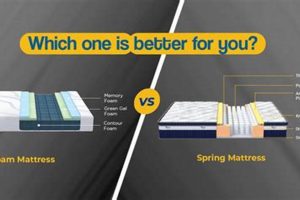

The selection of a suitable sleeping surface for young children is a decision requiring careful consideration. The two primary categories typically evaluated are those constructed with either polyurethane materials or an internal coil system. These options represent distinct approaches to providing support and comfort during sleep, each possessing unique characteristics affecting a child’s rest.

The appropriate sleeping surface plays a critical role in supporting spinal alignment and promoting restful sleep, factors crucial for the physical development of young children. Historically, innerspring designs were prevalent, evolving over time with advancements in coil technology and padding materials. More recently, foam constructions have gained popularity due to their conforming properties and potential hypoallergenic benefits. The choice often depends on balancing factors like firmness, breathability, and individual needs.

The subsequent sections will delve into the specific attributes of these two mattress types, outlining their respective advantages and disadvantages. This analysis will encompass aspects such as material composition, support structure, potential allergenic properties, and considerations for safety standards to aid in making an informed decision regarding a child’s sleep environment.

Guidance on Selecting a Sleeping Surface for Young Children

Selecting an appropriate sleeping surface for a young child necessitates considering several factors to ensure safety, comfort, and optimal development. This section provides specific guidance to assist in this decision-making process.

Tip 1: Firmness Evaluation: The selected surface should offer adequate firmness to support proper spinal alignment. A surface that is too soft can pose a suffocation risk and hinder healthy skeletal development.

Tip 2: Material Composition Review: Investigate the materials used in construction. Opt for options certified as free from harmful chemicals, such as phthalates and formaldehyde, to minimize potential exposure to volatile organic compounds (VOCs).

Tip 3: Safety Standard Verification: Confirm adherence to established safety standards, such as those set by the Consumer Product Safety Commission (CPSC). Ensure the selected product meets or exceeds these requirements.

Tip 4: Hypoallergenic Properties Assessment: Consider options with hypoallergenic properties, particularly if the child has known allergies or sensitivities. Dust mite resistance is a crucial factor in minimizing allergen exposure.

Tip 5: Breathability Considerations: Evaluate the breathability of the material to promote airflow and regulate temperature. Overheating can disrupt sleep and increase the risk of Sudden Infant Death Syndrome (SIDS).

Tip 6: Size and Fit Validation: Prior to purchase, confirm that the dimensions of the surface are compatible with the existing crib or toddler bed frame. A snug fit is essential to prevent gaps and potential entrapment hazards.

Tip 7: Durability Assessment: Assess the anticipated lifespan and durability of the product. Select a robust option designed to withstand regular use and maintain its structural integrity over time.

Careful attention to firmness, material safety, and adherence to standards are paramount. Prioritizing these elements contributes significantly to a safe and supportive sleep environment, positively influencing a child’s health and well-being.

The following section will provide an overall summary of key factors to consider in choosing the best option.

1. Firmness

Firmness is a critical attribute when selecting a sleeping surface for toddlers, directly impacting safety and spinal development. The appropriate level of firmness is essential for ensuring proper support and minimizing potential risks.

- Infant Safety and Suffocation Risk

Excessive softness can pose a suffocation hazard for infants and toddlers who lack the motor skills to reposition themselves if their face becomes pressed against the surface. A firm surface reduces the likelihood of airway obstruction. This is a primary safety concern when choosing between material types.

- Spinal Alignment and Skeletal Development

Adequate firmness provides essential support for the developing spine, promoting proper alignment during sleep. Insufficient support can contribute to poor posture and musculoskeletal issues later in life. Both types should be designed with this in mind.

- Foam Density and Compression

In foam constructions, firmness is determined by foam density and compression. Higher-density foams offer greater resistance and support, while lower-density foams tend to be softer and less supportive. The density impacts how much the material yields under a child’s weight.

- Spring Gauge and Coil Count

In spring constructions, firmness is influenced by spring gauge (thickness) and coil count. Higher-gauge springs and a greater number of coils generally result in a firmer surface. These factors determine the level of support the innerspring provides.

The relationship between firmness and toddler sleeping surfaces is multifaceted, encompassing safety concerns, developmental considerations, and material characteristics. Careful evaluation of these factors is essential in selecting an appropriate surface that prioritizes the child’s health and well-being. Whether foam or spring, the construction must address firmness requirements for safe sleep.

2. Support

Adequate support in sleeping surfaces directly impacts a toddler’s spinal alignment and musculoskeletal development. The selected sleeping surface must maintain a neutral spinal position, preventing excessive curvature or pressure points. Insufficient support can lead to discomfort, restless sleep, and potential long-term postural issues. In foam options, support is derived from the density and composition of the material. Higher-density foam distributes weight evenly, minimizing pressure points and providing consistent support across the body. Conversely, in spring options, support originates from the coil system, where the gauge and arrangement of coils determine the level of resistance and weight distribution.

The practical implications of selecting a support system become apparent when considering a toddler’s sleep patterns and physical development. For example, a toddler transitioning from a crib may require a firmer surface than an older child to maintain spinal alignment. Conversely, a toddler with specific musculoskeletal conditions may benefit from a more conforming surface that cushions pressure points. Furthermore, the long-term effects of insufficient support can manifest as chronic back pain or postural abnormalities. Therefore, a precise evaluation of the support characteristics of the sleeping surface is essential to mitigate these potential risks.

In summary, adequate support is a fundamental requirement in a toddler sleeping surface, irrespective of whether it is constructed with foam or spring materials. The ability to maintain spinal alignment and distribute weight evenly is crucial for promoting restful sleep and preventing musculoskeletal issues. The selection should consider the child’s individual needs, developmental stage, and any specific medical conditions to ensure that the selected sleeping surface provides optimal support.

3. Safety Standards

Safety standards are a critical component in the selection and manufacturing of sleeping surfaces intended for toddlers. These standards are designed to mitigate potential hazards and ensure the well-being of young children during sleep. The absence of adherence to established safety protocols can result in significant risks, ranging from exposure to harmful chemicals to structural instability. For example, the Consumer Product Safety Commission (CPSC) sets specific guidelines regarding flammability, chemical content, and physical construction. Mattresses failing to meet these requirements may contain toxins such as phthalates or formaldehyde, which can negatively impact a child’s health. Furthermore, structural deficiencies can create entrapment hazards, posing a suffocation risk.

Compliance with safety standards involves rigorous testing and certification processes. Manufacturers must demonstrate that their products meet or exceed established benchmarks before they can be marketed for toddler use. Independent testing laboratories often play a crucial role in verifying adherence to these standards. Examples include CertiPUR-US certification for foam products, which ensures that the foam is made without ozone depleters, flame retardants, heavy metals, and other potentially harmful substances. For spring constructions, standards address coil integrity and padding materials to prevent protrusion or detachment, which could lead to injury. Regular monitoring and updates to these standards are essential to adapt to new materials and manufacturing techniques.

In summary, safety standards are not merely optional considerations but integral requirements for sleeping surfaces used by toddlers. These standards safeguard against chemical exposure, structural hazards, and flammability risks. Parents and caregivers should prioritize products that explicitly state compliance with recognized safety certifications, ensuring a safer sleep environment for the child. The proactive enforcement and continuous refinement of these standards are crucial for mitigating potential risks and promoting the health and well-being of young children.

4. Material Composition

The materials constituting a sleeping surface for toddlers directly influence safety, durability, comfort, and potential allergen exposure. Analyzing the composition of foam and spring constructions is essential for informed decision-making.

- Foam Density and Type

Foam options vary in density and type, ranging from polyurethane to memory foam and latex. Density determines firmness and support, while foam type impacts factors such as breathability and hypoallergenic properties. For example, high-density polyurethane provides firmer support, whereas memory foam conforms to the body, distributing weight. The implications are that a higher density foam will tend to have less breathability, thereby increasing risk of overheating.

- Spring Coil Configuration and Metal Type

Spring constructions rely on the coil configuration (e.g., Bonnell, pocketed) and metal type (e.g., steel). The coil configuration affects support and motion isolation, and the metal must be resilient and non-toxic. Pocketed coils, for instance, reduce motion transfer, while steel gauge impacts durability. The choice of steel is important, as recycled or lower-quality material can cause sagging or degradation of the product over a short amount of time.

- Cover Fabric and Fire Retardants

The cover fabric influences breathability, moisture management, and allergen resistance. Additionally, fire retardants are incorporated to meet safety standards, though the specific chemicals used vary, and some are preferable due to lower toxicity. Organic cotton or bamboo fabrics enhance breathability, while chemical fire barriers must meet regulatory requirements. It’s important to check if the product being evaluated used safe fire retardants, such as inherently flame-resistant fibers like wool or silica, or whether more toxic chemicals were used.

- Adhesives and Binding Agents

Adhesives and binding agents are used to hold components together in both foam and spring constructions. These can be a source of volatile organic compounds (VOCs), which may affect air quality and trigger sensitivities. Low-VOC or water-based adhesives are preferable for minimizing potential health impacts, but are also usually lower strength or higher cost. Always verify the adhesive type used during the manufacturing process to ensure health and safety is maintained.

Therefore, a thorough review of material composition is critical when selecting between foam and spring options, and the selection process should prioritize options with certified materials and transparent manufacturing processes. Prioritization of materials has a direct impact on the safety, comfort, and long-term value of a toddler’s sleep environment.

5. Breathability

Breathability, as it pertains to sleeping surfaces for toddlers, refers to the capacity of the materials to allow air to circulate, facilitating the dissipation of heat and moisture. Insufficient breathability can lead to increased body temperature, resulting in discomfort, restless sleep, and, in extreme cases, an elevated risk of Sudden Infant Death Syndrome (SIDS). The material construction of a sleeping surface significantly influences its breathability. Foam structures, particularly those with closed-cell designs, inherently possess lower breathability compared to spring configurations. In contrast, spring constructions, with their open internal architecture, permit greater airflow, naturally aiding in temperature regulation.

The selection of material, therefore, should consider the ambient climate and the child’s individual physiology. For instance, toddlers residing in warmer climates or those prone to overheating during sleep may benefit from spring designs or foam options incorporating ventilation channels. Examples of such design features include perforated foam layers or integrated mesh panels. The absence of adequate breathability can create a microclimate around the child, increasing the risk of skin irritation and promoting the growth of bacteria or mold. Conversely, a breathable sleeping surface promotes evaporative cooling, contributing to a more comfortable and hygienic sleep environment.

In summary, breathability is a critical attribute of sleeping surfaces designed for toddlers. The material composition, whether foam or spring, directly affects airflow and temperature regulation. Prioritizing breathable materials or designs that enhance ventilation is essential for promoting restful sleep, minimizing potential health risks, and ensuring a safe and comfortable sleep environment. This understanding underscores the practical significance of carefully evaluating breathability when selecting a suitable sleeping surface for young children.

6. Durability

Durability, in the context of a sleeping surface for young children, refers to the ability to withstand prolonged use and maintain structural integrity over time. The selection of a sleeping surface with adequate durability is essential, considering the frequency of use and potential for spills or accidents. This factor plays a pivotal role in the long-term value and safety of the product.

- Material Resilience and Deformation

The inherent resilience of the materials used significantly influences durability. Foam options can exhibit compression over time, particularly in high-pressure areas, leading to reduced support and potential sagging. Spring systems may experience coil fatigue or breakage, compromising the surface’s structural integrity. The long-term ramifications include uneven support and a diminished lifespan.

- Construction Quality and Joinery

The quality of construction, including the method of joining components, impacts overall durability. Poorly constructed seams or inadequate adhesive application can result in separation of layers or premature wear. Reinforced edges and robust stitching are indicators of enhanced durability, contributing to the longevity of the product.

- Resistance to Moisture and Staining

The ability to resist moisture penetration and staining is crucial for maintaining a hygienic sleep environment and preserving the integrity of the sleeping surface. Spills and accidents are common occurrences, necessitating a surface that can be easily cleaned and sanitized. Moisture-resistant fabrics and waterproof liners can significantly extend the lifespan by preventing microbial growth and material degradation.

- Weight Capacity and Intended Use

The specified weight capacity and intended use guidelines must be adhered to in order to ensure durability. Exceeding the weight limit or subjecting the sleeping surface to inappropriate use can accelerate wear and potentially compromise structural integrity. Following the manufacturer’s recommendations is essential for maximizing the lifespan and safety of the product.

The facets of material resilience, construction quality, moisture resistance, and adherence to weight capacity contribute to the overall durability of either foam or spring mattresses. Careful evaluation of these factors aids in selecting a product that offers long-term value, maintains its structural integrity, and provides a safe and supportive sleep environment for the growing child.

7. Size Compatibility

The proper dimensions are a non-negotiable aspect of the toddler sleeping surface. Ensuring the selected foam or spring design precisely fits the intended crib or toddler bed frame is paramount for safety and functionality.

- Standard Crib Dimensions

Standard cribs adhere to specific internal dimensions, typically around 28 inches wide by 52 inches long. The chosen mattress must snugly fit within these parameters, preventing gaps where a child could become trapped. Compliance with these established dimensions is not optional; it is a fundamental safety requirement.

- Toddler Bed Frame Variations

Toddler beds, while often designed to accommodate standard crib dimensions, can exhibit slight variations. Prior to selecting a mattress, precise measurements of the internal frame are essential to confirm compatibility. A mismatch in size can compromise safety and necessitate purchasing a different frame or mattress.

- Gap Prevention and Safety Hazards

Gaps between the mattress edge and the bed frame create potential entrapment hazards. Even seemingly small gaps can pose a significant risk to a mobile toddler. Therefore, verifying a snug fit around the entire perimeter of the mattress is critical to minimizing the risk of injury.

- Impact on Mattress Performance

Size compatibility influences the performance and longevity of the sleeping surface. A mattress that is too small may shift or slide during use, potentially leading to uneven support and accelerated wear. Conversely, an oversized mattress may be difficult to install and could compromise the structural integrity of the bed frame.

Therefore, confirming that the correct measurements are taken from both the sleeping surface and the frame provides a safe sleep for the toddler. A properly sized mattress not only minimizes safety hazards but also ensures optimal support and extended product lifespan.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection and use of sleeping surfaces designed for toddlers. These responses aim to provide clarity and inform decision-making based on established safety guidelines and best practices.

Question 1: What level of firmness is recommended for a toddler sleeping surface?

A firm surface is recommended to ensure proper spinal support and reduce the risk of suffocation. Avoid surfaces that excessively conform to the body, as these can pose a safety hazard for young children.

Question 2: How often should a toddler sleeping surface be replaced?

The lifespan of a sleeping surface varies depending on material quality and usage. Regular inspection for signs of wear, sagging, or damage is essential. Replacement is warranted if the surface no longer provides adequate support or exhibits safety concerns.

Question 3: What safety certifications should be considered when selecting a sleeping surface?

Certifications such as CertiPUR-US (for foam) and those indicating compliance with Consumer Product Safety Commission (CPSC) standards are important. These certifications verify adherence to safety guidelines regarding chemical content and flammability.

Question 4: How can potential allergens be minimized in a toddler’s sleep environment?

Select hypoallergenic materials, such as those resistant to dust mites, and regularly clean the sleeping surface. Consider using a protective cover to prevent allergen accumulation.

Question 5: What are the key considerations for breathability in a sleeping surface?

Breathable materials promote airflow and help regulate temperature. Opt for surfaces with ventilation channels or open-cell foam structures to reduce the risk of overheating.

Question 6: How important is size compatibility between the sleeping surface and the bed frame?

Precise size compatibility is crucial to prevent gaps where a child could become entrapped. Ensure the sleeping surface fits snugly within the bed frame, leaving no openings that could pose a safety hazard.

In summary, informed decision-making regarding sleeping surfaces involves careful consideration of firmness, safety certifications, allergen minimization, breathability, and size compatibility. Regular maintenance and adherence to safety guidelines contribute to a healthy and secure sleep environment.

The subsequent section will provide concluding remarks and summarize the key aspects of choosing a suitable sleeping surface for young children.

Conclusion

The exploration of foam or spring mattress options for toddlers reveals a nuanced decision-making process. Key considerations include firmness, safety standard compliance, material composition, breathability, durability, and size compatibility. Each factor contributes significantly to the safety, comfort, and long-term suitability of the sleeping surface.

The selection of the appropriate sleeping surface represents a critical investment in a child’s well-being. Prioritizing adherence to established safety standards and a thorough evaluation of individual needs remains paramount. Future research into advanced materials and enhanced safety features may further refine the options available, but a comprehensive understanding of existing factors ensures an informed and responsible choice.

![Easy How-To: Cut Foam Mattress Like a Pro [DIY Guide] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Easy How-To: Cut Foam Mattress Like a Pro [DIY Guide] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-335-300x200.jpg)