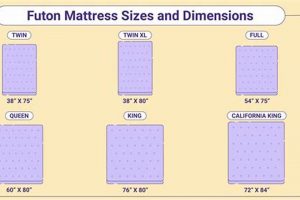

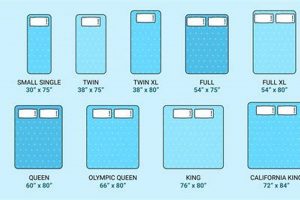

The measurements of an inflated air mattress, designated as “twin size,” generally conform to industry standards for a standard twin bed. These mattresses are designed to accommodate a single sleeper, offering a compact sleeping surface. These dimensions typically fall within a range of approximately 38-39 inches in width and 74-75 inches in length. The height can vary significantly depending on the model and intended use, ranging from a few inches for basic models to over a foot for elevated versions.

The standardization of these measurements allows consumers to readily find compatible bedding and ensures the mattress fits appropriately within spaces intended for a twin bed frame. This consistency is beneficial for temporary sleeping arrangements, guest accommodations, and situations where space is limited. The development of standardized air mattress sizing has evolved alongside the broader mattress industry, providing consumers with reliable expectations regarding product dimensions and compatibility.

Understanding these common measurements is the first step to effectively selecting an air mattress that meets specific needs. The following sections will delve into factors affecting these measurements, comparing different air mattress types, and providing guidance on choosing the right air mattress based on individual requirements.

The following guidelines provide insights into selecting air mattresses with appropriate measurements, ensuring optimal comfort and usability. These tips address factors influencing the accuracy and suitability of advertised measurements.

Tip 1: Verify Inflated Dimensions Post-Inflation: The advertised dimensions of an air mattress represent its approximate size when fully inflated. Inflate the mattress fully and measure its length and width to confirm it aligns with the intended space and ensures it meets listed specifications. Slight variations are common due to material elasticity and inflation level.

Tip 2: Consider Height for Ease of Access: Air mattress height impacts ease of getting in and out. Lower-profile mattresses are more stable, while elevated models offer convenience similar to a standard bed. Assess the user’s physical abilities and mobility needs to determine the optimal height.

Tip 3: Account for Occupant Weight and Distribution: Exceeding the weight capacity of an air mattress can cause sagging and compromise its structural integrity, thereby affecting its dimensions and overall support. Distribute weight evenly to prevent localized deformation and premature wear.

Tip 4: Factor in Room Temperature: Air pressure within the mattress fluctuates with temperature. Cold temperatures decrease pressure, potentially causing a perceived size reduction. Conversely, heat expands the air. Adjust inflation as needed to maintain desired firmness and dimensions.

Tip 5: Review Product Specifications for Deflated Size: Consider the deflated size of the air mattress, especially for storage purposes. Deflated dimensions impact ease of packing, transporting, and storing the mattress when not in use. Larger mattresses require more storage space.

Tip 6: Research Brand Reputation for Dimension Accuracy: Reputable manufacturers are more likely to adhere to accurate dimension specifications. Read reviews and compare models from different brands to gauge consistency and reliability of advertised measurements.

Adherence to these guidelines facilitates the selection of an appropriately sized air mattress that meets individual requirements and ensures lasting usability. Considering all factors will help in selecting the right product.

The subsequent sections will cover specific air mattress models, material composition, and mechanisms of air retention to further inform the purchasing decision.

1. Nominal Width (Inches)

The nominal width, measured in inches, of a twin size blow up mattress is a primary dimensional characteristic defining its compatibility with various bed frames, sleeping spaces, and user requirements. This measurement directly correlates to the mattress’s ability to comfortably accommodate a single sleeper while remaining within the spatial constraints typically associated with a twin-sized bed.

- Standardization and Bed Frame Compatibility

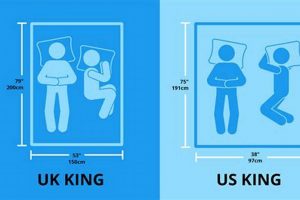

The nominal width is typically standardized around 38 inches for a twin-size air mattress. This standardization ensures that the inflated mattress will fit within a standard twin bed frame, preventing overhang or instability. Deviations from this standard can lead to compatibility issues, requiring careful consideration of frame dimensions before purchase.

- Impact on Sleeper Comfort and Space Utilization

The width directly influences the comfort level experienced by the sleeper, as it determines the available space for movement during sleep. A narrower width may feel restrictive, while a significantly wider mattress may not fit optimally in smaller rooms. Therefore, the nominal width must be balanced with individual preferences and room size limitations.

- Material Properties and Width Stability

The material used in the construction of the air mattress impacts the consistency of the nominal width when inflated. High-quality materials, such as reinforced PVC, are less prone to stretching or deformation, maintaining a more accurate width measurement over time. Inferior materials may expand unevenly, altering the nominal width and potentially reducing comfort.

- Effect on Seam Stress and Durability

The nominal width, combined with inflation pressure, influences stress on the seams of the air mattress. Wider mattresses may experience greater tensile forces along the seams, potentially leading to leaks or failures over extended use. The seam construction quality must therefore be robust enough to withstand these stresses, ensuring long-term durability.

The nominal width of a twin size blow up mattress is a critical parameter that affects not only its compatibility with bed frames but also the sleeper’s comfort, the stability of the inflated structure, and the overall durability of the product. Precise adherence to industry standards and the use of high-quality materials are essential in maintaining the intended nominal width and ensuring a satisfactory user experience.

2. Nominal Length (Inches)

The nominal length, measured in inches, is a crucial component of “twin size blow up mattress dimensions,” dictating the overall sleeping surface available. Its adherence to standardized measurements ensures compatibility with twin-sized beds and adequate accommodation for most single adults or children. Inaccurate length specifications can result in discomfort, inefficient use of space, and potential safety concerns. For example, if the nominal length falls significantly short of the typical 74-75 inches, a taller individual’s feet may hang off the edge, disrupting sleep quality. Conversely, an overestimation of the nominal length can lead to improper fitting within a standard bed frame, posing a tripping hazard or causing instability.

The practical significance of understanding the nominal length extends beyond basic comfort and space utilization. It also affects the structural integrity and longevity of the air mattress. When the length is disproportionate to the width, the mattress may be more susceptible to uneven weight distribution and stress on the seams, increasing the risk of leaks or ruptures. Furthermore, the nominal length influences the deflated storage size; longer mattresses require more space for packing and stowing when not in use. This becomes particularly relevant in settings where storage capacity is limited, such as apartments or guest rooms. Therefore, selecting an air mattress with an accurate and appropriate nominal length is imperative for maximizing its utility and lifespan.

In summary, the nominal length, a critical element of twin size blow up mattress dimensions, directly impacts comfort, compatibility, structural integrity, and storage convenience. The challenges associated with inaccurate nominal length measurements highlight the importance of verifying product specifications and selecting reputable manufacturers who adhere to industry standards. Ultimately, a precise understanding of nominal length facilitates informed purchasing decisions, ensuring the chosen air mattress effectively serves its intended purpose while minimizing potential drawbacks.

3. Inflated Height (Inches)

Inflated height, measured in inches, directly influences the overall functionality and suitability of a twin-size blow-up mattress. As a critical dimension, it affects ease of access, perceived comfort, and integration with existing furniture. An insufficient inflated height, for example, may necessitate a more strenuous effort to get in and out of the mattress, particularly for individuals with mobility limitations. Conversely, excessive height could result in instability or difficulty in finding appropriately sized bedding. The correlation between inflated height and the mattress’s overall stability also warrants consideration. Models with a lower profile, typically under 10 inches, often exhibit greater stability due to a lower center of gravity. Elevated models, exceeding 18 inches, may mimic the feel of a conventional bed but could be more prone to tipping if weight is unevenly distributed.

Real-world examples illustrate the practical significance of understanding inflated height. In guest accommodations, an elevated air mattress with a height comparable to a standard bed frame provides a more welcoming and comfortable experience for visitors. However, in a camping scenario, a low-profile mattress minimizes weight and bulk, facilitating transport and setup. Moreover, the intended use case can dictate the optimal height. For instance, a child’s air mattress should ideally have a lower profile to reduce the risk of falls. Accurate specification and adherence to advertised inflated height dimensions are paramount for ensuring user satisfaction and safety. Failure to account for this dimension can lead to dissatisfaction or, in certain circumstances, potentially hazardous situations.

In summary, inflated height is an integral component of the overall dimensions of a twin-size blow-up mattress, directly impacting accessibility, comfort, stability, and suitability for various applications. Understanding this dimension is essential for making informed purchasing decisions, ensuring that the selected mattress meets the user’s specific needs and circumstances. The challenges associated with inaccurate or misleading height specifications highlight the importance of verifying product details and considering the intended use environment before acquiring an inflatable sleeping solution.

4. Deflated Volume (Cubic Inches)

The deflated volume, measured in cubic inches, of a twin size blow up mattress, is a critical parameter that dictates the convenience of storage and transportation. This measurement quantifies the amount of space the mattress occupies when not inflated, influencing its portability and suitability for situations where space is limited.

- Impact on Storage Space Requirements

The deflated volume directly determines the amount of storage space needed. A smaller volume allows for easier storage in closets, car trunks, or under beds, proving advantageous for users with limited living or travel space. Larger deflated volumes necessitate more considerable storage accommodations.

- Influence on Portability and Transportation

A lower deflated volume results in a more compact and manageable package for transport. This aspect is particularly relevant for camping trips, travel, or emergency preparedness kits where minimizing bulk is essential. A mattress with a high deflated volume may be cumbersome and less practical for these purposes.

- Relationship with Material Composition and Thickness

The material used in the construction of the mattress, along with its thickness, significantly influences the deflated volume. Thicker, more durable materials may contribute to a larger deflated volume compared to thinner, lighter alternatives. However, advancements in material technology have led to more compact and foldable options without compromising durability.

- Considerations for Pumping and Deflation Mechanisms

The design and efficiency of the pumping and deflation mechanisms can indirectly affect the effective deflated volume. Mattresses with integrated pumps may have a larger overall deflated volume due to the space occupied by the pump components. Conversely, mattresses with efficient deflation systems can be compressed more thoroughly, reducing the overall deflated volume.

In conclusion, the deflated volume is a key consideration when evaluating the practicality and convenience of a twin size blow up mattress. Its influence on storage, transportation, material composition, and pumping mechanisms collectively determines the overall user experience. Selecting a mattress with an optimized deflated volume enhances its utility and adaptability to diverse scenarios where space conservation is paramount.

5. Weight Capacity (Pounds)

Weight capacity, measured in pounds, represents a critical specification for twin size blow up mattresses, indicating the maximum load the mattress can safely support without compromising structural integrity or user comfort. It is intrinsically linked to the mattress’s dimensions, construction materials, and intended use.

- Dimensional Stability and Load Distribution

Weight capacity is directly influenced by mattress dimensions. A larger surface area, inherent in a twin size mattress, provides a broader distribution of weight. Exceeding the specified weight limit can lead to localized stress concentration, causing deformation, seam failure, or reduced comfort due to sagging. Therefore, understanding dimensions is essential to preventing weight capacity failure.

- Material Properties and Structural Integrity

The materials used in constructing the air mattress, such as PVC thickness and seam welding techniques, determine its ability to withstand pressure exerted by the user’s weight. Higher weight capacities typically necessitate thicker, more robust materials and reinforced seams to prevent leaks or ruptures under load. The mattress dimensions dictate the amount of material used, influencing overall strength.

- Inflation Pressure and Support Level

Weight capacity is also related to the internal air pressure. Maintaining optimal inflation, based on the user’s weight, ensures adequate support and prevents bottoming out. Exceeding the weight limit can overstress the material, even at lower inflation pressures, potentially causing irreversible damage. The ideal internal pressure is dependent on the mattress dimensions to properly support the load.

- Intended Use and Durability Considerations

The intended application of the air mattress influences the importance of weight capacity. Frequent use or deployment in rugged environments requires a higher weight capacity and more durable construction to withstand prolonged stress. Occasional use for lighter individuals may allow for a lower weight capacity, but safety margins should still be considered. Air mattress dimensions are related to the intended use and determine the expected weight loads.

In summary, weight capacity is an indispensable factor when selecting a twin size blow up mattress, closely interconnected with mattress dimensions, material properties, inflation pressure, and intended use. Accurate assessment of these factors ensures optimal comfort, safety, and longevity of the inflatable sleeping surface.

6. Seam Construction Integrity

Seam construction integrity is paramount in determining the durability and longevity of a twin size blow up mattress. The method of joining the material panels directly affects the mattress’s ability to withstand internal pressure and external stress, especially considering its overall dimensions.

- Seam Welding Techniques and Dimensional Stability

Radio frequency (RF) welding and thermal welding are common techniques. RF welding fuses materials using electromagnetic energy, creating a strong, airtight bond. Thermal welding employs heat to melt and join materials. Superior seam welding techniques contribute to enhanced dimensional stability, preventing bulging or deformation when the mattress is inflated to its specified dimensions. For example, poorly welded seams may separate under pressure, causing the mattress to lose its shape and compromise its support.

- Seam Reinforcement and Stress Distribution

Reinforcement techniques, such as adding fabric tape or using multi-layered seams, distribute stress more evenly across the seam, reducing the risk of failure. Given the dimensions of a twin size mattress, inadequate reinforcement can lead to localized stress concentrations, particularly along the edges and corners. High-stress areas are more vulnerable to leaks or tears if the seams lack sufficient reinforcement.

- Material Compatibility and Seam Durability

The compatibility of the seam material with the mattress’s primary material is essential for a lasting bond. Dissimilar materials may exhibit different expansion and contraction rates with temperature changes, placing stress on the seam. The dimensions of the mattress influence the overall surface area of seams, increasing the potential for issues arising from material incompatibility. Therefore, choosing compatible materials is critical to maintaining seam durability over the lifespan of the mattress.

- Quality Control and Testing Protocols

Rigorous quality control measures and testing protocols are crucial for ensuring seam integrity. These measures include pressure testing, tensile strength testing, and visual inspections to detect any defects or weaknesses in the seams. Comprehensive testing simulates real-world conditions, validating the mattress’s ability to withstand normal use within its intended dimensions. Effective quality control minimizes the likelihood of seam-related failures after purchase.

In summation, seam construction integrity is a non-negotiable factor in the performance and longevity of a twin size blow up mattress. The welding techniques, reinforcement methods, material compatibility, and quality control protocols collectively determine the mattress’s ability to maintain its dimensions and provide reliable support. Neglecting any of these aspects can lead to premature failure and user dissatisfaction.

7. Material Thickness (Mils)

Material thickness, measured in mils (thousandths of an inch), constitutes a critical factor directly influencing the durability, puncture resistance, and overall performance of a twin-size blow-up mattress. The dimensions of the mattress directly affect the required material thickness to ensure adequate structural integrity. A larger surface area, inherent in twin-size mattresses, necessitates a greater material thickness to withstand the internal pressure generated during inflation and the external forces exerted by the user’s weight. Insufficient material thickness, relative to the dimensions, renders the mattress vulnerable to punctures, leaks, and premature failure. For instance, a mattress with a thin material construction, even if possessing adequate dimensions, will likely succumb to punctures from sharp objects or seam separation under normal use conditions.

Material thickness is also inextricably linked to the weight capacity and longevity of the product. Twin-size mattresses constructed with thicker materials can generally support higher weight loads and exhibit greater resistance to wear and tear. This is particularly relevant in scenarios involving frequent use or deployment in demanding environments, such as camping or temporary housing. Moreover, the manufacturing process is influenced by the selected material thickness. Thicker materials often require more advanced welding techniques and quality control measures to ensure consistent seam integrity, further impacting the overall cost and reliability of the product. Understanding the relationship between material thickness and dimensions empowers consumers to make informed purchasing decisions, selecting mattresses that align with their specific needs and usage scenarios.

In summary, material thickness in mils represents a pivotal attribute that determines the resilience and lifespan of a twin-size blow-up mattress. Its correlation with mattress dimensions directly affects the structural stability, puncture resistance, and weight-bearing capacity of the product. Recognizing the significance of this connection facilitates the selection of a durable and reliable inflatable sleeping solution. The challenges associated with inadequate material thickness highlight the importance of scrutinizing product specifications and considering intended use environments to ensure long-term satisfaction and prevent premature product failure.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the measurements of inflatable mattresses categorized as “twin size.” The information provided aims to clarify industry standards and assist in informed purchasing decisions.

Question 1: What are the typical inflated dimensions of a twin size blow up mattress?

Twin size air mattresses generally conform to standard twin bed dimensions, measuring approximately 38 inches in width and 75 inches in length. Height varies by model but typically ranges from 8 to 18 inches.

Question 2: Do all manufacturers adhere strictly to these dimensional standards?

While the stated dimensions serve as a general guideline, minor variations ( +/- 1-2 inches) may occur between brands due to differences in manufacturing processes or material elasticity.

Question 3: How does material thickness influence the durability of twin size blow up mattresses?

Greater material thickness, measured in mils, typically enhances puncture resistance and overall durability, enabling the mattress to withstand higher weight loads and resist wear and tear.

Question 4: What is the significance of weight capacity in relation to mattress dimensions?

Weight capacity specifies the maximum load the mattress can safely support without compromising structural integrity. Exceeding this limit can lead to sagging, seam failure, or reduced comfort, even if the dimensions appear adequate.

Question 5: How does the deflated volume impact the practicality of a twin size blow up mattress?

A smaller deflated volume facilitates easier storage and transportation, making the mattress more convenient for travel, camping, or situations with limited storage space. Larger deflated volumes necessitate more substantial storage accommodations.

Question 6: Why is seam construction integrity crucial for these types of mattresses?

Robust seam construction prevents air leakage and ensures the mattress maintains its intended dimensions under pressure. Inferior seams are prone to failure, reducing the mattress’s lifespan and compromising its support.

Understanding these dimensional aspects and related factors is essential for selecting a twin size blow up mattress that meets specific needs and provides reliable performance.

The following section will provide resources for locating reliable product specifications and customer reviews.

Conclusion

The exploration of twin size blow up mattress dimensions reveals their significance in determining comfort, durability, and suitability for various applications. Accurate measurements, material quality, and seam construction are critical factors influencing overall product performance. Understanding these elements empowers consumers to select an air mattress that meets their specific needs and expectations.

Given the variability in manufacturing standards and the potential for dimensional inaccuracies, thorough research and careful evaluation of product specifications are essential. Prioritizing these considerations ensures a worthwhile investment and promotes long-term satisfaction with the chosen inflatable sleeping solution.