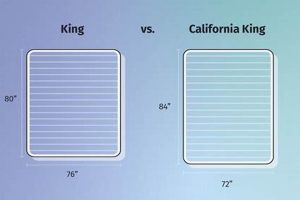

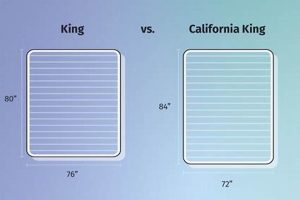

A substantial support structure crafted from metal designed to hold a large-sized sleeping surface. These frames typically accommodate mattresses measuring approximately 76 inches wide by 80 inches long. An example would be a wrought iron construction designed to elevate a bed off the floor.

These structures offer durability and strength, providing a stable foundation for restful sleep. Their robust nature often leads to extended lifespans compared to alternatives. Furthermore, the open design can promote airflow beneath the mattress, potentially mitigating moisture buildup and contributing to improved hygiene. Historically, metal has been employed in bed frame construction due to its resilience and ease of fabrication.

The subsequent sections will delve into specific designs, materials used, assembly considerations, and factors to consider when selecting a suitable model for individual needs and preferences. Discussions will also cover maintenance tips and potential advantages over other frame types.

Essential Considerations for King Metal Mattress Frame Selection

Selecting an appropriate structure to support a king-sized mattress requires careful evaluation of several factors. These guidelines aim to provide clarity and assist in making an informed decision.

Tip 1: Prioritize Frame Strength: Evaluate the gauge of the metal and the design of the support structure. A thicker gauge metal and a robust design ensure adequate support for both the mattress and occupants, minimizing sagging and extending the mattress’s lifespan.

Tip 2: Assess Weight Capacity: Confirm the frame’s maximum weight capacity. This is critical to prevent structural failure, particularly for individuals or couples with above-average weight, or when using heavier mattress types, such as memory foam or latex.

Tip 3: Measure Available Space: Accurately measure the bedroom area before purchasing. A king-sized frame is substantial; ensure sufficient clearance for movement around the bed and other furniture to maintain comfortable room functionality.

Tip 4: Examine Assembly Requirements: Determine the complexity of assembly. Some frames require specialized tools or multiple individuals for setup. Consider pre-assembled options or professional assembly services if complex configurations are a concern.

Tip 5: Consider Headboard and Footboard Compatibility: If intending to attach a headboard or footboard, verify compatibility with the selected frame. Standardized mounting points are not universal; confirm proper alignment and attachment mechanisms.

Tip 6: Evaluate Center Support: Ensure the frame includes adequate center support. This prevents mattress sagging, particularly in the middle, and distributes weight evenly across the sleeping surface. Frames lacking sufficient center support are prone to premature wear.

Tip 7: Inspect for Sharp Edges or Protrusions: Before purchasing, thoroughly inspect the frame for any sharp edges, protruding screws, or other potential hazards. These can pose a risk of injury and should be addressed or avoided.

Adhering to these considerations will facilitate the selection of a structurally sound, appropriately sized, and safely assembled frame, enhancing sleeping comfort and longevity of the mattress.

The following sections will address maintenance procedures and comparative analyses of various frame materials and designs.

1. Durability and Stability

The inherent strength of metal directly contributes to both the durability and stability of a king-sized mattress support structure. A metal frame constructed from a high-gauge steel, for example, resists bending and deformation under the considerable weight of a king mattress and its occupants. This prevents premature sagging of the mattress, maintaining its intended shape and support characteristics over an extended period. In contrast, a frame utilizing a thinner gauge metal is susceptible to bending, leading to uneven weight distribution and ultimately, a compromised sleep surface.

Stability is equally critical; a robustly constructed metal frame minimizes wobbling and movement during sleep, further enhancing the overall sleep quality. Welded joints, as opposed to bolted connections alone, contribute to enhanced structural integrity. A real-world example of the benefit lies in the experience of individuals sharing the bed; the decreased motion transfer from a stable frame prevents disruptions when one partner moves during the night. The absence of creaking or shifting sounds, typical of less stable frames, enhances sleep quality.

In summary, the connection between metal durability and stability is fundamental to the long-term performance of a king-sized mattress frame. Compromises in metal quality directly impact mattress lifespan and sleep quality, highlighting the importance of selecting a frame constructed from robust materials with thoughtful engineering. Investing in durable and stable option represents a prudent investment in both sleep quality and long-term cost savings by prolonging the life of the mattress.

2. Weight Distribution

Effective weight distribution is paramount to the functionality and longevity of a king metal mattress frame. The frame’s design directly impacts how weight is dispersed across the mattress, affecting its support, comfort, and lifespan. A poorly designed frame concentrates pressure in certain areas, leading to sagging, uneven wear, and potential discomfort for the occupants. Conversely, a well-engineered frame evenly distributes the combined weight of the mattress and individuals using it, ensuring optimal support and prolonging the mattress’s usability.

Center support systems are crucial components for achieving proper weight distribution in king metal mattress frames. These systems, typically consisting of one or more vertical supports running along the frame’s center, counteract the tendency for the mattress to sag in the middle. An example of their importance is evident in comparing two identical mattresses: one used with a frame lacking center support and another used with a frame incorporating robust center support. The former will exhibit noticeable sagging and diminished support over time, whereas the latter will maintain its shape and comfort level for a longer duration. Furthermore, the choice of metal type and gauge also influences weight distribution. Thicker gauge steel offers superior resistance to bending and deformation, further contributing to even weight distribution and enhanced frame stability.

In conclusion, optimizing weight distribution within a king metal mattress frame directly correlates with improved sleep quality, enhanced mattress lifespan, and long-term value. The presence of adequate center support, coupled with the selection of durable materials, significantly contributes to achieving this optimization. Neglecting these considerations can lead to premature mattress degradation and compromised sleep comfort. Understanding the significance of weight distribution empowers consumers to make informed purchasing decisions, ensuring a durable and supportive sleep foundation.

3. Assembly Complexity

The assembly complexity inherent in a king metal mattress frame directly influences its purchase feasibility, set-up time, and long-term maintenance. The design of these frames, particularly concerning the number of component parts, the intricacy of joining mechanisms, and the requirement for specialized tools, determines the level of effort needed for initial construction. Higher assembly complexity correlates with increased setup time and potentially necessitates professional installation services, thereby adding to the overall cost. For example, a frame with numerous small parts, requiring precise alignment and tightening with Allen wrenches, poses a greater challenge than a frame utilizing a simpler clip-and-lock mechanism. This complexity factor is of particular significance for individuals with limited physical dexterity or time constraints.

Furthermore, the initial assembly process impacts subsequent disassembly and reassembly, often required during relocation. Intricate assemblies are prone to increased wear and tear on joining components during repeated assembly cycles, potentially compromising the frame’s structural integrity. Conversely, designs emphasizing ease of assembly and disassembly, through the use of fewer parts and robust connecting hardware, simplify both initial setup and future relocations. An illustrative example involves comparing two frames: one with numerous small screws that are easily stripped and another with larger, more durable bolts; the latter offers increased resilience during repeated use and less risk of component failure.

In summary, assembly complexity represents a critical factor in the overall value proposition of a king metal mattress frame. Consumers must carefully consider their own capabilities, time constraints, and potential relocation needs when evaluating this aspect. Frames prioritizing simple assembly offer distinct advantages in terms of reduced setup time, lower installation costs, and increased ease of relocation. A thorough assessment of assembly complexity empowers consumers to select a frame that aligns with their individual circumstances, ensuring a satisfactory ownership experience.

4. Compatibility (Headboards)

The compatibility of headboards with a king metal mattress frame is a crucial consideration, influencing both aesthetic appeal and structural integrity of the bed. Variations in frame designs and headboard attachment mechanisms necessitate careful evaluation to ensure a secure and visually harmonious integration.

- Standardized Mounting Systems

Certain king metal mattress frames incorporate standardized mounting systems designed to accommodate a wide range of headboard styles. These systems typically involve pre-drilled holes at specific intervals, conforming to industry norms. However, deviations from these standards exist, requiring verification of hole alignment and spacing between the frame and the intended headboard. A common issue arises when attempting to attach an antique headboard to a modern frame, as the hole patterns may differ significantly.

- Bracket Adaptability

Bracket adaptability refers to the adjustability of the brackets used to connect the headboard to the frame. Adjustable brackets allow for slight variations in headboard height and width, accommodating minor discrepancies in dimensions. However, the range of adjustability is limited; significant dimensional differences may necessitate custom-fabricated brackets or modifications to either the headboard or the frame. An example of this is a headboard that is wider than the king frame.

- Weight Considerations

The weight of the headboard is a factor affecting compatibility. Heavy headboards require robust frame construction to prevent instability or structural damage. Lightweight metal frames may lack the necessary support to accommodate substantial headboards, potentially leading to wobbling or even frame failure. It is crucial to verify that the frame’s weight capacity is sufficient to support the headboard’s mass. For example a headboard make of solid hardwood is heavier than an upholstered one.

- Attachment Hardware

The type and quality of attachment hardware significantly affect the security and longevity of the headboard-frame connection. Low-quality bolts, screws, or nuts are prone to loosening or stripping, leading to instability and potential safety hazards. It is recommended to use high-grade hardware, such as hardened steel bolts, and to periodically inspect and tighten the connections to maintain a secure bond. Inadequate hardware can cause the connection to fail and could damage the headboard or frame.

Successful headboard integration with a king metal mattress frame necessitates careful consideration of these facets. Incompatible headboards not only detract from the bed’s aesthetic appeal but also compromise its structural integrity and safety. Proper planning and verification of compatibility parameters are essential for a secure and visually pleasing outcome. Prior consideration prevents potential issues down the road.

5. Under-Bed Clearance

Under-bed clearance, a key dimensional characteristic of a king metal mattress frame, directly influences storage capacity and ease of cleaning. The vertical distance between the floor and the bottom of the frame determines the size and volume of items that can be stored beneath the bed, impacting room organization and space utilization. Insufficient clearance restricts storage options and hinders the ability to effectively clean beneath the bed, potentially contributing to dust and allergen accumulation. A low-profile frame, for instance, may offer a modern aesthetic but limit storage possibilities, whereas a frame with greater clearance accommodates larger storage containers or facilitates easier vacuuming.

The impact of under-bed clearance extends to accessibility. Frames with ample clearance allow for easier retrieval of stored items and simplify the process of reaching items that may have fallen beneath the bed. Individuals with mobility limitations may find increased clearance particularly beneficial, as it reduces the strain associated with bending and reaching. Consider, for example, an individual recovering from surgery: a frame with sufficient clearance enables easier access to medical supplies or assistive devices stored beneath the bed, thereby enhancing convenience and comfort during recovery. Moreover, robotic vacuum cleaners require a minimum clearance to operate effectively, making this dimension a practical consideration for homeowners utilizing automated cleaning solutions.

In summary, the under-bed clearance of a king metal mattress frame is not merely a stylistic element but a functional attribute impacting storage capacity, accessibility, and hygiene. Insufficient clearance can compromise storage efficiency and cleaning ease, while adequate clearance enhances both aspects. Therefore, prospective buyers should carefully evaluate their storage needs and cleaning preferences when selecting a frame, ensuring that the under-bed clearance aligns with their individual requirements. Choosing a frame with ample clearance will reduce the need for other storage solutions.

Frequently Asked Questions

The following addresses common inquiries regarding king metal mattress frames, providing definitive answers to assist in informed decision-making.

Question 1: What gauge of metal is recommended for a king metal mattress frame to ensure adequate support?

A minimum of 14-gauge steel is recommended for the main structural components of a king metal mattress frame. Heavier gauges, such as 12-gauge or 10-gauge, provide enhanced durability and weight-bearing capacity, particularly for heavier mattresses or multiple occupants.

Question 2: Does the presence of center support in a king metal mattress frame significantly impact mattress lifespan?

Yes, center support is critical for preventing mattress sagging, especially in the middle. Frames lacking adequate center support often lead to premature mattress wear and reduced comfort. The center support helps distribute weight more evenly across the mattress.

Question 3: What are the common assembly challenges associated with king metal mattress frames, and how can they be mitigated?

Common assembly challenges include difficulty aligning components, missing hardware, and unclear instructions. Mitigating these challenges involves carefully inspecting all parts before assembly, utilizing online resources for visual guidance, and contacting the manufacturer for missing or damaged components.

Question 4: Are all king metal mattress frames compatible with standard king-sized headboards?

Not all frames are universally compatible. Variations in headboard attachment mechanisms and mounting hole patterns necessitate careful verification of compatibility specifications. Measurement of the existing headboard is important prior to frame selection.

Question 5: How does under-bed clearance impact the suitability of a king metal mattress frame?

Under-bed clearance determines storage capacity and ease of cleaning. Sufficient clearance allows for storing larger items and facilitates vacuuming beneath the bed, contributing to improved hygiene. The higher the under bed clearance makes cleaning easier.

Question 6: What maintenance procedures are recommended for king metal mattress frames to ensure long-term stability and prevent squeaking?

Regular maintenance involves periodically tightening all bolts and screws, lubricating joints with silicone-based lubricant to prevent squeaking, and inspecting the frame for signs of rust or corrosion. These inspections and actions will help prolong the life of the frame.

Selecting a frame with an adequate gauge of metal, the right support and compatible hardware will ensure the longevity of the frame as well as quality of sleep.

The subsequent section will examine specific designs and materials that compose these frames, providing a detailed overview of available options.

King Metal Mattress Frame

This article has explored critical facets of the king metal mattress frame, emphasizing the importance of durability, weight distribution, assembly considerations, headboard compatibility, and under-bed clearance. The gauge of metal, presence of center support, and ease of assembly are identified as key factors influencing long-term performance and user satisfaction. Furthermore, the significance of verifying headboard compatibility and evaluating under-bed clearance to meet individual storage and accessibility needs has been underscored.

Selecting an appropriate king metal mattress frame represents a significant investment in sleep quality and mattress longevity. Careful consideration of the factors discussed herein is essential to ensure a stable, supportive, and functional sleep environment. By prioritizing informed decision-making, consumers can optimize their investment and enhance their overall sleep experience. Further research into specific frame designs and materials is encouraged to align selection with individual requirements and preferences.