted by the materials it is made of, its structure, and how well it can allow air flow. If sleeping surfaces have poor temperature regulation, they are more likely to cause night sweats, sleeping problems, and a non-conducive sleeping temperature in general.

These considerations underscore the importance of prioritizing comfort support when selecting a sleeping surface. By addressing spinal alignment, pressure point relief, temperature regulation, and vibration dampening, a suitably designed sleeping surface can contribute significantly to the well-being and operational effectiveness of professional drivers. These factors directly impact fatigue management, safety, and long-term health outcomes within the demanding context of commercial transportation.

4. Fire Resistance

The fire resistance of a sleeping surface within a commercial vehicle sleeper berth is not merely a desirable feature but a mandatory safety requirement dictated by federal regulations. The materials used in these components must meet specific flammability standards to mitigate fire hazards and protect drivers in the event of an accident or other emergency. The connection between the physical materials and their resistance to flames is direct. Non-compliant materials can rapidly ignite and spread flames, exacerbating risks, while compliant materials inhibit fire spread and provide occupants additional time to escape.

Federal Motor Vehicle Safety Standard (FMVSS) 302 outlines the minimum fire resistance requirements for materials used in vehicle interiors, including sleeping surfaces. This standard dictates the maximum burn rate allowed for these materials when exposed to a controlled ignition source. Real-life examples underscore the critical importance of compliance. Incidents involving truck fires have demonstrated that non-compliant interior components can contribute significantly to the rapid spread of flames, increasing the risk of severe injuries or fatalities. Conversely, compliant materials can slow the progression of a fire, providing valuable time for drivers to evacuate safely.

Understanding the significance of fire resistance in the context of the sleeper berth sleeping surface is paramount for fleet operators and drivers alike. Compliance with FMVSS 302 and the selection of materials that exceed minimum fire resistance requirements represents a proactive approach to safety management. Challenges remain in ensuring consistent compliance across all manufacturers and products. However, diligent verification of material specifications and adherence to regulatory standards are essential for minimizing fire-related risks and protecting the well-being of professional drivers.

5. Hygiene Maintenance

The prolonged use and confined environment of a commercial vehicle sleeper berth necessitate diligent attention to hygiene maintenance. The sleeping surface, in particular, serves as a potential reservoir for contaminants, including dust mites, allergens, bacteria, and fungi. The direct connection between the material composition of the mattress and its propensity to harbor these contaminants underscores the importance of selecting appropriate materials and implementing consistent cleaning protocols. Failure to maintain adequate hygiene can lead to skin irritation, respiratory issues, allergic reactions, and other health problems for the driver. Consider, for instance, that a driver spending hundreds of hours each month in the sleeper berth, without proper hygiene protocols, may be exposed to higher concentrations of allergens than someone in a typical home environment.

Effective hygiene maintenance strategies involve several key components. Regular vacuuming removes surface debris and dust mites. The use of mattress protectors or encasements provides a barrier against spills and allergens, simplifying cleaning efforts. Periodically sanitizing with appropriate cleaning agents eliminates bacteria and fungi. The frequency and intensity of cleaning should be adjusted based on the level of usage and environmental conditions. For example, if a driver transports livestock or operates in dusty environments, more frequent and thorough cleaning may be necessary. Furthermore, proper ventilation of the sleeper berth is crucial for reducing moisture buildup and inhibiting the growth of mold and mildew.

In summary, hygiene maintenance is not merely a cosmetic concern but a critical aspect of driver health and safety within the commercial transportation industry. Selecting a sleeping surface with antimicrobial properties and implementing a consistent cleaning regimen can significantly reduce the risk of health problems associated with prolonged exposure to contaminants. Addressing the hygiene requirements of the sleeper berth sleeping surface is a fundamental element of responsible fleet management and driver well-being.

Frequently Asked Questions

This section addresses common inquiries concerning sleeping arrangements within a commercial vehicle.

Question 1: What constitutes a standard dimension for a sleeping surface in a sleeper berth?

While dimensions vary, typical measurements range from 32 to 42 inches in width and 72 to 80 inches in length. Actual measurements depend on the specific sleeper berth configuration. Precise measurements of the available space are crucial prior to purchase.

Question 2: Is flame retardancy a mandatory requirement for materials used in a sleeper berth sleeping surface?

Yes. Federal Motor Vehicle Safety Standard (FMVSS) 302 mandates that all materials used in vehicle interiors, including sleeping surfaces, meet specific flame resistance standards. Compliance is essential for safety and legal operation.

Question 3: How frequently should a sleeper berth sleeping surface be cleaned?

Cleaning frequency depends on usage and environmental conditions. However, a minimum of monthly vacuuming and quarterly sanitization is recommended. More frequent cleaning may be necessary in dusty or high-traffic environments.

Question 4: What type of material is most suitable for a heavy-duty commercial vehicle application?

High-density foam, innerspring systems with tempered steel coils, and hybrid designs offer durability and support. The outer fabric should be constructed from a heavy-duty, abrasion-resistant material such as reinforced polyester or vinyl.

Question 5: What are the potential health consequences of neglecting hygiene maintenance?

Neglecting hygiene can lead to the accumulation of dust mites, allergens, bacteria, and fungi. Potential health consequences include skin irritation, respiratory issues, allergic reactions, and other adverse health effects.

Question 6: How does the thickness of the sleeping surface affect comfort and available space?

Thickness impacts both comfort and headroom. An excessively thick product may reduce headroom, while a thinner product may compromise support. Selecting a thickness that balances comfort and available space is important.

A well-informed purchase supports the health and safety of commercial drivers.

The next section will focus on the future trends in the market and how technology is influencing the field.

Conclusion

This exploration has addressed the significance of a properly specified and maintained tractor trailer sleeper mattress. Critical considerations span material composition, dimensional accuracy, fire resistance, and hygiene protocols. Each of these facets directly contributes to driver well-being, regulatory compliance, and operational safety.

The information presented is intended to foster informed decision-making regarding these components. Prioritizing quality and adhering to maintenance schedules is an investment in the health and professional longevity of commercial drivers, as well as the overall safety and efficiency of transportation operations.

![Best Sleeping Bag with Air Mattress [Sleep Soundly!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Sleeping Bag with Air Mattress [Sleep Soundly!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1805-300x200.jpg)

![Top-Rated: Best Foldable Mattress for Every Night Sleep [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top-Rated: Best Foldable Mattress for Every Night Sleep [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1804-300x200.jpg)

![Find Your Dream Bed: Sleep Train Mattress Center [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Dream Bed: Sleep Train Mattress Center [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1803-300x200.jpg)