A sleeping platform designed to fit the dimensions of a recreational vehicle and accommodate two adults is a critical component of mobile living. Typically measuring around 60 inches wide by 80 inches long, this sleeping surface offers a balance between comfort and space efficiency within the confines of a motorhome. These specialized sleeping solutions frequently utilize materials engineered for resilience and support, essential for travel and variable conditions.

The availability of a comfortable and appropriately sized bed significantly enhances the travel experience, contributing to restful sleep and overall well-being on the road. Historically, recreational vehicle sleeping arrangements were often rudimentary, but advancements in material science and manufacturing have led to improved comfort and support. This evolution is driven by the increasing demand for higher quality amenities in recreational vehicles, reflecting a shift towards more extended and comfortable travel.

Subsequent sections will explore the various types available, factors to consider when selecting one, and maintenance tips to ensure longevity and hygiene. This analysis will empower readers to make informed decisions, optimizing their sleeping arrangements for enhanced travel comfort.

Optimizing Your Motorhome Queen Size Mattress Experience

Maximizing the comfort and lifespan of a recreational vehicle sleeping platform requires careful consideration and proactive measures. The following tips offer guidance on selection, maintenance, and optimization.

Tip 1: Assess Dimensions Accurately: Prior to purchase, meticulously measure the available space within the recreational vehicle. Ensure the selected model provides adequate clearance and maneuverability within the sleeping area.

Tip 2: Prioritize Material Quality: Opt for materials known for durability, breathability, and support. Memory foam, latex, or hybrid constructions often provide superior comfort and longevity compared to traditional innerspring options.

Tip 3: Invest in a Protective Cover: A waterproof and hypoallergenic cover safeguards the sleeping surface from spills, stains, and allergens, extending its lifespan and promoting hygiene.

Tip 4: Rotate Regularly: Consistent rotation equalizes wear and tear, preventing sagging and maintaining uniform support across the entire surface.

Tip 5: Ventilate Thoroughly: Allow for adequate ventilation to prevent moisture buildup and mildew growth. Regularly remove bedding and elevate the surface when possible to promote airflow.

Tip 6: Consider a Mattress Topper: A topper can enhance comfort and provide additional support. Select a topper that complements the existing sleeping surface and addresses specific comfort preferences.

Tip 7: Address Sagging Promptly: If sagging occurs, investigate potential causes such as inadequate support or material degradation. Consider replacing the sleeping platform or reinforcing the underlying support structure.

Implementing these strategies will contribute to a more comfortable and hygienic sleeping environment within the recreational vehicle, prolonging the life of the unit and enhancing the overall travel experience.

The subsequent section will summarize the key considerations for selecting the ideal sleeping platform and provide concluding remarks on maximizing comfort while traveling.

1. Dimensions

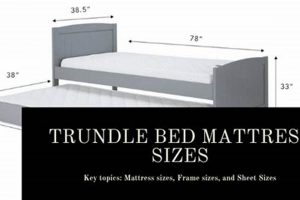

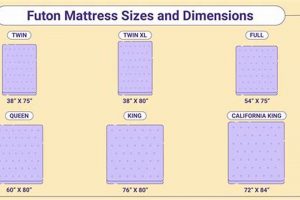

The dimensions of a sleeping platform designed for a recreational vehicle are inextricably linked to its functionality and suitability. A standard “motorhome queen size mattress” nominally measures 60 inches in width and 80 inches in length. Deviations from these standard dimensions, even by a few inches, can render the item incompatible with the intended sleeping space within the recreational vehicle. This incompatibility arises because recreational vehicle manufacturers often design sleeping areas with precise constraints, leaving minimal tolerance for oversized units. For example, attempting to fit a sleeping surface that is even two inches wider than the designated space can obstruct passageways, impede access to storage compartments, or prevent the complete closure of slide-outs. Therefore, accurate measurement and adherence to specified dimensions are paramount for a successful installation.

Furthermore, the dimensions influence the overall comfort experienced by occupants. While a “motorhome queen size mattress” provides sufficient sleeping space for two adults, variations in length or width can significantly affect the ability to stretch out and sleep comfortably. A shorter unit may lead to cramped conditions, while an excessively narrow unit might result in disturbed sleep due to limited personal space. The practical implications of incorrect dimensions extend beyond comfort, potentially impacting sleep quality and overall well-being during travel. Cases abound of individuals struggling with sleep deprivation on extended trips due to ill-fitting and uncomfortable sleeping arrangements. This, in turn, can affect driving safety and the enjoyment of the travel experience.

In summary, the relationship between dimensions and a recreational vehicle sleeping platform is fundamental. Precise dimensions are essential for proper fit, functionality, and occupant comfort. Failure to account for these dimensional constraints can lead to significant inconvenience, diminished sleep quality, and a compromised travel experience. Attention to detail in measuring and selecting the appropriately sized sleeping unit is, therefore, a critical factor in ensuring a positive and restful journey. The dimensional accuracy is essential for long-term comfort in any RV adventure.

2. Material Composition

The materials used in construction directly impact the comfort, durability, and overall suitability of a recreational vehicle sleeping platform. Choices range from traditional innerspring designs to advanced memory foam, latex, and hybrid constructions. The selection of materials influences factors such as weight, breathability, support, and resistance to mold and mildew, all critical considerations within the confined and often variable environmental conditions of a motorhome. For example, a sleeping surface utilizing open-cell memory foam can offer superior pressure relief and contouring compared to a traditional innerspring model, potentially alleviating discomfort for individuals with back pain. Conversely, a closed-cell foam may trap heat and moisture, leading to discomfort and promoting the growth of microorganisms. Consequently, the material composition acts as a primary determinant of user satisfaction and product longevity.

The impact of material choices extends beyond individual comfort. A heavy unit can negatively affect fuel efficiency and vehicle handling, especially in smaller recreational vehicles. Conversely, a lightweight design may compromise support and durability. Furthermore, materials with inherent antimicrobial properties can help maintain hygiene, particularly in environments prone to temperature fluctuations and humidity. For instance, latex possesses natural antimicrobial properties, making it a suitable choice for individuals with allergies or sensitivities. The practical application of this understanding is evident in the growing popularity of hybrid units, which combine the benefits of different materials to optimize comfort, support, and weight. A hybrid unit might incorporate a layer of memory foam for pressure relief, supported by a coil system for enhanced stability and airflow.

In conclusion, material composition is a foundational element of any “motorhome queen size mattress,” influencing comfort, durability, weight, and hygiene. Careful consideration of these factors is essential for selecting a sleeping surface that meets the specific needs of the traveler and the demands of the recreational vehicle environment. While advanced materials offer potential benefits, a thorough understanding of their properties and limitations is necessary to avoid unintended consequences. The challenges in choosing the ideal composition lie in balancing competing priorities such as comfort, weight, and cost, ultimately linking back to the broader theme of optimizing the travel experience within the constraints of a motorhome.

3. Support Structure

The underlying framework is a critical determinant of comfort, durability, and longevity. It directly impacts weight distribution, motion isolation, and overall structural integrity. A robust support system ensures that the sleeping surface maintains its shape and provides consistent support across its entire area, preventing sagging and promoting proper spinal alignment. The specific design and materials used in the support structure are key differentiating factors among various sleeping platform models.

- Innerspring Coils

Traditional innerspring systems consist of interconnected metal coils that provide support through compression. Coil gauge and design influence firmness and responsiveness. Examples include Bonnell coils, known for affordability and durability, and pocketed coils, which offer enhanced motion isolation by individually encasing each coil. The spacing and arrangement of coils directly affect weight distribution. Inadequate coil density can lead to uneven support and premature sagging, especially in high-traffic areas of the sleeping surface. The resilience of innerspring systems often degrades faster when subjected to frequent movement and vibrations commonly experienced during motorhome travel.

- Foam Core

All-foam constructions utilize a high-density foam core to provide support and stability. Foam density is a critical factor, with higher densities offering greater support and resistance to compression. Examples include high-density polyurethane foam, which is cost-effective and provides a firm base, and latex foam, which offers superior elasticity, breathability, and durability. Foam core systems excel in motion isolation, minimizing disturbance from a sleeping partner’s movements. However, inadequate foam density can result in premature softening and sagging, reducing the lifespan. Proper ventilation is also essential to prevent moisture buildup within the foam core.

- Hybrid Systems

Hybrid systems combine elements of both innerspring and foam constructions to optimize comfort and support. Typically, these systems feature a layer of pocketed coils for targeted support and motion isolation, topped with layers of foam for pressure relief and contouring. Hybrid systems offer a balance of responsiveness and cushioning, accommodating a wider range of sleeping preferences. However, the complexity of hybrid designs can increase cost and weight. The quality of both the coil system and foam layers is essential for ensuring long-term performance. Inferior materials can compromise the integrity of the support structure, leading to premature wear and reduced comfort.

- Platform Foundations

The platform on which the sleeping platform rests contributes significantly to its overall support. Slatted platforms, often made of wood or metal, provide airflow and allow for even weight distribution. Solid platforms offer maximum support but can restrict airflow and potentially trap moisture. The spacing and strength of slats are critical, as excessive spacing can lead to sagging between slats. Similarly, the material and construction of a solid platform must be robust enough to withstand the weight of the sleeping platform and its occupants. Improper foundation support can negate the benefits of even the highest quality “motorhome queen size mattress.”

These facets of support systems are important factors that influence the longevity and durability of this type of sleeping surface. Selecting a type based on its components and performance is essential to comfort.

4. Weight Considerations

The weight of a “motorhome queen size mattress” exerts a direct influence on fuel efficiency, vehicle handling, and overall load capacity. Excessive weight reduces fuel mileage, increases stress on suspension components, and can compromise maneuverability. The cumulative effect of added weight, including the sleeping surface and its occupants, must remain within the recreational vehicle’s gross vehicle weight rating (GVWR) to ensure safe operation. Exceeding the GVWR can lead to mechanical failures, reduced braking performance, and increased risk of accidents. For instance, a motorhome already near its maximum weight capacity may experience significant handling instability after adding a heavy sleeping surface, particularly on winding roads or during sudden maneuvers. The selection, therefore, necessitates a careful balance between comfort and weight, often involving trade-offs in material choices and construction techniques. A lightweight model, while preserving fuel efficiency, might sacrifice some degree of support or durability, whereas a heavier model may provide superior comfort but negatively impact vehicle performance.

Practical implications extend to storage considerations. A lighter sleeping platform is easier to handle and maneuver, facilitating cleaning and maintenance. Conversely, a heavier unit requires additional effort and may necessitate specialized equipment for removal or repositioning. Consider, for example, the scenario of replacing a worn-out sleeping surface in a motorhome. A lighter unit can be managed by a single person, while a heavier unit might require two individuals or the assistance of mechanical lifting devices. The selection affects not only the immediate impact on vehicle performance but also the long-term maintenance and operational costs. This interaction highlights the necessity for integrating “weight considerations” into the initial selection criteria, aligning the decision with the vehicle’s specifications and the owner’s physical capabilities.

In summary, “weight considerations” constitute an essential component of the decision-making process when selecting a “motorhome queen size mattress.” The weight directly affects fuel consumption, vehicle handling, and load capacity, necessitating a strategic balance between comfort, durability, and operational efficiency. Failure to adequately address this factor can result in compromised vehicle performance, increased maintenance costs, and potential safety hazards. The challenges lie in identifying the optimal weight range that satisfies comfort requirements while remaining compatible with the vehicle’s limitations, requiring a comprehensive understanding of the vehicle’s specifications and the available product options. The goal is to enhance the travel experience by ensuring both comfort and safety within the constraints of the mobile environment.

5. Ventilation Properties

The effectiveness with which a “motorhome queen size mattress” facilitates air circulation is a pivotal factor influencing comfort, hygiene, and longevity. Inadequate ventilation leads to moisture accumulation, fostering mold and mildew growth, compromising sleep quality, and shortening the product’s lifespan. Optimizing airflow is thus essential for maintaining a healthy and comfortable sleeping environment within the confines of a recreational vehicle.

- Material Breathability

The inherent breathability of constituent materials significantly impacts ventilation. Open-cell foam structures, such as latex or certain memory foam variants, promote greater airflow compared to closed-cell alternatives. For example, a sleeping surface constructed with open-cell memory foam allows for better moisture evaporation, reducing the risk of overheating and microbial growth. In contrast, a closed-cell foam traps heat and moisture, creating a conducive environment for mold and mildew. The selection of materials with superior breathability is a primary strategy for enhancing ventilation. Considerations should include the material’s inherent properties and its ability to wick away moisture from the sleeping surface.

- Construction Techniques

The construction methodology influences ventilation. Channeling and contouring techniques within the core of the sleeping platform create pathways for air circulation. These channels facilitate the movement of air, dissipating heat and reducing moisture buildup. For example, a sleeping surface with strategically placed vertical channels promotes airflow beneath the occupant, preventing heat from becoming trapped. The effectiveness of these techniques depends on the channel design, material permeability, and the overall structure of the sleeping surface. Poorly designed channels can impede airflow, negating the intended benefits. Proper construction techniques are thus essential for optimizing ventilation.

- Support Platform Design

The design of the platform upon which the sleeping platform rests impacts ventilation. Slatted platforms offer superior airflow compared to solid platforms. The spacing between slats allows for air to circulate beneath the sleeping surface, preventing moisture from accumulating. Conversely, a solid platform restricts airflow, potentially leading to moisture buildup and microbial growth. For instance, a recreational vehicle with a solid platform may require additional measures to promote ventilation, such as the use of a dehumidifier or the installation of ventilation vents. The selection of a platform that facilitates airflow is crucial for maintaining a dry and hygienic sleeping environment.

- Cover Materials and Design

The choice of cover materials and its design contribute significantly to overall ventilation. Breathable fabrics, such as cotton or specialized performance textiles, enhance air circulation and moisture wicking. Conversely, impermeable covers, such as vinyl, restrict airflow and trap moisture. The cover design can further enhance ventilation through the incorporation of mesh panels or perforated materials. For example, a sleeping surface with a breathable cover and mesh side panels promotes airflow and reduces the risk of overheating. The proper selection of cover materials and thoughtful design are essential for optimizing ventilation.

These facets material breathability, construction techniques, support platform design, and cover materials collectively determine the ventilation properties of a “motorhome queen size mattress”. By carefully considering these factors, it becomes possible to mitigate moisture accumulation, inhibit microbial growth, and maintain a comfortable sleeping environment within the unique conditions of a recreational vehicle. Optimizing ventilation enhances not only the occupant’s comfort but also the longevity and hygiene of the sleeping arrangement.

6. Durability Assessment

The sustained performance of a “motorhome queen size mattress” under the rigors of travel is paramount. Durability assessment, therefore, constitutes a critical phase in the selection process, ensuring long-term comfort and value. The resilience of a mobile sleeping platform is tested by constant motion, temperature fluctuations, and varying levels of humidity, necessitating rigorous evaluation of construction and materials.

- Material Fatigue Resistance

The capacity of constituent materials to withstand repeated stress is central to durability. Foam densities, coil gauges, and fabric tensile strengths directly correlate with the ability of a sleeping platform to resist sagging, deformation, and tearing. For example, a high-density memory foam possesses a greater resistance to compression set than a low-density alternative, maintaining its shape and support over extended use. Similarly, tightly woven fabrics exhibit greater tear resistance compared to loosely woven materials, prolonging the lifespan of the cover. Inadequate material fatigue resistance results in premature wear and a diminished level of comfort.

- Seam and Stitch Integrity

The robustness of seams and stitching directly impacts the structural integrity. Weak seams or poorly executed stitches are prone to unraveling under stress, compromising the overall stability of the cover and internal components. The use of high-quality threads and reinforced stitching techniques enhances seam strength, preventing premature failure. The susceptibility of seams to abrasion and environmental degradation necessitates rigorous testing to ensure they withstand the challenges of mobile use. Failures in seam integrity can lead to exposed internal components and a compromised sleeping surface.

- Resistance to Environmental Factors

Exposure to humidity, temperature fluctuations, and sunlight can degrade materials over time. Foam can crumble, fabrics can fade, and metal components can corrode. Incorporating materials with inherent resistance to these environmental factors extends the lifespan. For instance, UV-resistant fabrics prevent fading and deterioration from prolonged sun exposure, while antimicrobial treatments inhibit mold and mildew growth in humid conditions. Evaluating a sleeping platform’s resistance to environmental degradation is essential for ensuring longevity in diverse climates and travel conditions.

- Foundation Compatibility and Support

The degree to which a sleeping platform is adequately supported by its foundation directly influences its durability. Inadequate support can lead to uneven weight distribution, accelerated wear, and premature sagging. Compatibility between the sleeping surface and the support structure is crucial for optimal performance. A slatted foundation with insufficient spacing can result in localized stress points, while an improperly sized frame can cause edge compression. Assessing the foundation and ensuring it provides adequate and uniform support contributes to the long-term durability and stability of the sleeping platform.

Assessing these facets of a “motorhome queen size mattress” enables informed purchasing decisions. Durability assessment, focusing on material fatigue resistance, seam integrity, environmental factors, and foundation compatibility, directly addresses the longevity and performance. Through careful evaluation, it is possible to ensure a prolonged and comfortable sleeping experience, enhancing the overall enjoyment and value of the motorhome lifestyle.

Frequently Asked Questions about “Motorhome Queen Size Mattress”

The following questions address common inquiries and misconceptions regarding sleeping platforms designed for recreational vehicles, offering clarity on critical aspects to consider before purchase.

Question 1: What are the standard dimensions for a “motorhome queen size mattress,” and why are these dimensions critical?

The standard dimensions are typically 60 inches in width and 80 inches in length. Adherence to these dimensions is critical because recreational vehicle sleeping areas are often precisely designed, leaving minimal tolerance for oversized units. Deviations can impede access, hinder functionality, or prevent complete closure of slide-outs.

Question 2: What material properties should be prioritized when selecting a “motorhome queen size mattress,” and why?

Material properties such as breathability, support, and resistance to mold and mildew should be prioritized. These factors directly influence comfort, hygiene, and longevity within the confined and often variable environmental conditions of a motorhome. Open-cell foam, for example, promotes superior airflow, reducing moisture accumulation.

Question 3: How does the support structure of a “motorhome queen size mattress” impact its performance, and what options are available?

The support structure determines weight distribution, motion isolation, and overall structural integrity. Options include innerspring coils, foam cores, and hybrid systems. Each offers varying degrees of support, responsiveness, and durability. A robust support system prevents sagging and promotes proper spinal alignment.

Question 4: Why are weight considerations crucial when choosing a “motorhome queen size mattress,” and what are the potential consequences of ignoring this factor?

Weight is crucial due to its impact on fuel efficiency, vehicle handling, and overall load capacity. Exceeding the recreational vehicle’s gross vehicle weight rating (GVWR) can lead to mechanical failures, reduced braking performance, and an increased risk of accidents.

Question 5: How can adequate ventilation be ensured for a “motorhome queen size mattress,” and why is it important?

Ventilation can be ensured through the selection of breathable materials, channeling construction techniques, and a slatted platform design. Adequate ventilation is vital for preventing moisture accumulation, inhibiting mold and mildew growth, and maintaining a healthy sleeping environment.

Question 6: What key factors should be considered when assessing the durability of a “motorhome queen size mattress,” and how can these factors be evaluated?

Key factors include material fatigue resistance, seam and stitch integrity, resistance to environmental factors, and foundation compatibility. These factors can be evaluated by examining material specifications, inspecting construction quality, and considering the intended usage conditions.

The key takeaways emphasize the importance of considering dimensions, material properties, support structure, weight, ventilation, and durability to select a sleeping platform optimized for the unique demands of mobile living.

The subsequent section will provide concluding remarks, summarizing essential aspects discussed in the article.

Conclusion

This exploration of “motorhome queen size mattress” has underscored the multifaceted considerations crucial for informed decision-making. Dimensions, material composition, support structure, weight considerations, ventilation properties, and durability assessment each contribute significantly to the suitability and longevity of a sleeping platform within a recreational vehicle. Optimal selection necessitates careful evaluation of these interdependent factors to ensure both comfort and safety.

The selection process should prioritize a holistic understanding of the user’s needs and the vehicle’s limitations. By diligently addressing these factors, one can enhance the travel experience, optimize sleep quality, and maximize the value of the investment. The principles outlined herein serve as a foundation for ensuring long-term comfort and satisfaction in the unique environment of mobile living.