Standard measurements for bedding designed for a single-size bed are critical for a proper fit. These measurements, typically around 39 inches wide and 75 inches long, ensure the sheet adequately covers the mattress without excessive looseness or tightness. Fitted sheets often include a pocket depth specification, indicating the thickness of mattress they accommodate. For example, a fitted sheet might be described as suitable for mattresses up to 12 inches deep.

Accurate bedding size selection prevents sheets from slipping off during use, contributing to sleep comfort and hygiene. Historically, variations in bed sizes necessitated careful attention to matching bedding; standardization has simplified this process, but knowing specific measurements remains important, especially when dealing with older or non-standard mattresses. Correctly sized linens also prolong the lifespan of both the mattress and the bedding by reducing stress on the fabric and preventing premature wear.

Understanding the established measurements is the foundation for choosing appropriate bedding. Subsequent discussions will delve into specific types of sheets available, materials, and care instructions, all of which build upon the base knowledge of proper size adherence.

Tips on Selecting Appropriately Sized Bedding

Selecting bedding that corresponds correctly to standard measurements ensures optimal comfort, longevity, and hygiene. These tips are designed to guide purchasers through the process.

Tip 1: Verify Mattress Dimensions. Measure the width, length, and depth of the mattress before purchasing sheets. Manufacturer labels are not always accurate, and mattresses can deviate from standard sizing.

Tip 2: Consider Pocket Depth. Pay attention to the fitted sheet’s pocket depth. A pocket depth that is too shallow will result in the sheet pulling off the mattress; a pocket depth that is too deep may create excess fabric and a loose fit.

Tip 3: Account for Mattress Toppers. If using a mattress topper, incorporate its thickness into the mattress depth measurement. This is essential for ensuring the fitted sheet adequately covers both the mattress and the topper.

Tip 4: Prioritize Fitted Sheet Fit. The fitted sheet is the most critical component in terms of sizing. A properly fitted sheet minimizes movement during sleep and protects the mattress.

Tip 5: Examine Fabric Shrinkage. Certain fabrics, like cotton, are prone to shrinkage after washing. Consider purchasing sheets slightly larger than needed to compensate for potential shrinkage.

Tip 6: Review Product Specifications. Carefully review the product specifications provided by the manufacturer or retailer. These specifications should include detailed measurements and material information.

Tip 7: Read Customer Reviews. Customer reviews can provide valuable insights into the accuracy of product sizing and the overall fit of the sheets.

Adhering to these tips increases the likelihood of selecting sheets that perfectly complement the bed, promoting a restful sleep environment and extending the life of both the mattress and the bedding.

The following section addresses the diverse range of materials used in sheet production and their respective characteristics, providing a more comprehensive understanding of sheet selection.

1. Width

The lateral measurement fundamentally dictates how effectively a sheet covers the surface of a single-size sleeping platform. Inadequate breadth leads to exposure of the mattress, diminishing hygiene and comfort, while excessive breadth introduces bunching and improper fit.

- Standard Bed Size Compliance

The typical dimension is approximately 39 inches. Sheets adhering to this specification are designed to correspond with the industry-standard width of single-size mattresses. Deviations from this standard compromise the sheet’s ability to properly fit the mattress.

- Fabric Stretch and Recovery

The inherent stretch of the material influences the perceived fit. Fabrics with minimal elasticity require precise conformity to width measurements, whereas materials with greater give offer some tolerance. However, excessive stretching can lead to premature wear and diminished lifespan.

- Manufacturing Tolerances

Manufacturing processes inevitably introduce minor variations in size. Reputable manufacturers maintain strict quality control measures to minimize these deviations. Sheets with significant variances may exhibit fitting issues, underscoring the importance of considering brand reputation.

- Impact of Mattress Encasements

The presence of a mattress encasement, intended to protect against allergens and bed bugs, alters the effective width of the sleeping surface. Selecting sheets with slightly increased breadth can compensate for the added girth introduced by the encasement, ensuring a secure and comfortable fit.

Consideration of material properties, manufacturing precision, and auxiliary mattress components is critical when evaluating the adequacy of breadth. Proper selection based on these factors contributes to optimal sleep comfort and extended product life, directly influencing the overall value proposition.

2. Length

The longitudinal measurement constitutes a crucial element when considering bedding for single-size mattresses. Insufficient length leads to incomplete coverage, potentially leaving portions of the mattress exposed and hindering the fitted sheet’s ability to remain securely in place. The standard for this dimension is approximately 75 inches, aligning with the established length of single mattresses. For example, if a sheet is significantly shorter than this measurement, it will invariably slip off the ends of the mattress during use, compromising comfort and mattress protection.

The material composition directly affects perceived length. Some fabrics, like tightly woven cotton, exhibit minimal elasticity, demanding precise length conformity. Conversely, knits or blends containing synthetic fibers may offer greater flexibility. This flexibility provides some degree of tolerance. However, excessive stretching to compensate for inadequate length stresses the material, potentially leading to rips or tears, thereby diminishing the lifespan. The use of bed frames with headboards or footboards further emphasizes length accuracy; sheets that are too short will be impossible to secure properly.

Ultimately, the careful consideration of length, factoring in material properties, manufacturing tolerances, and bed frame design, directly impacts overall satisfaction. Prioritizing dimensional accuracy in this regard contributes to a secure, comfortable sleeping environment and optimizes the longevity of both the bedding and mattress. A mismatch in this area fundamentally undermines the purpose of protective and comfortable bedding. Failing to account for this length can negate the benefits of other sheet qualities such as thread count or material type.

3. Pocket Depth

Pocket depth, a critical element of bedding specifications, indicates the fitted sheet’s capacity to accommodate varying mattress thicknesses. Within the context of single-size bedding, precise pocket depth is not merely a matter of aesthetic preference, but a functional necessity that directly impacts the sheet’s ability to remain securely positioned on the mattress. An insufficient pocket depth, relative to mattress thickness, results in the fitted sheet slipping off the corners, thereby compromising sleep quality and increasing wear and tear on both the sheet and mattress. For example, a mattress measuring 12 inches in thickness requires a sheet with a pocket depth of at least 12 inches, and ideally a bit more to ensure secure corner anchoring.

Conversely, an excessively deep pocket depth, while less problematic than an insufficient one, can lead to bunching and an uneven sleeping surface. This excess fabric may also contribute to increased movement of the sheet during sleep, diminishing overall comfort. Consider a scenario where a 6-inch mattress is paired with a fitted sheet designed for 15-inch mattresses; the resulting slack creates a less-than-ideal sleeping experience. The presence of mattress toppers introduces a further layer of complexity, necessitating the addition of the topper’s thickness to the mattress depth when selecting appropriate sheets.

Ultimately, careful attention to pocket depth, ensuring a close match to the mattress’s combined thickness (including any toppers), is crucial for optimal performance. The challenge lies in accurately measuring mattress depth and interpreting manufacturers’ pocket depth specifications. The link between these measurements significantly influences sleep comfort and the longevity of bedding investments, underscoring the practical significance of meticulous selection and measurement practices.

4. Shrinkage

Shrinkage, the reduction in dimensions of textile products after washing or exposure to heat, directly impacts the suitability of bedding. Considering the established measurements, a manufacturer’s stated dimensions may be inaccurate after initial laundering. For example, a newly purchased fitted sheet labeled as 39 inches wide by 75 inches long could shrink by 2-3% after washing, resulting in an actual width closer to 38 inches and a length nearing 73 inches. This dimensional change may render the sheet difficult to fit or, in extreme cases, unusable on a standard single mattress. The degree of shrinkage varies depending on the fiber content and weave of the fabric.

Different materials exhibit varying degrees of shrinkage. Natural fibers, particularly cotton, are more susceptible to shrinkage than synthetic blends. Weave construction also plays a significant role; tighter weaves generally experience less shrinkage than looser weaves. Fabric pre-treatment, such as pre-shrinking, is a method employed by manufacturers to mitigate this issue. Consumers must consider anticipated shrinkage when purchasing bedding, opting for slightly larger dimensions than the mattress size or choosing pre-shrunk products. Reviewing product care labels and customer reviews regarding shrinkage can inform purchasing decisions.

Ignoring the potential for shrinkage compromises the initial investment in appropriately sized bedding. A lack of awareness may result in sheets that are too small for the intended mattress, causing discomfort and reducing the lifespan of both the sheets and the mattress. Purchasing bedding from manufacturers known for pre-treating their fabrics and carefully reviewing customer feedback on shrinkage rates constitutes proactive mitigation. Acknowledging this factor ensures long-term satisfaction and a proper fit even after repeated laundering.

5. Elastic Strength

Elastic strength within the context of sheets designed for single mattresses refers to the ability of the elastic component, typically located within the fitted sheet’s perimeter, to maintain its tension and recovery after repeated stretching. This characteristic directly impacts the sheet’s capacity to remain securely anchored to the mattress, thereby influencing both comfort and longevity.

- Corner Security and Slippage Prevention

Elastic strength is paramount in maintaining corner security. A fitted sheet with robust elasticity will resist slippage, preventing the sheet from detaching from the mattress during use. For example, elastic that readily loses its stretch will result in the sheet corners popping off the mattress, requiring frequent readjustment. Strong elastic ensures the sheet remains taut and in place, particularly important given the dimensions. The impact of diminished elastic strength translates directly to compromised sleep quality due to movement and bunching of the sheet.

- Accommodating Mattress Thickness Variations

Elastic strength allows a degree of accommodation for mattresses that may deviate slightly from standard measurements. In situations where a single-size mattress is marginally thicker or thinner than average, a fitted sheet with resilient elastic can compensate for these differences. This inherent flexibility extends the sheet’s usability across a wider range of mattresses. For instance, fitted sheets with weak elastic may prove inadequate for mattresses with toppers, while strong elastic offers a more adaptable fit.

- Durability and Resistance to Degradation

The durability of the elastic directly influences the sheet’s overall lifespan. High-quality elastic retains its strength and elasticity over numerous wash cycles, resisting degradation caused by heat and detergent. Inferior elastic, conversely, becomes brittle and loses its stretch prematurely, necessitating frequent sheet replacements. A sheet that claims to conform to the single measurements will quickly fall short if the elastic degrades.

- Material Composition and Elasticity Correlation

The type of material used in the sheet’s construction interacts with the elastic strength. Materials with inherent give or stretch, such as knit fabrics, may require less elastic strength to maintain a secure fit. Conversely, tightly woven materials with limited stretch benefit from stronger elastic to ensure proper anchoring. These woven materials must have strong elastic to make up for this inability to stretch.

In summary, adequate elastic strength is not simply a supplementary feature but an integral characteristic that determines a sheet’s ability to properly function with a single-size mattress. The interplay between elastic strength, mattress dimensions, and sheet material ultimately dictates the overall comfort, durability, and value proposition of bedding.

6. Thread Count

Thread count, often cited as a determinant of sheet quality, denotes the number of horizontal (weft) and vertical (warp) threads woven into one square inch of fabric. While generally associated with softness and durability, its relevance must be considered in conjunction with other factors, especially when selecting bedding for twin-size mattresses.

- Perception vs. Reality in Relation to Bedding Size

Higher thread counts are frequently marketed as indicative of superior quality; however, this correlation is not absolute. A sheet with a high thread count that does not properly fit a twin mattress (approximately 39 inches wide by 75 inches long) offers no practical advantage. Inaccurately sized or poorly constructed sheets, regardless of thread count, will compromise comfort and longevity. Marketing emphasis can overshadow the more critical aspect of dimensional precision.

- Material Composition Influence

The type of fiber significantly impacts the perceived quality and performance. For instance, a cotton sheet with a moderate thread count (e.g., 300-400) may feel softer and more breathable than a polyester blend sheet with a purportedly higher thread count (e.g., 600). The inherent properties of the fiber, such as staple length and yarn quality, exert a more significant influence on the tactile experience than thread count alone. This applies equally to sheets designed for single beds; material remains a factor in user comfort regardless of bed size.

- Weave Type and Its Relationship to Thread Count

The weave pattern affects both the hand feel and the durability. Percale, a plain weave, often results in crisp, durable sheets, while sateen, a satin weave, produces a softer, more lustrous fabric. Two sheets with identical thread counts may exhibit markedly different characteristics based on their weave. A sateen weave with a lower thread count may feel softer than a percale weave with a higher count. Given the standardized dimensions, the weave’s impact on breathability is a core factor.

- Impact on Durability and Longevity

While high thread counts can contribute to durability, the quality of the yarns used is paramount. Inferior yarns, even in high-thread-count sheets, are prone to pilling, tearing, and reduced lifespan. Sheets constructed with long-staple cotton, regardless of thread count, generally exhibit greater durability. In the context of this discussion, higher quality results in greater satisfaction.

In conclusion, while thread count is a relevant factor when assessing sheets for single mattresses, it should not be the sole determinant of purchase decisions. Material composition, weave type, and overall construction quality must also be considered. A sheet with a modest thread count but superior material and construction may offer a more comfortable and durable option than a sheet with a high thread count of inferior quality. It is more appropriate to consider fiber and size than just thread count.

Frequently Asked Questions

This section addresses common inquiries regarding bedding sizes, focusing on factors that impact fit, comfort, and overall satisfaction.

Question 1: What are the standard measurements for sheets designed for single mattresses?

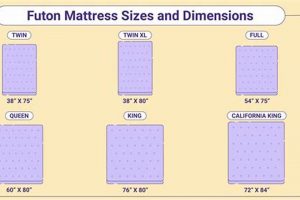

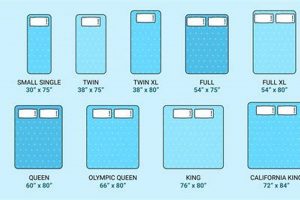

Standard single-size sheets are designed for mattresses approximately 39 inches in width and 75 inches in length. These measurements ensure adequate coverage and a secure fit.

Question 2: How does mattress thickness affect sheet selection?

Mattress thickness, particularly the pocket depth of the fitted sheet, is crucial. The pocket depth should equal or slightly exceed the mattress thickness to prevent the sheet from slipping off.

Question 3: Does thread count guarantee quality bedding?

Thread count is one indicator of quality, but material composition, weave, and yarn quality are equally important. A higher thread count does not automatically equate to superior comfort or durability.

Question 4: How should shrinkage be factored into the bedding selection process?

Anticipate potential shrinkage, especially with natural fibers like cotton. Consider purchasing sheets slightly larger than the mattress or opting for pre-shrunk materials.

Question 5: What role does elastic strength play in fitted sheet performance?

Elastic strength is crucial for maintaining corner security and preventing the fitted sheet from slipping. High-quality elastic retains its tension after repeated use and washing.

Question 6: How do mattress toppers influence sheet sizing requirements?

When using a mattress topper, include its thickness in the overall mattress depth measurement. The fitted sheet’s pocket depth must accommodate both the mattress and the topper.

Understanding these key factors empowers informed decisions when selecting bedding, resulting in optimal comfort and extended product lifespan.

The following section details the care and maintenance strategies that prolong the life of sheets and maintain their dimensional integrity.

Conclusion

The selection of appropriately sized bedding, adhering to established measurements, is paramount for optimal comfort, durability, and hygiene. This exploration of single mattress sheet dimensions highlights the critical interplay between width, length, pocket depth, shrinkage, elastic strength, and thread count. Careful consideration of these factors is essential for ensuring a secure, comfortable sleeping surface and maximizing the lifespan of both bedding and mattresses.

A thorough understanding of these dimensional aspects empowers consumers to make informed purchasing decisions, mitigating potential fitment issues and fostering long-term satisfaction. Prioritizing precision in measurement and recognizing the influence of material properties constitutes a prudent investment in sleep quality and overall well-being. Future advancements in textile technology may further refine sizing standards and enhance the performance of bedding materials; however, adherence to fundamental principles will remain crucial for achieving optimal results.