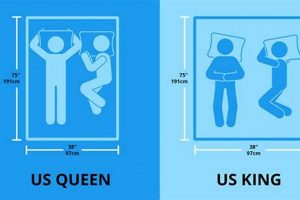

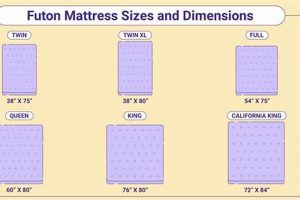

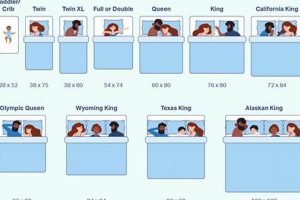

Determining the accurate dimensions of a bed is a critical step before purchasing new bedding, ordering custom linens, or replacing an existing foundation. This process involves carefully obtaining measurements of the mattress’s length, width, and sometimes, its depth or thickness. For instance, a queen-size mattress typically measures 60 inches in width and 80 inches in length, but slight variations can occur between manufacturers or models.

Precise dimension identification ensures compatibility with bed frames, prevents ill-fitting sheets, and contributes to overall sleep comfort. Historically, standardized sizes were developed to streamline manufacturing and purchasing processes, benefiting both consumers and the bedding industry. Accurate measurements prevent unnecessary returns and exchanges, saving time and resources.

The subsequent sections will provide detailed guidance on the tools and techniques required to obtain accurate mattress dimensions, addressing potential challenges and offering solutions for irregular or unusually shaped mattresses.

Guidance on Mattress Dimension Assessment

The following recommendations offer a structured approach to achieving precise mattress dimension measurements, essential for informed decision-making in bedding and sleep-related purchases.

Tip 1: Utilize Appropriate Tools: Employ a rigid measuring tape, preferably metal, for greater accuracy. Cloth tapes can stretch or distort, leading to imprecise readings.

Tip 2: Ensure Mattress Flatness: Before measuring, verify the mattress is lying flat on a level surface. Uneven surfaces can skew measurements.

Tip 3: Measure Length First: Extend the measuring tape from one end of the mattress to the other, ensuring it runs along the center line to obtain the length dimension.

Tip 4: Measure Width Next: Similarly, measure across the mattress, from side to side, again ensuring the tape runs along the centerline for the width dimension.

Tip 5: Account for Bulges or Padding: If the mattress has significant bulges or extra padding along the edges, take measurements at the widest points to ensure accurate frame compatibility.

Tip 6: Document Measurements Immediately: Record the obtained dimensions in inches or centimeters, ensuring clear labeling of length, width, and, if relevant, thickness.

Tip 7: Verify Manufacturer Specifications: Compare the obtained measurements with the manufacturer’s stated dimensions to identify any discrepancies and account for potential variations.

Adhering to these guidelines minimizes errors in dimension assessment, leading to more informed purchasing decisions and ensuring proper fit with bedding and bed frames.

The concluding section will summarize the importance of accurate mattress dimension assessment and highlight potential resources for further assistance.

1. Precise tape placement

Precise tape placement directly influences the accuracy of the data obtained when assessing bed dimensions. Erroneous positioning of the measuring instrument can result in skewed length and width values, ultimately undermining the integrity of the measurement process. For instance, if the tape measure deviates even slightly from a straight line along the mattress’s edge, the recorded length will be an overestimation. Such inaccuracies can lead to the selection of ill-fitting bed frames or bedding, resulting in financial losses and practical inconveniences.

The central axis of the mattress serves as a critical reference point for accurate tape positioning. Measuring along this centerline minimizes the impact of edge irregularities or slight variations in mattress shape. Furthermore, ensuring the tape measure lies flat against the mattress surface eliminates slack, which can introduce additional measurement errors. A practical application of this principle involves using a straight edge or ruler as a guide to maintain consistent tape alignment, particularly when measuring mattresses with rounded corners or uneven surfaces. This methodical approach enhances the reliability of the obtained data, contributing to informed decision-making in bedding selection.

In summary, diligent attention to tape placement is an indispensable component of the overall measurement procedure. By adhering to principles of straight alignment and surface contact, one minimizes the potential for errors and achieves a more accurate representation of the mattress dimensions. The challenges associated with irregular mattress shapes can be mitigated through the use of supplementary tools and meticulous technique, ultimately ensuring that the bedding purchased is appropriately sized and functional. Understanding the impact of Precise tape placement plays a crucial role in measure mattress size effectively.

2. Account for pillow tops

The presence of a pillow top significantly impacts the overall dimensions of a mattress, necessitating a modified approach to measurement. These additional layers of padding, sewn atop the main mattress structure, increase the mattress’s thickness. Consequently, neglecting to account for the pillow top during measurement results in an underestimation of the mattress’s total depth. This discrepancy can cause difficulties when selecting appropriately sized sheets or when assessing the compatibility of the mattress with existing bed frames. For example, standard fitted sheets designed for mattresses with a 12-inch depth may be inadequate for a pillow-top mattress exceeding 14 inches, leading to improper fit and potential slippage.

The process of accurately capturing the dimensions of a pillow-top mattress requires careful attention to the protruding edges of the added layer. Instead of pressing the measuring tape directly onto the firm surface of the main mattress, the tape must conform to the contours of the pillow top, capturing its full height at various points. Averaging these measurements provides a more precise representation of the mattress’s overall thickness. Additionally, when assessing the length and width, potential compression of the pillow top under pressure should be considered. Applying consistent, moderate pressure during measurement replicates real-world conditions and yields more accurate results.

In summary, accounting for the pillow top is an essential component of accurate mattress measurement. The consequences of neglecting this feature can range from ill-fitting bedding to incompatibility with existing frames. By adopting a measurement technique that acknowledges the pillow top’s added dimensions and potential for compression, individuals can ensure a proper fit and avoid unnecessary expenses associated with incorrect sizing. Understanding how to account for pillow tops plays an integral role to measure mattress size effectively.

3. Measure at widest points

The instruction to “measure at widest points” is intrinsically linked to the accurate determination of mattress dimensions. Dimensional assessment, as it applies to mattresses, aims to define the maximum space a mattress will occupy within a given environment, such as a bed frame. Therefore, identification of the mattress’s widest points, whether resulting from deliberate design or unintentional bulging, becomes critical for ensuring compatibility. Failure to adhere to this practice can lead to selection of inappropriately sized bed frames or bedding, resulting in functional impairment and aesthetic concerns. For instance, a mattress with bulges exceeding the internal dimensions of a bed frame will prevent proper seating, creating an unstable and potentially hazardous sleeping surface. The instruction has great impact to measure mattress size accurately.

Practical application of the “measure at widest points” principle involves a comprehensive visual and tactile inspection of the mattress before measurement. Irregularities in shape, such as protruding edges, reinforced seams, or areas of concentrated padding, should be identified. The measuring tape should then be positioned to capture the maximum distance across these points, rather than simply measuring along the apparent straight lines of the mattress. In cases of significant asymmetry, multiple width measurements may be necessary to accurately represent the mattress’s overall dimensions. These measurements should then be compared to the manufacturer’s specifications to identify any discrepancies and inform purchasing decisions.

In summary, “measure at widest points” serves as a fundamental directive in dimensional assessment. Its purpose is to ensure that the measured dimensions accurately reflect the maximum space occupied by the mattress, thereby preventing compatibility issues with bed frames and bedding. This technique ensures the proper assessment of mattresses, preventing problems and ensuring both optimal functionality and aesthetic harmony. Understanding the importance of accurate measurement is key to successfully completing this task. Measuring at the widest points is a very important direction on how to measure mattress size.

4. Verify against specs

The process of mattress dimension assessment culminates in the critical step of verification against specifications. This comparison serves as a quality control measure, mitigating the potential for errors introduced during the measurement process. Discrepancies between measured values and manufacturer-stated dimensions can arise from various sources, including measurement inaccuracies, manufacturing tolerances, or post-production deformation. The act of verification, therefore, provides an opportunity to identify and rectify these deviations before making purchasing decisions. Failure to verify measured dimensions against published specifications can result in the selection of incompatible bedding or bed frames, leading to unnecessary financial burdens and practical inconveniences. For example, if measured dimensions are significantly smaller than specified dimensions, the fitted sheets may be excessively loose, resulting in discomfort and reduced lifespan. Conversely, if measured dimensions exceed specifications, the mattress may not fit within a designated bed frame, compromising structural integrity and creating a safety hazard.

The practical application of verification involves obtaining the manufacturer’s specifications from reliable sources, such as product labels, online listings, or customer service representatives. These specifications typically include length, width, and depth dimensions, expressed in standard units of measurement. A direct comparison is then performed, noting any deviations that fall outside acceptable tolerance ranges. Significant discrepancies warrant further investigation, potentially involving re-measurement using calibrated instruments or consultation with a bedding expert. Furthermore, the verification process extends beyond simple dimensional comparison. It also encompasses an assessment of other relevant specifications, such as mattress weight, construction materials, and warranty terms. This holistic approach ensures that the selected mattress aligns with both dimensional requirements and performance expectations.

In summary, “verify against specs” represents a vital component of the complete process. Its primary function is to validate the accuracy of measured dimensions and to identify potential discrepancies that may compromise compatibility or performance. This verification step requires diligence and careful attention to detail, but the benefits of preventing purchasing errors and ensuring optimal product suitability outweigh the associated effort. This helps on how to measure mattress size effectively.

5. Consider mattress depth

Mattress depth, or thickness, forms a critical dimension when accurately assessing overall mattress size. It directly influences the selection of appropriately sized bedding, particularly fitted sheets. Neglecting mattress depth during dimension assessment frequently results in sheets that are either too shallow, failing to fully cover the mattress, or excessively deep, leading to a loose and potentially uncomfortable sleeping surface. For instance, a mattress measuring 14 inches in depth requires fitted sheets specifically designed to accommodate that thickness; standard sheets intended for 10-inch mattresses will prove inadequate. Furthermore, mattress depth affects the overall height of the bed, influencing the ease of ingress and egress, particularly for individuals with mobility limitations. The measurement of mattress depth provides a more accurate assessment of measure mattress size.

Practical consideration of mattress depth extends beyond sheet selection. When purchasing new bed frames, the frame’s internal dimensions and support structure must accommodate the mattress’s depth to ensure proper weight distribution and structural stability. Insufficient frame depth can lead to mattress overhang, increasing the risk of damage or collapse. Conversely, excessive frame depth may result in the mattress sitting too low, reducing accessibility and potentially compromising airflow. Also, when integrating an adjustable base, you need to consider mattress depth, you need to make sure the depth matches the adjustable base.

In summary, considering mattress depth is an indispensable element of accurate dimension assessment. It prevents bedding compatibility issues, ensures appropriate bed height, and promotes overall sleeping comfort and safety. Accurate depth measurement contributes to informed purchasing decisions, minimizing the likelihood of costly errors and maximizing the lifespan of both the mattress and associated bedding components. Mattress depth is an important factor of how to measure mattress size correctly.

6. Document all dimensions

The comprehensive dimensional characterization of a mattress necessitates meticulous documentation of all measurements obtained. This practice directly addresses the inherent potential for errors and ambiguities that may arise during the measurement process or in subsequent interpretation. Accurate dimension assessment involves recording length, width, and depth, as well as any deviations from a rectangular profile. Neglecting to document these dimensions comprehensively undermines the utility of the exercise, rendering the gathered data incomplete and susceptible to misinterpretation. For example, without written records, individuals may struggle to recall precise measurements weeks or months after the initial assessment, particularly if the mattress is an irregular shape or has undergone significant wear. This lack of documentation can then lead to the selection of mismatched bedding or ill-fitting bed frames, negating the intended benefits of dimension assessment.

The practical implications of dimension documentation extend beyond immediate purchasing decisions. Accurate records facilitate future reference for warranty claims, insurance purposes, or resale transactions. In cases of mattress defects or damage, photographic evidence coupled with documented dimensions provides essential documentation to support claims. Furthermore, when selling or donating a mattress, providing potential buyers or recipients with precise dimensions enhances transparency and reduces the likelihood of compatibility issues. The documentation also serves as a baseline for monitoring changes in mattress dimensions over time, identifying potential sagging or deformation that may impact sleep quality.

In conclusion, the practice of documenting all mattress dimensions is not merely a procedural formality but a fundamental component of accurate assessment. It mitigates the risk of errors, facilitates informed decision-making, and provides a valuable resource for future reference. Comprehensive documentation transforms dimensional data into a tangible asset, enhancing the longevity and utility of the mattress and promoting responsible consumer practices. This directly improves the results of how to measure mattress size effectively.

7. Level surface crucial

The requirement for a level surface when determining mattress dimensions is fundamental to obtaining accurate measurements. An uneven surface introduces variations in compression and support across the mattress, leading to distortions in its shape. These distortions, in turn, directly influence the measured length, width, and potentially even the depth, rendering the collected data unreliable. The intended purpose of dimension assessmentto facilitate proper bedding selection and ensure bed frame compatibilityis then undermined.

The effect of a non-level surface manifests in several ways. For example, if one corner of the mattress rests higher than the others, the measured length and width may appear shorter due to the mattress conforming to the angled plane. Furthermore, differential compression on the uneven surface can alter the distribution of internal materials, leading to bulges or depressions that skew measurements. The practical application of this principle involves ensuring the mattress is placed on a flat, solid surface prior to any measurement attempts. A solid floor is preferable to a bed frame with flexible slats, which may themselves contribute to unevenness. Correct measurement process increases accuracy, so understanding of how to measure mattress size is important.

In conclusion, the principle of ensuring a level surface is not merely a suggestion, but a prerequisite for accurate mattress dimension assessment. It mitigates the risk of measurement distortions caused by uneven support and compression, ensuring that the obtained data is reliable and suitable for informed decision-making. Adherence to this principle enhances the integrity of the measurement process and contributes to successful bedding selection and bed frame compatibility. It helps you with the process of how to measure mattress size.

Frequently Asked Questions

The following addresses common inquiries related to the precise determination of bed dimensions, providing clarity on optimal techniques and addressing potential sources of error.

Question 1: Are mattress sizes truly standardized?

While mattress sizes are generally standardized (e.g., Twin, Queen, King), slight variations between manufacturers and models can occur. Verification of actual dimensions is advisable.

Question 2: What tool yields the most precise measurements?

A rigid metal measuring tape provides the most accurate results. Cloth tapes are susceptible to stretching and distortion.

Question 3: At what point on the mattress should measurements be taken?

Measurements should be taken at the widest points, accounting for any bulges, pillow tops, or irregularities in shape.

Question 4: Is depth measurement as vital as length and width?

The measurement of depth (thickness) is essential, particularly for selecting appropriately sized fitted sheets. Disregarding depth can lead to improper sheet fit.

Question 5: How does one accurately measure an irregularly shaped mattress?

For irregularly shaped mattresses, multiple measurements should be taken at various points, documenting all dimensions to create a comprehensive profile.

Question 6: Why is a level surface necessary for accurate measurement?

A level surface prevents distortion of the mattress shape, ensuring that the measurements reflect the true dimensions without bias from uneven support.

Accurate mattress measurement is a crucial step in selecting appropriate bedding and bed frames, ultimately contributing to a more comfortable and restful sleep environment.

The concluding section summarizes key takeaways and provides guidance on seeking expert assistance for complex dimension assessment scenarios.

How to Measure Mattress Size

The preceding sections have provided a comprehensive exploration of “how to measure mattress size,” emphasizing the importance of precise techniques and meticulous attention to detail. Accurate dimension assessment necessitates the use of appropriate tools, adherence to established methodologies, and critical verification against manufacturer specifications. The inherent complexities associated with mattress shape, depth, and surface irregularities demand a systematic approach to minimize measurement errors and maximize the utility of the collected data.

Neglecting the outlined principles can lead to compromised bedding selection, bed frame incompatibility, and ultimately, a suboptimal sleep experience. Therefore, diligent application of these measurement protocols is essential for informed decision-making and responsible consumerism. This process improves how to measure mattress size and improves sleep.