A foundational support structure designed for accommodating a specific brand of mattress is often required for optimal performance and longevity. These structures provide a stable platform, preventing sagging and ensuring proper weight distribution. For instance, selecting the appropriate support system is crucial when using a bed-in-a-box mattress to maintain its intended feel and structural integrity.

The correct foundation is paramount for several reasons. It directly impacts sleep quality by contributing to overall comfort and support. Moreover, it can influence the lifespan of the mattress; an inadequate base may void warranties or lead to premature wear. Historically, various materials and designs have been employed, from simple wooden slats to more sophisticated metal frameworks, each offering distinct advantages.

The following sections will delve into the different types of support systems available, compatibility considerations, factors to consider when making a purchase, and maintenance recommendations to ensure long-term satisfaction with your sleep setup.

Selecting an Appropriate Foundation

Proper selection ensures the longevity and performance of the mattress.

Tip 1: Verify Compatibility. Before purchase, confirm that the foundation is explicitly approved for use with the intended mattress model. Incompatible support may compromise mattress integrity.

Tip 2: Assess Support Type. Slat systems, solid platforms, and adjustable bases each offer varying degrees of support. Evaluate individual needs and preferences, considering factors such as weight and sleeping position.

Tip 3: Consider Height Preferences. Foundation height influences overall bed height. Ensure that the combined height of the foundation and mattress provides comfortable entry and exit.

Tip 4: Evaluate Frame Material. Steel frames offer durability and support for heavier individuals. Wooden frames provide aesthetic appeal and can offer sufficient support with proper construction and slat spacing.

Tip 5: Inspect Slat Spacing. When selecting a slatted foundation, confirm that slat spacing adheres to the manufacturer’s recommendations. Excessive gaps may lead to mattress sagging and reduced support.

Tip 6: Examine Weight Capacity. Verify that the chosen foundation can accommodate the combined weight of the mattress and occupants. Exceeding weight limits can result in structural damage and compromised support.

Tip 7: Review Warranty Implications. Confirm that using a specific foundation will not void the mattress warranty. Incompatibility may negate coverage for defects or damage.

Implementing these recommendations will contribute to a more supportive and durable sleep environment, maximizing the benefits of a quality mattress.

The subsequent section will address maintenance practices to further extend the lifespan of the foundation and mattress.

1. Support and Durability

The relationship between support, durability, and a specific brand’s mattress platform is critical for ensuring mattress longevity and maintaining sleep quality. The foundation must provide adequate structural support to prevent sagging and premature wear, while also being constructed of durable materials capable of withstanding long-term use.

- Material Composition and Structural Integrity

The materials used in construction directly impact the foundation’s ability to support the mattress effectively. Steel frameworks generally offer superior durability and weight-bearing capacity compared to wood or composite materials. Proper welding and reinforcement in steel designs, or the use of solid hardwoods in wooden platforms, are crucial for preventing structural failure under stress.

- Slat Design and Spacing

For slatted platforms, the spacing between slats is a critical determinant of support. Excessive spacing can lead to mattress sagging between the slats, compromising support and accelerating wear. Closer slat spacing, ideally less than three inches, provides more uniform support and extends the mattress’s lifespan. The material and thickness of the slats themselves also contribute to overall durability.

- Weight Capacity and Load Distribution

A foundation’s weight capacity must exceed the combined weight of the mattress and its occupants. Exceeding the weight limit can result in structural damage, such as bent or broken slats, compromising support and potentially voiding warranties. Effective load distribution across the entire surface of the foundation is essential for preventing localized stress points.

- Resistance to Wear and Environmental Factors

The foundation’s materials must be resistant to common wear and tear, including scratches, dents, and moisture damage. Exposure to humidity can weaken wooden platforms, while inadequate finishes on metal frames can lead to rust and corrosion. Protective coatings and durable finishes enhance resistance to environmental factors and prolong the foundation’s service life.

The aspects of material composition, slat design, weight capacity, and environmental resistance collectively determine the overall support and durability of a mattress platform. Selecting a foundation engineered with these factors in mind is paramount for maximizing the mattress’s performance and ensuring long-term satisfaction.

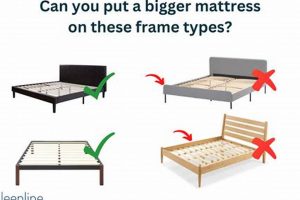

2. Size Compatibility

Size compatibility between a mattress and its support structure is a foundational element impacting both the mattress’s performance and longevity. A misaligned size, where the support is either too large or too small, induces uneven weight distribution. This unevenness can cause premature wear and tear, leading to sagging, indentations, and a compromised sleeping surface. As an example, if a queen-size mattress is placed on a full-size support, the overhanging edges lack support, leading to eventual deformation.

The precision of size matching influences structural integrity. A support structure slightly larger than the mattress may allow movement, resulting in friction and abrasion against the support’s edges. Conversely, a foundation smaller than the mattress forces the mattress to compress and deform along its edges, altering its intended firmness and support characteristics. Consider a scenario where a king-size mattress is forced onto a California king support; this results in distortion of the mattress’s internal components. Accurate size matching ensures that the mattress rests uniformly across the entire support surface.

In summary, size compatibility is not merely a matter of convenience, but a critical aspect of maintaining the mattress’s intended characteristics and extending its lifespan. Deviations from the prescribed dimensions can precipitate structural issues, void warranties, and diminish sleep quality. Therefore, verifying size compatibility is a prerequisite for optimal mattress performance.

3. Slat Spacing

Slat spacing, a critical design element within a support structure, directly influences mattress performance and longevity. Inadequate slat spacing compromises the uniform support necessary for maintaining mattress integrity. Specifically, excessive gaps between slats can lead to localized sagging, particularly in regions bearing the most weight, such as the sleeper’s hips and shoulders. This localized sagging creates uneven pressure distribution, accelerating wear and potentially altering the intended firmness and support characteristics of the mattress. For instance, if a mattress is placed on a support structure with slats spaced more than a few inches apart, the regions unsupported by the slats will gradually compress, leading to indentations and reduced comfort.

The effects of slat spacing are particularly relevant to specific mattress types. Mattresses composed primarily of memory foam, for example, tend to be more susceptible to sagging when unsupported. In these cases, the foam conforms to the spaces between the slats, creating pressure points and diminishing the mattress’s ability to provide proper spinal alignment. Conversely, innerspring mattresses, while somewhat more resilient, can still experience coil distortion and premature wear if the slat spacing is excessive. The presence of a thin support board on top of the slats mitigates the risks associated with improper slat spacing, but it is not a complete substitute for a properly designed support structure.

In conclusion, adequate slat spacing is not merely a design consideration but a functional requirement for maximizing mattress lifespan and maintaining sleep quality. Excessive spacing introduces vulnerabilities that can compromise support, accelerate wear, and diminish the mattress’s overall performance. Therefore, careful attention must be paid to slat spacing when selecting or evaluating a support structure, as it directly impacts the long-term integrity and comfort of the mattress.

4. Material Quality

The selection of materials directly affects the performance and longevity of support structures designed for specific mattresses. The structural integrity, weight-bearing capacity, and resistance to environmental factors are all intrinsically linked to the grade and type of materials employed. For instance, steel platforms constructed from high-gauge steel offer greater durability and resistance to bending or deformation compared to those utilizing thinner, lower-quality metals. Similarly, hardwood frames, when properly sourced and treated, provide superior stability and resistance to warping compared to those constructed from softwood or composite materials. An inferior material base will degrade the customer experience of the mattresses, regardless of the quality of the mattress itself.

Variations in material quality can manifest in several practical ways. Supports constructed from low-density particleboard are prone to cracking and crumbling under stress, potentially leading to mattress sagging and premature wear. Conversely, platforms crafted from solid wood, such as oak or maple, exhibit greater resistance to physical damage and can maintain their structural integrity over extended periods. Similarly, the quality of the finish applied to a metal frame influences its resistance to rust and corrosion. A powder-coated finish provides a more durable and protective barrier than a simple painted surface. As an example, consider two platforms: one constructed from untreated pine and another from kiln-dried oak. The former is susceptible to moisture damage and insect infestation, while the latter exhibits superior resistance to these detrimental effects.

In summary, material quality represents a fundamental consideration in the design and selection of supports for a mattress. It directly affects structural integrity, resistance to wear, and overall lifespan. Prioritizing high-quality materials is essential for ensuring that the support structure provides adequate and consistent support, thereby maximizing the performance and longevity of the mattress and, ultimately, promoting restful sleep. Overlooking material aspects may lead to premature failure, compromised comfort, and financial burden.

5. Warranty Compliance

Adherence to warranty stipulations regarding support systems is critical for maintaining the validity of mattress warranties. Deviations from manufacturer-specified support requirements can void the warranty, leaving consumers responsible for repair or replacement costs should defects arise.

- Approved Support Types

Mattress warranties often explicitly define acceptable support types, such as solid platforms, specific slat configurations, or adjustable bases. Failure to utilize an approved support can invalidate the warranty, regardless of whether the support directly caused the mattress defect. For instance, using a box spring with a mattress designed for a solid platform might void the warranty due to improper support.

- Slat Spacing and Dimensions

If a slatted support is permitted, warranties frequently stipulate maximum slat spacing and minimum slat dimensions. Exceeding the allowed gap between slats or using slats of insufficient thickness can compromise support and potentially void the warranty. As an example, a warranty might require slats to be no more than 3 inches apart and at least 1 inch thick; deviation from these specifications could invalidate coverage.

- Weight Capacity Requirements

Mattress supports must possess sufficient weight capacity to accommodate the mattress and occupants. Exceeding the stated weight limit can lead to structural damage and void the warranty. If a support is rated for 500 pounds and regularly bears 700 pounds, any resulting mattress damage may not be covered under warranty.

- Documentation and Proof of Purchase

In the event of a warranty claim, consumers may be required to provide documentation demonstrating that the support structure complied with warranty requirements. This may include receipts, specifications sheets, or photographs. Failure to provide adequate documentation could result in denial of the warranty claim.

Warranty compliance concerning support structures is not merely a technicality but a crucial aspect of protecting the investment in a mattress. Understanding and adhering to the manufacturer’s specifications regarding support systems ensures that the warranty remains valid, providing recourse in the event of defects or premature failure. Neglecting these requirements can result in significant financial burden and the loss of warranty protection.

Frequently Asked Questions

The following section addresses common inquiries regarding support systems, clarifying crucial considerations for optimal performance and longevity.

Question 1: What constitutes an appropriate support structure for a specific mattress?

An appropriate support system provides uniform weight distribution, prevents sagging, and maintains the mattress’s intended firmness. Specific requirements vary based on mattress construction and manufacturer recommendations. Failure to adhere to these recommendations may compromise performance and void warranties.

Question 2: Does the type of support structure influence the longevity of the mattress?

Yes. An incompatible or inadequate support system can accelerate wear and tear, leading to premature sagging, indentations, and reduced lifespan. A properly selected and maintained support extends the mattress’s functional lifespan.

Question 3: Can any type of support structure be used with a specific mattress?

No. Certain mattress types are designed for specific support systems. For example, some mattresses require solid platforms, while others perform optimally with slatted foundations or adjustable bases. Refer to the manufacturer’s guidelines to ensure compatibility.

Question 4: How does slat spacing affect mattress performance?

Excessive slat spacing compromises support, leading to localized sagging and uneven weight distribution. Insufficient spacing can lead to mattress compression and structural damage. Optimal slat spacing adheres to the manufacturer’s specifications.

Question 5: Will using a non-recommended support structure void the mattress warranty?

Yes, in many cases. Mattress warranties often stipulate specific support requirements. Deviating from these requirements may invalidate the warranty, leaving consumers responsible for repair or replacement costs.

Question 6: What factors should be considered when selecting a support structure?

Key factors include mattress compatibility, weight capacity, material quality, slat spacing (if applicable), height preferences, and warranty compliance. Thorough consideration of these factors ensures optimal performance and long-term satisfaction.

In summary, choosing the correct foundation ensures longevity and performance of the mattress.

The subsequent section will address maintenance practices to further extend the lifespan of the foundation and mattress.

Frames for Casper Mattress

This exploration has underscored the critical role of proper support systems in maximizing the lifespan and performance of mattresses. Selecting compatible frames for Casper mattress is not a mere accessory choice; it is a fundamental requirement for maintaining mattress integrity and ensuring optimal sleep quality. Inadequate or incompatible supports can compromise structural integrity, void warranties, and diminish the overall benefits intended by the mattress design. The factors of material quality, slat spacing, size compatibility, and adherence to warranty requirements collectively determine the effectiveness of any support structure.

Therefore, diligent evaluation of these considerations is paramount for consumers seeking to protect their investment and experience the full potential of their sleep system. Prioritizing compatible and well-constructed frames for Casper mattress ensures long-term satisfaction, supports restful sleep, and mitigates the risks associated with premature mattress failure. Careful consideration before purchase yields significant long-term benefits.

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)

![Best Extra Long Twin Mattress Frame [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Extra Long Twin Mattress Frame [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3164-300x200.jpg)

![Best Bed Frame for Tempurpedic Mattress [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Bed Frame for Tempurpedic Mattress [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3163-300x200.jpg)

![Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3162-300x200.jpg)