The dimensions of a portable crib’s sleeping surface are a crucial consideration when selecting accessories and ensuring infant safety. These measurements typically adhere to standardized regulations established to minimize risks associated with ill-fitting bedding. For example, a common dimension for these surfaces is approximately 24 inches wide by 38 inches long.

Adherence to standardized measurements offers several benefits. It provides parents and caregivers with assurance that any accessories designed for portable cribs, such as fitted sheets and mattresses, will fit securely and prevent potential hazards like suffocation or entanglement. Historically, variations in dimensions led to safety concerns, prompting the establishment of these standards to protect infants.

The following sections will delve into specific aspects of selecting appropriate sleeping surfaces for portable cribs, focusing on materials, thickness considerations, and essential safety guidelines to guarantee a secure and comfortable environment for the child.

Considerations for Portable Crib Mattress Selection

Selecting an appropriate sleeping surface for a portable crib requires careful evaluation. Several factors influence safety, comfort, and overall suitability for the intended use.

Tip 1: Verify Dimensional Accuracy: Confirm that the replacement mattress adheres precisely to the inner dimensions of the portable crib. Gaps between the mattress and the crib’s sides can create hazardous entrapment areas.

Tip 2: Assess Firmness: The mattress should exhibit sufficient firmness to prevent indentations that could pose a suffocation risk. A firm surface supports proper infant development and reduces the risk of SIDS.

Tip 3: Examine Material Composition: Opt for mattresses constructed from non-toxic, hypoallergenic materials. Certifications such as GREENGUARD Gold indicate that the product has been tested for chemical emissions and contributes to healthier indoor air quality.

Tip 4: Evaluate Thickness: While some mattresses may be thicker than others, ensure that the chosen thickness does not compromise the crib’s safety regulations. Exceeding the recommended thickness could reduce the height of the side rails, increasing the risk of falls.

Tip 5: Check for Waterproofing: A waterproof or water-resistant cover is essential to protect the mattress core from spills and accidents. This feature simplifies cleaning and prevents the growth of mold and bacteria.

Tip 6: Review Safety Certifications: Look for mattresses that meet or exceed safety standards established by organizations such as the Consumer Product Safety Commission (CPSC). These certifications provide assurance of product safety and compliance.

Tip 7: Inspect Stitching and Seams: Examine the stitching and seams for durability and integrity. Weak or frayed seams can lead to mattress degradation and create potential hazards.

Prioritizing these considerations contributes to a secure and comfortable sleep environment for infants using portable cribs, promoting both safety and well-being.

The subsequent section will address common concerns related to portable crib mattress care and maintenance, ensuring longevity and continued safety.

1. Standard dimensions

Standard dimensions, as they relate to portable crib sleeping surfaces, are not arbitrary figures. They are meticulously established specifications intended to ensure infant safety and compatibility across various product lines. Adherence to these standards is critical in preventing hazards associated with improper fit and potential entrapment.

- Defined Length and Width

The prescribed length and width, typically 24 inches by 38 inches, serve as a baseline for manufacturers. Deviation from these dimensions can result in gaps between the mattress and the crib’s frame, creating a risk of infant entrapment. For example, a mattress that is even slightly smaller than the standard can allow a baby to become wedged, potentially leading to suffocation.

- Mandatory Thickness Limitations

Regulatory bodies establish limitations on thickness to maintain the integrity of the crib’s safety features. An excessively thick mattress reduces the height of the crib’s side rails, negating their protective function and increasing the likelihood of a child falling out. These limitations are carefully calibrated to balance comfort and safety.

- Corner Radius Specifications

The corner radius, or the roundness of the corners, is standardized to prevent sharp edges and ensure a snug fit within the crib’s frame. Deviations can lead to ill-fitting bedding and increased wear and tear on the mattress itself. These specifications contribute to both safety and the longevity of the product.

- Material Rigidity Requirements

Standard dimensions also implicitly dictate material rigidity. A mattress that is too soft or pliable can create indentations, increasing the risk of suffocation. The specified dimensions are designed to work in conjunction with appropriate material firmness to provide a safe and supportive sleep surface for infants.

These dimensional standards are not mere suggestions; they are fundamental requirements for ensuring the safety and well-being of infants. Understanding and adhering to these dimensions is crucial for both manufacturers and consumers in selecting and using portable crib sleeping surfaces.

2. Thickness Variations

Thickness variations within portable crib mattresses are a critical component directly influencing safety and functionality. The prescribed dimensions of a portable crib dictate a limited range of acceptable mattress thicknesses. Deviations from this range can compromise the crib’s intended safety features. A mattress exceeding the specified thickness reduces the height of the crib’s side rails. This diminished rail height lessens its protective function, potentially allowing a child to climb out or fall over the side. Conversely, a mattress that is too thin may not provide adequate support, leading to discomfort and potentially contributing to unsafe sleep positions. A practical example of this risk is the potential for a thinner mattress to conform excessively to the infant’s body, increasing the risk of suffocation if the infant rolls onto their stomach. Thus, maintaining proper thickness is essential for safety.

The interaction between thickness and overall crib dimensions has regulatory implications. Safety standards, such as those established by the Consumer Product Safety Commission (CPSC), specify acceptable thickness ranges for portable crib mattresses. Compliance with these standards ensures that the mattress adequately fills the crib space without compromising side rail height. Furthermore, the thickness of the mattress affects the fit of fitted sheets. Overly thick mattresses may stretch sheets beyond their intended capacity, potentially leading to tearing or detachment, creating a loose bedding hazard. Therefore, the thickness variation must align with the intended sheet size for the crib to prevent safety risks.

In summary, the thickness of a portable crib mattress is inextricably linked to its safety and functionality. Adherence to prescribed thickness ranges is critical for maintaining adequate side rail height, ensuring proper support, and preventing hazards associated with loose bedding. Manufacturers and caregivers must consider the thickness variation within the context of the overall crib dimensions and applicable safety standards to ensure a safe sleep environment for the infant. Choosing the correct thickness is important to guarantee a secure environment.

3. Weight limits

The stated weight limit of a portable crib is directly correlated with the dimensions of its sleeping surface, or “pack n play mattress size”, and the structural integrity of the crib frame. The manufacturer establishes this limit based on comprehensive testing to ensure the product’s safe use throughout its intended lifespan. Exceeding the weight limit places undue stress on the mattress and supporting structure, potentially leading to mattress deformation, frame damage, or even complete structural failure. A practical example is a situation where a toddler significantly exceeds the prescribed weight; the mattress may sag excessively, compromising the child’s comfort and potentially creating an unsafe sleeping position. This interrelationship highlights the significance of understanding the weight limitations as an integral component of the overall “pack n play mattress size” considerations.

Further analysis reveals that weight distribution across the “pack n play mattress size” also plays a critical role. A concentrated weight load in a single area can cause localized stress, exceeding the material’s yield strength and leading to permanent deformation. For instance, if a child consistently sleeps in the same corner of the crib and is near the upper end of the weight limit, the mattress in that area may become noticeably compressed over time. Moreover, the relationship between weight limits and “pack n play mattress size” can influence the crib’s stability. Excessive weight can destabilize the crib, particularly models with lightweight frames or less robust locking mechanisms, increasing the risk of tipping or collapse.

In conclusion, the interplay between weight limits and “pack n play mattress size” is a critical safety consideration that impacts product lifespan and infant safety. Manufacturers set weight limits based on dimensional and structural characteristics, and exceeding these limits can compromise both comfort and safety. Understanding this relationship is essential for caregivers to ensure they are providing a safe sleeping environment for their child. Challenges arise when weight limits are not clearly communicated or when parents underestimate their child’s weight, underscoring the importance of careful attention to product specifications and regular monitoring of the child’s growth.

4. Firmness levels

The firmness level of a portable crib mattress is intrinsically linked to its dimensions, or “pack n play mattress size,” and constitutes a crucial safety factor for infants. A direct correlation exists between the available surface area and the required firmness to ensure adequate support and minimize suffocation risks. Insufficient firmness on a standard-sized mattress can create indentations, particularly under an infant’s head, increasing the potential for airway obstruction. In contrast, excessive firmness, although reducing suffocation risk, may compromise comfort and potentially hinder healthy skeletal development. Understanding this interplay is essential, as selecting a mattress with inappropriate firmness based on “pack n play mattress size” can have significant safety implications. For example, an overly soft mattress in a smaller portable crib may conform too closely to the infant’s face, creating a hazardous environment.

Further analysis reveals that the firmness level influences weight distribution across the “pack n play mattress size.” An appropriately firm mattress distributes the infant’s weight evenly, preventing localized pressure points that could cause discomfort or impede circulation. However, a mattress that lacks sufficient firmness may allow excessive weight concentration in certain areas, leading to uneven support and potential safety hazards. Moreover, the firmness level must also complement the fitted sheet’s elasticity and tension. A sheet stretched too tightly over a firm mattress may create a drum-like effect, increasing the risk of the infant rolling into an unsafe position. Conversely, a loose sheet on a softer mattress may bunch up, creating a suffocation hazard. These examples demonstrate that the selection process must account for the combined effect of mattress firmness, “pack n play mattress size”, and sheet compatibility.

In summary, the relationship between firmness level and “pack n play mattress size” represents a critical safety consideration in portable crib mattress selection. The appropriate firmness ensures adequate support, minimizes suffocation risks, and promotes healthy development. Challenges arise when caregivers rely solely on subjective assessments of firmness without considering the broader context of crib dimensions and safety standards. Thus, it is imperative to consult manufacturer guidelines and regulatory recommendations to make informed decisions that prioritize infant safety. Adherence to established firmness standards, coupled with proper mattress size, is essential for ensuring a secure sleep environment.

5. Material composition

The material composition of a portable crib mattress is inextricably linked to its overall dimensions, specifically “pack n play mattress size”, affecting both safety and durability. The interaction between the materials used and the intended dimensions dictates the mattress’s ability to maintain structural integrity and provide a safe sleep surface. For example, a mattress utilizing low-density foam may conform excessively to an infant’s body, increasing suffocation risk, while a mattress constructed with improperly cured chemicals can release volatile organic compounds (VOCs), impacting air quality. The selected materials must complement the mattress’s size, ensuring that the product remains firm and supportive without posing chemical hazards. Material selection is not merely a cosmetic choice but a critical determinant of safety and compliance with established standards.

Further examination reveals that the relationship between material composition and “pack n play mattress size” influences the mattress’s performance over time. For instance, a mattress using lower-quality materials may degrade more rapidly, losing its firmness and increasing the risk of unsafe indentations. The type of cover material also plays a significant role. A non-breathable cover can lead to overheating and discomfort, while a cover that is not waterproof can allow moisture to penetrate the mattress core, fostering bacterial growth. Therefore, material composition should be carefully aligned with the intended use of the “pack n play mattress size,” considering factors such as durability, breathability, and ease of cleaning. Instances of mattress recalls due to non-compliant or hazardous materials emphasize the practical significance of this understanding. For instance, mattresses containing prohibited phthalates or lead have been recalled due to potential health risks to infants. The choice of materials affects breathability and support that make material composition important for safety.

In conclusion, the composition of materials and its relationship to “pack n play mattress size” represents a multifaceted safety consideration. Material selection impacts structural integrity, breathability, chemical emissions, and overall durability. Manufacturers must adhere to stringent material standards and testing protocols to mitigate potential risks. Parents and caregivers must prioritize mattresses constructed from non-toxic, breathable, and durable materials, ensuring alignment with established safety guidelines for “pack n play mattress size”. Selecting the right material composition ensures structural integrity and overall safety.

6. Corner Radius

The corner radius of a portable crib mattress is a dimensional specification often overlooked, yet it plays a vital role in ensuring a secure and proper fit within the crib frame. This characteristic defines the curvature of the mattress corners, directly impacting its compatibility with the crib’s design and overall safety performance.

- Ensuring Snug Fit and Preventing Gaps

The primary function of the corner radius is to provide a close fit between the mattress and the crib’s corners. If the corner radius is too sharp, gaps may exist, creating potential entrapment hazards for infants. Conversely, if the radius is too large, the mattress may not seat properly, leading to instability and increasing the risk of the mattress shifting during use. Consistent corner radius dimensions on “pack n play mattress size” are vital for a safe fit.

- Standardization and Regulatory Compliance

Regulatory standards, such as those enforced by the Consumer Product Safety Commission (CPSC), often specify acceptable ranges for corner radii in portable crib mattresses. Adherence to these standards ensures that the mattress meets minimum safety requirements and reduces the risk of injuries associated with ill-fitting bedding. These regulations are designed to promote consistency across different manufacturers and product lines.

- Impact on Fitted Sheet Compatibility

The corner radius also influences the fit of fitted sheets. If the mattress corners are too square, the fitted sheet may be difficult to install and may not stay securely in place. This can result in loose fabric that poses a suffocation hazard. A properly designed corner radius ensures that the fitted sheet conforms smoothly to the mattress, maintaining a tight and secure fit. Fitted sheet selection and corner radius on “pack n play mattress size” can directly impact safety.

- Material Stress and Durability Considerations

The corner radius can affect the stress distribution within the mattress material, particularly in foam or layered constructions. Sharp corners can create stress concentrations, leading to premature wear and tear. A well-rounded corner radius distributes stress more evenly, improving the mattress’s overall durability and extending its lifespan. Attention to corner radius ensures the mattress on “pack n play mattress size” is durable.

The corner radius, though seemingly a minor detail, is an integral component of the overall “pack n play mattress size” considerations. It influences fit, safety, sheet compatibility, and durability, underscoring the importance of adhering to established standards and selecting mattresses with properly designed corner radii. Ensuring a precise corner radius optimizes safety and product longevity.

7. Edge Support

Edge support in portable crib mattresses is a critical, albeit often overlooked, feature directly impacting safety and usability. The correlation between edge support and “pack n play mattress size” is paramount in determining the structural integrity and overall performance of the mattress. Insufficient edge support can compromise safety and reduce the effective lifespan of the product.

- Prevention of Sagging and Compression

Adequate edge support prevents mattress sagging and compression, particularly along the perimeter. When a child presses against the edge, a mattress with poor support may collapse inward, creating a potential entrapment hazard. Enhanced edge support ensures the mattress maintains its shape, providing a uniform and stable sleep surface. This is particularly important in smaller mattresses where the child is more likely to be near the edges. Example: a baby crawling around and getting their foot trapped by the sagging edge.

- Maximizing Usable Surface Area

Strong edge support maximizes the usable surface area of the mattress. With robust edges, the entire mattress surface becomes a viable sleeping space, preventing the child from rolling towards the edge and potentially falling out. A mattress lacking adequate edge support effectively reduces the sleep area, as the edges become unstable and unsafe for the child to occupy. This is more likely with larger size infants.

- Enhancing Structural Integrity and Durability

Edge support contributes significantly to the mattress’s overall structural integrity and durability. Reinforced edges help the mattress withstand daily use and prevent premature wear and tear. Mattresses with weak edges are more susceptible to damage, leading to a shorter lifespan and increased safety risks over time. This is amplified on mattresses frequently used and transported.

- Facilitating Easier Ingress and Egress

Solid edge support facilitates easier and safer ingress and egress from the crib. A firm edge provides a stable surface for the child to push against when sitting up or attempting to climb out, reducing the risk of falls and injuries. Conversely, a soft edge can make it difficult for the child to gain leverage, increasing the likelihood of accidents. This is especially important as a child becomes mobile.

The features of edge support are vital to consider relative to the “pack n play mattress size”. The implementation of robust edge support systems ensures the mattress retains its intended dimensions, provides a safer sleep environment, and extends the usable life of the product. Failure to consider edge support when selecting a portable crib mattress can lead to compromised safety and reduced product longevity.

Frequently Asked Questions

The following questions and answers address common inquiries regarding the dimensions of portable crib mattresses, emphasizing safety and functionality.

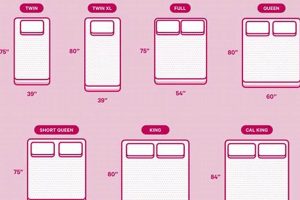

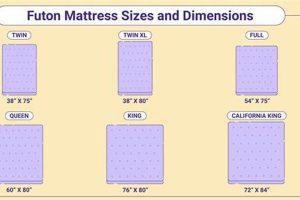

Question 1: What are the standard dimensions for a pack n play mattress?

The typical dimensions for a portable crib mattress are approximately 24 inches wide and 38 inches long. These measurements are intended to fit standard-sized portable cribs. Variations may exist, but adherence to established safety standards is paramount.

Question 2: Can a thicker mattress be used in a pack n play?

Using a mattress thicker than the manufacturer’s recommendation is not advisable. Exceeding the specified thickness reduces the height of the side rails, increasing the risk of falls. Safety regulations dictate maximum mattress thickness to maintain adequate rail height.

Question 3: How does mattress firmness relate to pack n play mattress size?

Mattress firmness should complement the dimensions of the portable crib. A mattress that is too soft may create indentations, posing a suffocation hazard. A firm, supportive surface is essential to ensure proper infant development and minimize risks.

Question 4: What should be considered when replacing a pack n play mattress?

When replacing a mattress, verify that the replacement adheres precisely to the inner dimensions of the portable crib. Gaps between the mattress and the crib’s sides can create dangerous entrapment areas. Also, ensure the material is non-toxic and meets relevant safety certifications.

Question 5: How does material composition affect the suitability of a pack n play mattress?

The materials used in a portable crib mattress must be non-toxic and breathable. Avoid mattresses containing harmful chemicals or those that emit volatile organic compounds (VOCs). A waterproof cover is also recommended to prevent bacterial growth and simplify cleaning.

Question 6: Are there specific weight limits for pack n play mattresses?

Yes, portable cribs and their mattresses have specified weight limits. Exceeding these limits can compromise the mattress’s structural integrity and potentially lead to unsafe sleeping conditions. Adhere to the manufacturer’s guidelines to ensure the safety of the infant.

In summary, selecting an appropriate portable crib mattress involves careful consideration of dimensions, firmness, material composition, and weight limits. Adherence to safety standards is crucial for creating a secure sleep environment.

The following section will provide a checklist for purchasing “pack n play mattress size” to summarize the contents.

Conclusion

The preceding exploration of pack n play mattress size has illuminated several critical aspects concerning infant safety and product functionality. Standardized dimensions, firmness levels, material composition, weight limits, corner radius specifications, and edge support mechanisms each play a crucial role in ensuring a secure and appropriate sleep environment. Adherence to established guidelines and regulations is paramount in mitigating potential hazards associated with ill-fitting or substandard mattresses. Furthermore, an understanding of these dimensional properties is essential for both manufacturers and consumers in selecting and utilizing these products responsibly.

Given the potential consequences of neglecting these considerations, rigorous evaluation of pack n play mattress size remains imperative. Continued vigilance in monitoring product compliance and promoting awareness of safety standards will contribute significantly to minimizing risks and safeguarding the well-being of infants. It is crucial for caregivers to stay informed and proactive in their efforts to create a secure sleep environment, ensuring the health and safety of the child are prioritized above all else.